Patents

Literature

86results about How to "Control clamping force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

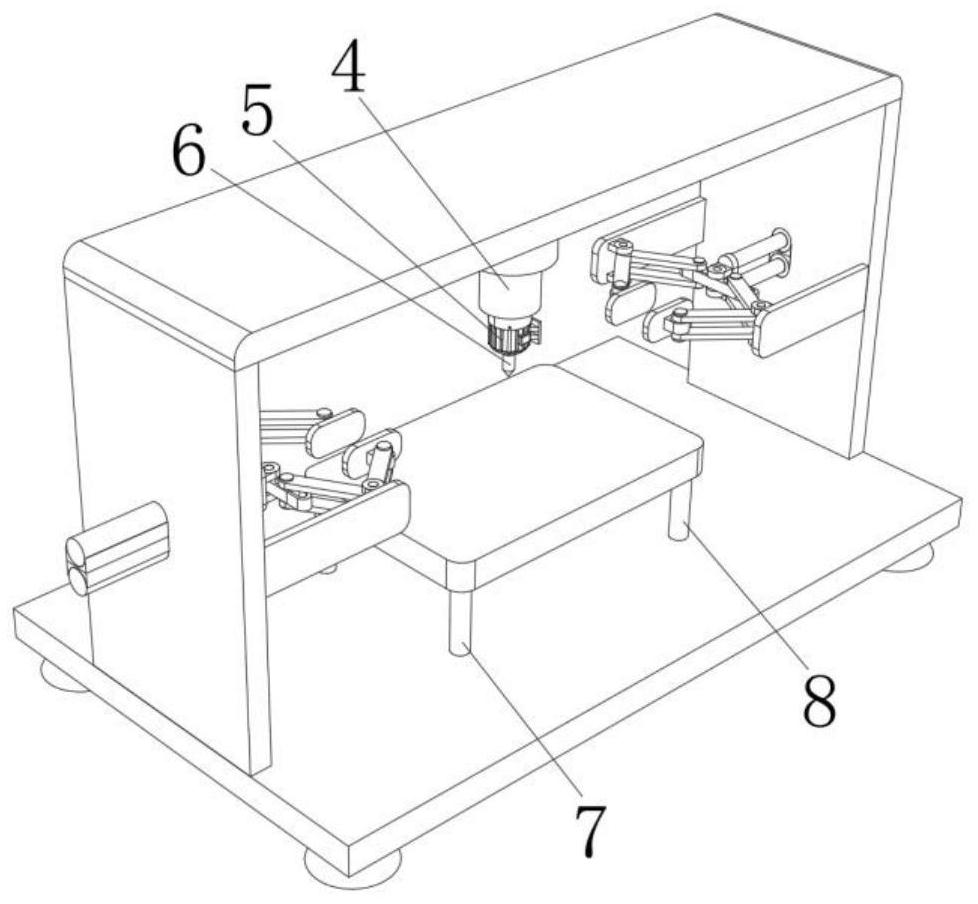

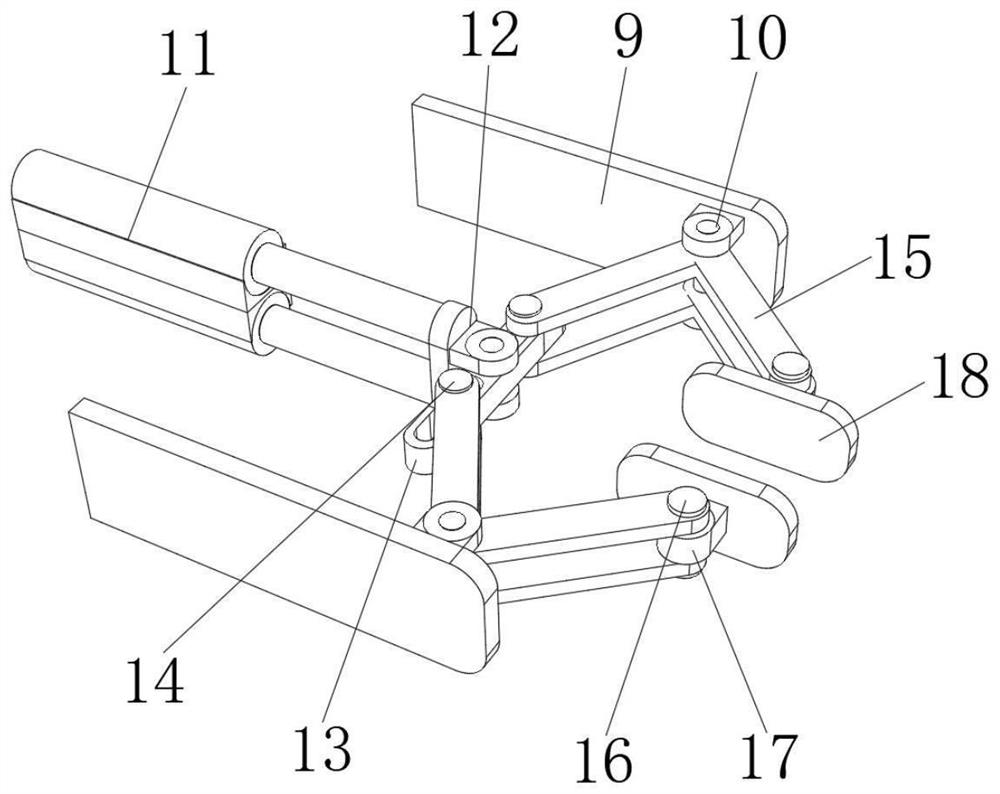

Mechanical carrying jaw

InactiveCN107472899AControl clamping forceAvoid deformationConveyorsSortingEngineeringMechanical engineering

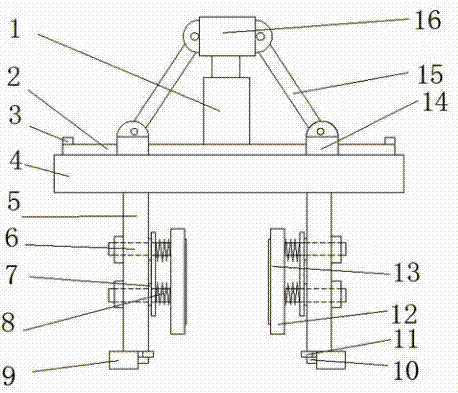

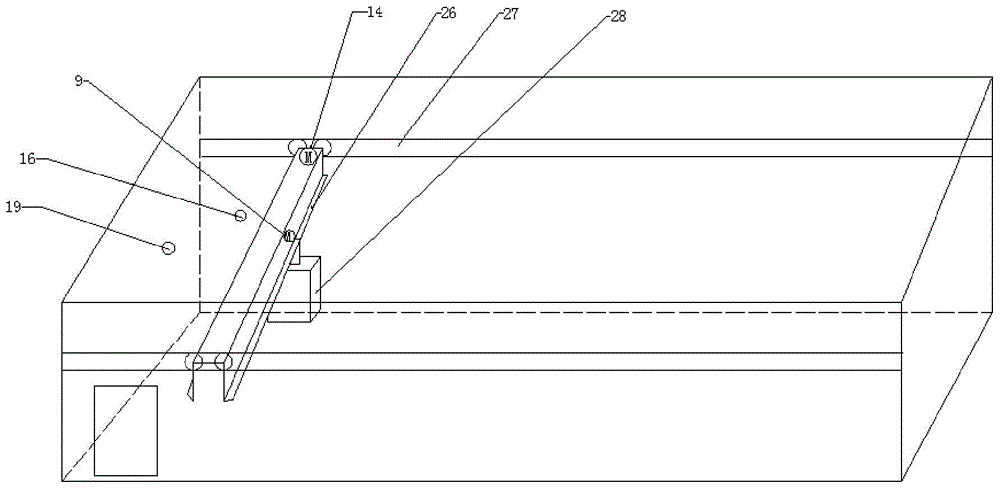

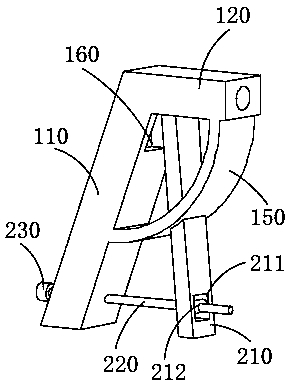

The invention relates to the technical field of logistics automation sorting, in particular to a handling mechanical claw, which includes a connecting plate, a connecting seat connected to a mechanical arm is arranged at the rear end of the connecting plate, a gripper is arranged on the lower side of the connecting plate, and There are two slide grooves on the top of the jaws, and there is a bump that matches the slide grooves above the jaws. A movable block is connected above the bumps on each jaw, and the movable block is connected with the clamping device. There is a pressure detection device, and the pressure detection device and the control device are linked together. A load-bearing device is arranged under the jaws, and the control device controls the connection with the clamping device and the load-bearing device. The present invention can control the clamping force on the package by installing a pressure detection device on the jaws, and the control device can control the position of the clamping device after receiving the pressure value detected by the pressure detection device, so as to prevent excessive clamping of the package from causing Deformation, a load-bearing device is set under the jaws to ensure the smooth transfer of the package.

Owner:ZHEJIANG UNIV

End effector and application thereof

InactiveCN103358312AReduce labor intensitySimple structureBreathing protectionGripping headsEmergency rescueEngineering

Owner:SOUTH CHINA AGRI UNIV

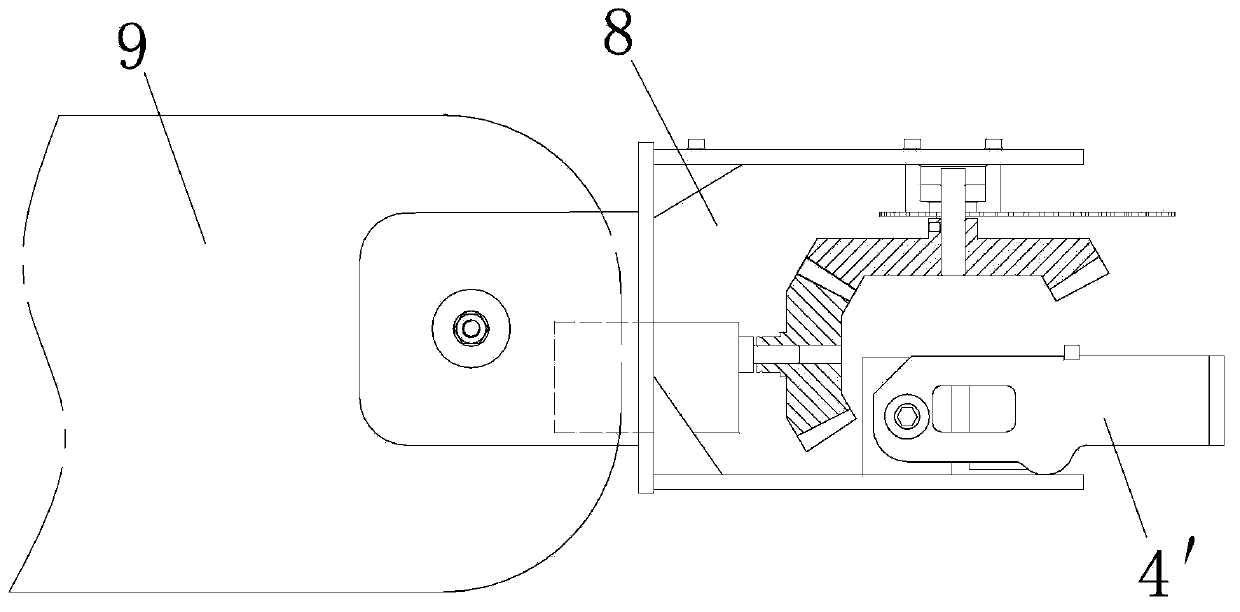

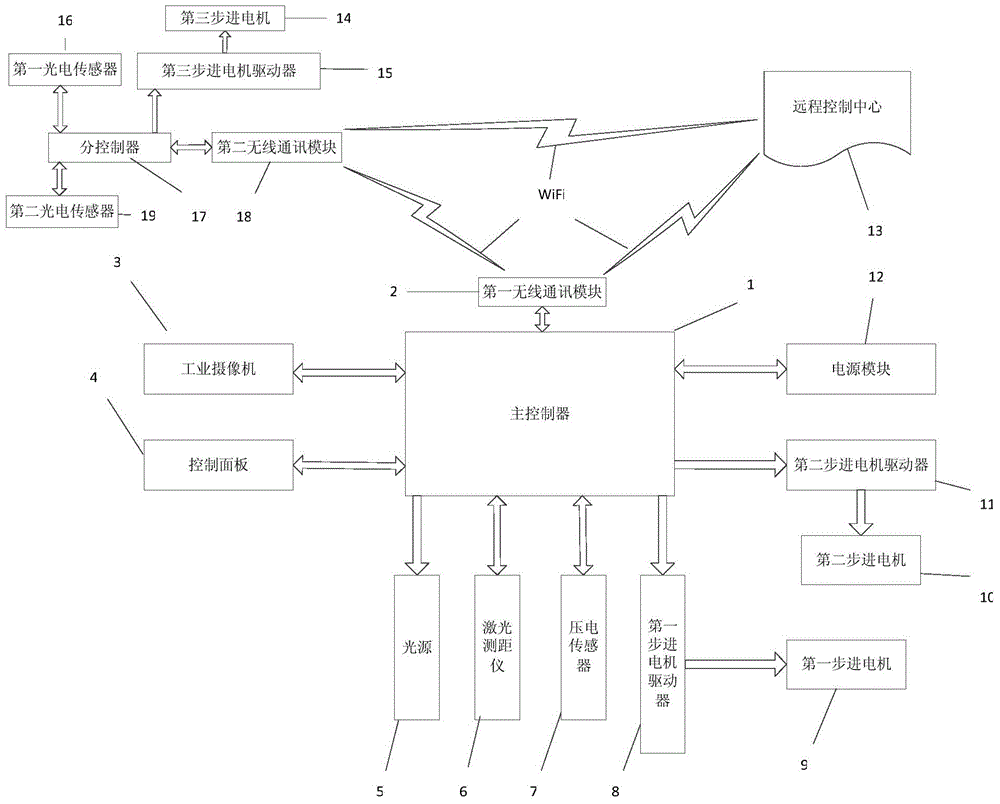

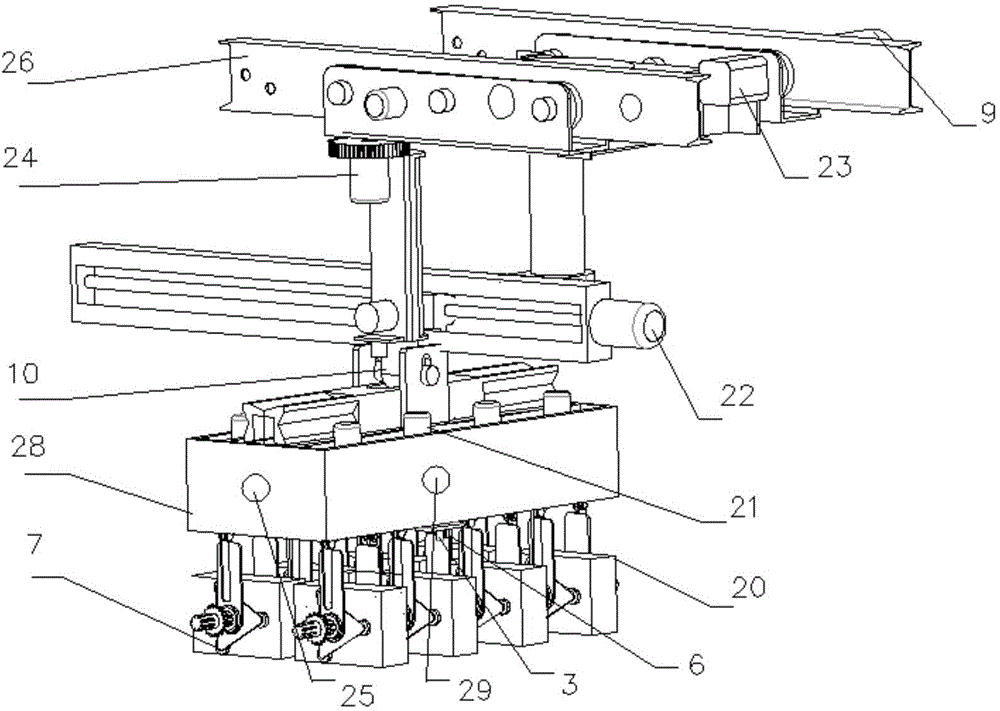

Solid brewing yeast turning precisely-positioned mechanical hand control system and method

The invention provides a solid brewing yeast turning precisely-positioned mechanical hand control system and method. The system comprises a main controller, a camera, a laser range finder, a power supply module, a first photoelectric sensor, a second photoelectric sensor and a sub-controller, wherein the mechanical hand is provided with a first photoelectric sensor reflection plate and a second photoelectric sensor reflection plate; the first photoelectric sensor, the second photoelectric sensor and a third stepper motor driver are respectively connected with the sub-controller; a first stepper motor driver, a second stepper motor driver, a fourth stepper motor driver, a fifth stepper motor driver, an adjusting motor, a clamping stepper motor, the camera and the laser range finder are respectively connected with the main controller, and the sub-controller is connected with the main controller. The mechanical hand is firstly roughly positioned and then precisely positioned, so that the positioning time is greatly shortened, and the working efficiency is improved.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

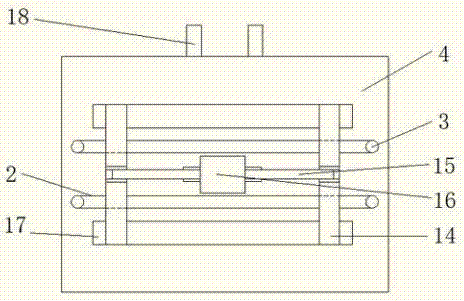

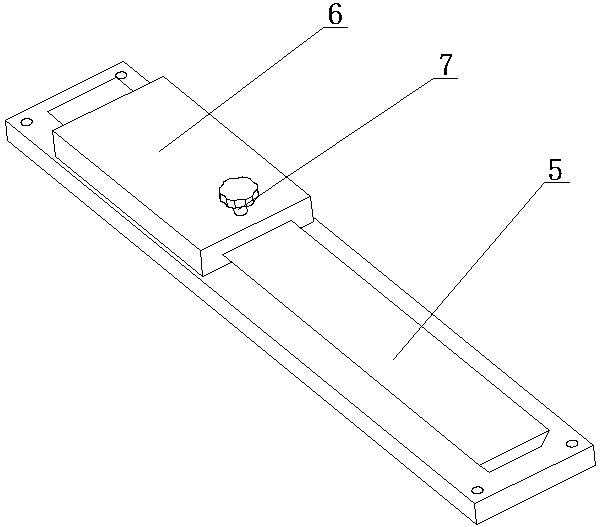

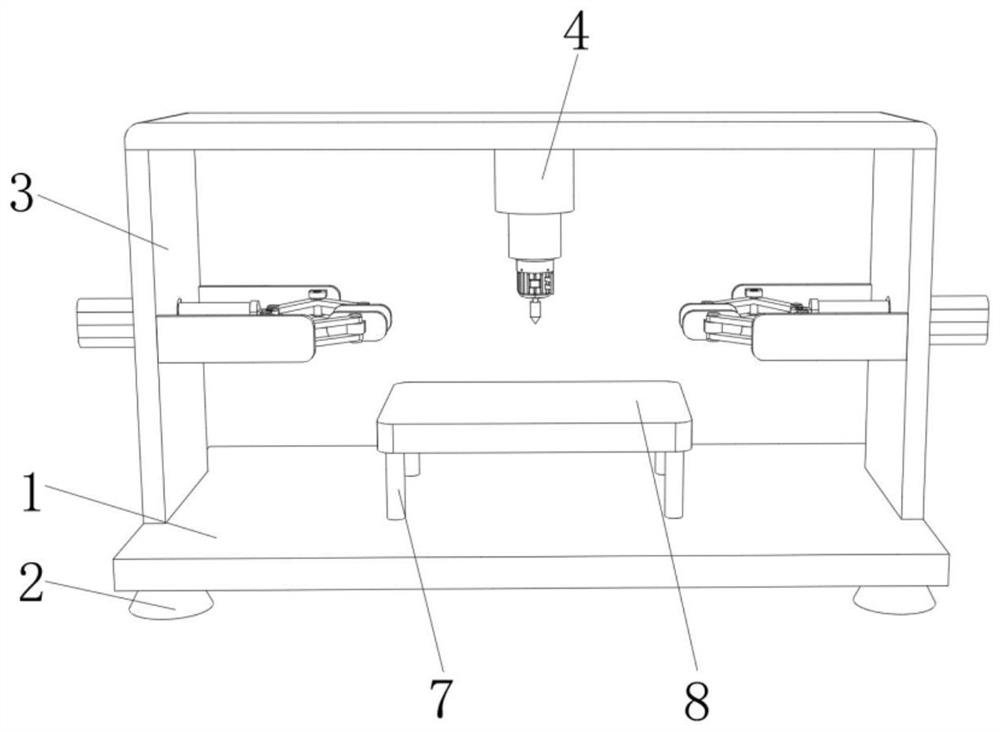

Full-automatic mobile phone film sticking device and film sticking method

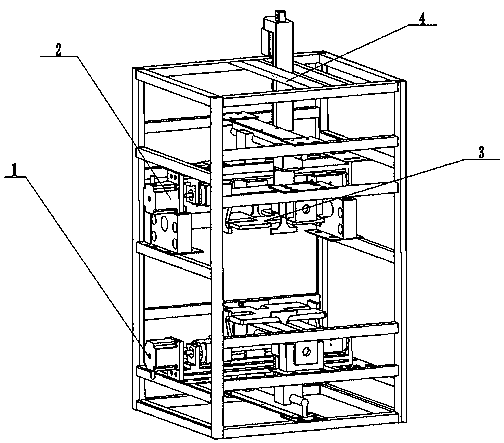

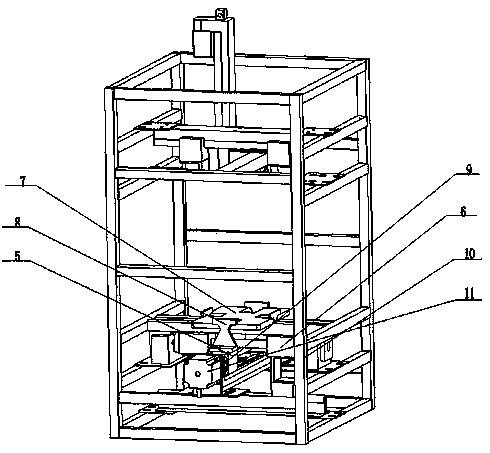

The invention relates to a full-automatic mobile phone film sticking device and film sticking method, and belongs to the field of machinery. The device comprises a mobile phone positioning and clamping mechanism, a mobile phone film positioning and clamping mechanism, a film bottom plate removing mechanism and a mobile phone film sticking mechanism which are vertically distributed, wherein the mobile phone positioning and clamping mechanism is located on the lower side, the mobile phone film positioning and clamping mechanism is located in the middle, the film bottom plate removing mechanism is located in the middle and located on the lower side of the mobile phone film positioning and clamping mechanism, the mobile phone film sticking mechanism is positioned on the upper side, and the mobile phone positioning and clamping mechanism, the mobile phone film positioning and clamping mechanism, the film bottom plate removing mechanism and the mobile phone film sticking mechanism are all connected to a main frame body through bolts and corner pieces. The device has the advantages of being novel in concept, simple in structure and convenient to use, the full-automatic mobile phone film sticking function can be realized on mobile phone toughened films, the device is widely applicable to mobile phones of various sizes and various models, the production efficiency is greatly improved, and practicability is high.

