Inorganic silicate coating, preparation method thereof and application of coating

An inorganic silicate and coating technology, applied in alkali metal silicate coatings, fireproof coatings, antifouling/underwater coatings, etc., can solve allergic symptoms and respiratory diseases, low adhesion between coatings and walls, and inability to To achieve VOC and other problems, to achieve the effect of good mildew resistance and fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

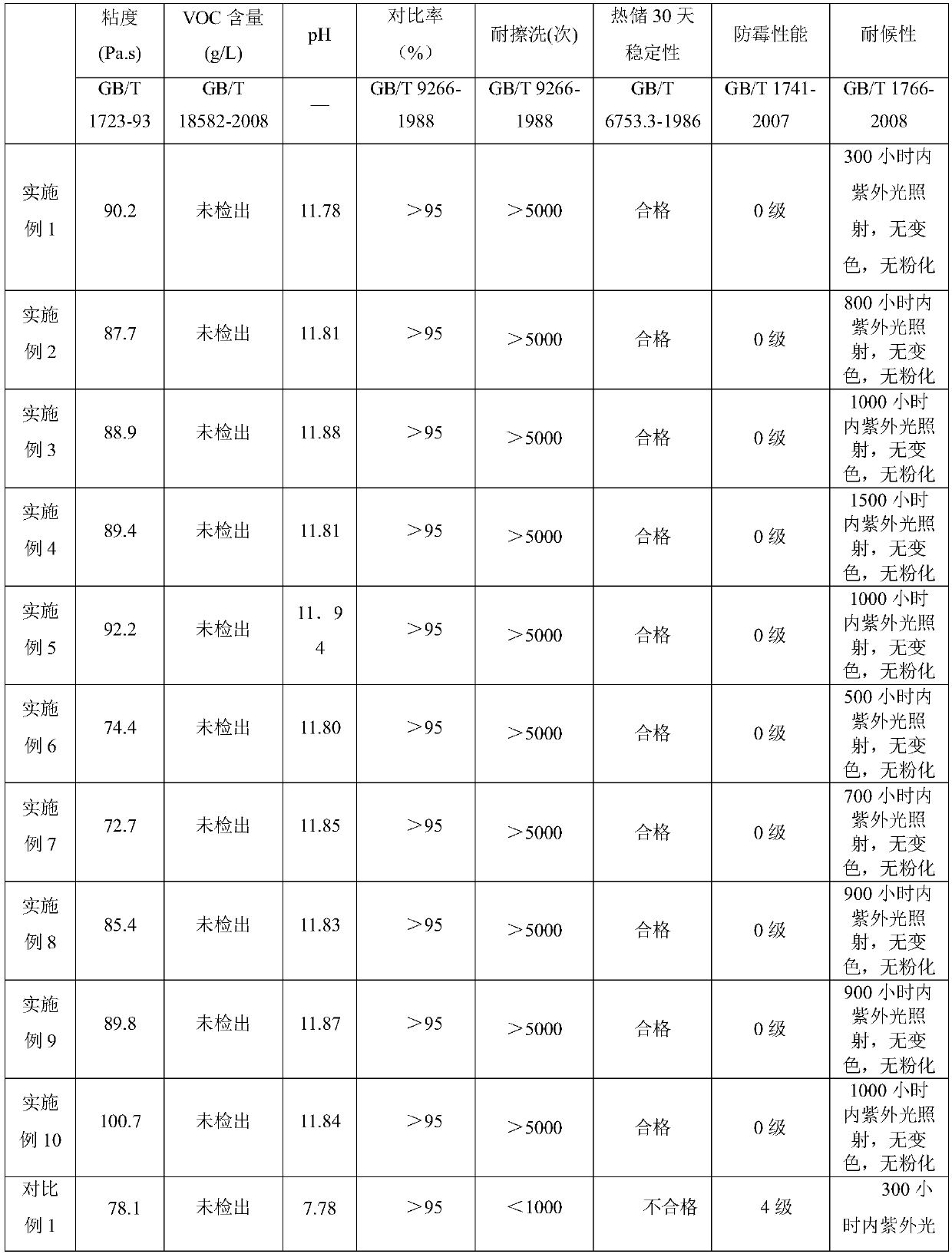

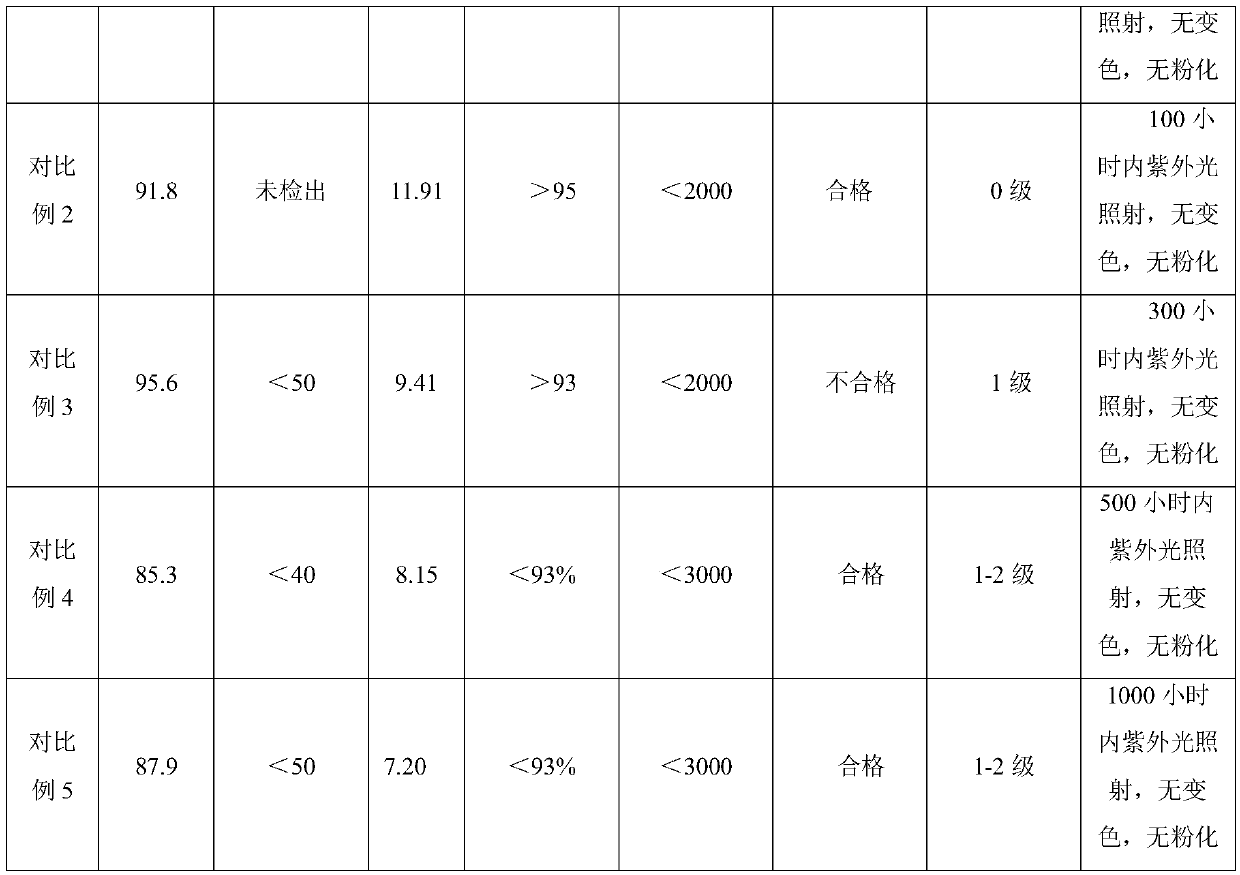

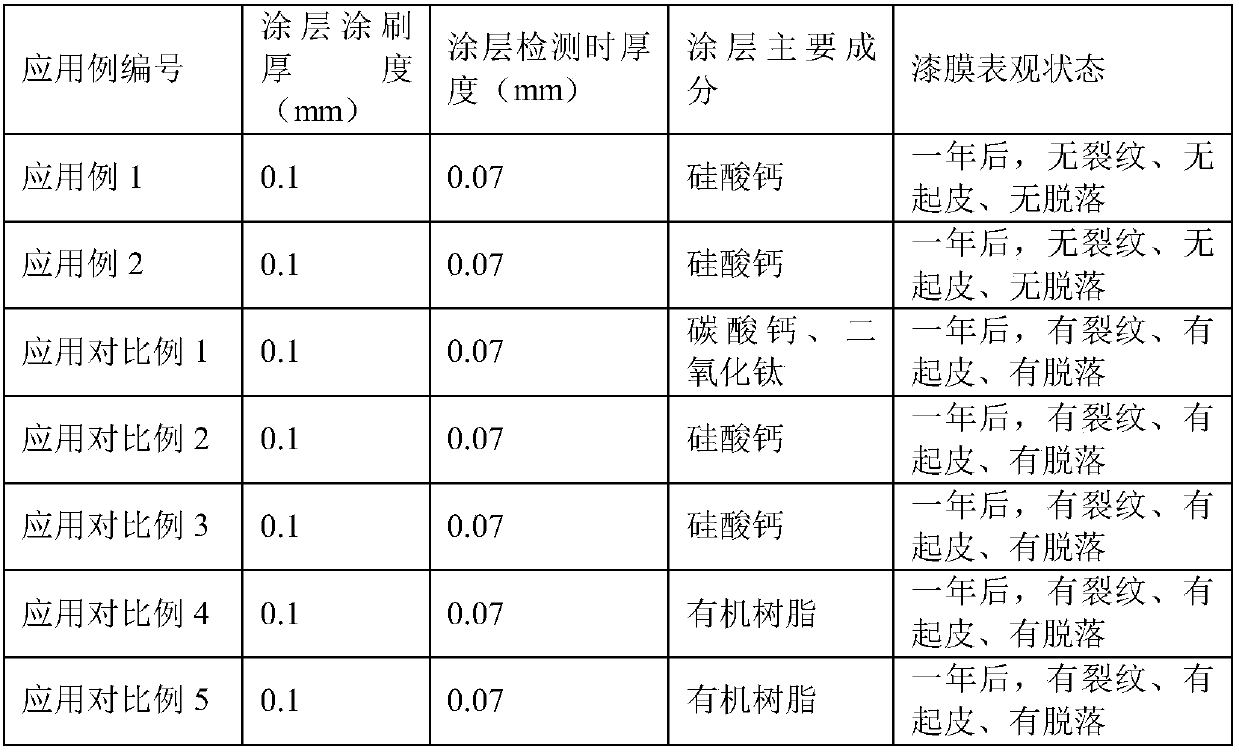

Examples

Embodiment 1

[0033] A kind of inorganic silicate coating that is applicable to interior wall is prepared by following steps:

[0034] Start the mixer, add 18kg of deionized water into the mixing tank, add 500g of hydroxymethyl cellulose while stirring, stir for 5min, then add 500g of polyacrylic acid sodium salt, 300g of sodium dodecylbenzene sulfate and