Preparation method of ultra-thin ultra-low dilution rate high-temperature alloy cladding layer for garbage incinerator

A waste incinerator and high-temperature alloy technology, which is applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve problems such as limited effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

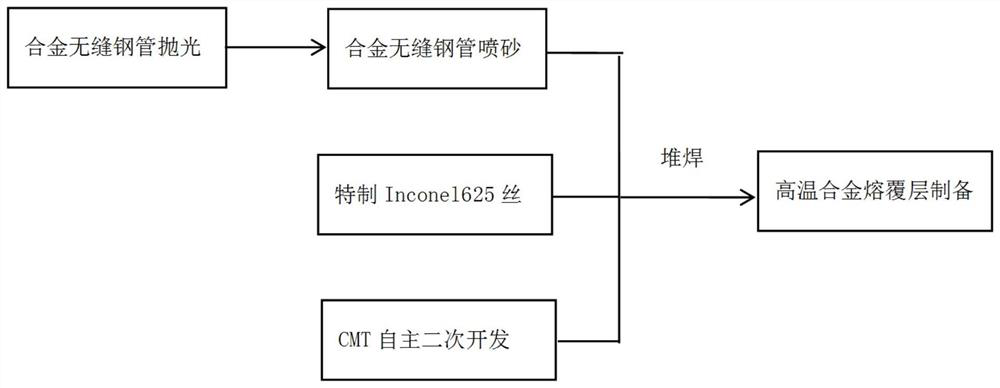

Method used

Image

Examples

example 1

[0051] Example 1: An ultra-thin ultra-low dilution superalloy cladding layer for a waste incinerator

[0052] 1. The thickness of the superalloy cladding layer is ≥1.2mm.

[0053] 2. The mass percentage of the main components of the cladding layer: Ni: 58-64%, Cr: 20%-23%, Mo: 8%-10%, Nb: 3.15%-4.15%.

[0054] 3. Dilution rate Fe≤3.0%.

[0055] Using the ultra-thin and ultra-low dilution superalloy cladding layer of the present invention, the appearance and thickness of the superalloy anti-corrosion coating are detected and fed back: the weld seam of the cladding layer is still clear, the thickness reduction is not obvious, and the composition is normal, etc., indicating that Excellent corrosion resistance.

example 2

[0056] Example 2: An ultra-thin ultra-low dilution superalloy cladding layer for a waste incinerator

[0057] 1. The thickness of superalloy cladding layer is ≥2.0mm.

[0058] 2. The mass percentage of the main components of the cladding layer: Ni: 58-64%, Cr: 20%-23%, Mo: 8%-10%, Nb: 3.15%-4.15%.

[0059] 3. Dilution rate Fe≤3.0%.

[0060] Using the ultra-thin and ultra-low dilution rate high-temperature alloy cladding layer of the present invention, the appearance and thickness of the superalloy anti-corrosion coating are detected and fed back: the welding seam of the cladding layer is slightly corroded, and the thickness reduction rate is less than the design requirement. The composition of the layer is normal, indicating that the anti-corrosion performance is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com