Cold isostatic pressing forming preparation method of tungsten oxide-based ceramic target material

A technology of cold isostatic pressing and ceramic target material, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problem of not being able to prepare tungsten oxide-based ceramic target material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] 1. Preparation of doped submicron tungsten oxide-based powder:

[0095] 1) Prepare raw materials: prepare ammonium metatungstate with a purity ≥ 99.99%, and the doping source element components in this embodiment are calculated as Mo:Li:Zr=5:10:1 according to the molar ratio; prepare MoO with the corresponding element ratio 2 , Li 2 O, ZrO 2 Doping source powder, purity ≥ 99.99%; the mass ratio of ammonium metatungstate added to doping source powder is 87:13.

[0096] It is also feasible to purchase other elemental metals, alloy inorganic salts, and organic salts of corresponding elements for the doping source powder, and the effect is similar.

[0097] 2) preparing a premix solution, fully dissolving pure water, organic monomer acrylamide, and crosslinking agent N'N'-methylenebisacrylamide in a weight ratio of 100:10:1 to form a premix solution;

[0098] 3) Preparation of slurry: Add the pure ammonium metatungstate and doping source powder prepared in step 1) to the...

Embodiment 2

[0120] The difference between this example and Example 1 is that the mass fraction of tungsten in the powder is 85% based on tungsten oxide, and the mass fraction of the doping source is 15%. : Zr=10:5:1;

[0121] The remaining steps are the same as in Example 1. The relative density of the obtained tungsten oxide-based ceramics measured by the drainage method is 98.5%, the average grain size is 4.5 μm, the doping elements enter the ceramic lattice, and there is no obvious second phase. The electrical conductivity of the ceramic body is 15S / cm.

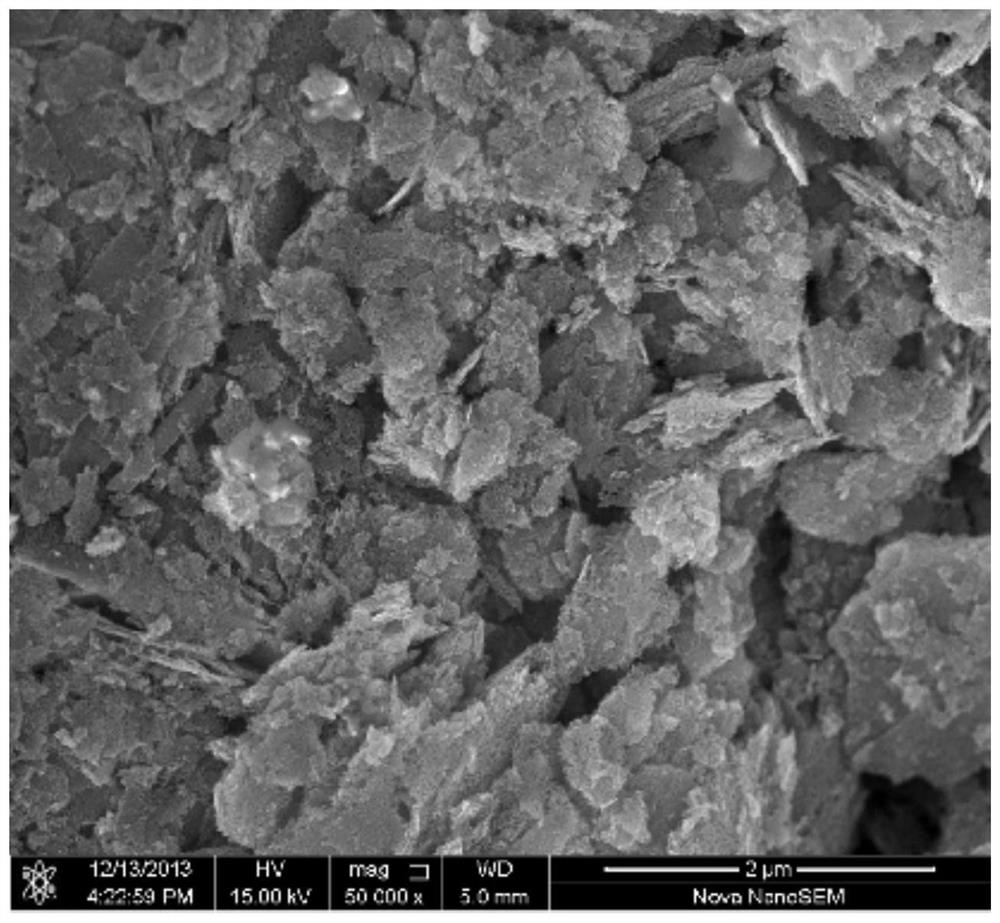

[0122] The electron micrographs of the ceramics prepared in this embodiment are as follows: Figure 5 shown.

Embodiment 3

[0124] 1. Preparation of doped submicron tungsten oxide-based powder:

[0125] 1) Prepare raw materials: prepare ammonium metatungstate with a purity ≥99.99%, and the doping source element components of this embodiment are calculated as Ti:Mo:Zr=10:1:1 according to the molar ratio; prepare the oxidation of the corresponding element ratio Titanium, molybdenum oxide, zirconia doping source powder, purity ≥ 99.999%; the mass ratio of added ammonium metatungstate to doping source powder is 92.2:7.8.

[0126] It is also feasible to purchase other elemental metals, alloy inorganic salts, and organic salts of corresponding elements for the doping source powder, and the effect is similar.

[0127] 2) To prepare a premix solution, the pure water and the organic monomer are a combination of polyvinyl alcohol and polyacrylic acid, wherein the ratio of polyvinyl alcohol to polyacrylic acid is 1:1, and the crosslinking agent is polyethylene glycol, polyethylene glycol A combination of alc...

PUM

| Property | Measurement | Unit |

|---|---|---|

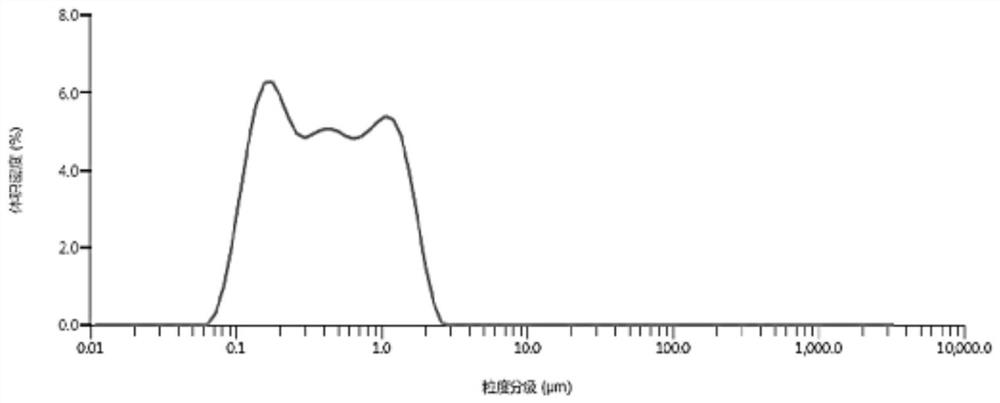

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com