Winding device for cable production

A winding device and cable technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of inconvenient removal of cables, poor use effect, loose cables, etc., and achieve better use effect Good, auxiliary cable movement, to avoid the effect of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

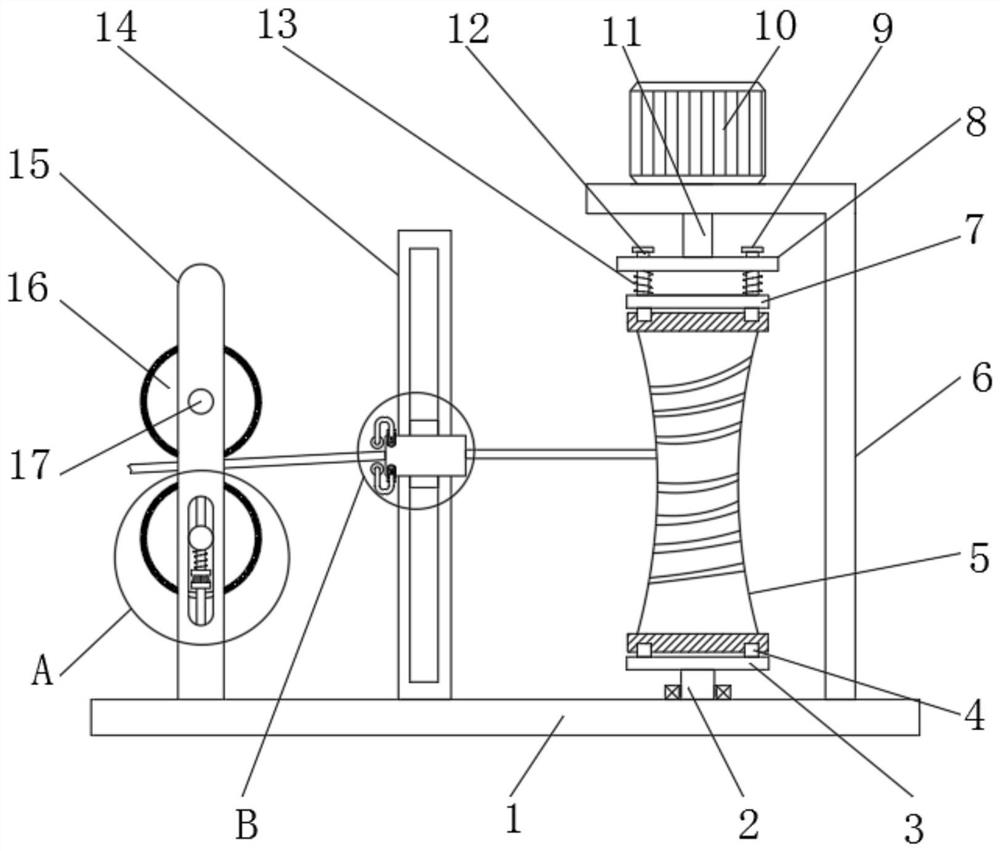

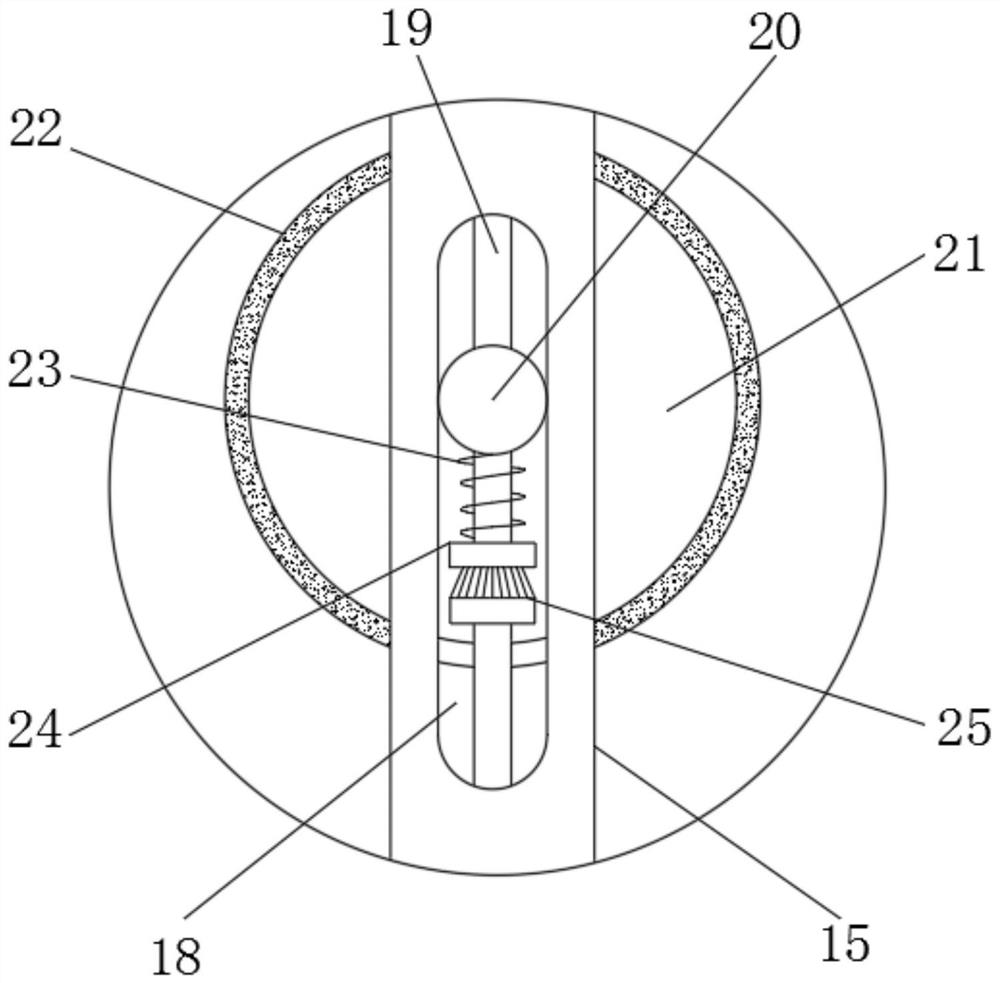

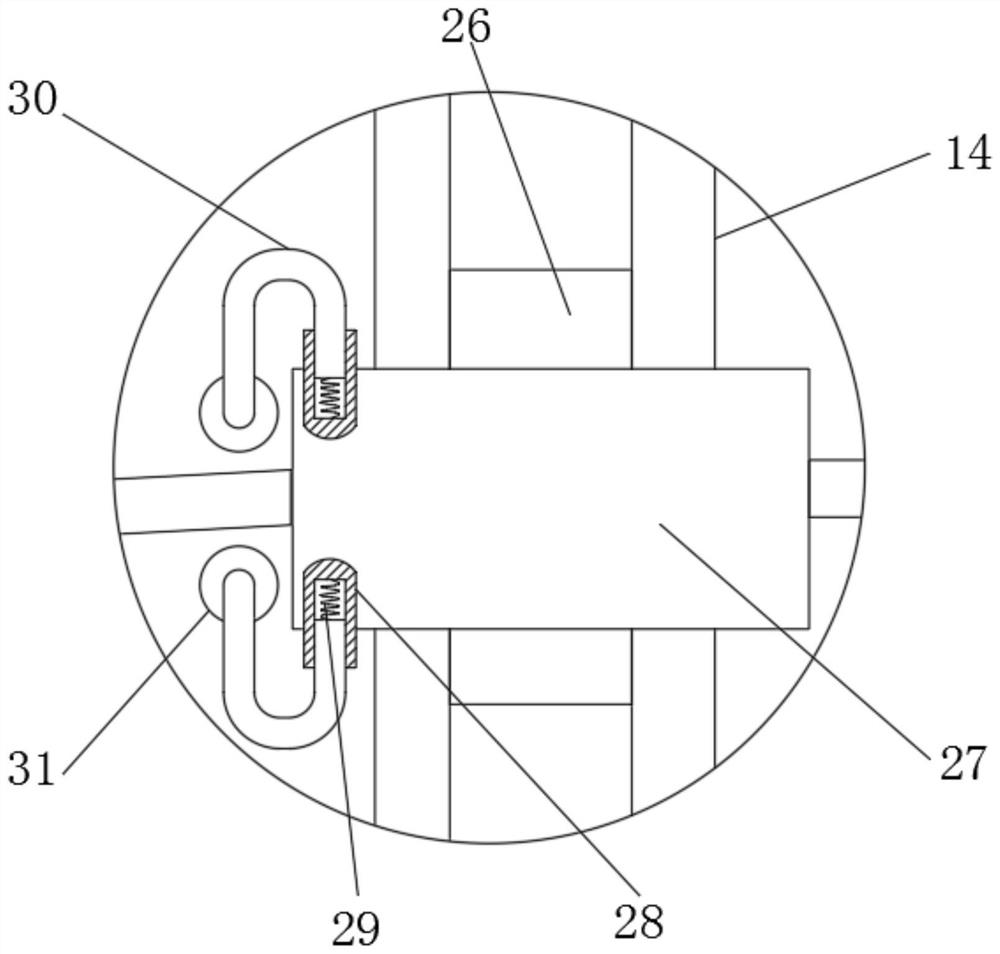

[0029] refer to Figure 1-4 , a winding device for cable production, comprising a bottom plate 1 and a winding roller 5, a mounting frame 6 is fixedly connected to the top outer wall of the bottom plate 1, and a motor 10 is arranged on the top outer wall of the mounting frame 6, and one end of the output shaft of the motor 10 is set There is a rotating shaft 11, and the bottom end of the rotating shaft 11 is provided with a turntable 8, and the top outer wall of the turntable 8 is provided with equidistant circularly distributed through holes, and the inner wall of the through hole is slidingly provided with a limit pin 12, and the top of the limit pin 12 is set There is a stopper 9, and the bottom end of the limit pin 12 is provided with an upper splint 7, the outer wall of the limit pin 12 is sleeved with a first spring 13, the top outer wall of the bottom plate 1 is provided with a movable shaft 2 through bearing rotation, and the movable shaft 2 is provided with a lower cl...

Embodiment 2

[0038] refer to Figure 5 , a winding device for cable production. Compared with Embodiment 1, this embodiment also includes universal wheels 32 at the four corners of the bottom outer wall of the bottom plate 1 .

[0039] Working principle: when in use, the universal wheels 32 located at the bottom of the bottom plate 1 make the device easy to move and more flexible to use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com