Owner:JILIN UNIV

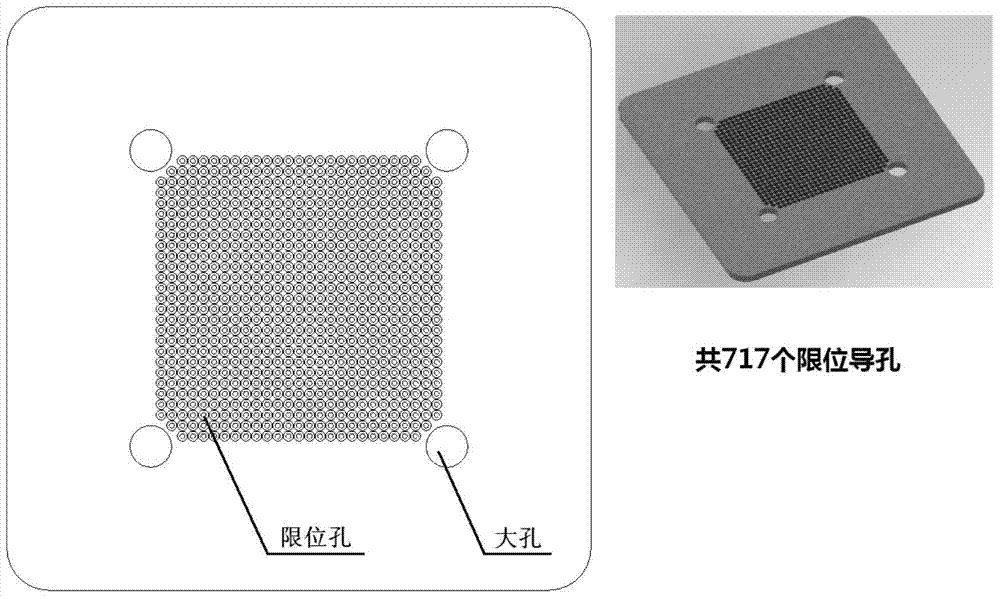

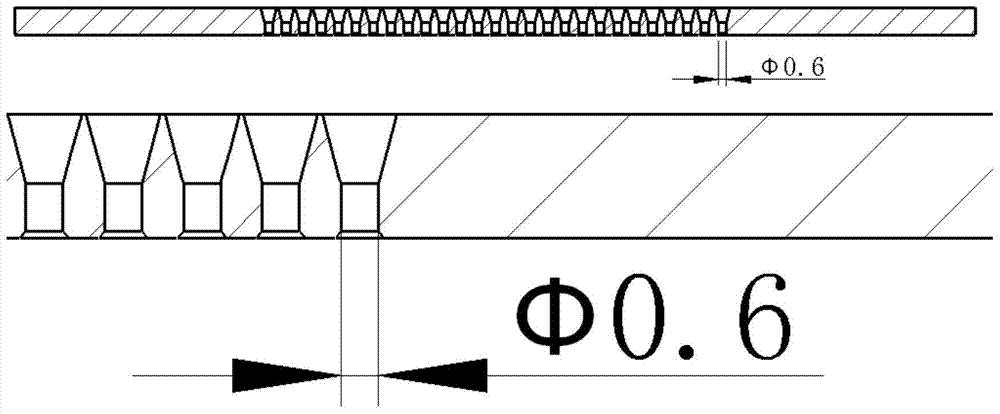

Tooling for reconditioning pin in ceramic column grid array (CCGA)

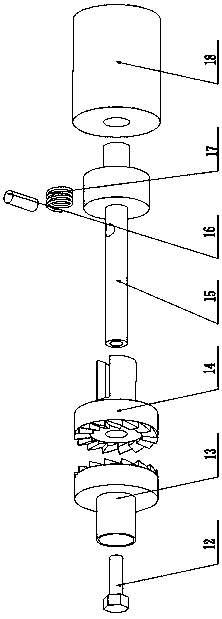

ActiveCN103700607AControl the amount of grindingControl clamping forceSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSandpaper

The invention relates to a tooling for reconditioning a pin in a ceramic column grid array (CCGA), belonging to the technical field of the CCGA. In the tooling for removing an oxidized layer, the exposure quantity of the pin of the CCGA device, relative to a clamping plate, can be adjusted by an adjusting washer, and is properly controlled to be about 0.1mm. An operator slightly grinds special abrasive paper stably by holding a pressure block handle, so as to achieve the purpose of removing the oxidized layer on the welded surface of the pin. The tooling is convenient to operate in the overall process, good in grinding effect, and capable of improving the overall planeness of the welded surface while the oxidized layer on the welded surface of the pin is removed.

Owner:BEIJING RES INST OF TELEMETRY +1

Clamping mechanism

InactiveCN106737793ARealize opening and closingCompact structureProgramme-controlled manipulatorGripping headsEngineeringPower unit

The invention provides a clamping mechanism, and relates to the technical field of clamping devices. The clamping mechanism comprises a clamping jaw which is composed of a driving arm and a driven arm, and the driving arm and the driven arm are oppositely arranged. The driving arm and the driven arm each comprise a clamping part and a transmission part, and the driving arm and the driven arm are pivoted on a base through the respective transmission parts. At least a part of each transmission part is arc, the arc portion of the transmission part of the driving arm is provided with driving teeth, and the arc portion of the transmission part of the driven arm is provided with driven teeth capable of being engaged with the driving teeth. The driving arm and the driven arm are in engaged transmission. The driving arm is connected with a power unit for driving the driving arm to rotate. The clamping mechanism is used for solving the technical problems that in the prior art, a clamping mechanism is complex in structure and high in cost.

Owner:王安基

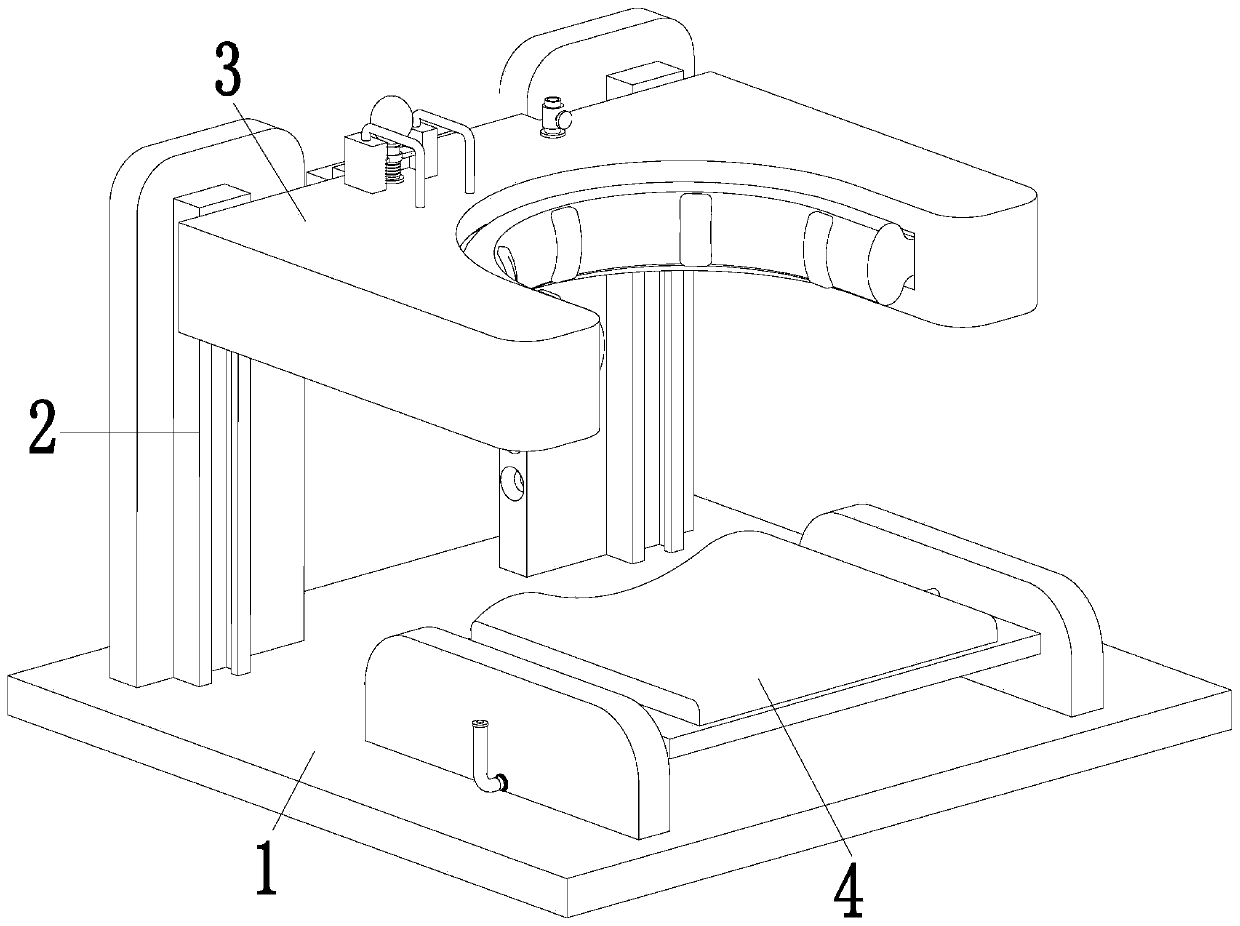

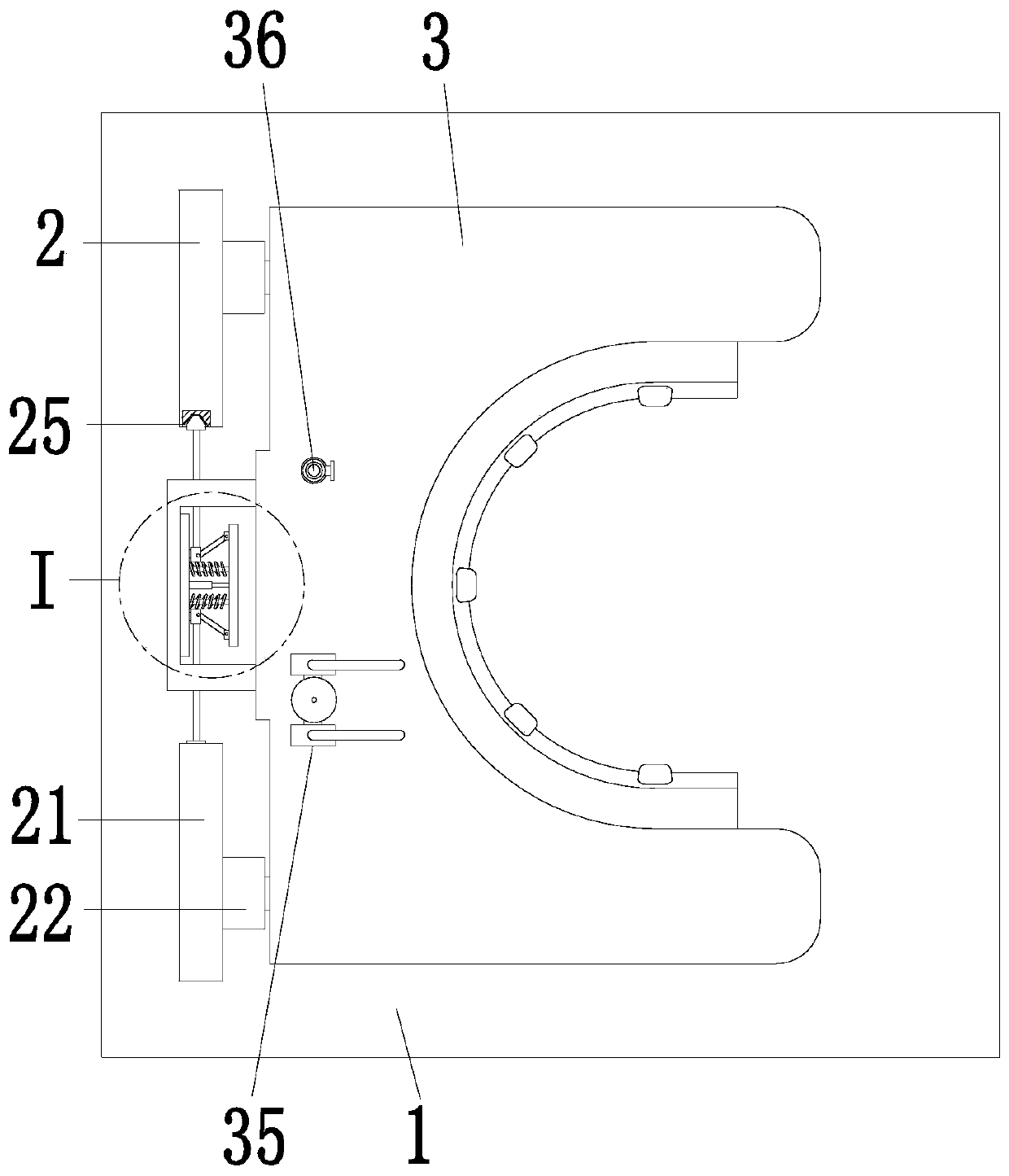

Image examination posture placing fixing device

ActiveCN109805952AAvoid damageAvoid ArtifactsPatient positioning for diagnosticsComputerised tomographsEngineering

The invention relates to an image examination posture placing fixing device which comprises a bottom plate, an adjusting device, a clamping device and a head pillow device, wherein the adjusting device is arranged on the left side of the upper end of the bottom plate, the clamping device is arranged at the upper end of the right side of the adjusting device, the head pillow device is arranged on the right side of the upper end of the bottom plate, and the clamping device is arranged above the head pillow device. The image examination posture placing fixing device disclosed by the invention cansolve the problems that existing equipment generally cannot effectively clamp the head of an examinee in CT image examination, so that a false image can appear in image shooting; meanwhile, when thehead is clamped, a nose-up pitch angle of the head of the patient cannot be adjusted. The image examination posture placing fixing device can achieve the purposes of automatically clamping the head ofthe patient and adjusting the angle of the head, has a good clamping effect, can prevent the head from shaking and can avoid the false image; meanwhile, the image examination posture placing fixing device has the advantages of effectively controlling clamping force, avoiding damage to the head of the patient and the like.

Owner:JILIN UNIV

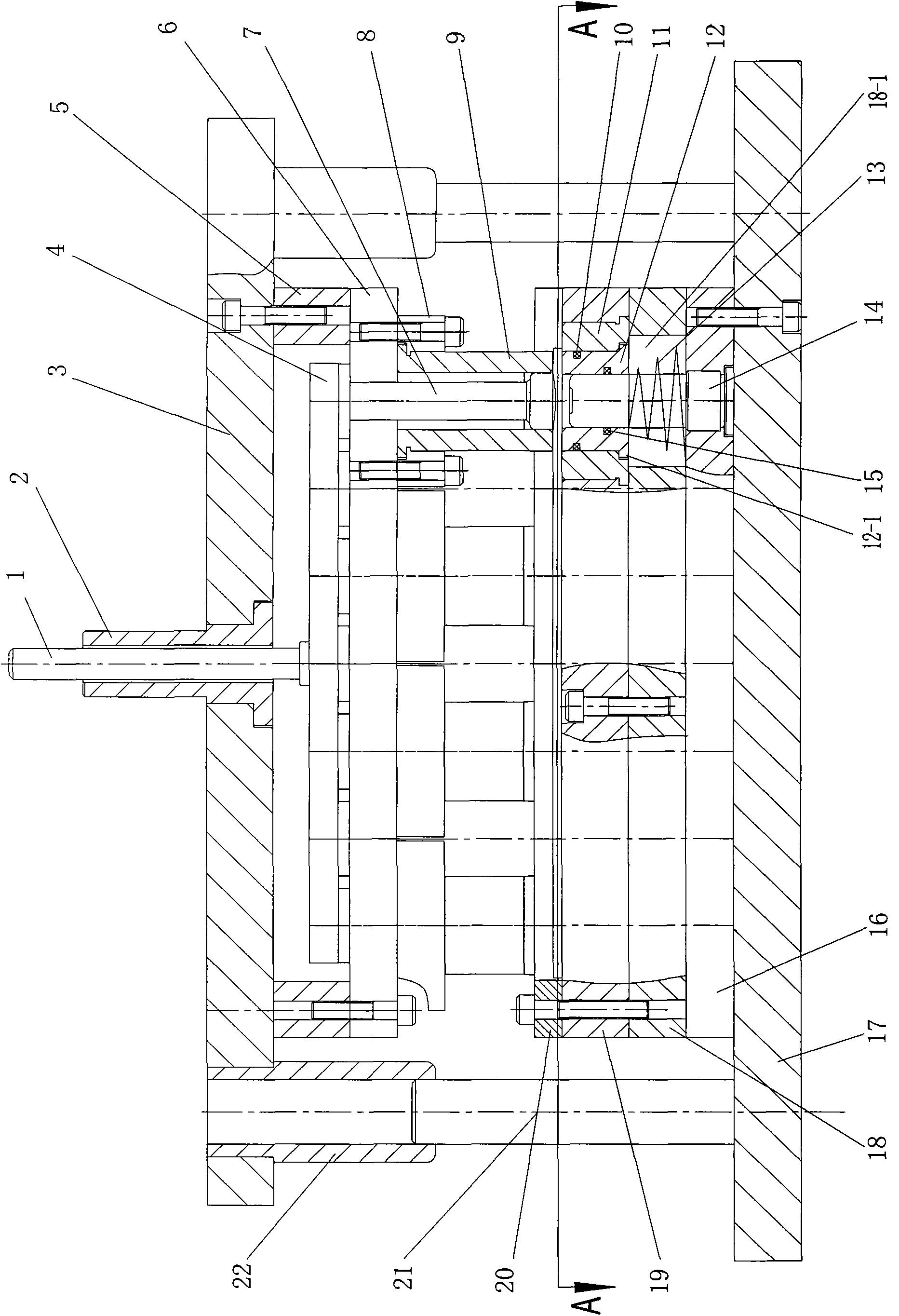

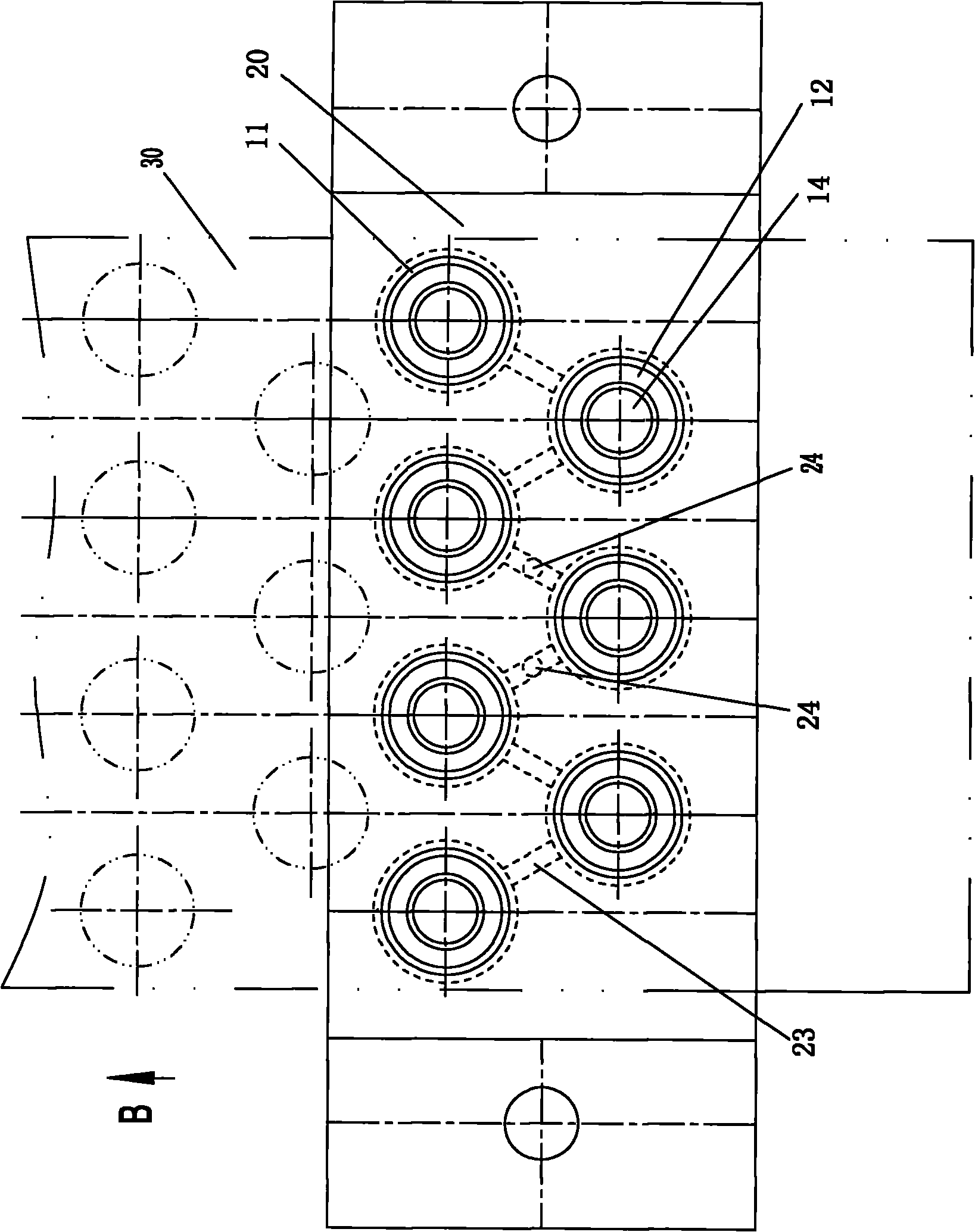

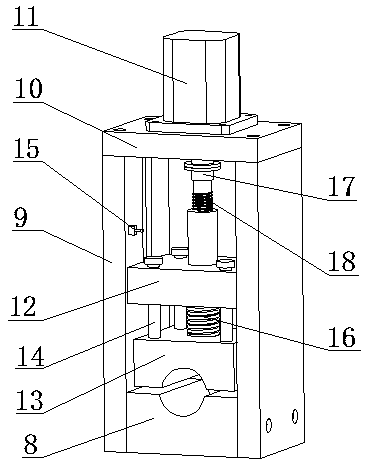

Blanking and drawing composite die for aluminium shell of capacitor

ActiveCN101930855AThe amount of elongation (plastic deformation) is equalAvoid tearingShaping toolsCapacitor manufactureEngineeringAtmospheric pressure

The invention relates to a blanking and drawing composite die. The provided die has the characteristics of good product quality, high production efficiency and low cost. The invention adopts a technical scheme that: the blanking and drawing composite die for an aluminium shell of a capacitor comprises a lower die seat and an upper die seat, wherein a plurality of vertically arranged female dies are fixed on the lower die seat; a male die is vertically fixed in the centre of the cavity of each female die; and a plurality of female and male dies which are matched with the female dies and the male dies one by one are fixed on the upper die seat. The blanking and drawing composite die is characterized in that: a pressure ring capable of vertically sliding is sleeved on each male die respectively; an upward pressure is applied by a pressure spring onto the bottom end of the pressure ring; the outer circumferential surface of the pressure ring is matched with the female dies; and a convex edge for limiting the outer circumferential surface is arranged on the outer circumferential surface. A pneumatic tube network is also arranged in the lower die seat, wherein the pneumatic tube network is respectively communicated with the cavity of each female die so as to apply the upward air pressure onto the pressure ring; and air from an external air source is supplied to the pneumatic tube network through an externally connected air pipe.

