Automatic winding machine and winding method for roll type membrane element protective net

An external protection, roll-type membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of inaccurate size of membrane elements, low production efficiency, and loose winding, and achieve high production efficiency. , low cost, fast bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

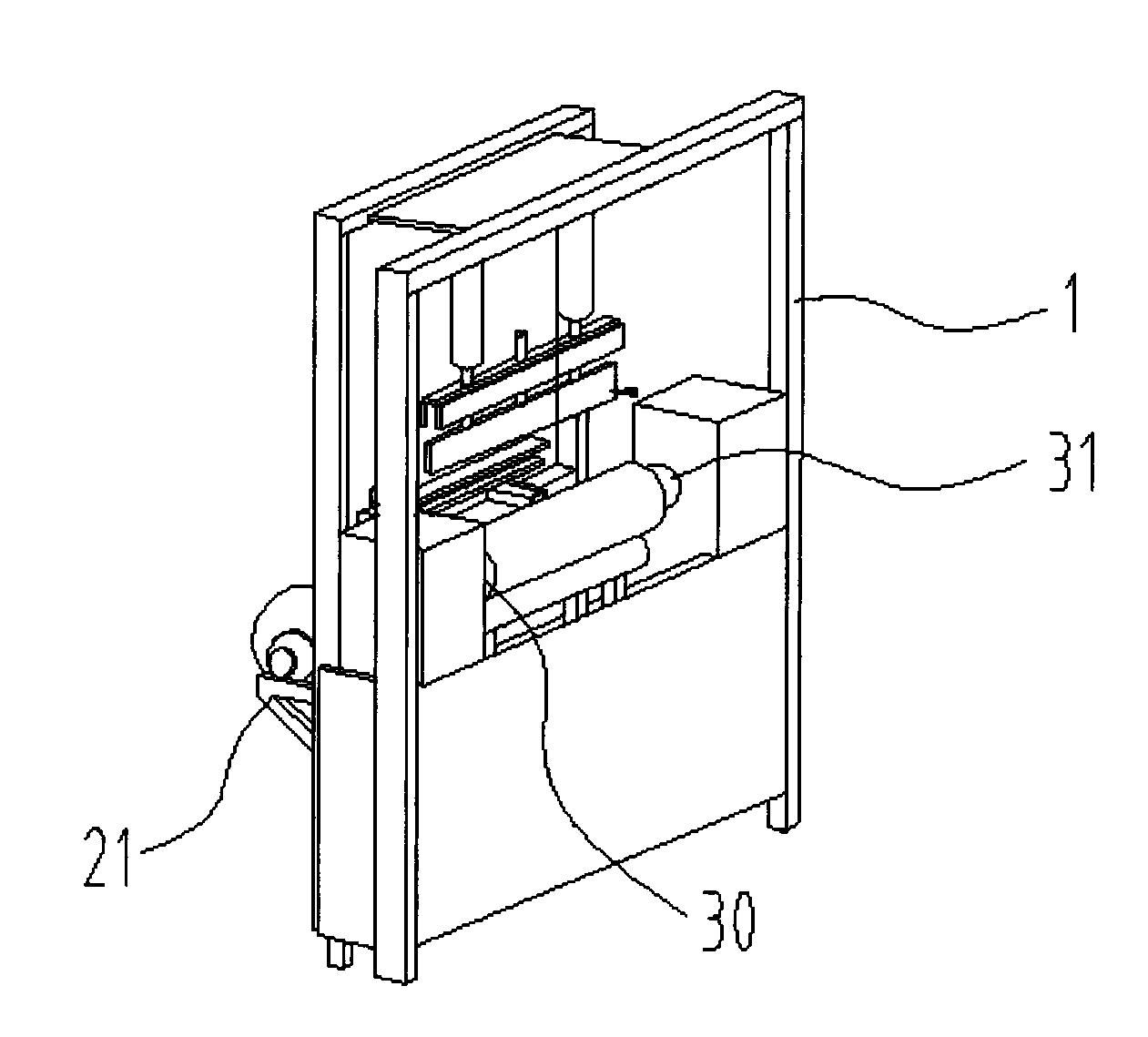

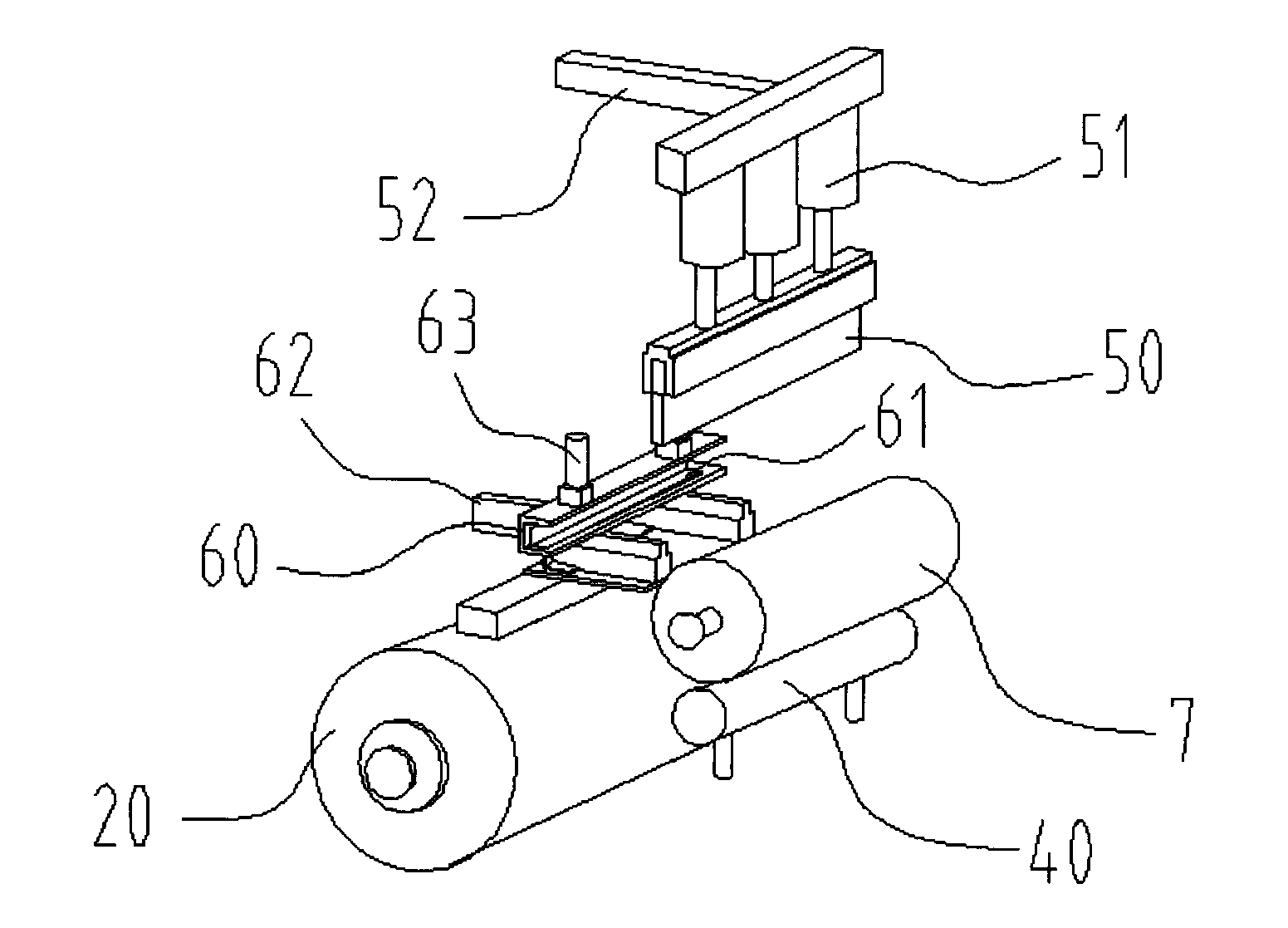

[0043] Example 1: figure 1 , 2 As shown, an automatic winding machine for a roll-type membrane element outer protection net includes: a frame 1, a feeding system, a positioning system, a clamping system, a heating system and an auxiliary system.

[0044] The feeding system includes an outer protective net roll 20 and a support frame 21 welded to the rear side of the frame, and the reel of the outer protective net roll 20 is rotatably supported on the support frame 21 .

[0045] The positioning system includes a left ejector pin 30, a right ejector pin 31, and a left ejector pin driving motor that drives the left ejector pin 30 to rotate, which are fixed on the frame 1. The membrane element 7 to be processed is positioned at the ejector pin holes at both ends thereof. between the left and right thimbles.

[0046] The frame 1 is provided with a guide rail, the left ejector pin 30 is slidably arranged on the guide rail, and a left ejector pin driving cylinder is arranged below ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com