Reinforced type silicon rubber self-adhesion insulated rubber tape

A technology of insulating tape and silicone rubber, which is applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of unprolonged service life, damage to insulating coils, loss of viscosity of the tape, etc., to achieve improved leakage resistance, Enhanced strength and tight wrapping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

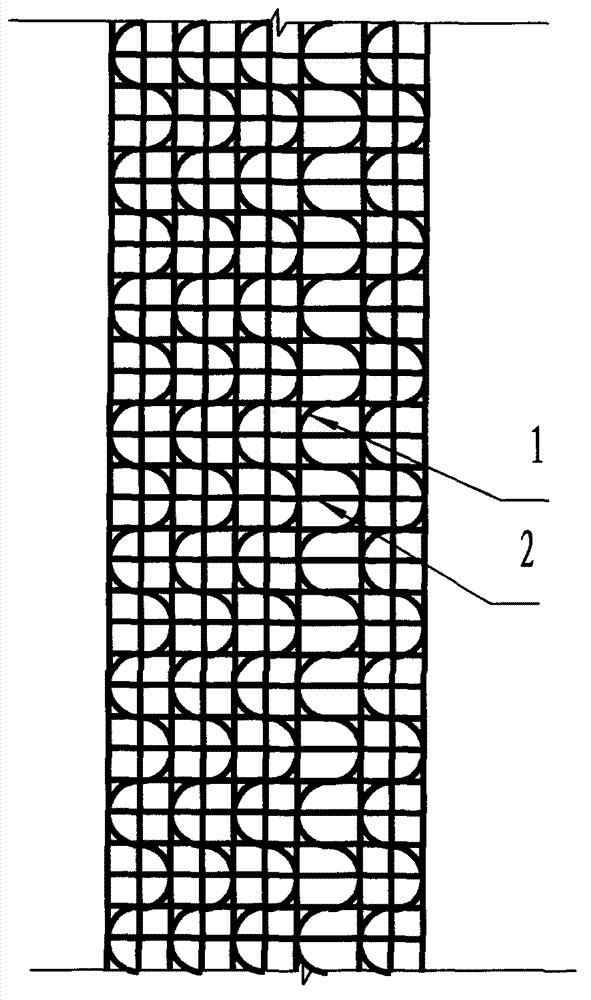

[0014] Take 30kg of 110 methyl vinyl silicone rubber, 10kg of fumed silica, 5kg of silicon boron tackifier, 0.5kg of bis-pentasulfurizing agent, and 0.2kg of iron red colorant, and mix the above-mentioned raw materials into the open-type Knead in the mixer, put it into the melt glue box to make glue, and apply it to both sides of the cotton fiber cloth, such as figure 1 As shown, the warp direction of the cotton fiber cloth is S-shaped bending, the stretching amount along the warp 1 direction is large, and the deformation along the weft 2 direction is small. Then, enter the microwave vulcanization device for vulcanization, and finally crimp and cut.

Embodiment 2

[0016] Get 60kg of 110-2 methyl vinyl silicone rubber, 25kg of fumed silica, 20kg of silicon boron tackifier, 0.5kg of dry sand yellow colorant, 5kg of hydroxyl silicone oil softener, and 5kg of bis-pentasulfurizing agent. Mix it into an open mixer at a temperature below 80°C for kneading, put it into a melt box to make glue, apply it to both sides of the cotton fiber cloth, and then enter a microwave vulcanization device for vulcanization, then crimp and cut.

Embodiment 3

[0018] Get 45kg of 107 methyl vinyl silicone rubber, 18kg of fumed silica, 12kg of silicon boron tackifier, 2.5kg of hydroxy silicone oil softener, 0.35kg of iron red coloring agent, 3kg of double dipentasulfurizing agent, and mix the above-mentioned raw materials at 80 Mix it below ℃ and put it into an open mixer for kneading, put it into the melt box to make glue, apply it to both sides of the cotton fiber cloth with S-shaped bending in the warp direction, and then enter the microwave vulcanization device for vulcanization, then crimp and cut .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com