Owner:江苏奥星电子有限公司

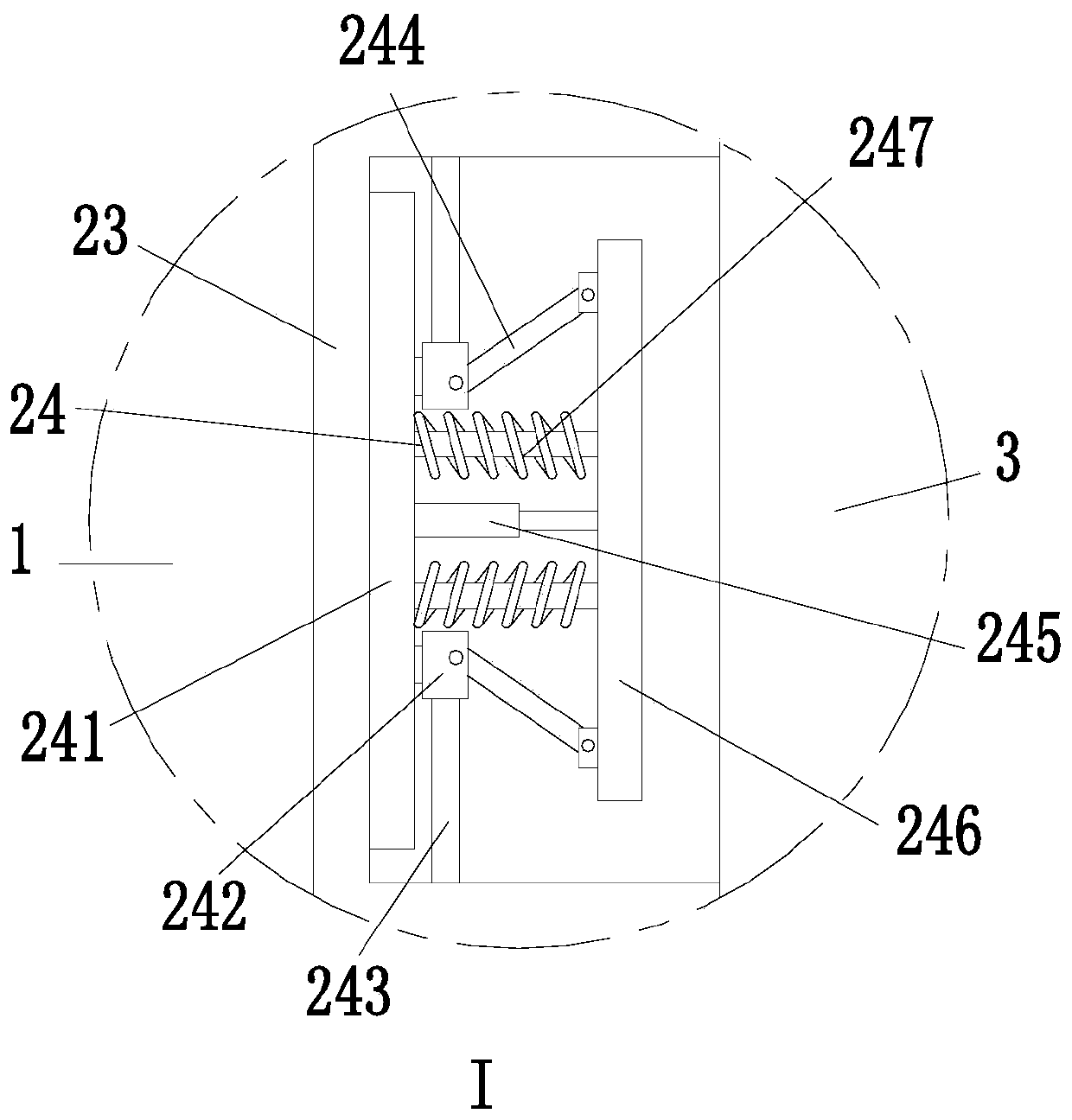

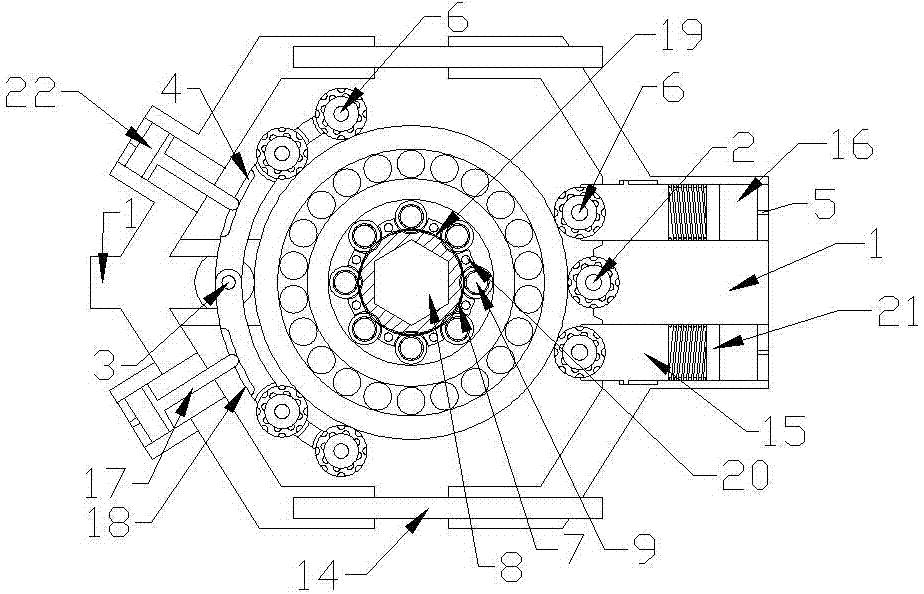

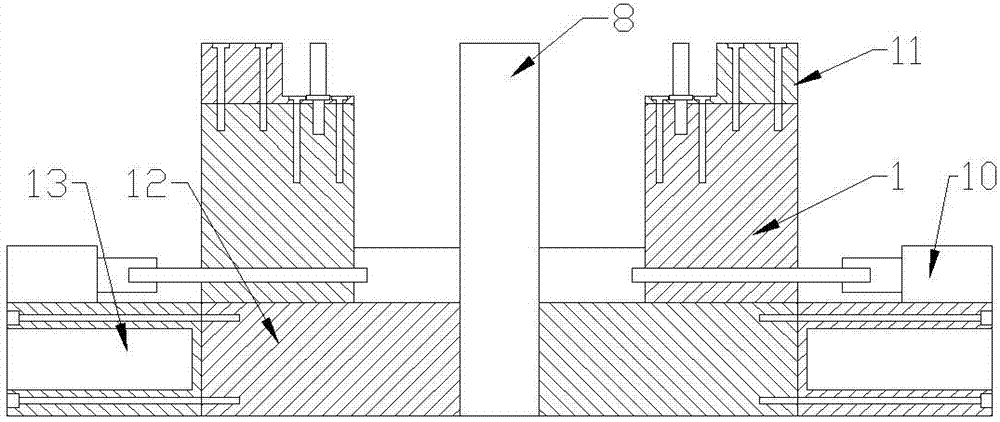

Swinging-type bearing roller installing fixture

InactiveCN107538198AAvoid forcing the bearing frameAvoid the situationMetal working apparatusEngineeringPiston

The invention relates to a swing type bearing roller installation tool, which includes a support, and a bearing inner frame fixing seat is arranged in the middle of the support. Outer frame pressing device; the bearing outer frame pressing device includes two sets of pushing mechanisms, the pushing mechanism includes a sliding block that is slidably connected with the support and a linear drive mechanism installed on the support for pushing the sliding block, one of the sliding blocks There is a bearing outer frame supporting mechanism on the upper part, and a bearing outer frame pushing mechanism is arranged on the other sliding block; the bearing outer frame supporting mechanism includes two mirror-symmetrical clamping arms arranged on one of the sliding blocks, and the other sliding block The compression mechanism driven by air pressure on the block is also provided with a supporting frame on the two sliding blocks, and the supporting frames are movably connected by a sliding sleeve structure. The pushing piston of the clamping arm is provided with a bar-shaped groove corresponding to the pushing rod of the pushing piston on the clamping arm.

Owner:JIANGYIN JIB WD PRECISION

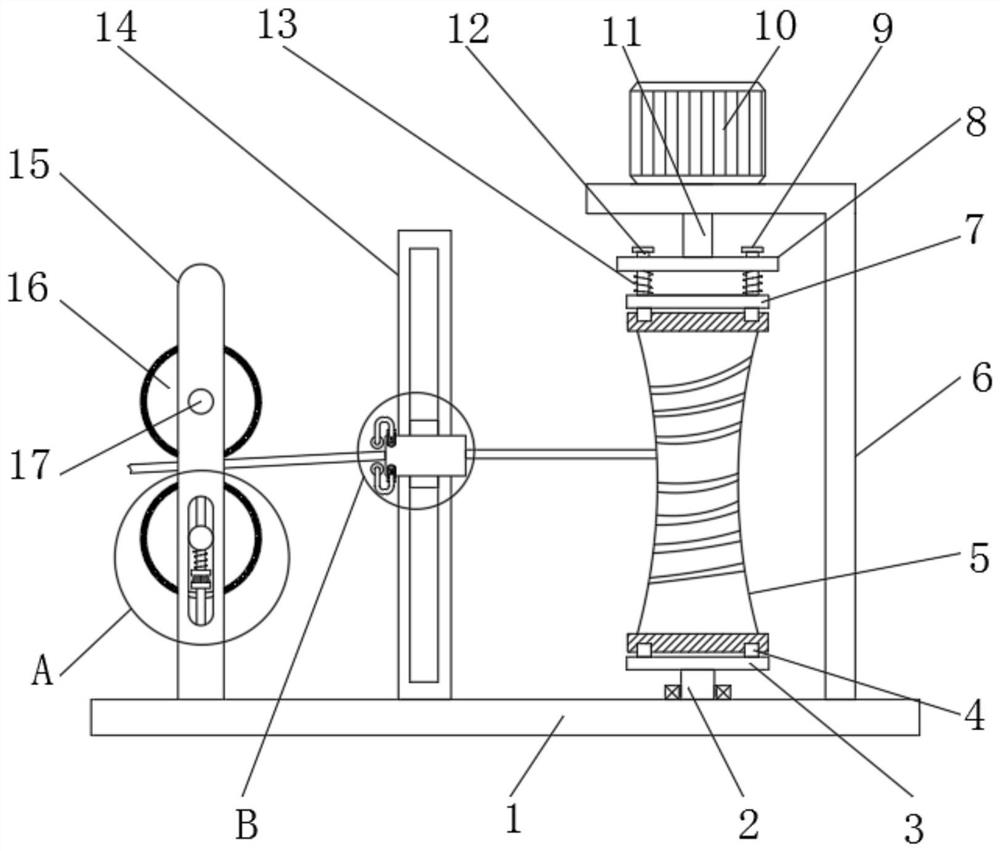

Winding device for cable production

The invention discloses a winding device for cable production. The winding device for cable production comprises a bottom plate and a winding roller; a mounting frame is fixedly connected to the outer wall of the top of the bottom plate, a motor is arranged on the outer wall of the top of the mounting frame, a rotating shaft is arranged at one end of an output shaft of the motor, and a rotating disc is arranged at the bottom end of the rotating shaft; through holes which are annularly distributed at equal intervals are formed in the outer wall of the top of the rotating disc, limiting pins are slidably arranged on the inner walls of the through holes, stop blocks are arranged at the top ends of the limiting pins, an upper clamping plate is arranged at the bottom ends of the limiting pins, the outer walls of the limiting pins are sleeved with first springs, a movable shaft is rotatably arranged on the outer wall of the top of the bottom plate through a bearing, and a lower clamping plate is arranged at the top end of the movable shaft. By means of the winding device, the winding roller can be easily taken down, replacement with a new winding roller can be conveniently carried out, use is quite convenient, a cable can be evenly wound around the winding roller, abrasion caused by contact between the cable and the inner wall of a cable guide cylinder is effectively avoided, and the use effect is better.

Owner:湖南鑫亿电缆有限公司

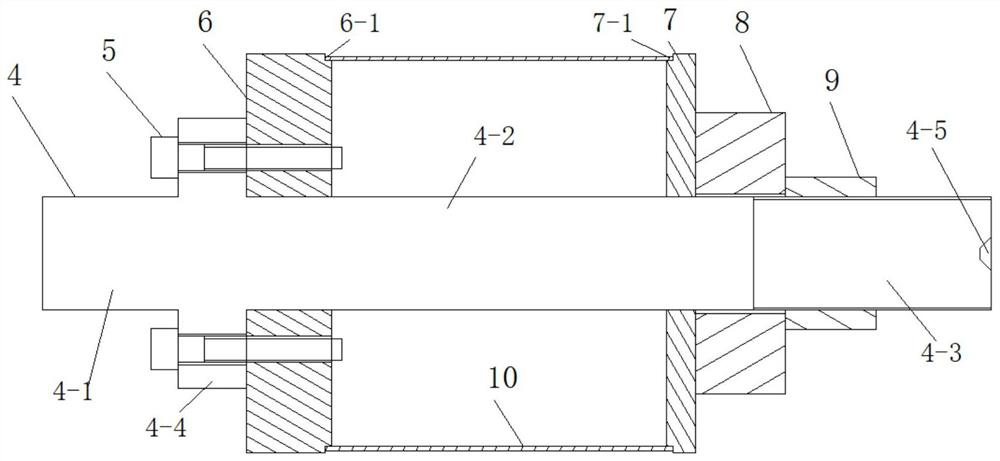

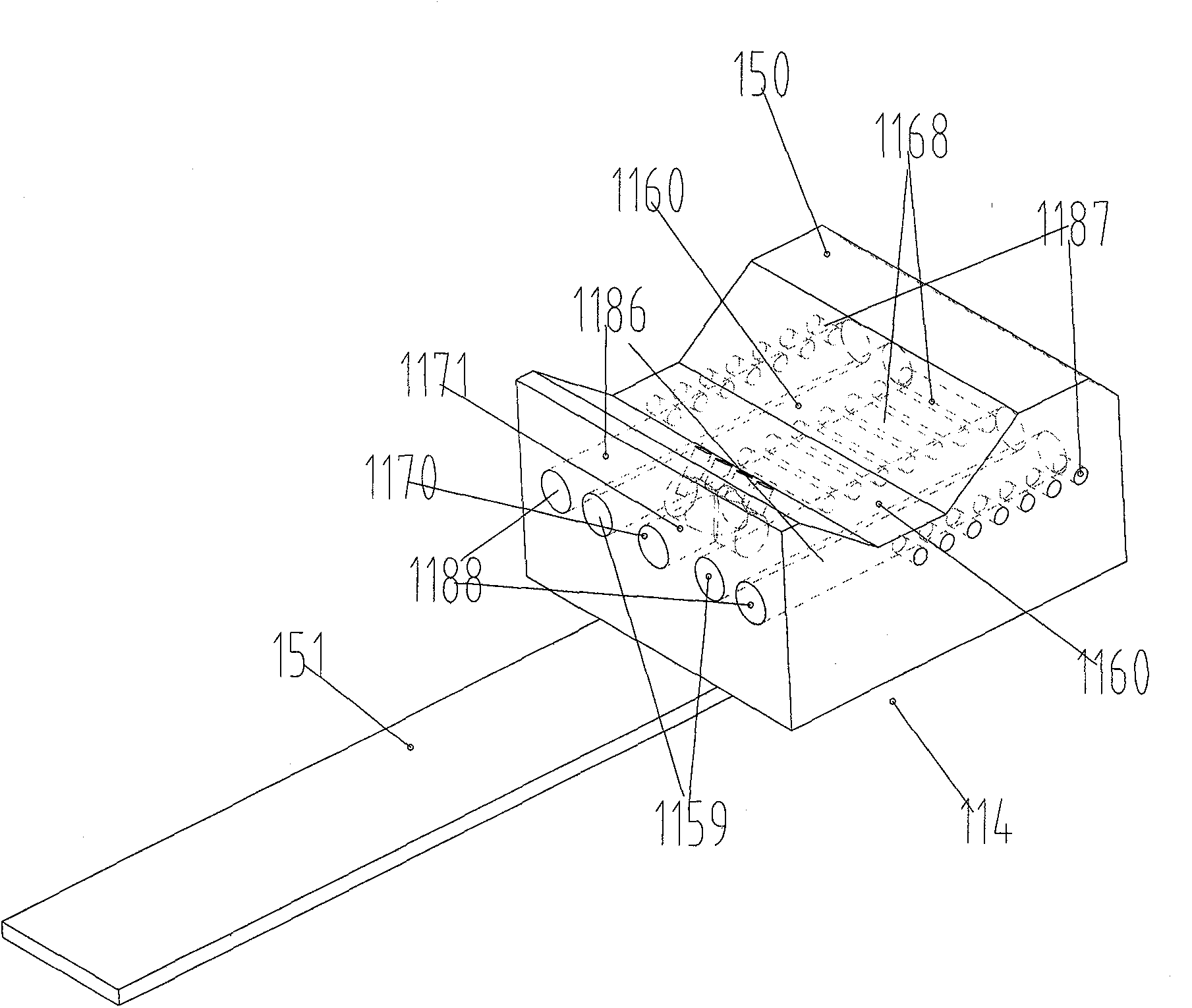

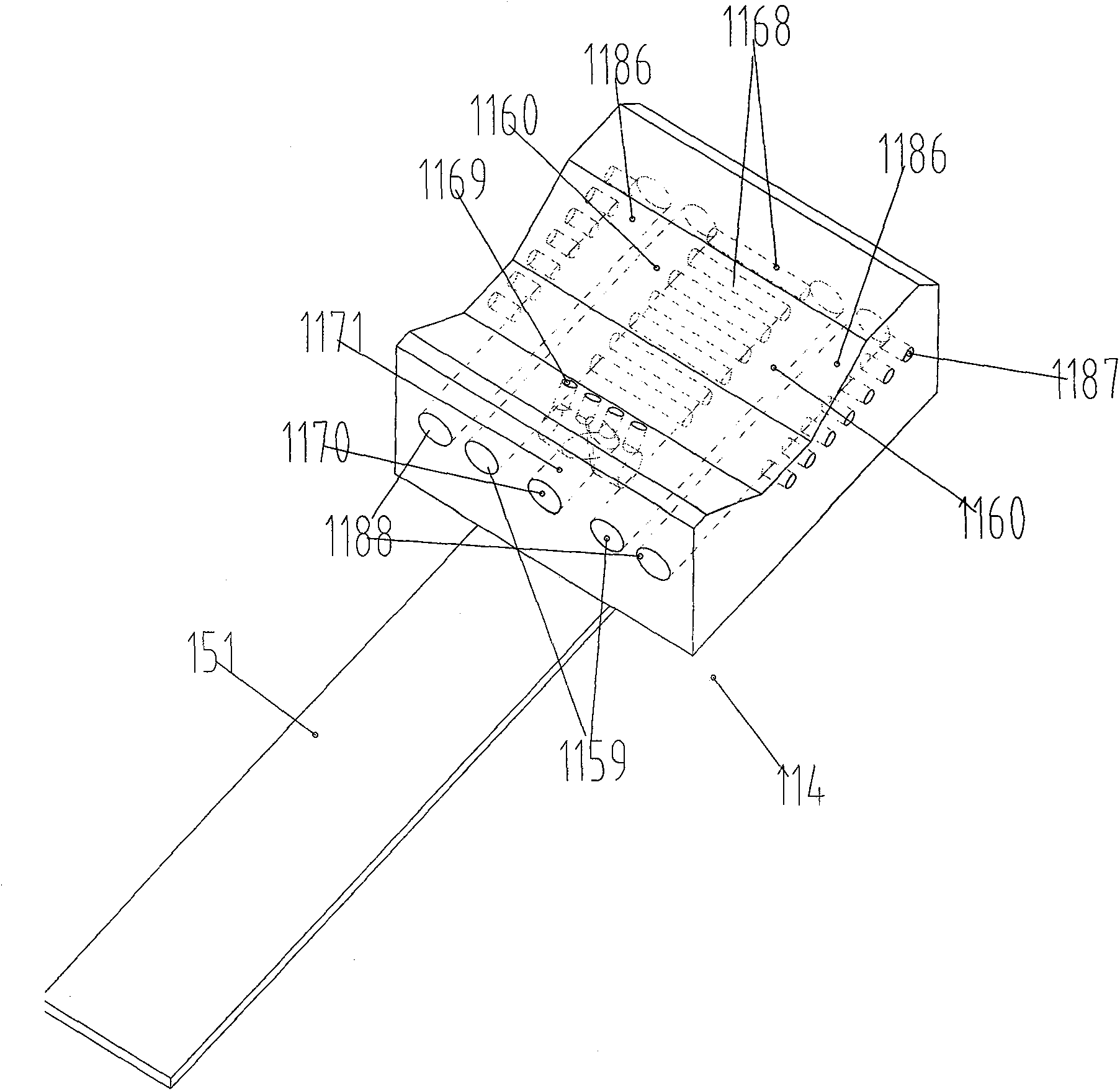

Cylindrical thin-walled workpiece machining and forming tool and method

InactiveCN112338601AImprove performanceGuaranteed dimensional accuracyElectron beam welding apparatusPositioning apparatusMachining processMachine tool

The invention discloses a cylindrical thin-walled workpiece machining and forming tool and method. The method comprises the steps of dividing a to-be-machined cylindrical thin-walled workpiece into aplurality of circular ring structures, accordingly machining each circular ring structure, assembling all machined circular ring structures together, carrying out vacuum electron beam welding so as toobtain a combined component, carrying out vacuum annealing and finish machining on the combined component to obtain the final cylindrical thin-wall workpiece. The machining tool comprises an inner-surface machining tool body, an outer-surface machining tool body and an assembling and welding tool body, the inner-surface machining tool body is used for clamping a circular ring structure when the inner surface of the circular ring structure is machined, the outer-surface machining tool body is used for clamping the circular ring structure when the outer surface of the circular ring structure ismachined, and the assembling and welding tool is used for assembling all the cylinders together when all the circular ring structures are welded into the combined component. According to the tool andmethod, the deformation of the cylindrical thin-walled workpiece in the machining process can be improved and controlled, and the machining precision is guaranteed.

Owner:SHAANXI HEYE SPECIAL STEEL TOOL

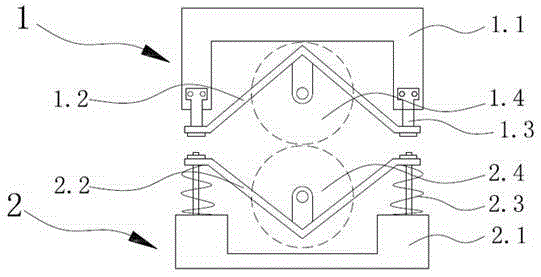

Cloth flattening device

The invention discloses a cloth flattening device which comprises an upper ironing device and a lower ironing device. The upper ironing device comprises an upper support and an upper mounting rack which is fixed to the upper support through a fixing support. An upper ironing roller is arranged on the upper mounting rack. The lower ironing device comprises a lower support and a lower mounting rack. The two ends of the lower mounting rack are connected with the lower support through adjusting springs. A lower ironing roller is arranged on the lower mounting rack. The cloth flattening device is reasonable in structural design, clamping force between the ironing rollers is controlled through the stroke of the adjusting springs, smoothness of cloth is effectively improved, folds are removed, and the use effect is good.

Owner:JIANGYIN QIANGDA MACHINERY MFG CO LTD

Intelligent association transfer robot arm for building construction site

InactiveCN112792831ASave human effortImprove work efficiencyGripping headsElectric machineryStress sensors

The invention discloses an intelligent association transfer robot arm for a building construction site. The intelligent association transfer robot arm for the building construction site comprises a clamping mechanism and a moving mechanism, the clamping mechanism comprises a rotating seat, a motor and a rotating frame, the motor is installed on the front portion of the rotating seat, the rotating frame is installed on the inner side of the rotating seat, a clamping frame is arranged on the rotating frame, an outer cylinder is arranged on the inner side of the clamping frame, an electric telescopic column is installed in the interior of the outer cylinder, an inner sliding column is installed on the telescopic portion of the electric telescopic column, a connecting plate is arranged on the inner sliding column, a pressure sensor is installed on the connecting plate, and a fixing plate is arranged on the pressure sensor. The intelligent association transfer robot arm for the building construction site is simple in structure, reasonable in design and low in production cost, glass can be well clamped and placed on a transport vehicle, meanwhile, the glass can be well protected from being damaged by clamping, and therefore manpower is greatly saved, the working efficiency is improved, glass materials are convenient to carry, and the practicability is high.

