Special flexible plastic circulation box for tobacco and manufacturing method thereof

A manufacturing method and turnover box technology, applied to rigid containers, containers, packaging, etc., can solve the problems of cigarette deformation, easily scratched cigarette turnover box, and easily scratched cigarettes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

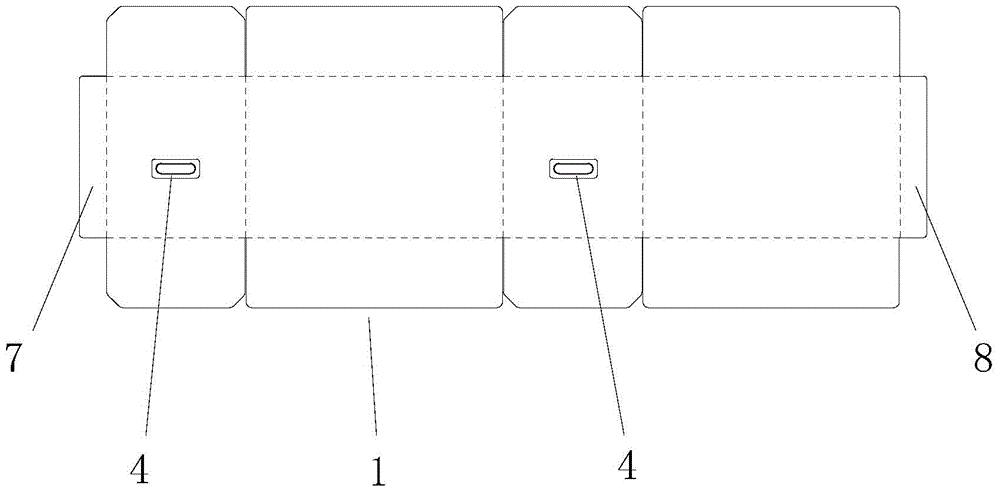

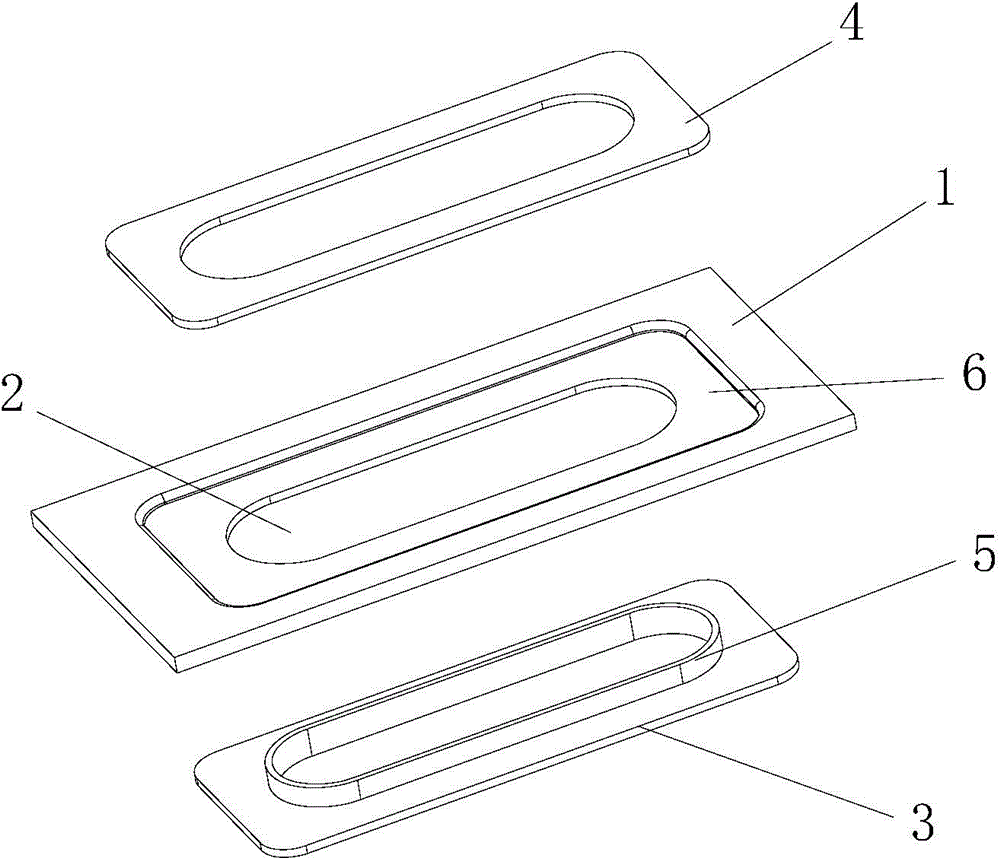

[0017] refer to Figure 1 to Figure 2 , a special soft plastic turnover box for tobacco, comprising a cuboid-shaped box body 1 made of PP hollow board, the side of the box body 1 is provided with a handle position 2, and the handle position 2 is equipped with a handle, The clasp is equivalent to forming an edge on the clasp position 2 to prevent the clasp position 2 from collapsing. The inner surface of the clasp is lower than the inner surface of the box 1 or is flush with the inner surface of the box 1 .

[0018] The handle is composed of an inner handle 4 installed on the inside of the casing 1 and an outer handle 3 installed on the outside of the casing 1. The inner handle 4 and the outer handle 3 can be made of hard plastic or soft plastic Made, the inner buckle hand piece 4 and the outer buckle hand piece 3 are provided with corresponding through holes, the outer buckle hand piece 3 is provided with an insertion portion 5 perpendicular to its surface, after assembly, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com