Galvanized iron wire winding device

A winding device and galvanized iron wire technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of uneven winding of iron wires, increased hidden dangers of accidents, heavy collection devices, etc., and achieve cost and operation Low maintenance costs, improved work efficiency, and the effect of protecting personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

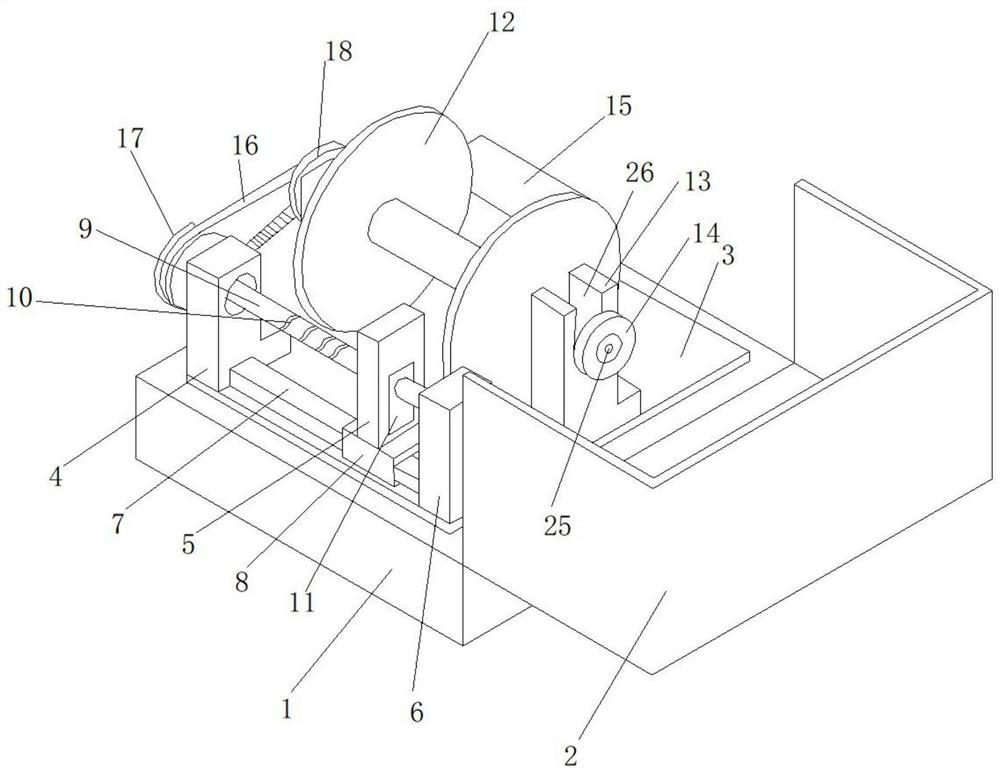

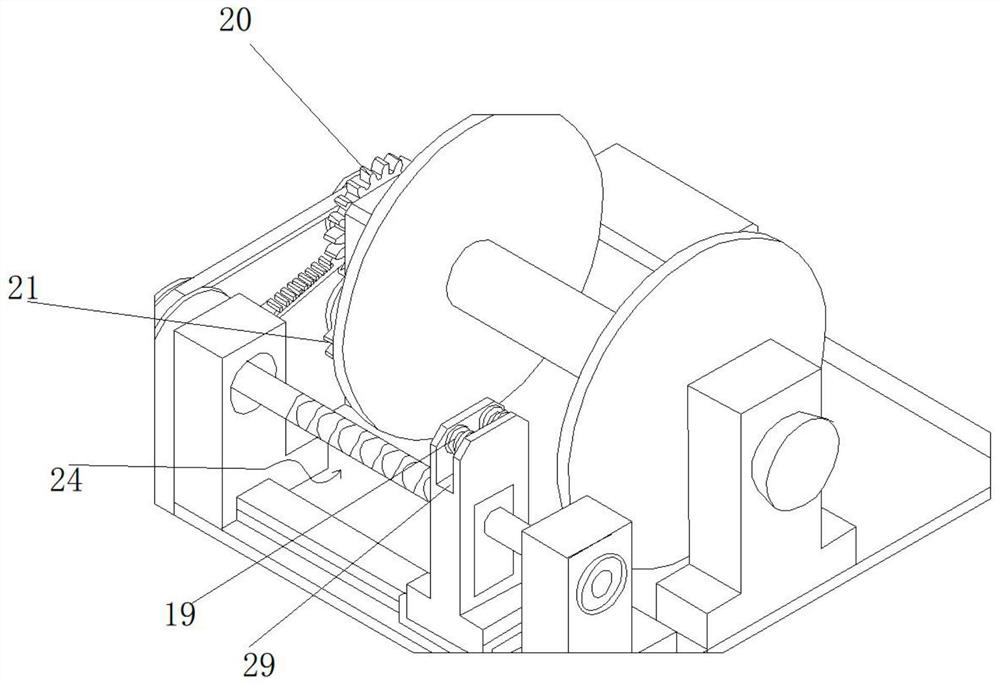

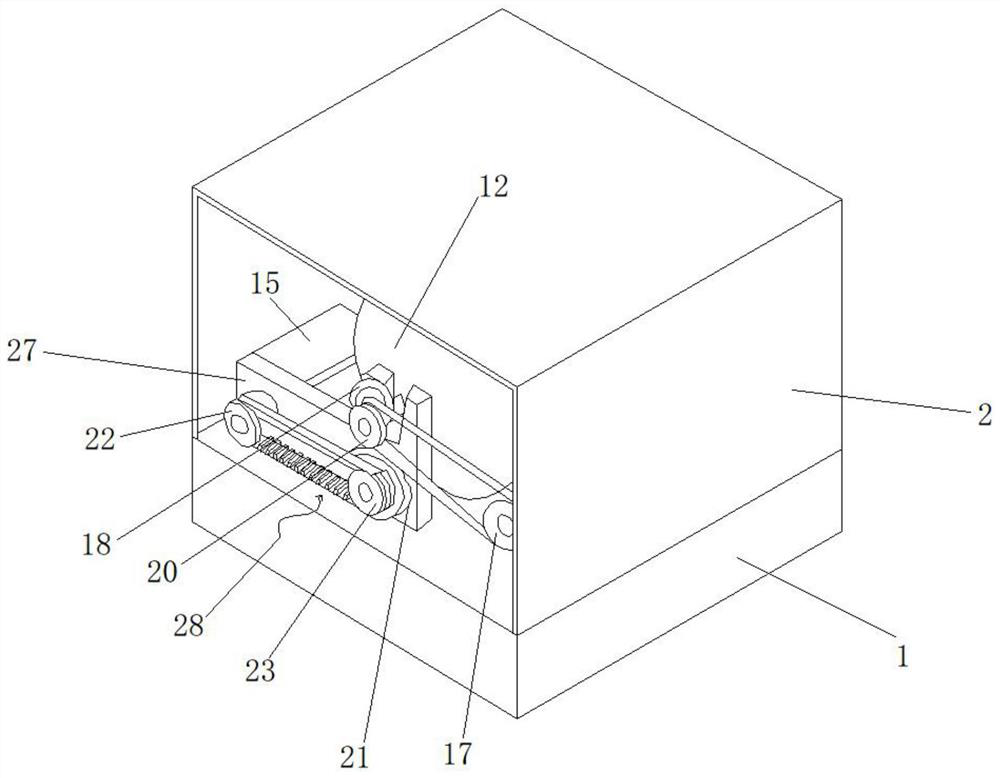

[0030] figure 1 It is a schematic diagram of the three-dimensional structure of the present invention, figure 2 It is a schematic diagram of an internal cross-sectional enlarged structure of the present invention, image 3 It is a three-dimensional side view of the present invention, such as figure 1 A winding device for galvanized iron wire shown includes a base 1, a protective cover 2, a lead wire structure, a transmission mechanism 28, and a collection roller 12. The protective cover 2 is arranged on the upper end of the base 1, and the protective cover 2 is connected to the base 1 in rotation to protect The cover 2 can be turned over. The upper end of base 1 is provided with console 3, and console 3 is fixedly connected with base 1, and console 3 is provided with lead wire mechanism 24, and lead wire mechanism 24 comprises support A4, support B5, support C6, slideway 7, tackle 8, wire The rod 9, the support A4 and the support C6 are fixed on the console 3, the slideway...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com