Owner:CHANGAN UNIV

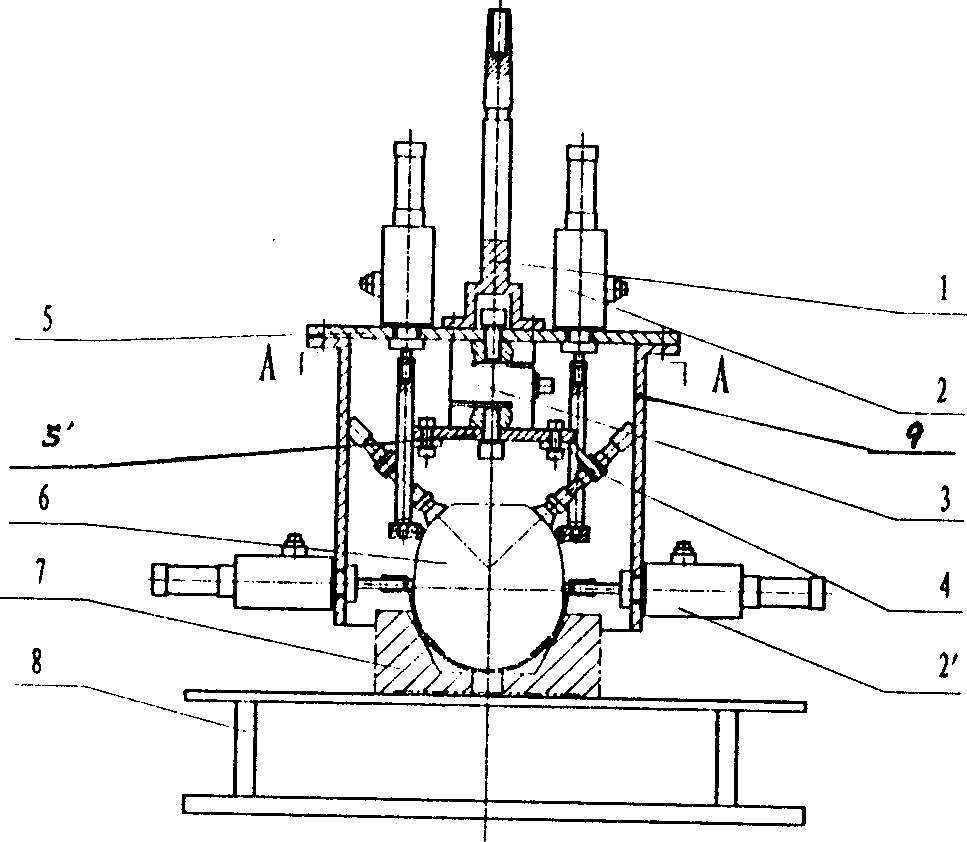

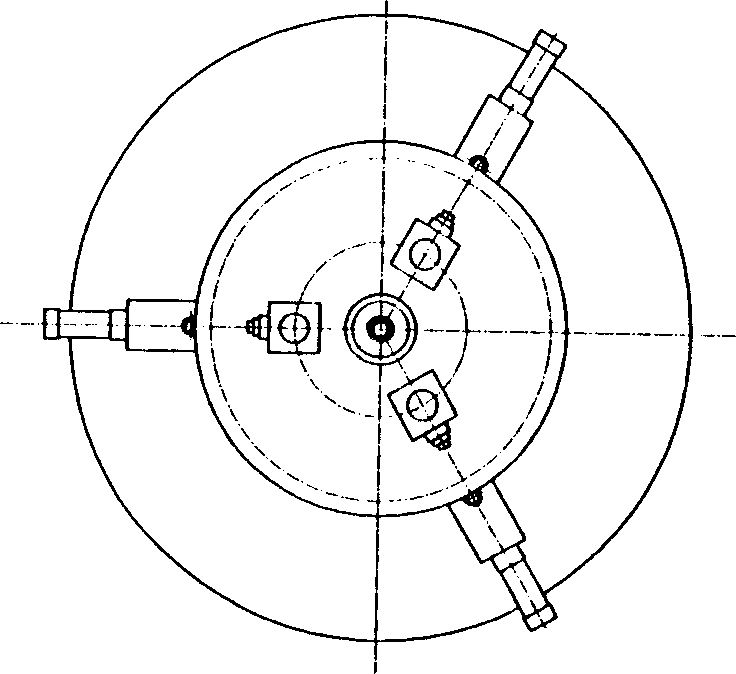

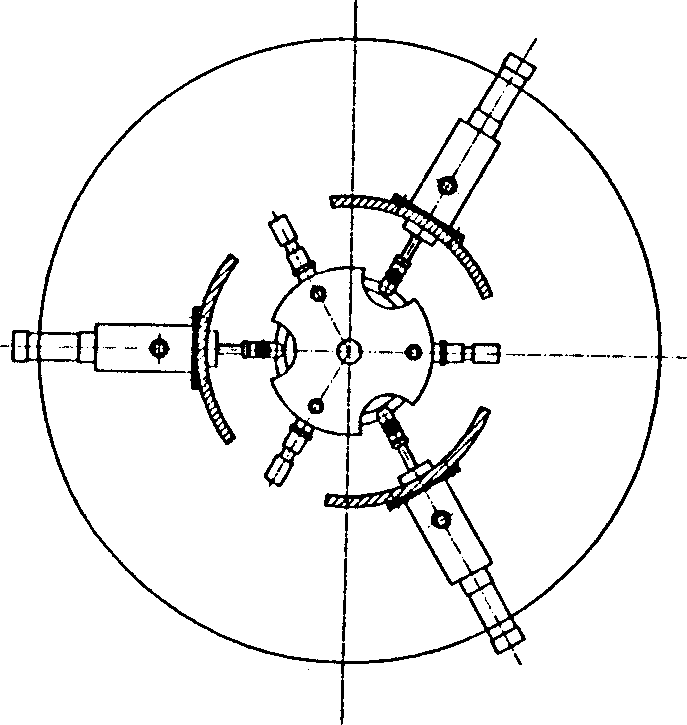

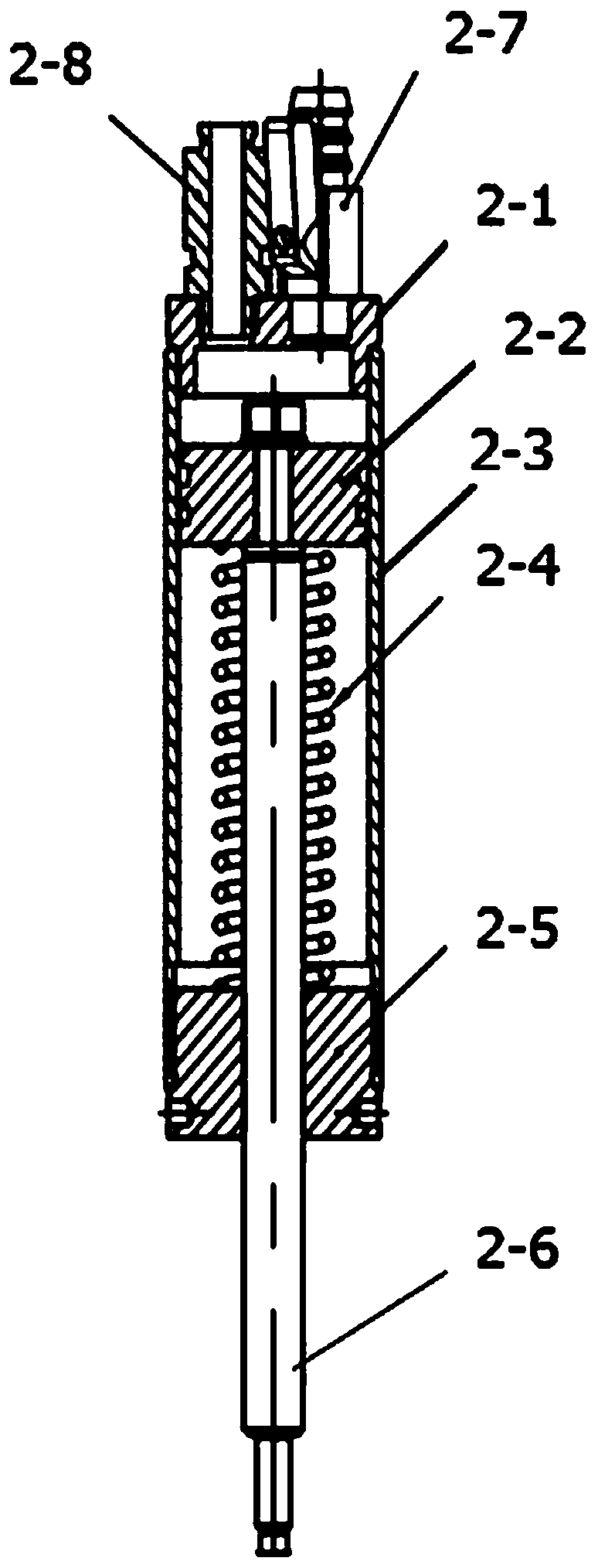

Special robot for gripping ball thinwall brittle shell body

The special robot for grabbing ball-shaped thin-wall brittle shell is formed from taper shank, positioning locking cylinders, pressure transducer and vacuum suction cup, in which the taper shank is mounted on the centre of supporting disk A, the vacuum suction cup is connected with supporting disk B, the pressure transducer is positioned between supporting disk A and supporting disk B, and they are coaxial, and the positioning locking cylinders are uniformly distributed on the surface of supporting disk A, under the supporting disk A and supporting plate is mounted, the positioning locking cylinders are mounted on the supporting plate, and uniformly distributed arround the pressure transducer. Said invention possesses feedback control function, and is suitable for grabbing ball-shaped thin-wall brittle shell body.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

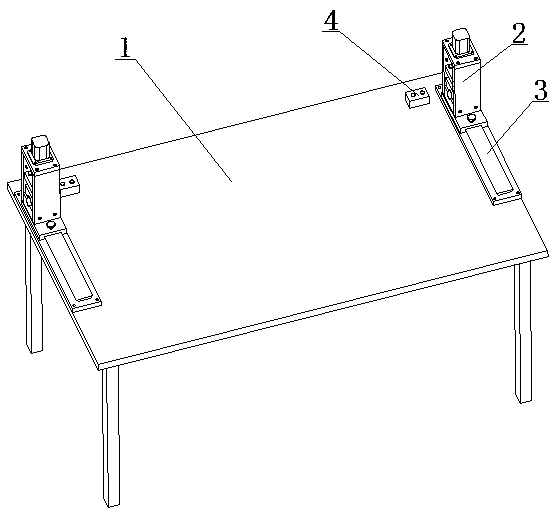

Optical cable fusion welding operation platform

The invention discloses an optical cable fusion welding operation platform. The optical cable fusion welding operation platform includes a work table, a clamping device for fixing an optical cable anda control module for controlling the clamping device, wherein the clamping device is adjustably connected to the two ends of the surface of the work table through an adjusting seat, the clamping device includes a clamping base and a moving clamping part, the moving clamping part is arranged above the clamping base and is driven by a motor to move relative to the moving clamping base, the motor iselectrically connected with the control module, the moving clamping part includes a moving plate, the moving plate is connected with the motor in a transmission mode, clamping blocks are arranged below the moving plate and directly face the clamping base, the moving plate and the clamping blocks are connected through springs, a stroke control mechanism is further arranged between the moving plateand the clamping blocks, and the relative moving distance of the moving plate and the clamping blocks is controlled through the stroke control mechanism. According to the optical cable fusion weldingoperation platform, when the optical cable is fastened and fixed, the magnitude of clamping force can be effectively controlled, and the problem that in an existing manual clamping device, the optical cable is damaged due to the fact that the size of the clamping force is difficult to control is avoided.

Owner:金华八达集团有限公司 +1

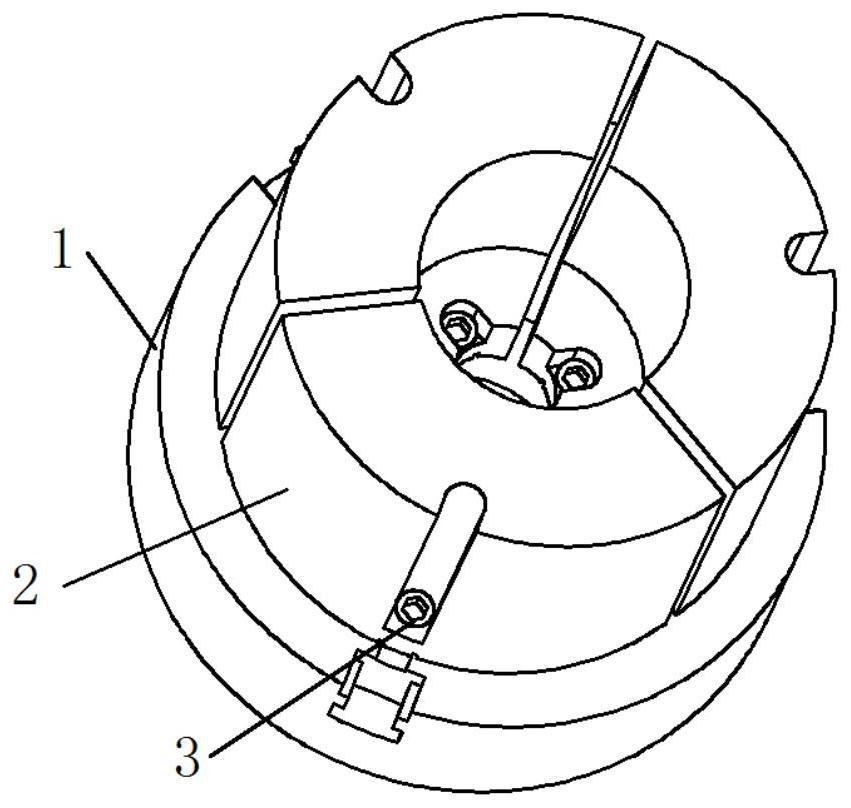

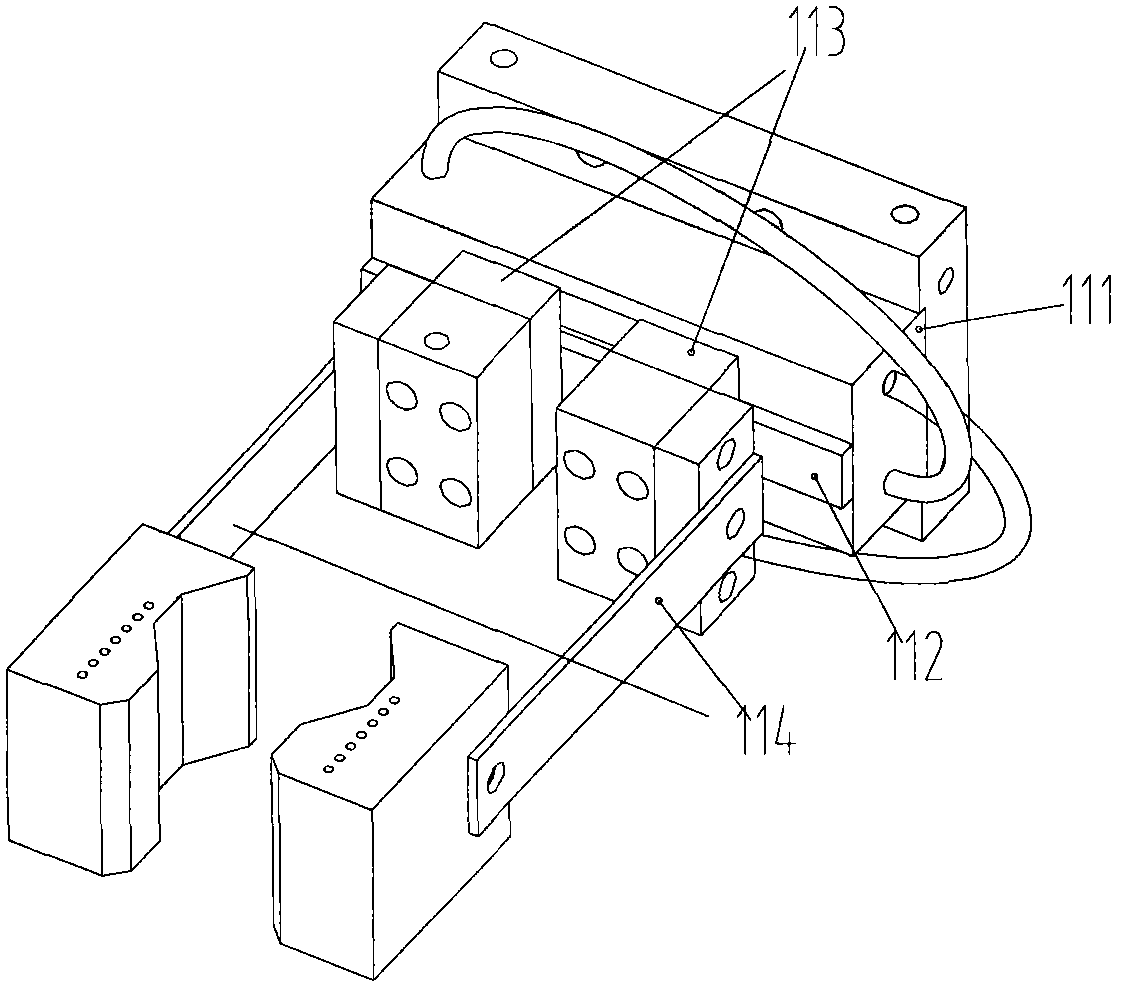

Compound forging manipulator

ActiveCN103878285AIncrease temperatureReduce the temperatureProgramme-controlled manipulatorForging/hammering/pressing machinesForging manipulatorRoom temperature

The invention relates to industrial automation device, in particular to an automation manipulator. The compound forging manipulator comprises a gripper and a finger. The gripper comprises a finger body, a guide rail, pistons, a plunger pin and sliders. The finger is fixedly connected to the sliders and comprises a finger tip and a bridge, one end of the bridge is fixedly connected to the sliders while the other end of the same is fixedly connected with the finger, and a clamping face is arranged on the finger. When a workpiece is impacted or bumped, affections of impact on the gripper can be avoided or reduced due to an elastic function of the finger. Graphite can be sprayed to a die while the workpiece is gripped simultaneously, so that production efficiency is improved; liquid fed into an inlet flows out of an outlet via a channel, heat accumulated through the fingers is taken away by the flowing liquid, temperature of the fingers can be greatly reduced, and the finger can be kept at constant temperature under working conditions; meanwhile, the high-temperature workpiece is subjected to quenching treatment.

Owner:ZHEJIANG WEILI METALFORMING MACHINERY

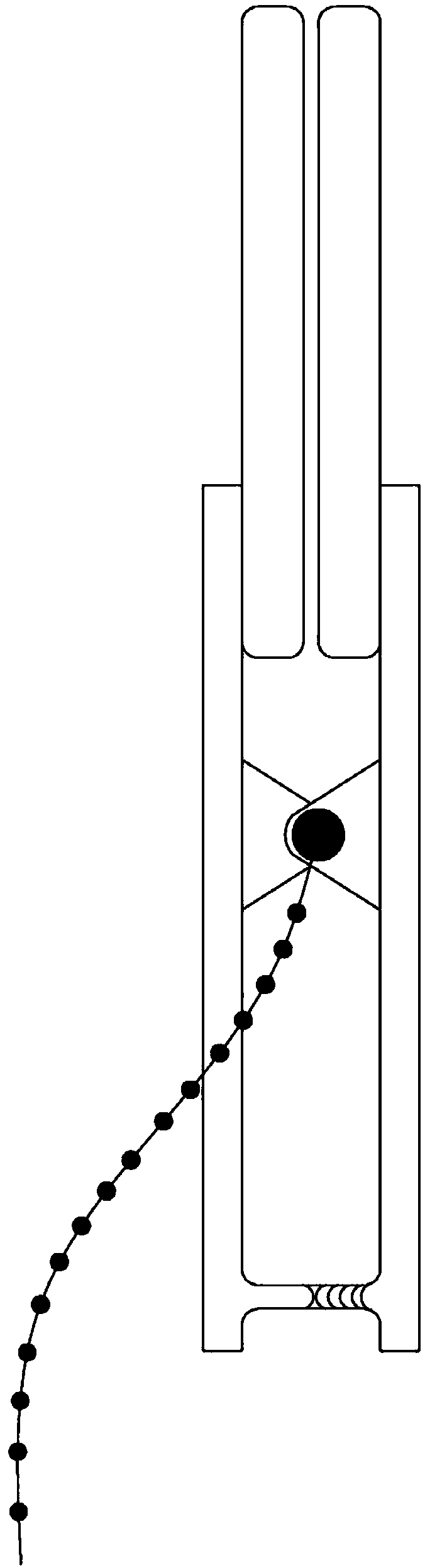

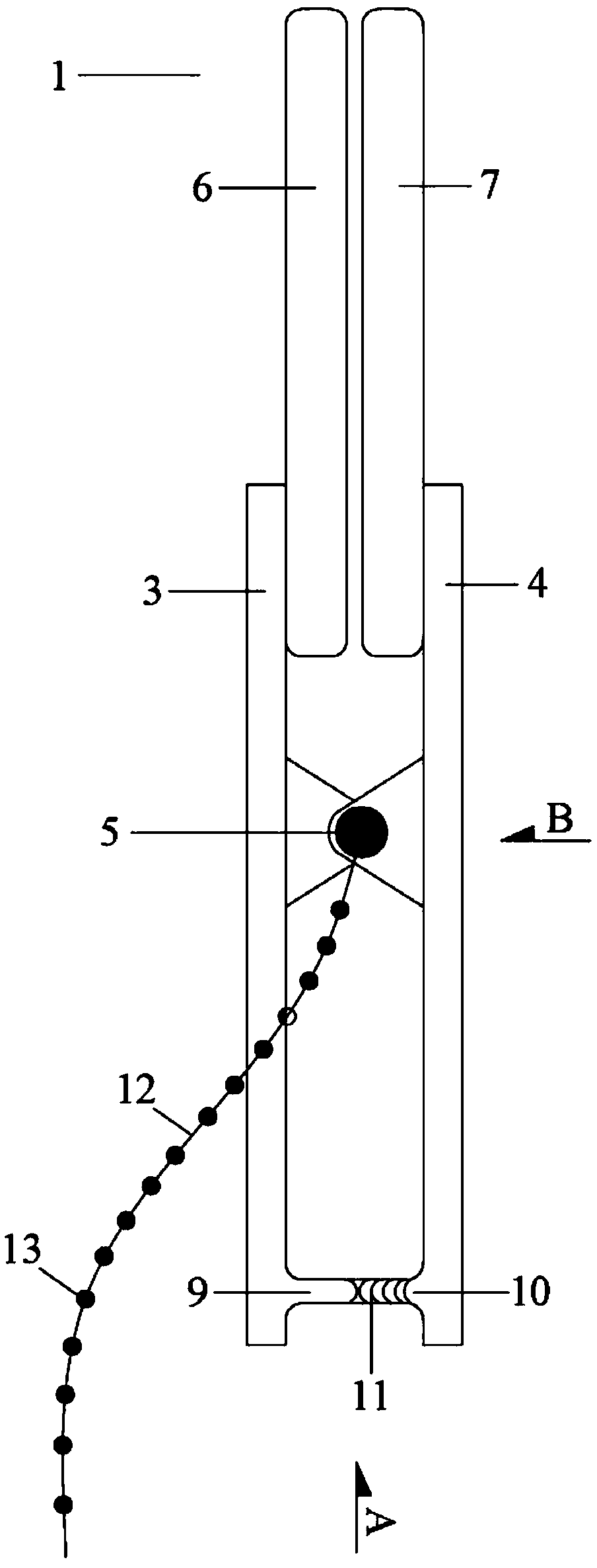

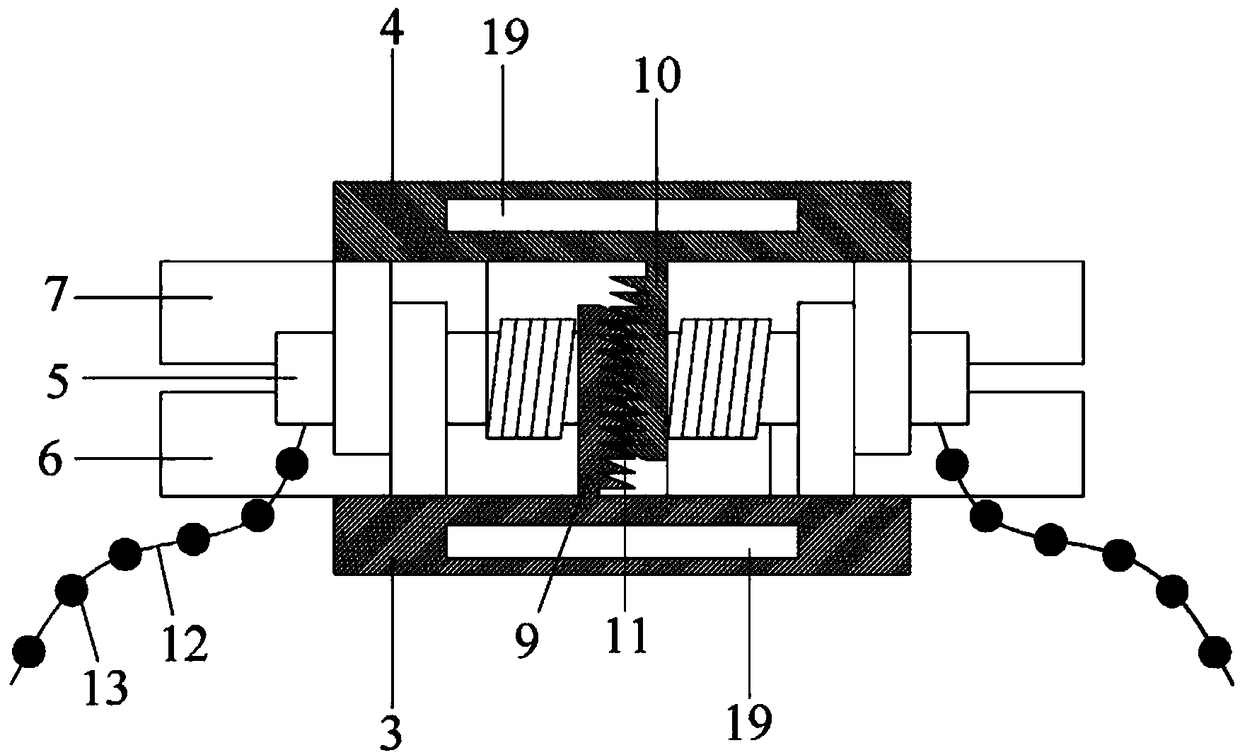

A thoracoscopic lung fixation device

The invention relates to the technical field of medical instruments, in particular to a thoracoscopic lung fixation device, comprising a lung clamping tool and a chest wall fixing device. The lung clamping tool comprises left and right clips, and two clips are articulated through a spring column. The head end of the clip is provided with a clip head, the tail end of the clip is provided with a rack, and the left rack and the right rack are provided with fixed clamping teeth capable of engaging with each other. The tail end of the clip is provided with a slot. Suspension wires are respectivelyarranged at the left and right ends of the spring columns, and the suspension wires are spaced at intervals of 1-3 cm position with beads. The chest wall fixing device comprises an elastic pipe, an inner clasp ring and an outer clasp ring respectively fixed at two ends, and a plurality of clasp grooves are arranged on the surface of the outer clasp ring. The device can reduce lung movement causedby beating and breathing of the heart, greatly reduce the range of lung movement during thoracoscopic operation, avoid lung movement from interfering with the operation of a doctor, and provide further guarantee for fine operation and operation safety of the operation.