mineral oil defoamer 300g, stir and disperse for 5min; add 19kg of titanium dioxide, 16kg of heavy calcium carbonate and 10kg of talcum powder under stirring, and stir for 30min; then add 200g of mineral oil defoamer, 10kg of styrene-acrylate emulsion, and 20kg of modified potassium silicate VB-2837, 1.0kg of anionic quaternary ammonium salt type stabilizer and 1.0kg of organosilicon hydrophobic agent, stir and mix evenly to obtain inorganic silicate coating.

Embodiment 2

[0036]The preparation method of the inorganic silicate coating of Example 2 is the same as that of Example 1, wherein the components and contents of each raw material are specifically: 20 kg of deionized water, 400 g of hydroxyethyl cellulose, 800 g of ammonium polyacrylate, 100 g of phosphoric acid ester, non- Silicon defoamer 100g, titanium dioxide 17kg, heavy calcium carbonate 15kg, talcum powder 10kg, pure acrylic emulsion 7kg, 21kg modified potassium silicate VB-2837, anionic quaternary ammonium salt type stabilizer 1kg and silicone hydrophobic agent 1kg , to prepare silicate coatings suitable for interior and exterior walls.

Embodiment 3

[0038] The preparation method of the inorganic silicate coating of Example 3 is the same as that of Example 1, wherein the components and contents of each raw material are specifically: 22 kg of deionized water, 250 g of hydroxypropyl cellulose, 200 g of methyl cellulose, 500 g of sodium polyacrylate, Sodium hexametaphosphate 300g, polyoxyethylene fatty alcohol ether 200g, mineral oil defoamer 100g, silicone defoamer 50g, non-silicon defoamer 50g, titanium dioxide 15kg, ground calcium carbonate 15kg, talcum powder 13kg , 5kg of silicon-acrylic emulsion, 22kg of modified potassium silicate VB-2837, 800g of anionic quaternary ammonium salt type stabilizer and 800g of organic silicon hydrophobic agent; prepare a silicate coating suitable for interior and exterior walls.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com