Preparation method of hollow fiber pipe in overlay film

A fiber tube and fiber braided tube technology, which is applied in the field of separation membrane preparation and modification, to achieve the effects of improving the performance of anti-backwash and anti-compression, increasing the binding force and expanding the application field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of film-coated hollow fiber tube of the present invention, its steps are as follows:

[0035] 1) Preparation of casting solution: Stir and dissolve high molecular polymer, organic solvent, additive, and porogen in different proportions at 40-80°C for 12-36h, and stand at 40-60°C for defoaming for 12-24h to obtain The required different homogeneous casting solutions are set aside;

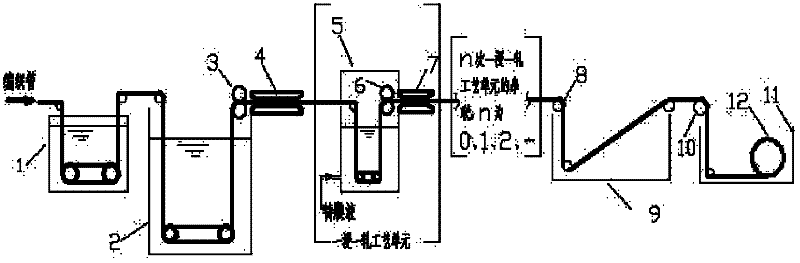

[0036] 2) Removal of oil stains on PET fiber braided tubes: such as figure 1 As shown, the PET fiber braided tube is immersed in the decontamination tank 1 filled with boiled NaOH (5-15wt%) solution for 10-20min to remove the oily dirt on the braided tube; then wash it with deionized water to remove the braided tube. NaOH remaining on the tube;

[0037] 3) Modification of the PET fiber braided tube: immerse the PET fiber braided tube in the modification tank 2 containing the modification solution for 5-15 minutes, so that the grafting agent in the modification solutio...

Embodiment 1

[0044] Using a dipping and rolling process (such as figure 1 Shown, namely n=0) prepare film-coated hollow fiber tube, its specific steps are as follows:

[0045] 1) Add certain components of polymers, organic solvents, additives, and porogens into the stirring tank to prepare a homogeneous casting solution, as shown in the table below;

[0046] 2) Immerse 24 ingots, 1.2 mm in outer diameter, and 40-mesh density PET fiber braided tube in a boiled 15 wt% NaOH solution for 10 minutes, and wash the remaining NaOH solution on the surface with deionized water;

[0047] 3) After decontamination, the fiber braided pipe is immersed in the modification solution for modification. The immersion time is 15 minutes, and then it is rolled at a rolling pressure of 0.6 MPa and a rolling speed of 5 m / min. Round tube heat setting mold;

[0048] 4) Immerse the modified braided tube in the casting solution for 10 minutes, apply a rolling force of 0.5 MPa to the braided tube with a rolling car a...

Embodiment 2

[0053] Using a dipping and rolling process (such as figure 1 Shown, namely n=0) prepare film-coated hollow fiber tube, its specific steps are as follows:

[0054] 1) Add certain components of polymers, organic solvents, additives, and porogens into the stirring tank to prepare a homogeneous casting solution, as shown in the table below;

[0055] 2) Immerse 24 ingots, 1.2 mm in outer diameter, and 40-mesh density PET fiber braided tube in a boiled 10 wt% NaOH solution for 15 minutes, and wash the residual NaOH solution on the surface with deionized water.

[0056] 3) After decontamination, the fiber braided pipe is immersed in the modifying solution for modification. The immersion time is 10 minutes, and then rolled at a rolling pressure of 0.7 MPa and a rolling speed of 2 m / min. After rolling, pass through a 160 ° C Round tube heat setting mold.

[0057] 4) Immerse the modified braided pipe in the casting solution for 8 minutes, apply a rolling force of 0.8 MPa to the braide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com