Owner:SHANGHAI FIRST PEOPLES HOSPITAL

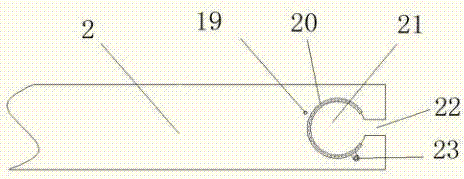

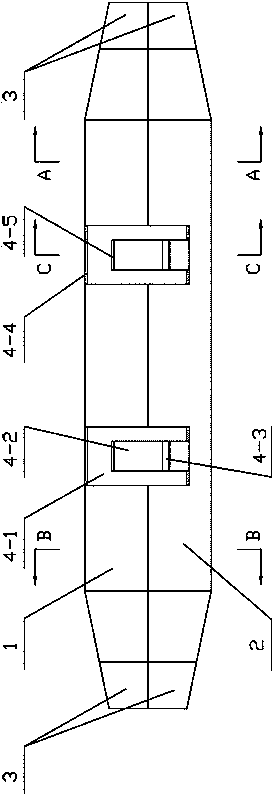

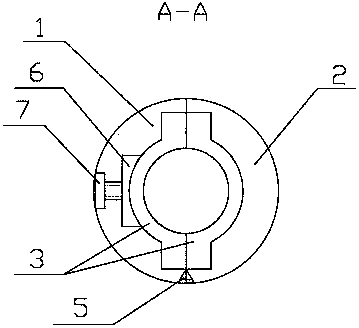

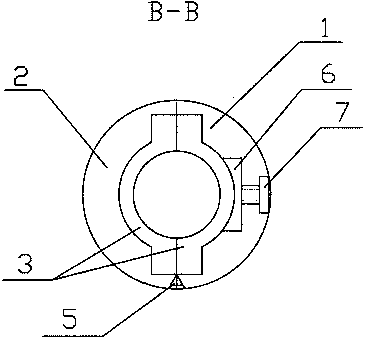

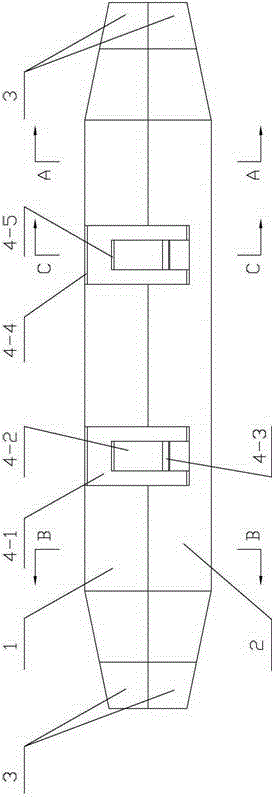

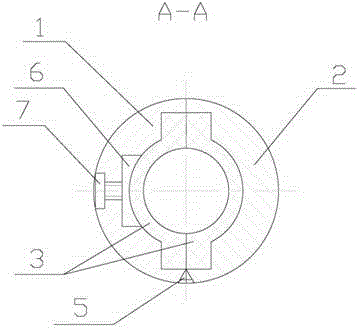

Counterweight device for towing-type linear array and towing-type linear array

ActiveCN104047994ARealize fixed depthImprove detection performanceWave based measurement systemsCounterweightsLocking mechanismEngineering

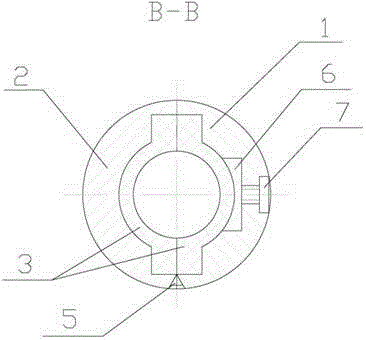

The invention provides a counterweight device for a towing-type linear array and the towing-type linear array. The counterweight device for the towing-type linear array comprises a first semi-cylinder counterweight block, a second semi-cylinder counterweight block, a buckle-type locking mechanism and a first hinge, wherein the section of each counterweight block is of a semi-circular ring shape; one contact surface of the first semi-cylinder counterweight block is connected with one contact surface of the second semi-cylinder counterweight block through the first hinge; when the opening angle of the first semi-cylinder counterweight block and the second semi-cylinder counterweight block is zero, the two counterweight blocks are matched with each other to form a hollow cylinder; when the first semi-cylinder counterweight block and the second semi-cylinder counterweight block are opened at a certain angle, a towing cable is placed in a hollow part of the cylinder; the buckle-type locking mechanism is used for clamping the first semi-cylinder counterweight block and the second semi-cylinder counterweight block on the towing cable placed in the hollow part when the opening angle is zero; a first conical flow guide section is further arranged at the end part of the cylinder formed by the first semi-cylinder counterweight block and the second semi-cylinder counterweight block.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

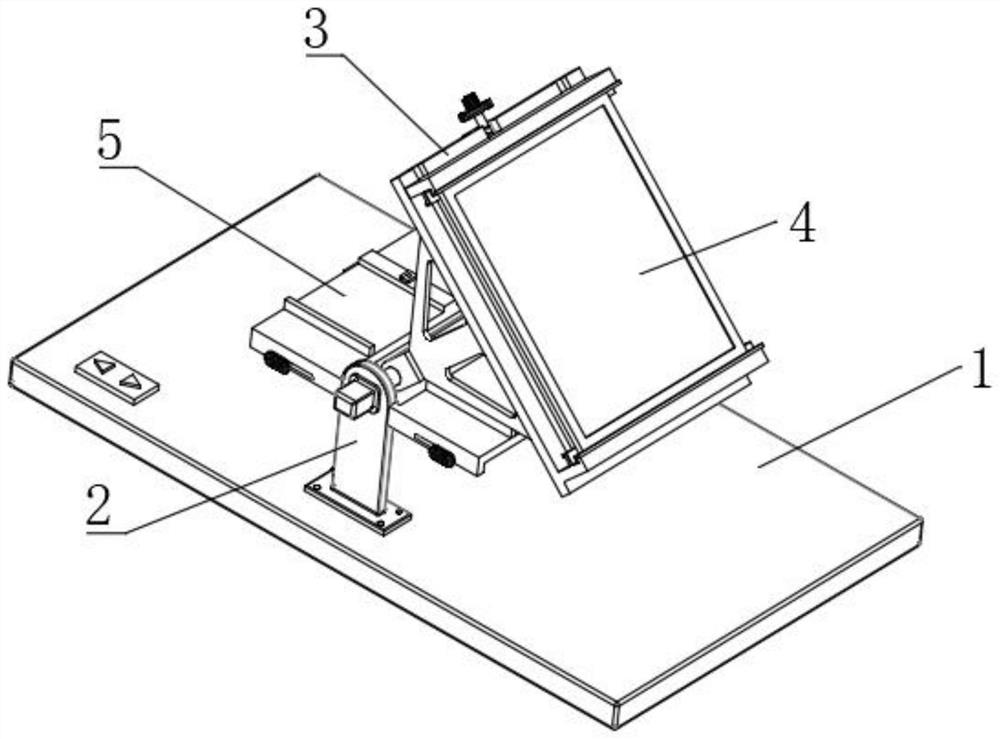

Photomask inclined drilling hole conversion adjusting support

ActiveCN112809408AAvoid damageConvenient and convenientPrecision positioning equipmentLarge fixed membersEngineeringMechanical engineering

The invention discloses a photomask inclined drilling hole conversion adjusting support in the technical field of photomasks. The photomask inclined drilling hole conversion adjusting support is characterized in that limiting components are mounted at the bottom of an overturning plate, the limiting components are mounted on two sides of the support, the overturning plate overturns towards two sides and is blocked by the limiting components and limited to a preset position, a clamping assembly is mounted on the overturning plate, a locking assembly is arranged at the bottom of the overturning plate, and the overturning plate is locked through the locking assembly after the overturning plate is overturned and adjusted. According to the support, the overturning plate can be overturned by certain angles on the two sides, drilling on the two sides is convenient, damage to a photomask caused by repeated moving and fixing is avoided, a fixed clamping plate and a movable clamping plate can rapidly complete protective clamping and fixing of the photomask, the influence of loosening in the drilling process on drilling is avoided, through the arranged limiting components, limiting can be conducted after the overturning plate is overturned, and it is ensured that a vertical drilling machine can drill 45-degree holes in the photomask.

Owner:江苏高光半导体材料有限公司

Instrument for endoscopic surgery in thoracic surgery department

ActiveCN110353802ARealize the clamping angleAchieve transformationSurgical instruments for heatingSurgical forcepsElectrocoagulationForceps

The invention discloses an instrument for an endoscopic surgery in the thoracic surgery department, and belongs to the technical field of medical instruments. The instrument comprises a hand-held frame, and further comprises a force adjustment mechanism movably connected with the hand-held frame and used for adjusting the clamping force of electrocoagulation forceps, clamping plates connected withthe force adjustment mechanism and a rotating mechanism used for driving the clamping plates to rotate, wherein the rotating mechanism is movably connected with the hand-held frame, and the rotatingmechanism is connected with the force adjustment mechanism; the number of the clamping plates is two. The instrument for the endoscopic surgery in the thoracic surgery department has the advantages that the clamping force can be finely adjusted, it is avoided that a medical worker controls the force by hand, the durability is improved, the clamping plates can be driven to rotate by the rotating mechanism so that free conversion of the clamping angle can be achieved without rotating the instrument, and the instrument can be disassembled for cleaning, which is beneficial to the sufficient disinfection.

