Air-jet vortex polyester yarn spinning device

A polyester yarn and vortex spinning technology, which is applied to spinning machines, open-end spinning machines, and continuous winding spinning machines, etc., can solve the problems of low twisting strength, insufficient yarn crossing depth, and To solve problems such as small crossing depth, achieve good twisting effect, improve spinning quality, and increase the effect of crossing depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

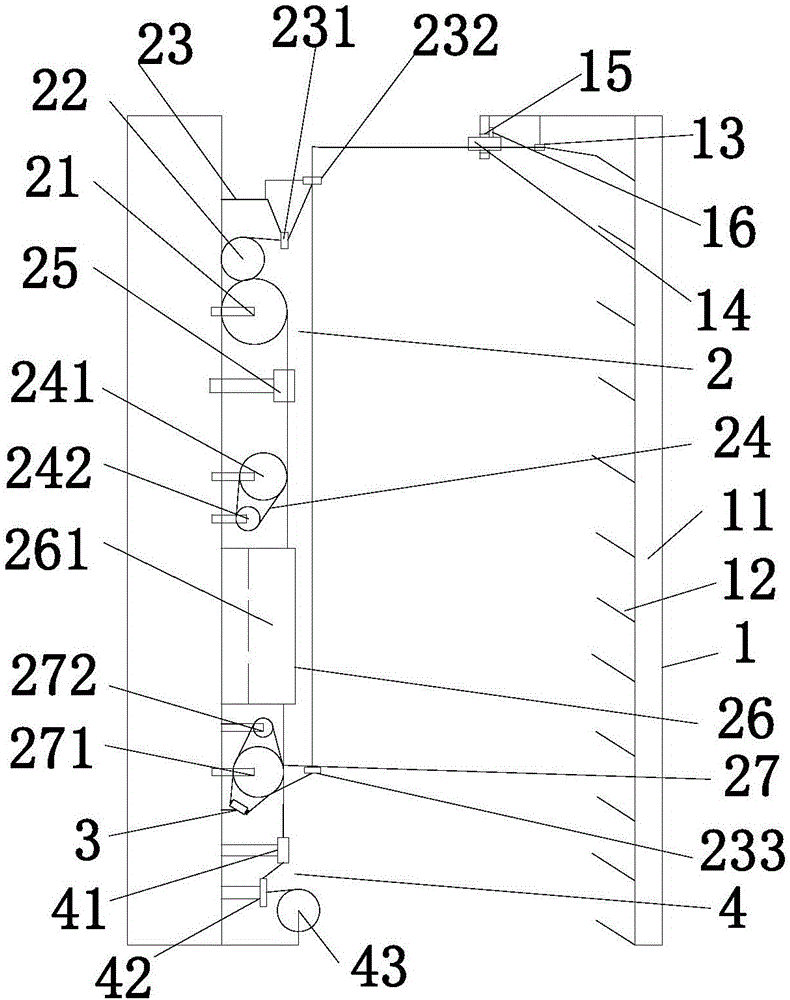

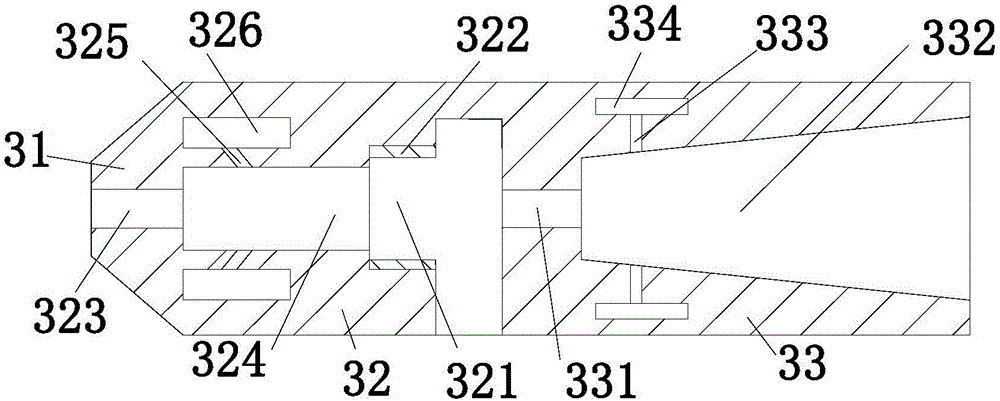

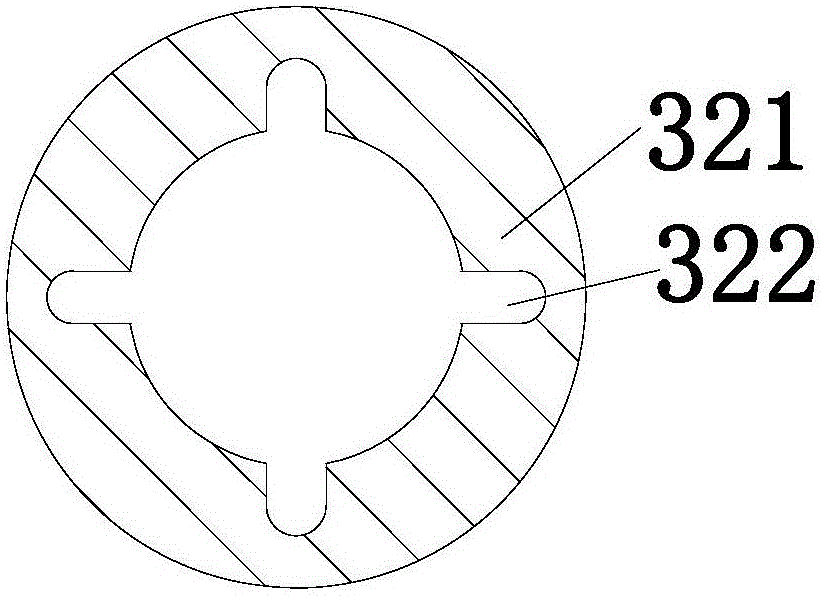

[0022] Embodiment 1: a kind of air-jet vortex spinning polyester yarn device, constitutes as figure 1 , figure 2 and image 3 As shown, it includes a raw material supply device 1, the raw material supply device 1 is connected with a yarn drafting device 2, the yarn drafting device 2 is connected with a yarn twisting device 3, and the yarn twisting device 3 is connected with a finished product winding device 4 The yarn twisting device 3 includes a housing 31, the housing 31 is provided with a first nozzle 32, the first nozzle 32 is connected with a second nozzle 33; the first nozzle 32 includes a first fiber opening tube 321, A plurality of helical grooves 322 are evenly formed on the inner wall of the first fiber opening tube 321 .

[0023] The first nozzle 32 includes a first suction port 323, the first suction port 323 is connected with a first yarn path 324, the first yarn path 324 is connected with a first fiber opening tube 321, and the first yarn path 324 is provided ...

Embodiment 2

[0031] Embodiment 2: a kind of air-jet vortex spinning polyester yarn device, constitutes as figure 1 , figure 2 and image 3 As shown, it includes a raw material supply device 1, the raw material supply device 1 is connected with a yarn drafting device 2, the yarn drafting device 2 is connected with a yarn twisting device 3, and the yarn twisting device 3 is connected with a finished product winding device 4 The yarn twisting device 3 includes a housing 31, the housing 31 is provided with a first nozzle 32, the first nozzle 32 is connected with a second nozzle 33; the first nozzle 32 includes a first fiber opening tube 321, A plurality of helical grooves 322 are evenly formed on the inner wall of the first fiber opening tube 321 .

[0032] The first nozzle 32 includes a first suction port 323, the first suction port 323 is connected with a first yarn path 324, the first yarn path 324 is connected with a first fiber opening tube 321, and the first yarn path 324 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com