Full-ceramic tile wall attaching anti-falling technology

A technology of anti-shedding and ceramic tiles, which is applied in the direction of covering/lining, construction, building construction, etc., can solve the problems of tiles falling off, easy to fall off, high hardness, etc., and achieve the effect of increasing the installation space and simplifying the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the examples.

[0016] An anti-shedding process for a full tile wall, which comprises the following steps:

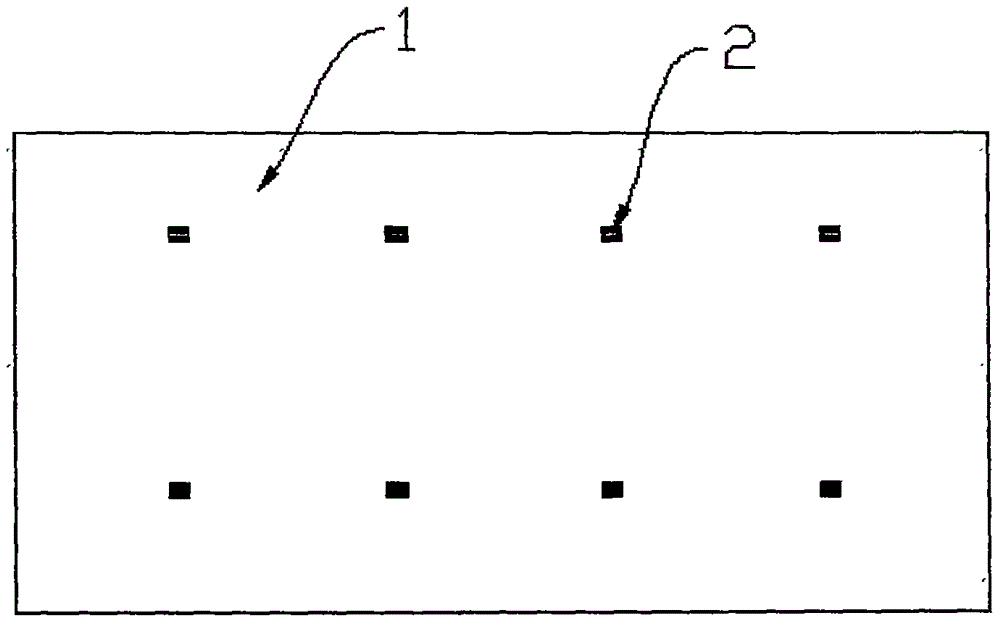

[0017] (1) First process the 800*800mm tiles into 400*800mm tiles, place the 400*800mm tiles flat on the ground, select 10*10*5mm steel plates, and evenly distribute 8 tiles on the tiles Fixed point, and then use marble glue to fix a steel plate at the set fixed point;

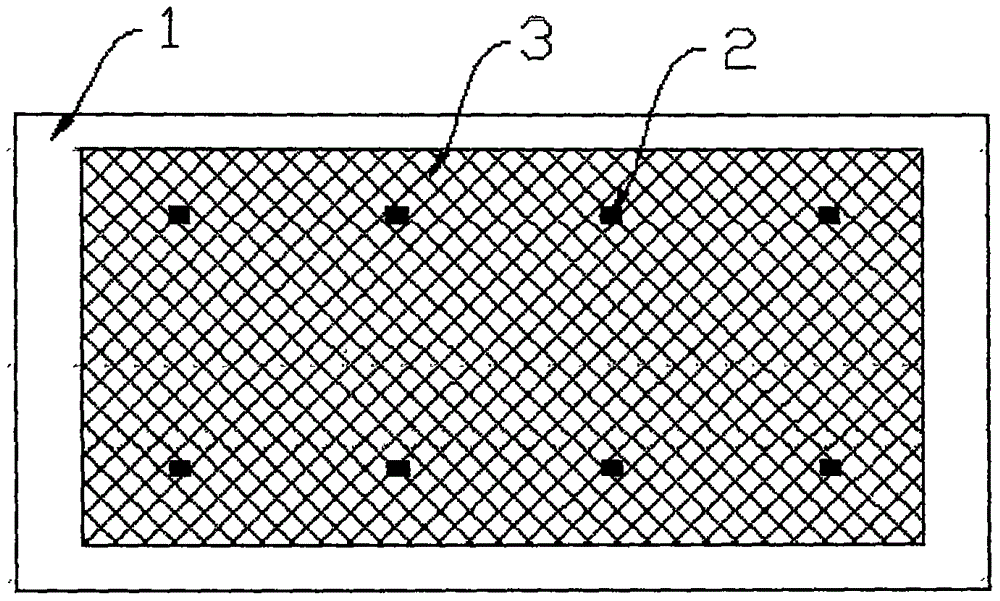

[0018] (2) Lay steel wire mesh on the tiles with steel plates, and fix the steel wire mesh and steel plates with marble glue;

[0019] (3) After the steel mesh is fixed, there is a gap of 5mm between the steel mesh and the ceramic tile, and cement is applied to the gap after the marble glue is dried;

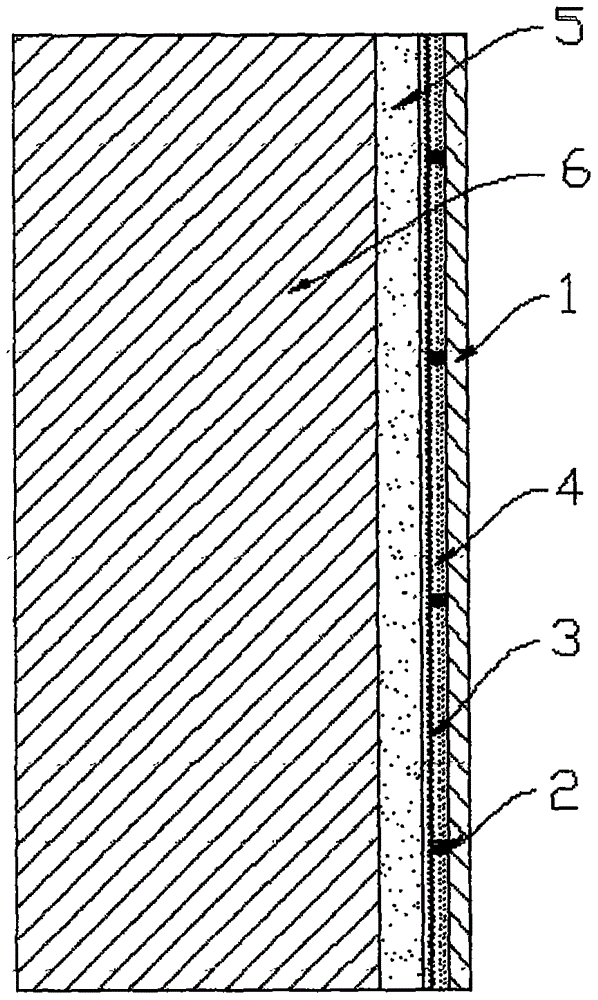

[0020] (4) After approving the cement on the wall, paste the tiles with cement on the wall, so that the cement on the tiles and the cement on the wall are integrated into one, which is relatively firm.

[0021] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com