Owner:JIANGYIN PEOPLES HOSPITAL

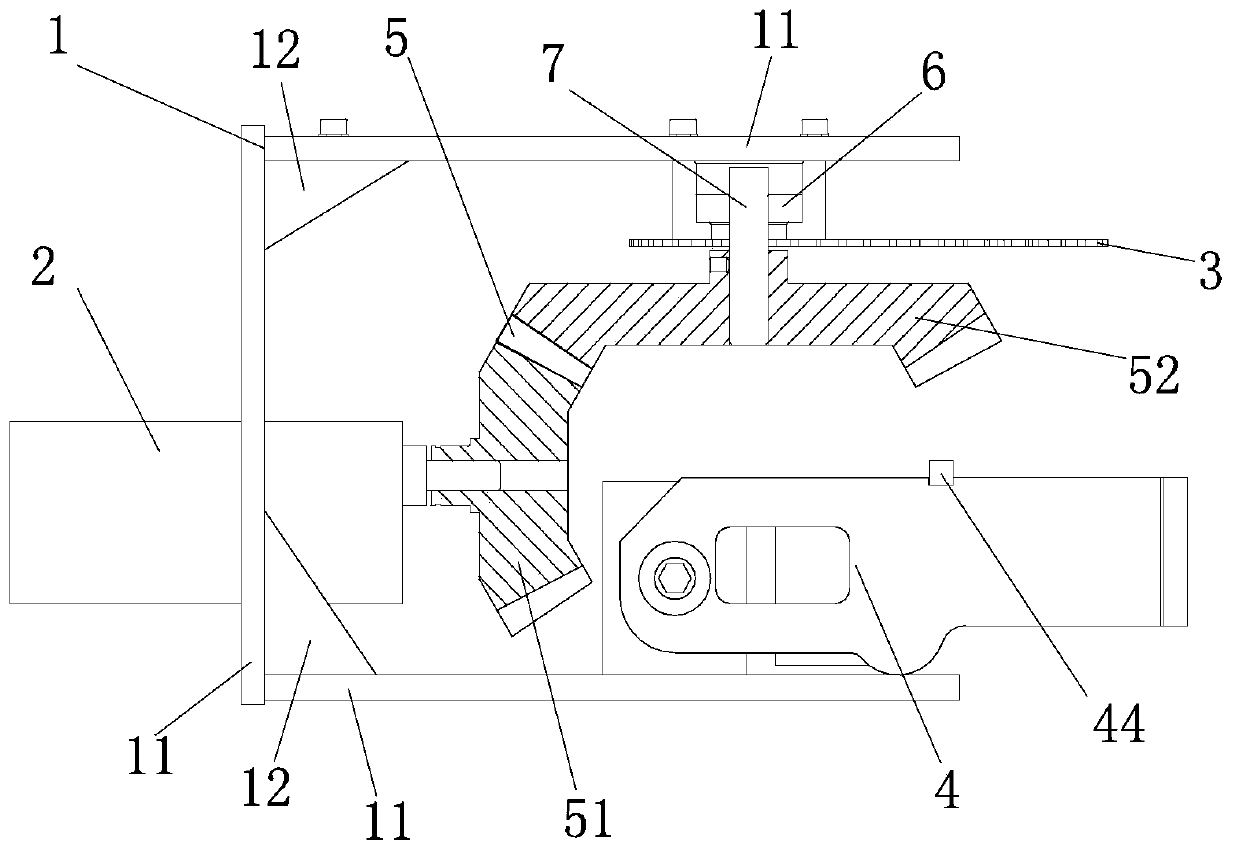

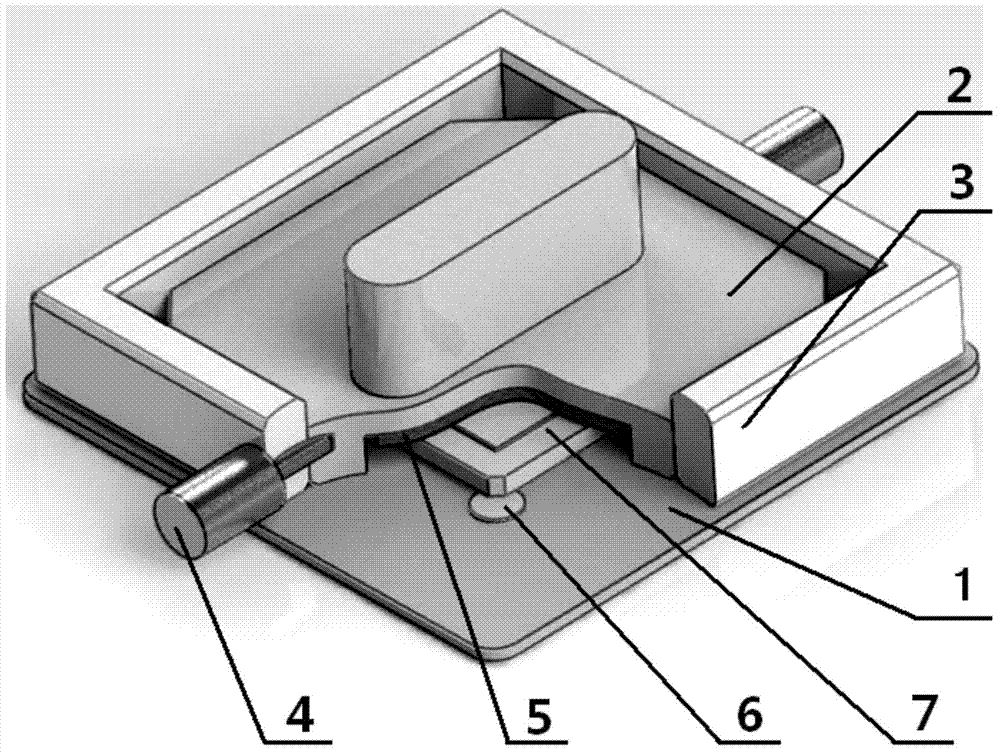

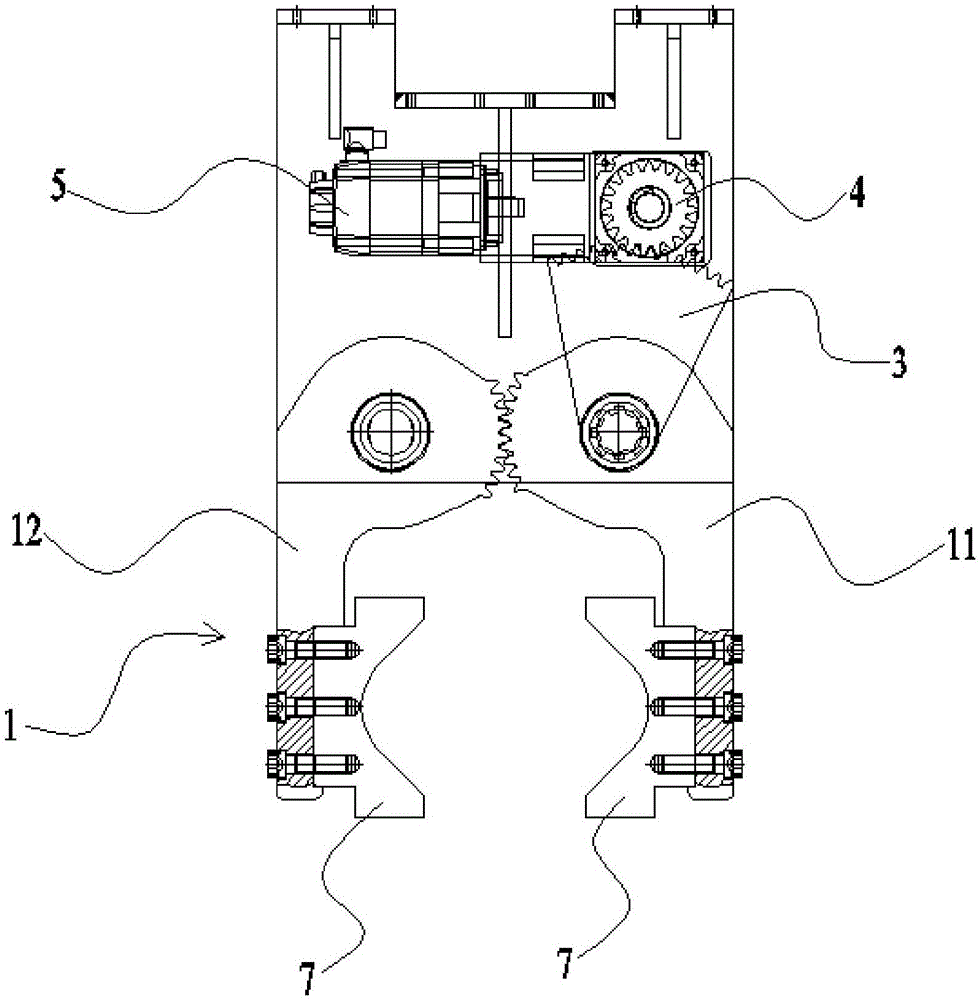

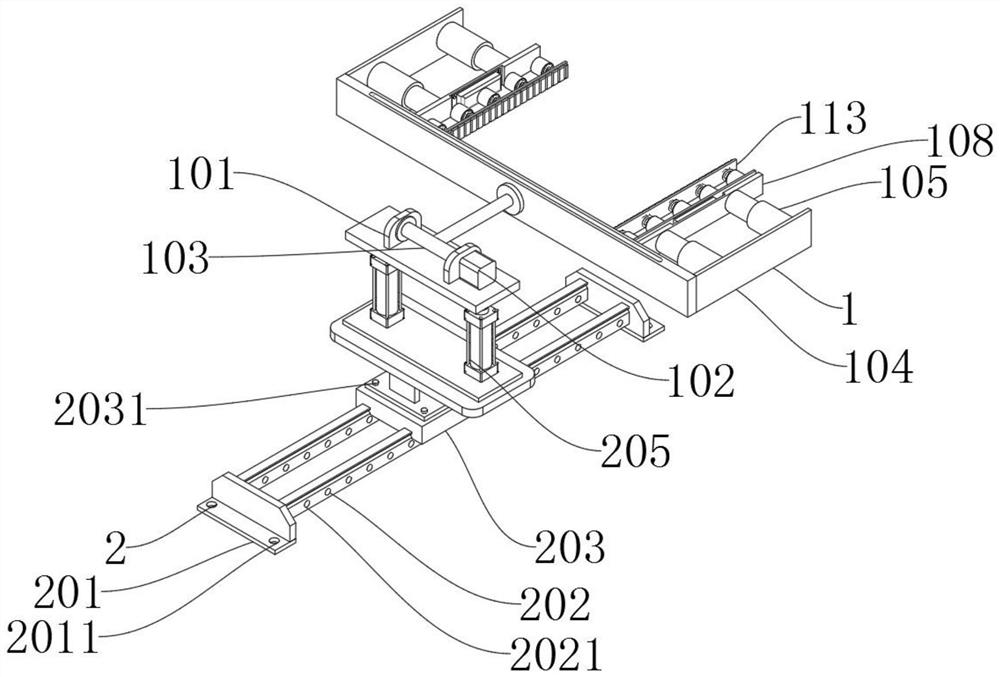

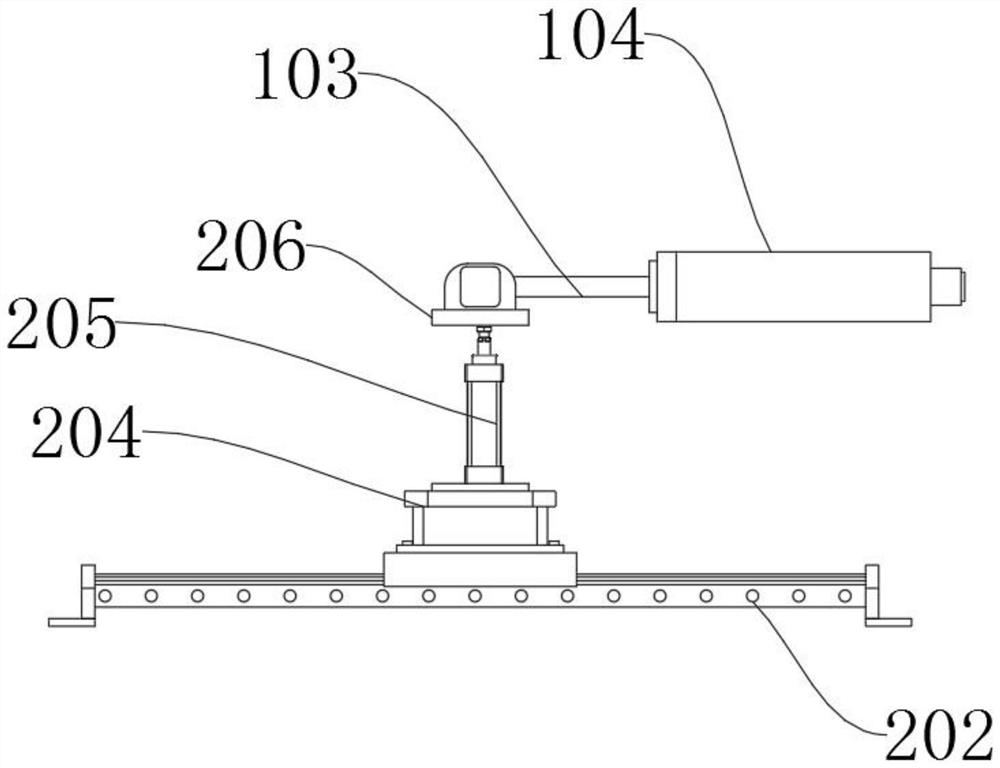

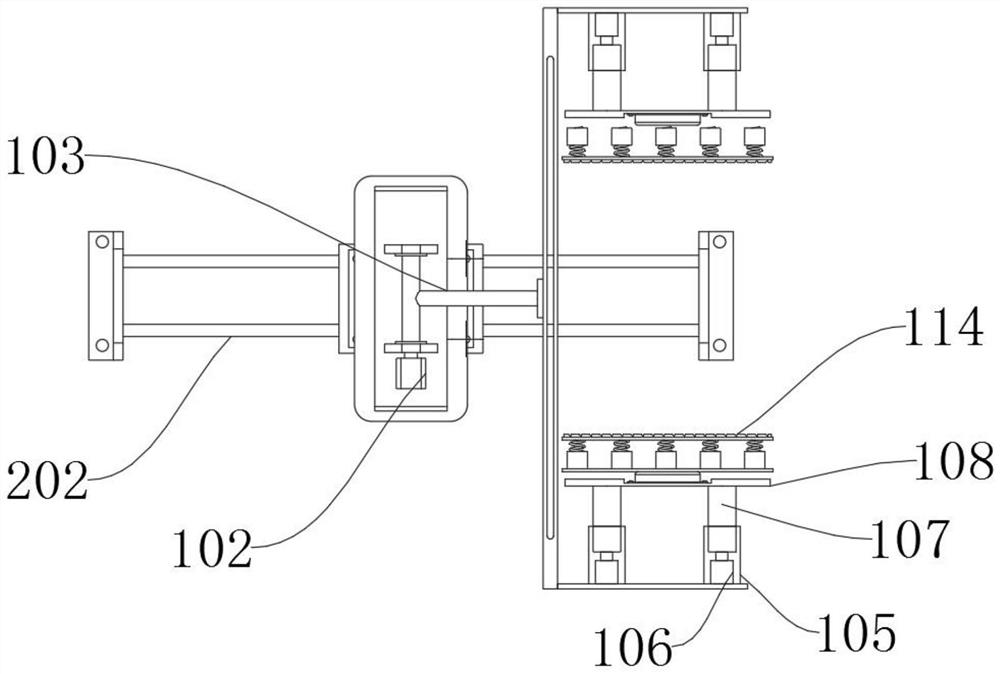

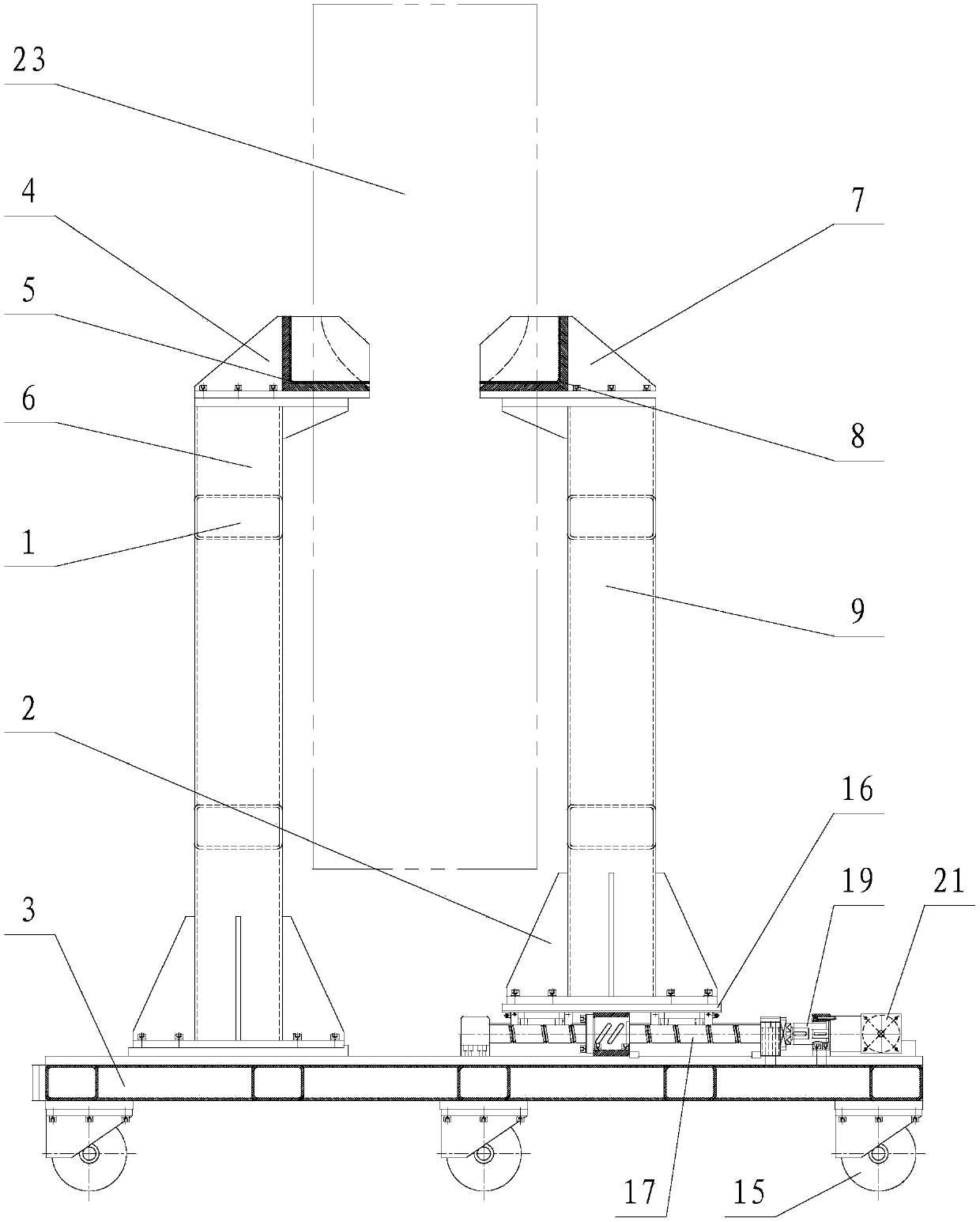

Movable heavy-load pallet based on clamping self-adaptive adjustment

ActiveCN109807579ALow costReasonable design structureMetal working apparatusAutomatic judgementReciprocating motion

The invention relates to a movable heavy-load pallet based on clamping self-adaptive adjustment. The movable heavy-load pallet is characterized in that one end of a fixed clamping support is installedon a movable base part, a fixed clamping tool is arranged at the other end of the fixed clamping support, a movable base is arranged on the movable base part, a ball screw is rotationally connected to the movable base, a movable base plate is connected with a nut which is in threaded connection with the ball screw, one end of a movable clamping support is installed on the movable base plate, a movable clamping tool is arranged at the other end of the movable clamping support, the ball screw is driven to rotate through a power output unit arranged on the movable base, the movable base plate isdriven by the nut to do reciprocating motion in the axial direction of the ball screw, then the movable clamping support and the movable clamping tool on the movable base plate are driven to move, and the movable clamping tool and the fixed clamping tool jointly clamp a turbine pump. According to the movable heavy-load pallet based on clamping self-adaptive adjustment, self-adaptive adjustment ofclamping, automatic judgement on the clamping state, automatic alarm of incorrect clamping, adjustment of the clamping force can be achieved, and then the movable heavy-load pallet device is suitablefor clamping and transferring multiple kinds of large-mass products with strict requirements on the clamping force.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

