Combined device for manufacturing stay wire of overhead line

A combined device and overhead line technology, which is applied in the field of overhead line pulling wire manufacturing combined device, can solve the problems of weak iron wire, poor contact of steel strands, high rigidity of steel strands, etc., so as to improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

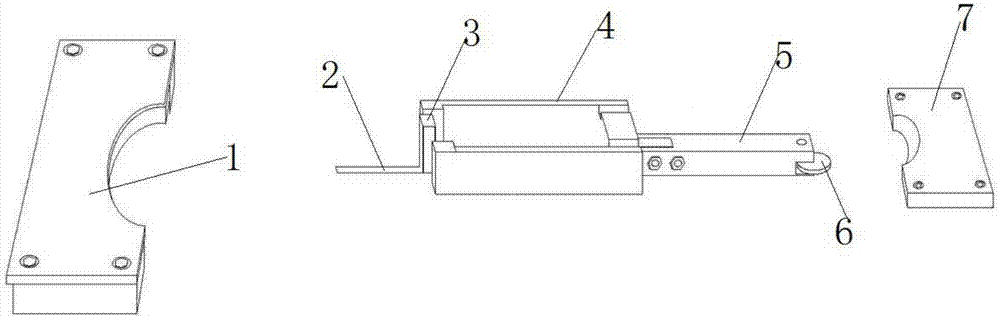

[0018] This embodiment provides a combination device for making overhead line guy wires, including: a model fixing mold, a chute, a wedge-shaped core pushing mold, a wedge-shaped pushing mold, a lower mold pushing rod, a lower mold, and an upper mold for bending and shaping steel strands; The chute, the wedge-shaped core push die, the wedge-shaped push die, the lower die push rod, and the lower die are located between the model fixed die and the steel strand bending and shaping upper die, one end of the chute is arranged in the wedge-shaped push die, and the wedge-shaped core The pushing mold can move in the chute, one end of the pushing rod of the lower mold is connected with the wedge-shaped pushing mold, and the lower mold is fixed at the other end.

[0019] Preferably, the model fixed mold and the steel strand bending and shaping upper mold are all provided with arc grooves, and the two arc groove structures are relatively arranged; the arc radian of the lower mold is the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com