Rolled plate hoisting gasket

A plate coil and liner technology, applied in the field of protective liner, can solve the problems of unsuitable balance beam operation mode, inconvenient use, large volume, etc., and achieve the effects of low cost, convenient use and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

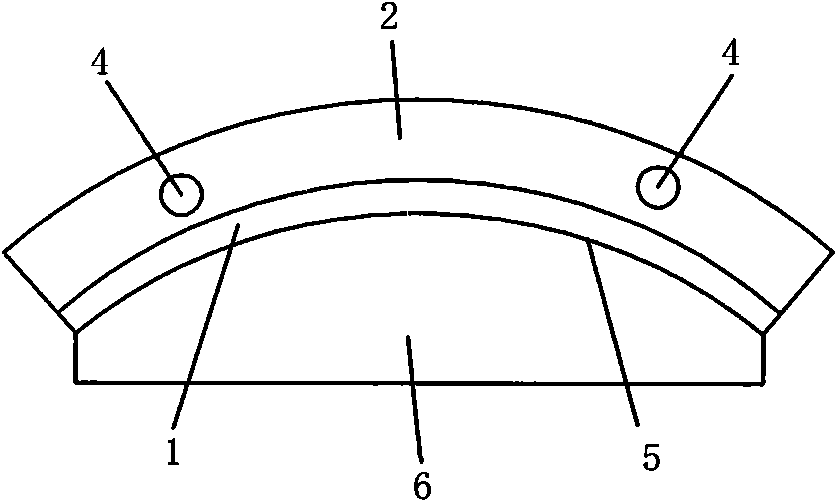

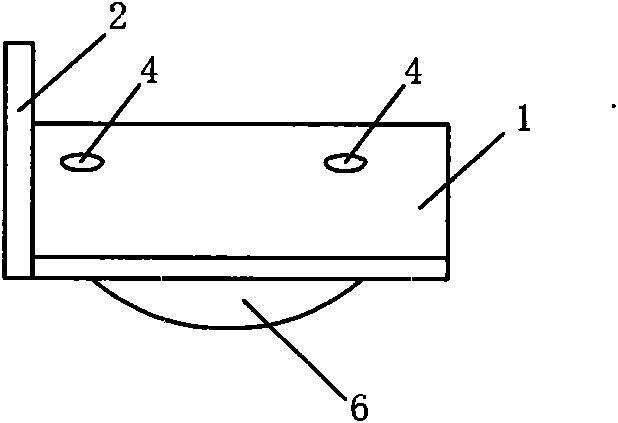

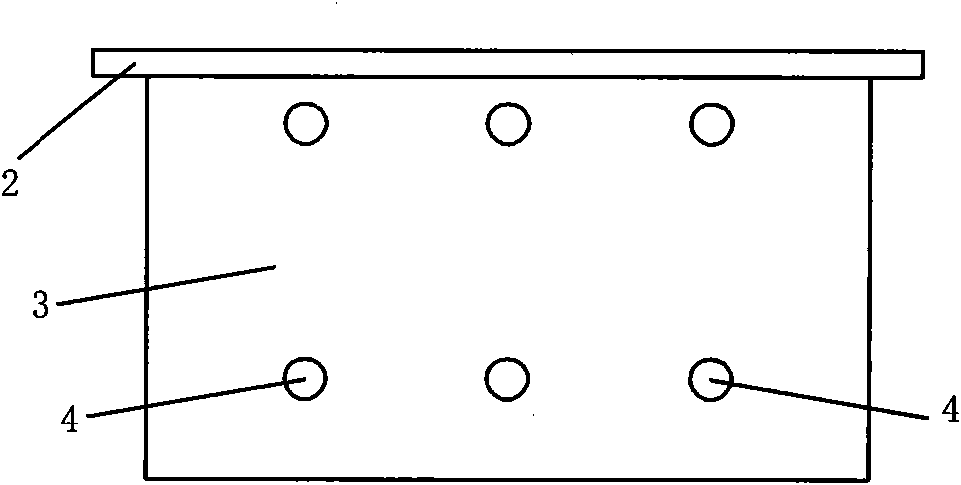

[0020] The coil hoisting liner of this embodiment is a preferred embodiment of the coil hoisting liner of the present invention, such as figure 1 , figure 2 and image 3 As shown, it includes an arc-shaped bent plate 1 that basically matches the inner circle of the plate coil. The curved plate 1 is formed with a vertical baffle 2 along one side of its arc edge. Ferromagnets 4 are arranged at intervals on the inner surface of the curved plate 2, and comb-shaped protrusions 6 are arranged on the inner arc surface 5 of the curved plate 1. The outer surface of the bump 6 is an arc surface (that is, the lower end of the section of the bump 6 is an arc-shaped side).

[0021] The state of the plate coil hoisting liner in this embodiment is as follows: Figure 5 As shown, it can be seen from the figure that the sling 8 passing through the inner ring 7 of the plate coil only contacts the bump 6 and no longer touches the corner of the bent plate 1 and the vertical baffle 2, thereby ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com