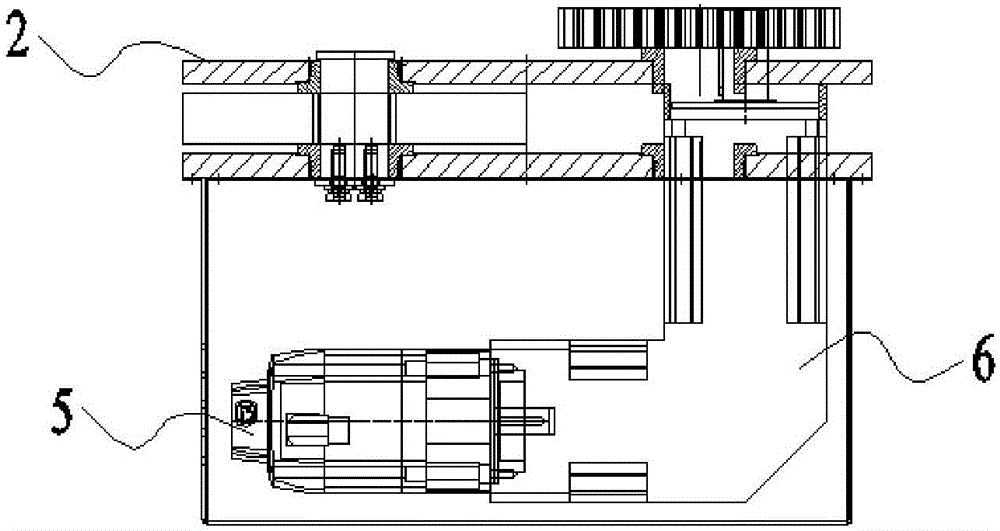

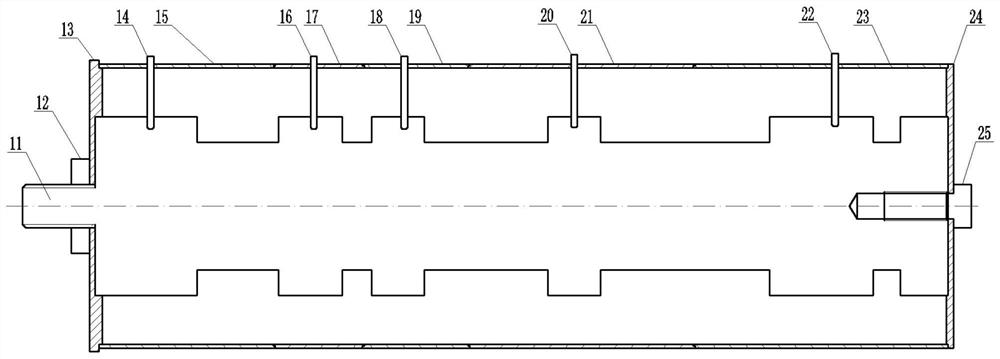

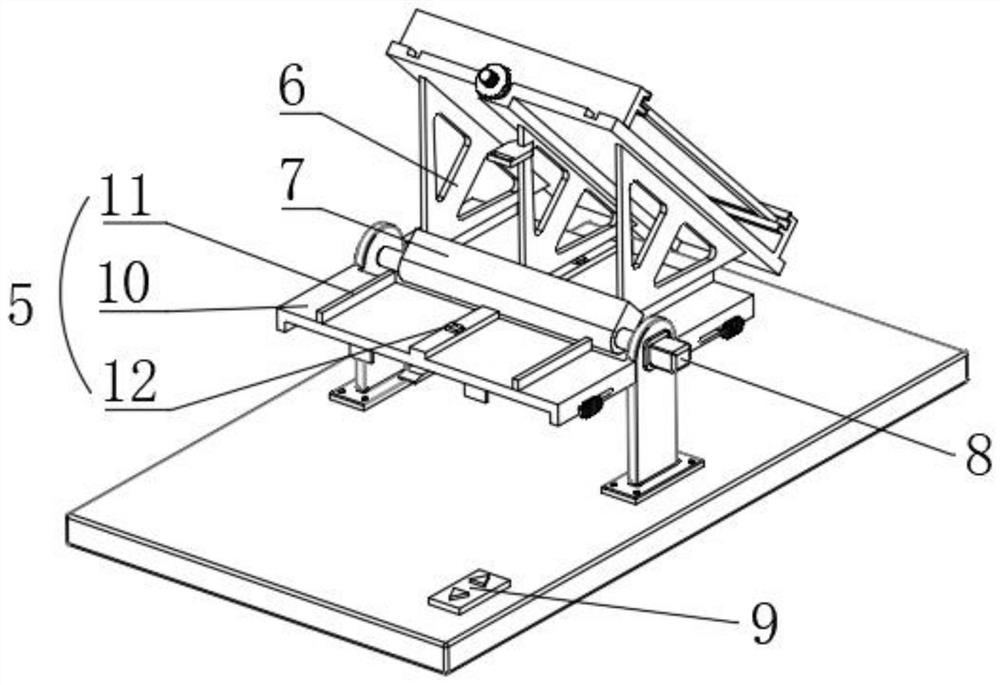

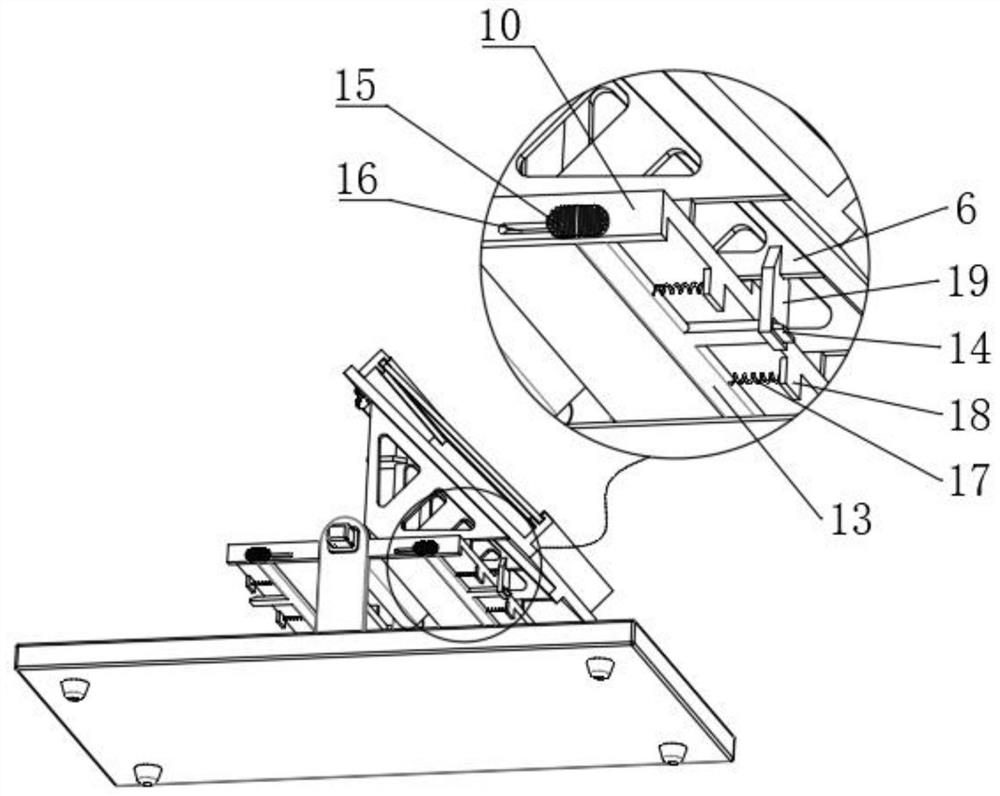

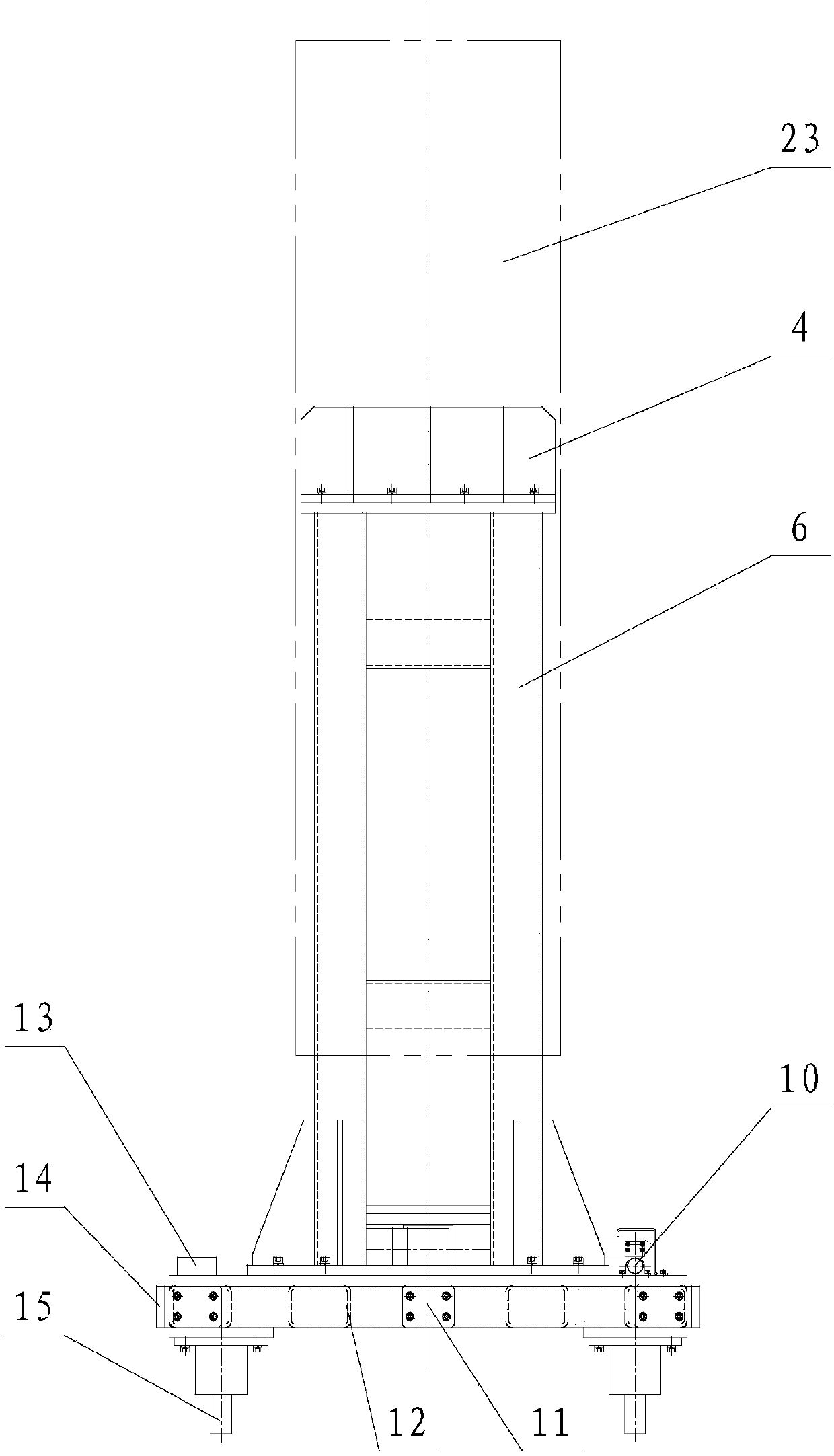

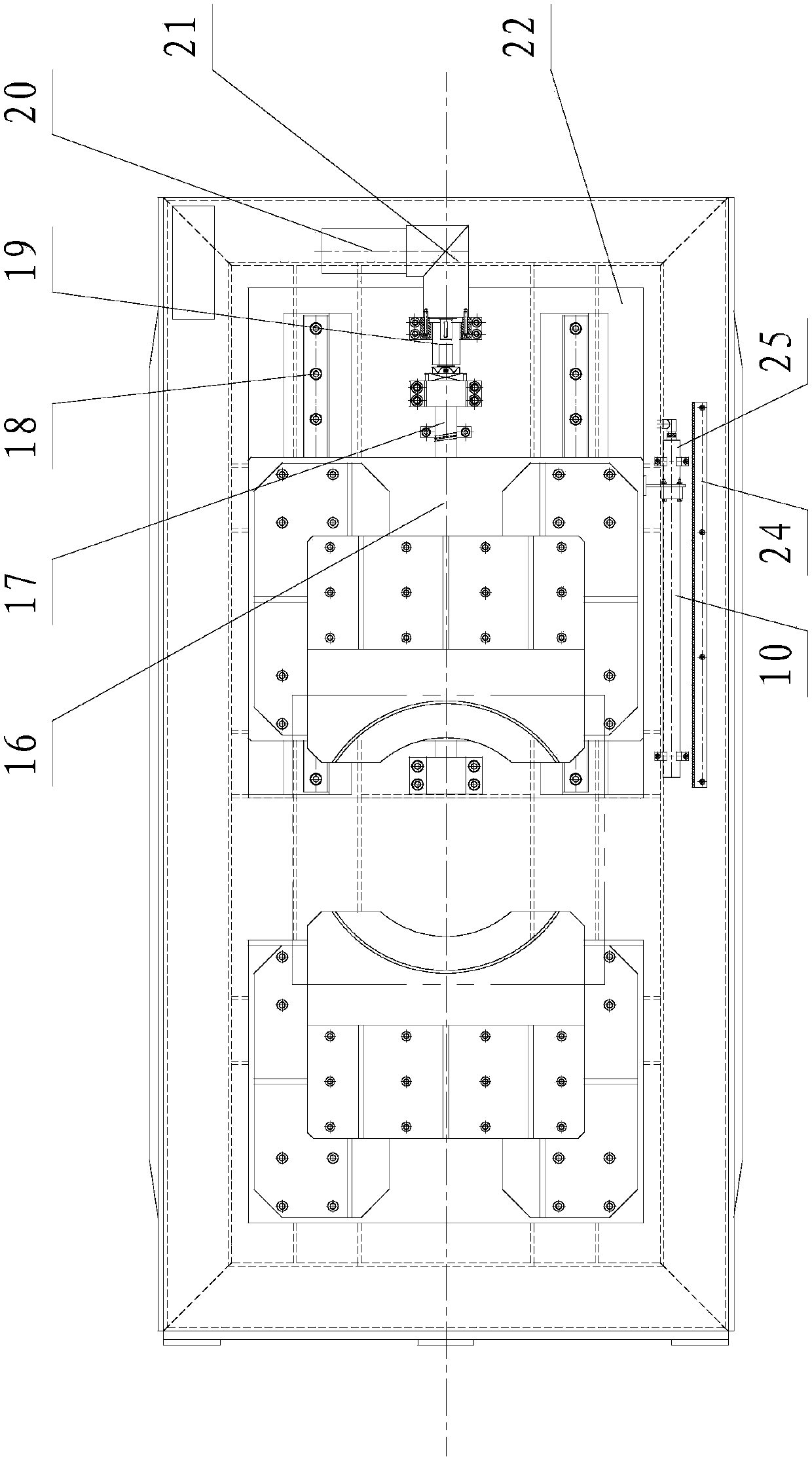

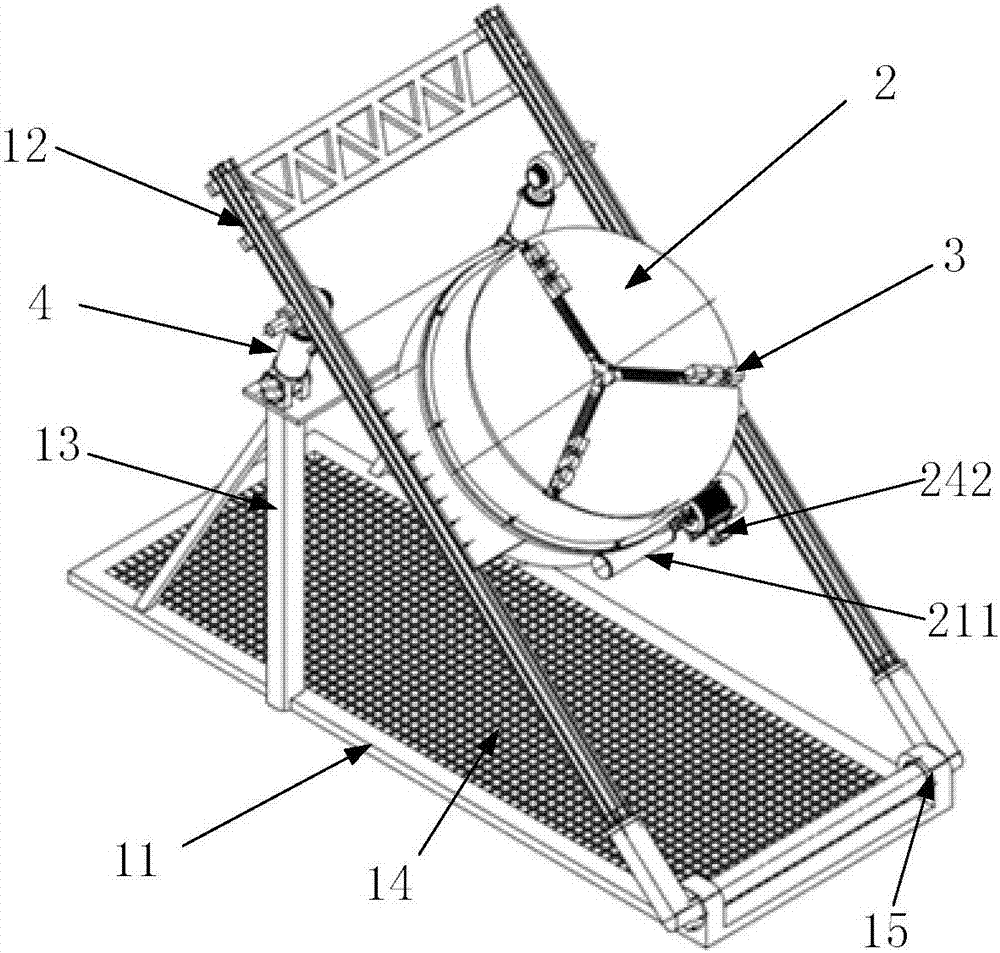

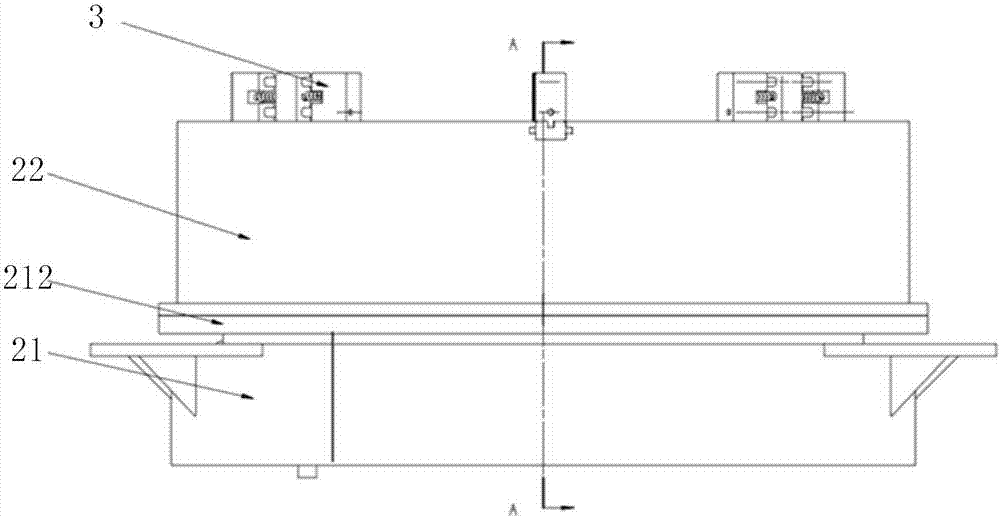

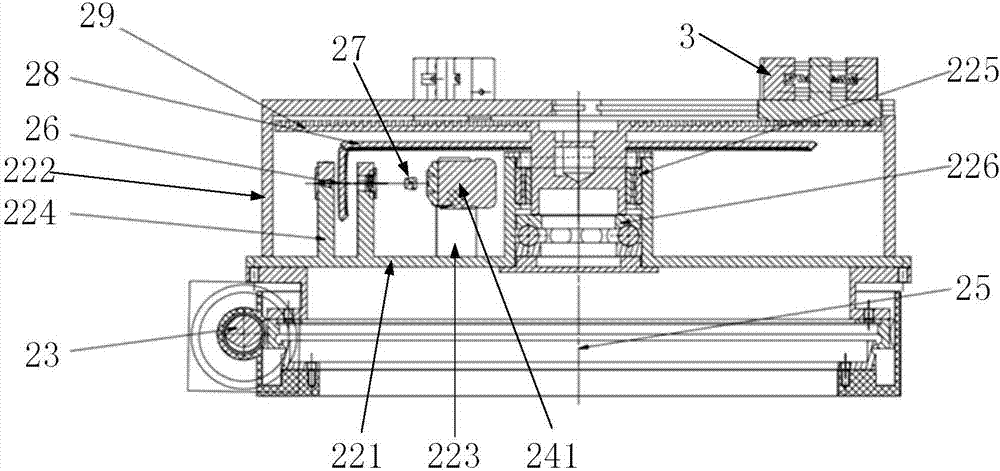

Electrically and hydraulically driven high-precision intelligent quenching machine tool for disc parts and control method for electrically and hydraulically driven high-precision intelligent quenching machine tool

ActiveCN107245559ALarge adjustment spaceReduce volatility and control difficultyFurnace typesHeat treatment process controlQuenchingThermal treatment

The invention discloses an electrically and hydraulically driven high-precision intelligent quenching machine tool for disc parts and a control method for the electrically and hydraulically driven high-precision intelligent quenching machine tool. The electrically and hydraulically driven high-precision intelligent quenching machine tool comprises an adjustable rack, a quenching workbench, a process parameter database and a control system, wherein the adjustable rack comprises a rack base and an inclined supporting frame; the quenching workbench comprises a rotary table and an intelligent clamping jaw; and the control system comprises a positioning detecting system, a clamping force control system and an operation monitoring system. The invention also discloses a control method. The electrically and hydraulically driven high-precision intelligent quenching machine tool can be suitable for quenching thermal treatment on a large scale of parts with different structural parameters, can determine key parameters such the optimal rack bracket inclination angle, quenching speed, quenching frequency and the like according to types of quenched workpieces, material properties and quenching technological requirements, and improves quenching parameter determining reasonability; and meanwhile, the operation monitoring system can be used for effectively monitoring process parameters in a quenching process, improves quenching efficiency, reliability and quality, and realizes an intelligent quenching process.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

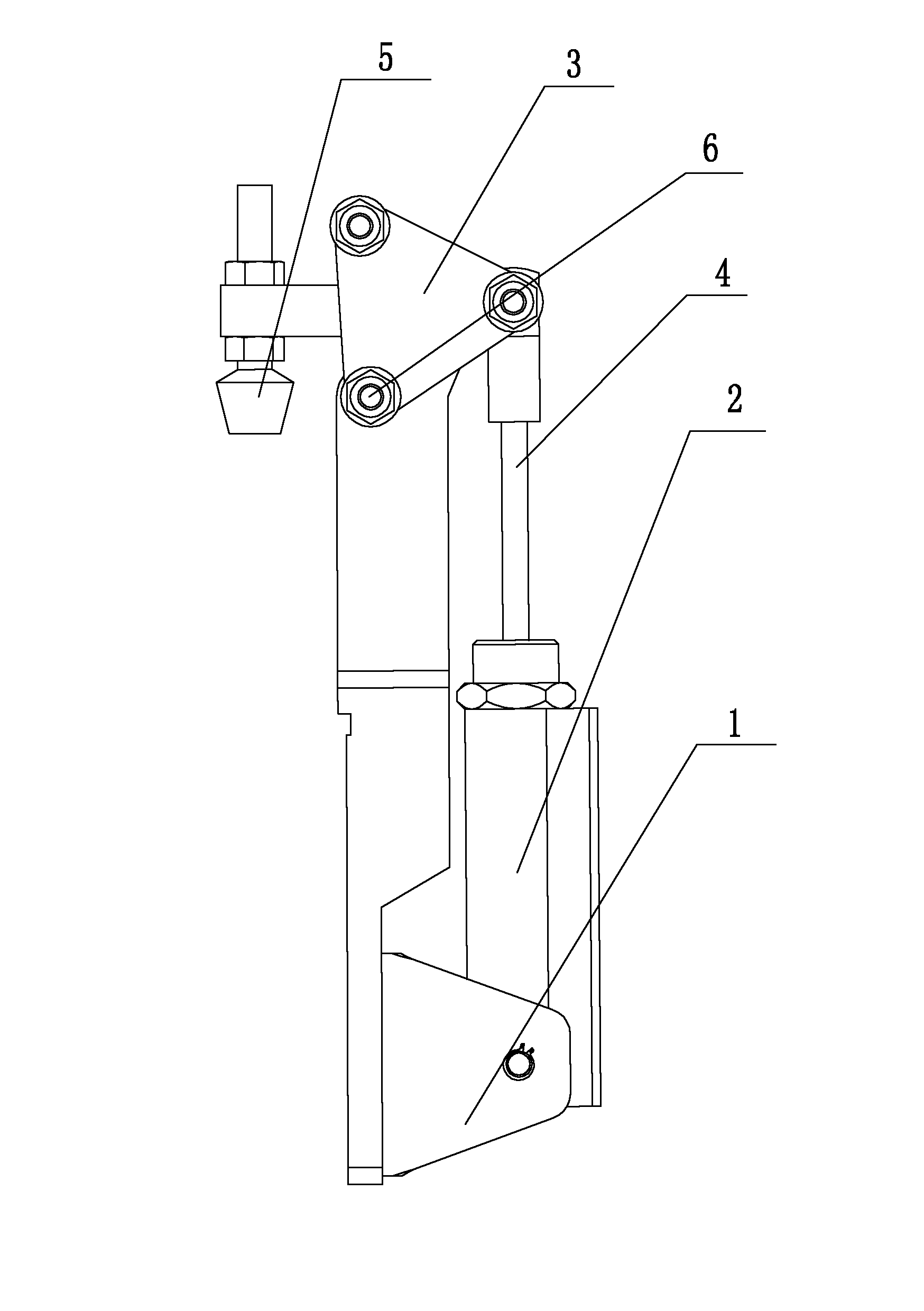

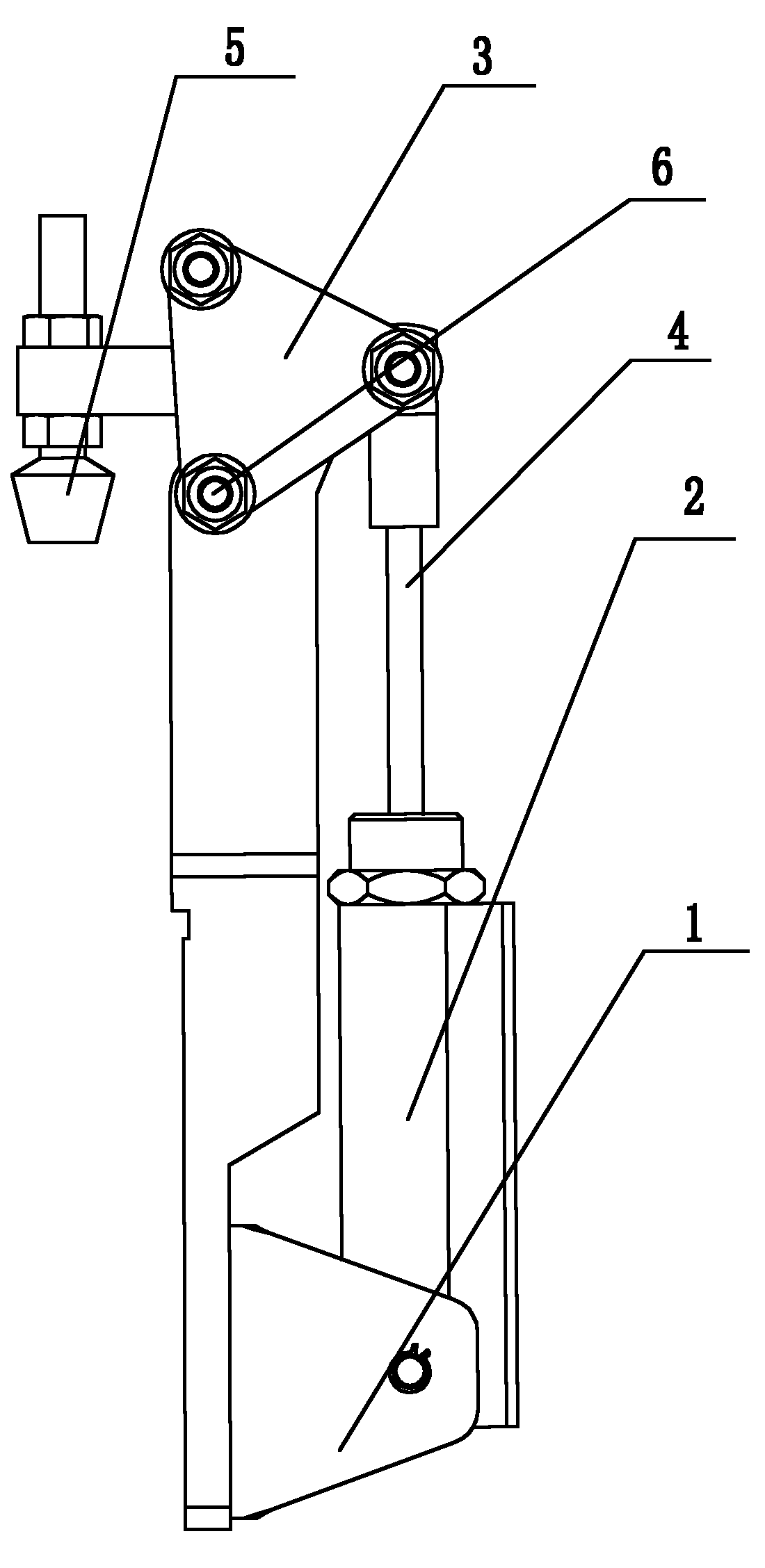

Clamping device for forklift accessory machining

InactiveCN112222477AGood clamping effectGood clamping forcePositioning apparatusBoring/drilling componentsElectric machineryDrill hole

The invention relates to the technical field of accessory machining clamping devices, and discloses a clamping device for forklift accessory machining. The clamping device comprises a fixing bottom plate, fixing bases are fixedly connected to the four corners of the lower surface of the fixing bottom plate, a portal frame is fixedly connected to the upper surface of the fixing bottom plate, the inner wall of the top of the portal frame is fixedly connected with a first electric push rod, and the output end of the first electric push rod is fixedly connected with a drilling motor. According tothe clamping device for forklift accessory machining, a second electric push rod drives a clamping linkage rod and a clamping plate to clamp and fix an accessory, a better clamping and fixing effect is achieved on the accessory in a special shape, a better clamping effect is achieved, meanwhile, the clamping force on the accessory can be better controlled, the situation that the accessory is damaged due to too large clamping force is effectively avoided, the accessory in a special shape can be clamped more stably, and the accessory can be better machined.

Owner:湖南川田机械制造有限公司

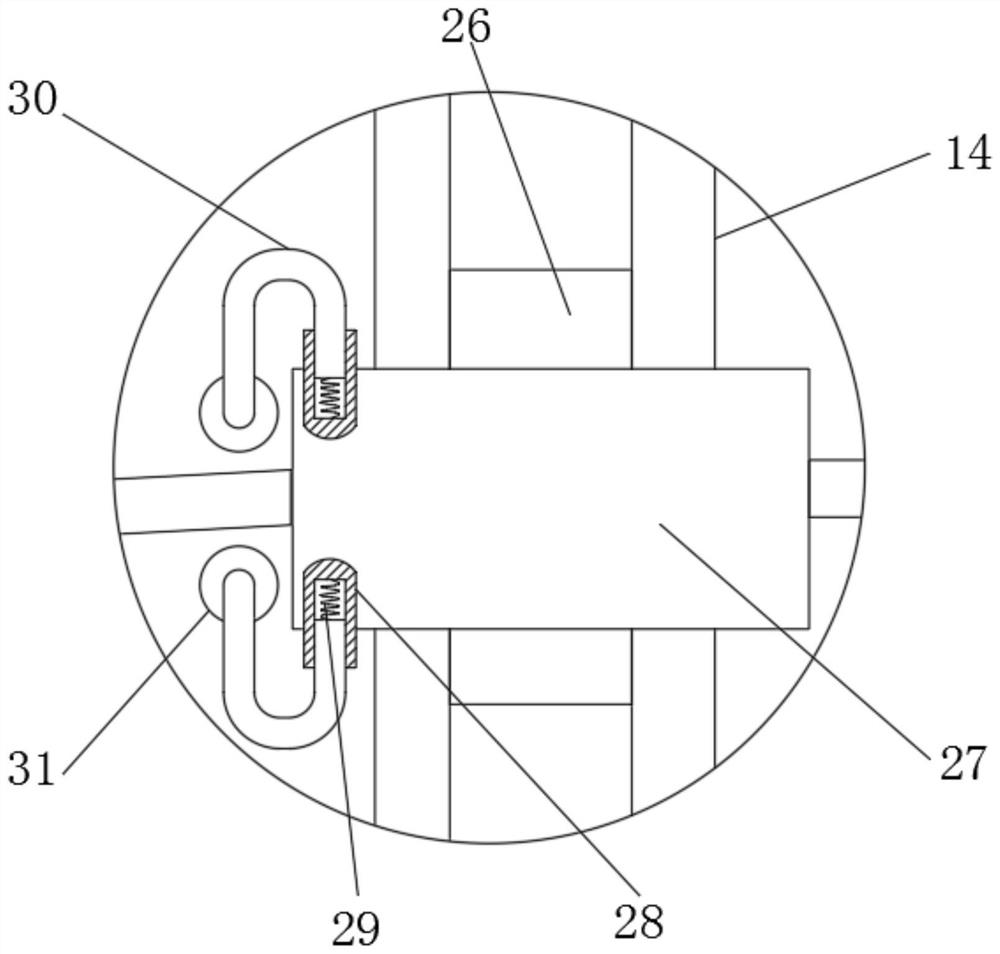

Workpiece clamping head structure

The invention provides a workpiece clamping head structure capable of stably and reliably clamping a workpiece, and the clamping force is easy to control, the workpiece clamping head structure is characterized in that the workpiece clamping head structure comprises a supporting seat, a clamping cylinder is fixed on the supporting seat, a lever connecting rod is hinged on the supporting seat, one end of the lever connecting rod is connected with a piston rod of the clamping cylinder, and a clamping block is fixed at the other end of the lever connecting rod.

Owner:无锡舒比德自动化科技有限公司

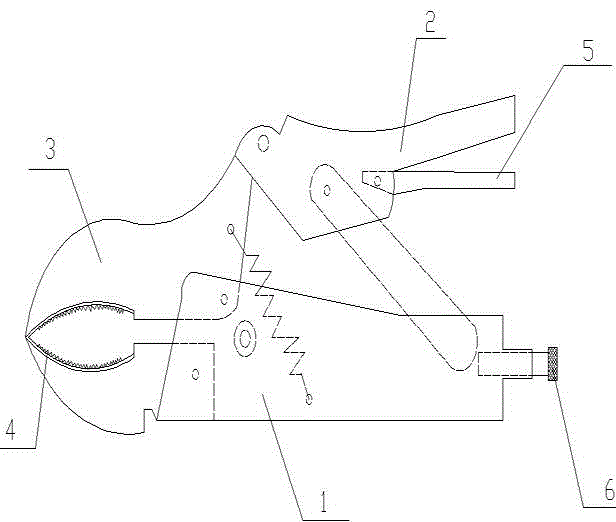

Curved jaw locking pliers

Curved jaw locking pliers comprise an upper pliers arm and a lower pliers arm. The upper pliers arm is connected with a pliers jaw through a rivet. A semicircular toothed pressing block is arranged on the lower portion of the pliers jaw. The lower pliers arm is fixed below the upper pliers arm. The lower pliers arm is connected with a pliers jaw through a rivet, and a semicircular toothed pressing block is arranged on the upper portion of the pliers jaw. A movable pressing rod is fixed to the lower pliers arm, and is connected with the lower pliers arm through a rivet. The upper pliers arm is provided with an adjusting nut which is located at the end of the upper pliers arm. The movable pressing rod is arranged at the end of the lower pliers arm. The semicircular toothed pressing blocks are vertical type sawteeth. According to the curved jaw locking pliers, due to the fact that an adjusting nut is arranged at the end of the upper pliers arm, the clamping force of the curved jaw locking pliers can be further controlled, and the curved jaw locking pliers can be used for processing workpieces made of different materials with different strengths; the teeth are vertical sawteeth, so that the biting force of the curved jaw locking pliers can be reinforced; and the workpieces can be clamped more tightly, and an operator can operate the pliers with less effort.

