Method for preparation of polyvinylidene fluoride membrane by complex thermally induced phase separation

A technology of polyvinylidene fluoride membrane and thermally induced phase separation, which is applied in semipermeable membrane separation, chemical instruments and methods, membrane technology, etc., and can solve problems such as unsatisfactory effect of ultra-microfiltration membrane and inability to meet the needs of industrial production , to achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1: Accurately weigh 255.032g of caprolactam, 45.012g of PVDF, and the mass fraction of PVDF is 15%. Stir the powder evenly and pour it into a 500ml beaker. The temperature of the oil bath used is 115°C. Heat the beaker under nitrogen protection until the caprolactam and The PVDF mixed powder was completely melted for 0.5 h, then the solution was stirred with an electric stirrer for 30 min, then stood in an oil bath for 20 min, and finally the beaker was naturally cooled to room temperature.

[0024] Step 2: Put the membrane solution obtained in Step 1 in a vacuum oven at a temperature of 115° C. to remelt the blend of caprolactam and PVDF.

[0025] Step 3: The membrane solution obtained in Step 2 was scraped to form a membrane, quickly placed in 10°C water, and the caprolactam was extracted for 48 hours to obtain a PVDF membrane.

[0026] The PVDF measured by this method has a flux of 1512.59L / m to pure water at 25°C 2 h,

Embodiment 2

[0028] Step 1: Accurately weigh 240.017g of caprolactam, 60.007g of PVDF, and the mass fraction of PVDF is 20%. Stir the powder evenly and pour it into a 500ml beaker. The temperature of the oil bath used is 130°C. Heat the beaker under nitrogen protection until the caprolactam and PVDF The mixed powder was completely melted for 0.7 h, then the solution was stirred with an electric stirrer for 30 min, then left to stand in an oil bath for 20 min, and finally the beaker was naturally cooled to room temperature.

[0029] Step 2: Put the membrane solution obtained in Step 1 in a vacuum oven at a temperature of 130° C. to remelt the blend of caprolactam and PVDF.

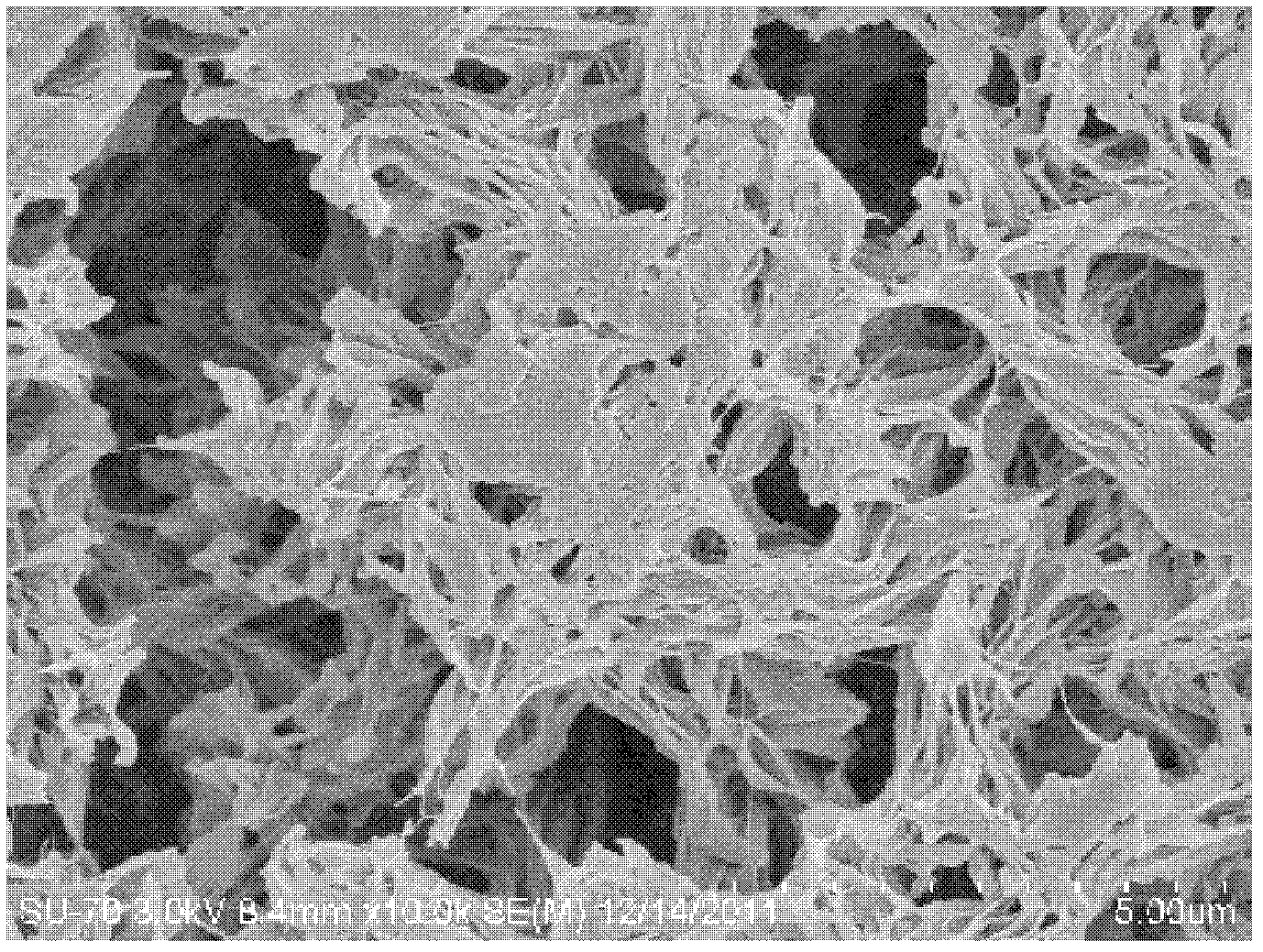

[0030] Step 3: Scrape the film obtained in step 2 into a film, quickly place it in water at 10°C, and extract the caprolactam in it. The extraction time is 48 hours to obtain a PVDF film. The SEM image of the formed film is as follows figure 2 shown.

[0031] The PVDF measured by this method has a pure water flux of 1...

Embodiment 3

[0033] Step 1: Accurately weigh 225.021g of caprolactam, PVDF.75.005g, and the mass fraction of PVDF is 25%. Stir the powder evenly and pour it into a 500ml beaker. The temperature of the oil bath used is 140°C. Heat the test tube under nitrogen protection until the caprolactam and The PVDF mixed powder was completely melted for 0.8 hours, then the solution was stirred with an electric stirrer for 30 minutes, and then stood in an oil bath for 20 minutes, and finally the beaker was naturally cooled to room temperature.

[0034] Step 2: Put the membrane liquid obtained in Step 1 in a vacuum oven at a temperature of 140°C to remelt the blend of caprolactam and PVDF.

[0035] Step 3: The membrane solution obtained in Step 2 was scraped into a membrane, quickly placed in 10°C water, and the caprolactam was extracted for 48 hours to obtain a PVDF membrane.

[0036] The flux of PVDF to 25°C pure water measured by this method is 39.76L / m 2 h

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com