Owner:仪征市神工五金工具厂

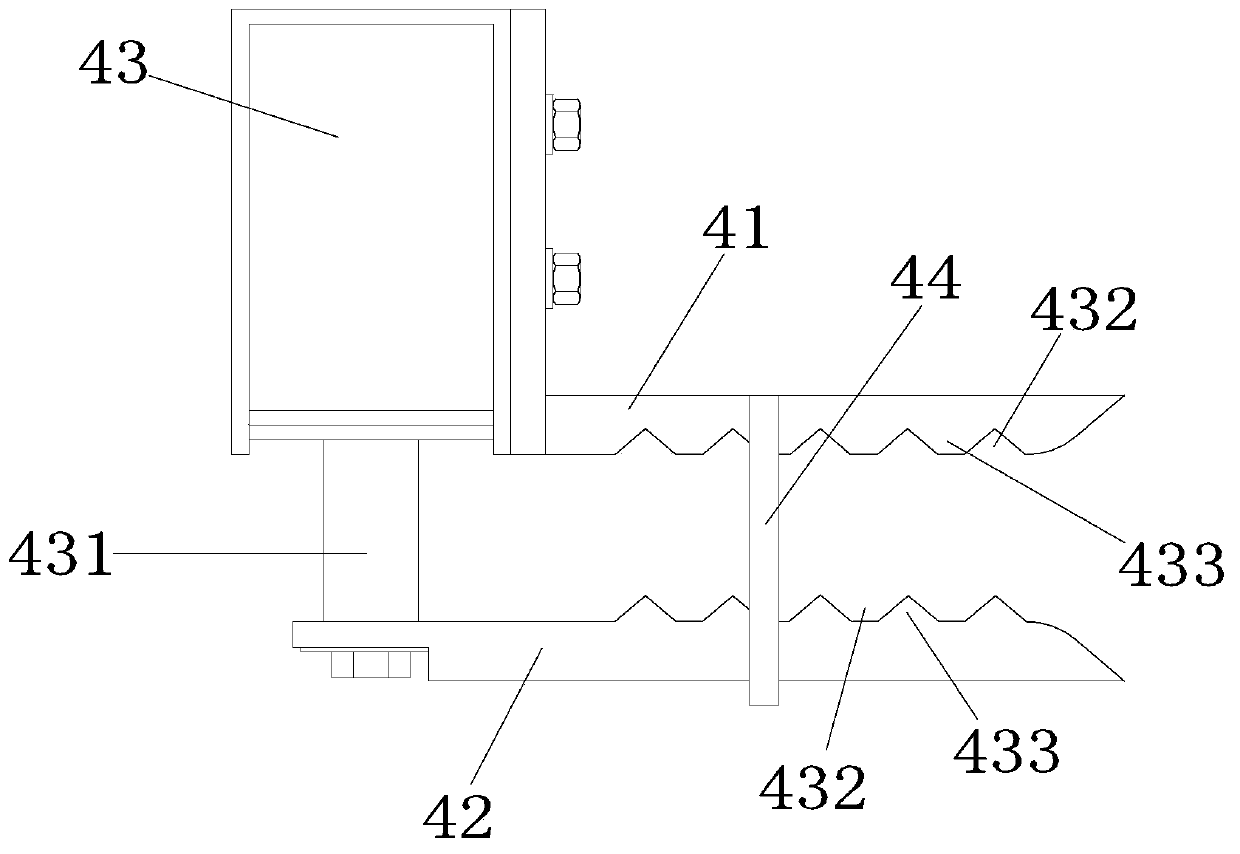

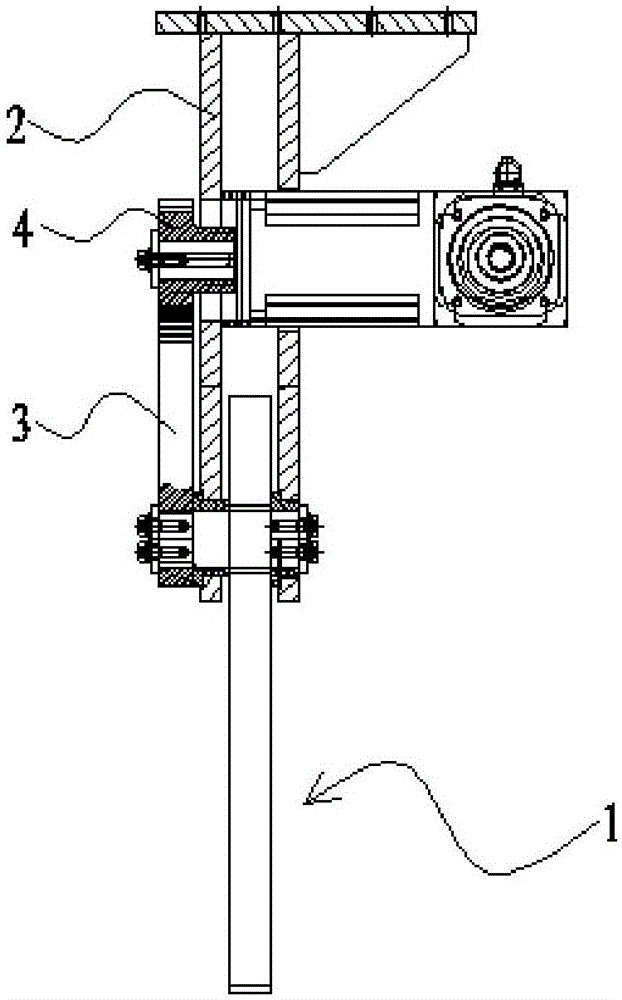

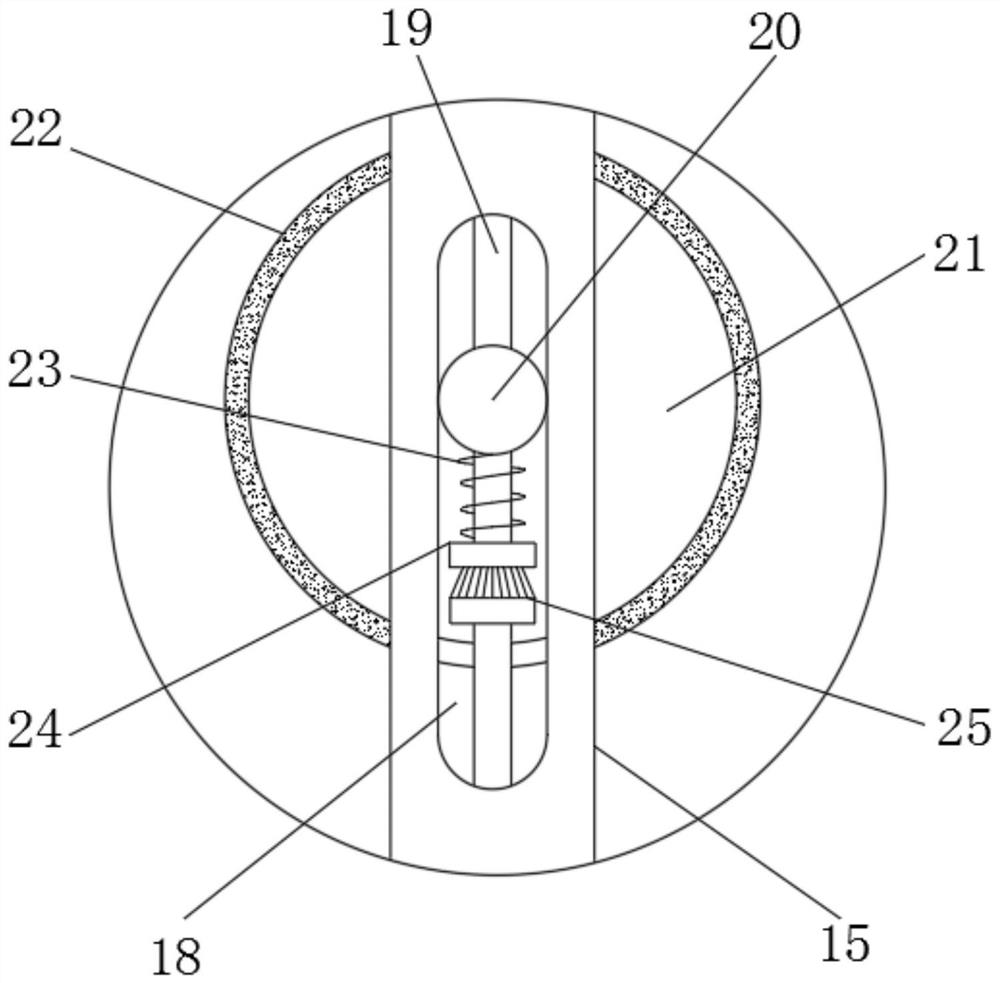

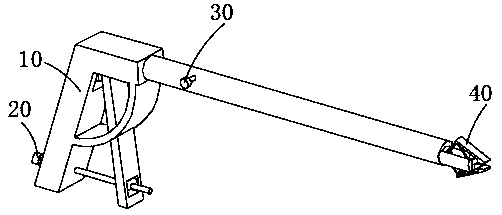

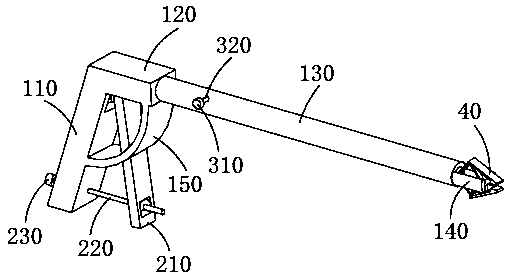

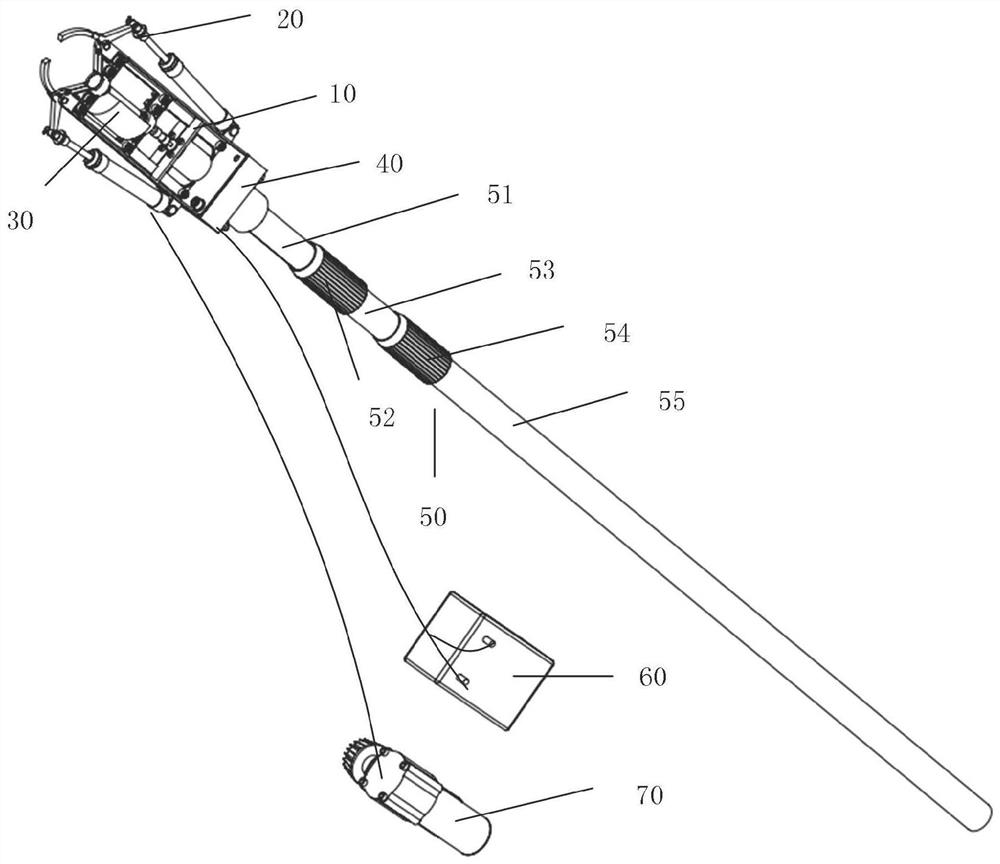

Portable torreya grandis picking machine based on branch vibration

PendingCN112840861AControl clamping forceRealize picking in batchesPicking devicesElectric machineryStructural engineering

The invention discloses a portable torreya grandis picking machine based on branch vibration. The portable torreya grandis picking machine based on branch vibration comprises a frame, a vibrating mechanism, clamping mechanisms, a vibration reduction rubber block and a telescopic rod mechanism, wherein the vibrating mechanism is located in the frame, the clamping mechanisms are connected with the two sides of the frame correspondingly, the bottom of the frame is connected with the first end of the vibration reduction rubber block; the telescopic rod mechanism is connected with the second end of the vibration reduction rubber block; a shell of a pneumatic push rod is connected with the frame through a pneumatic push rod connecting hole, the first end of a claw is connected with the frame through a claw connecting hole, and the pneumatic push rod is connected with the second end of the claw; a shell of the driving motor is fixedly connected with the frame through a motor connecting hole, the driving motor is connected with the first end of a coupler, the second end of the coupler is connected with the first end of a shaft, and the second end of the shaft penetrates through a first bearing, an eccentric wheel and a sleeve to be connected with a second bearing. According to the portable torreya grandis picking machine based on branch vibration, the whole machine is convenient to carry and suitable for fruit picking operation in mountainous regions; fruit picking is achieved through branch vibration, and compared with other vibration picking modes, damage to tree bodies is small.

Owner:慧诚自动化技术(宁波)有限公司 +1

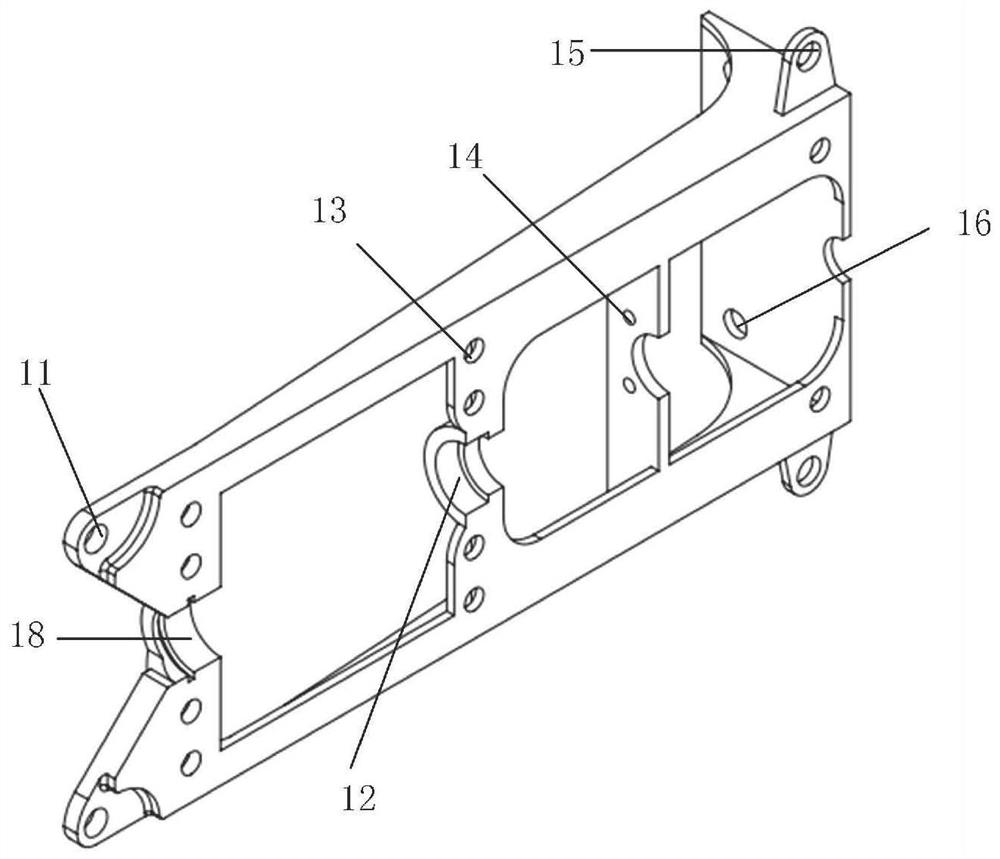

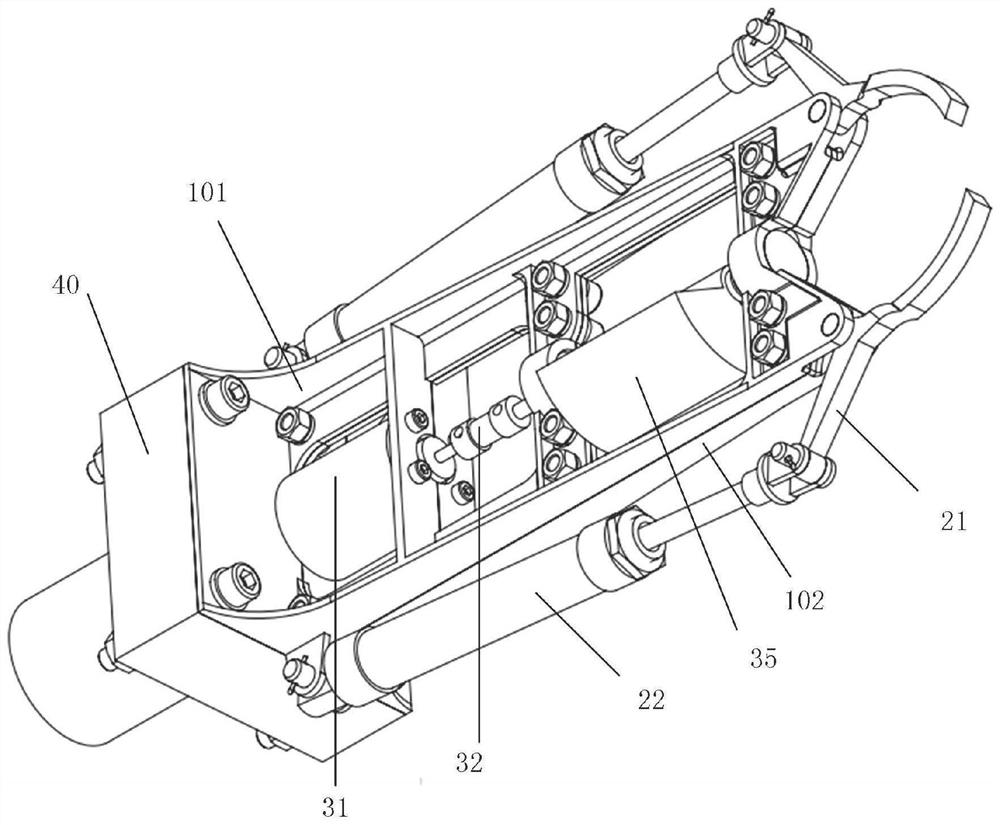

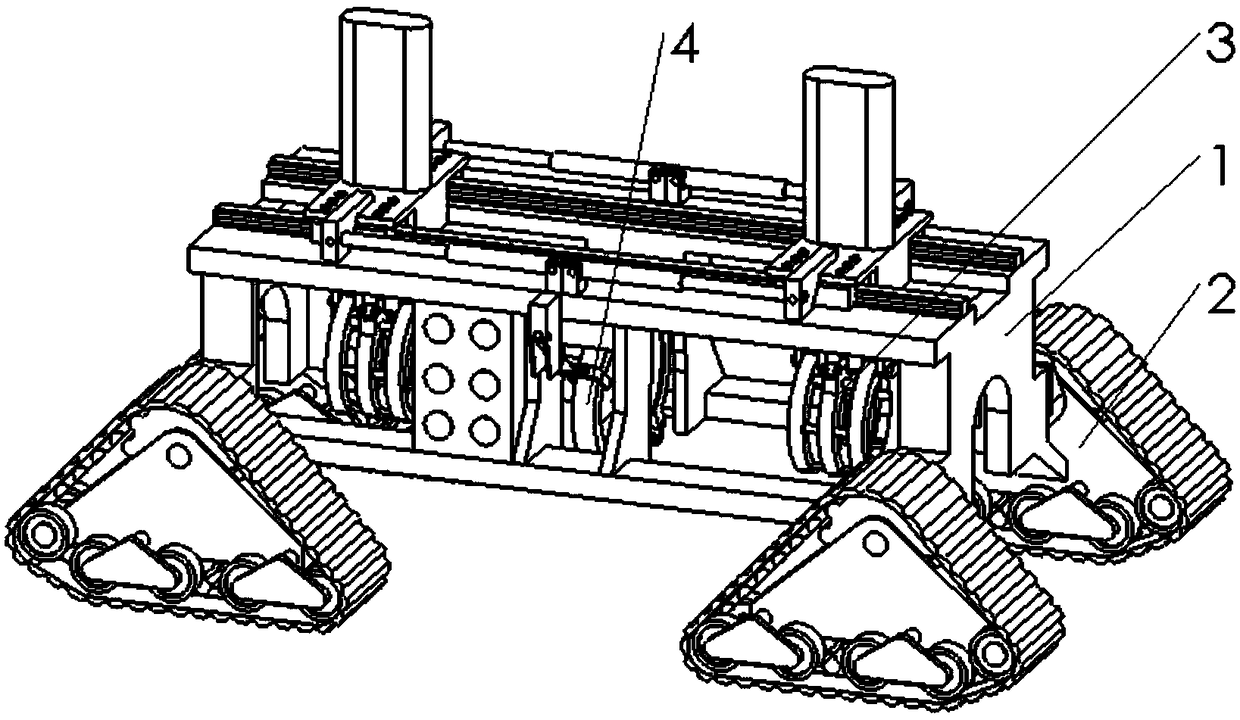

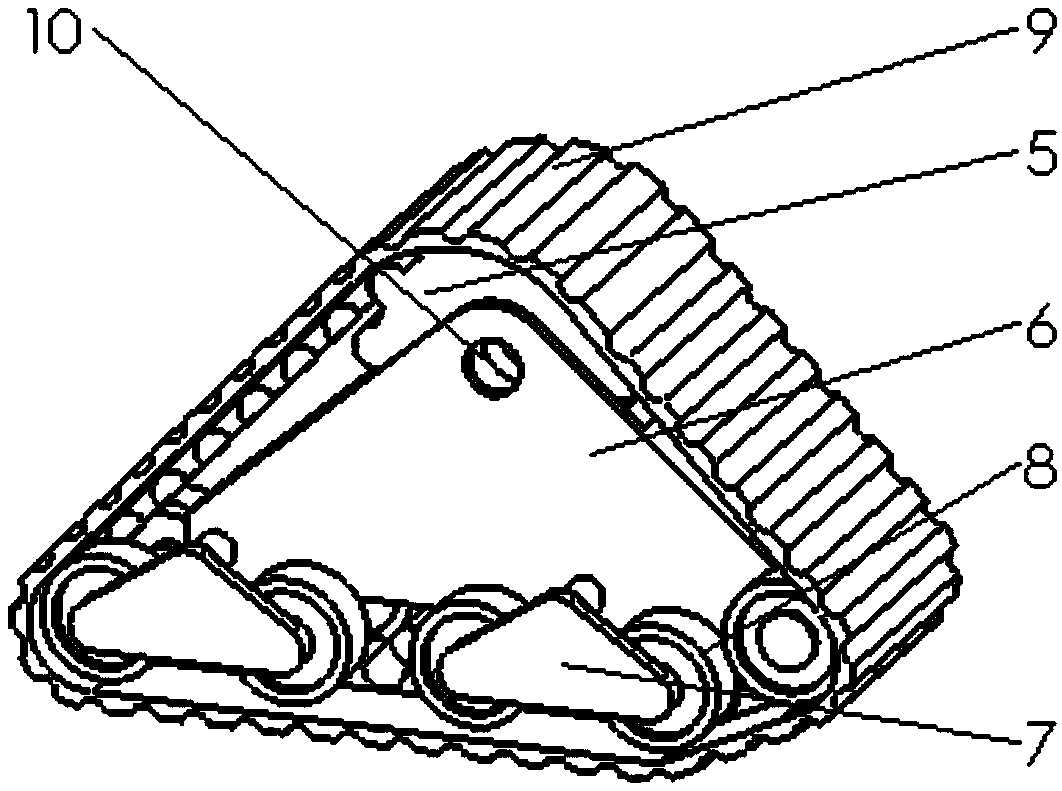

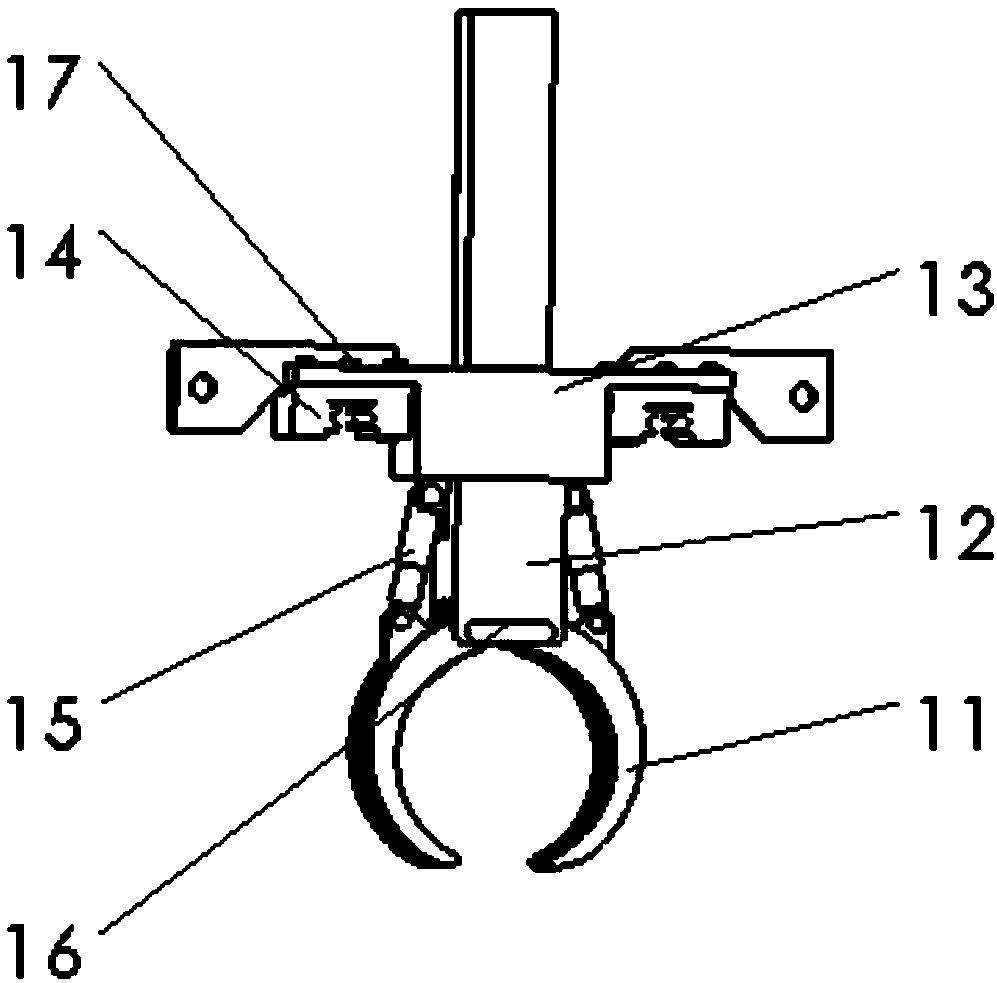

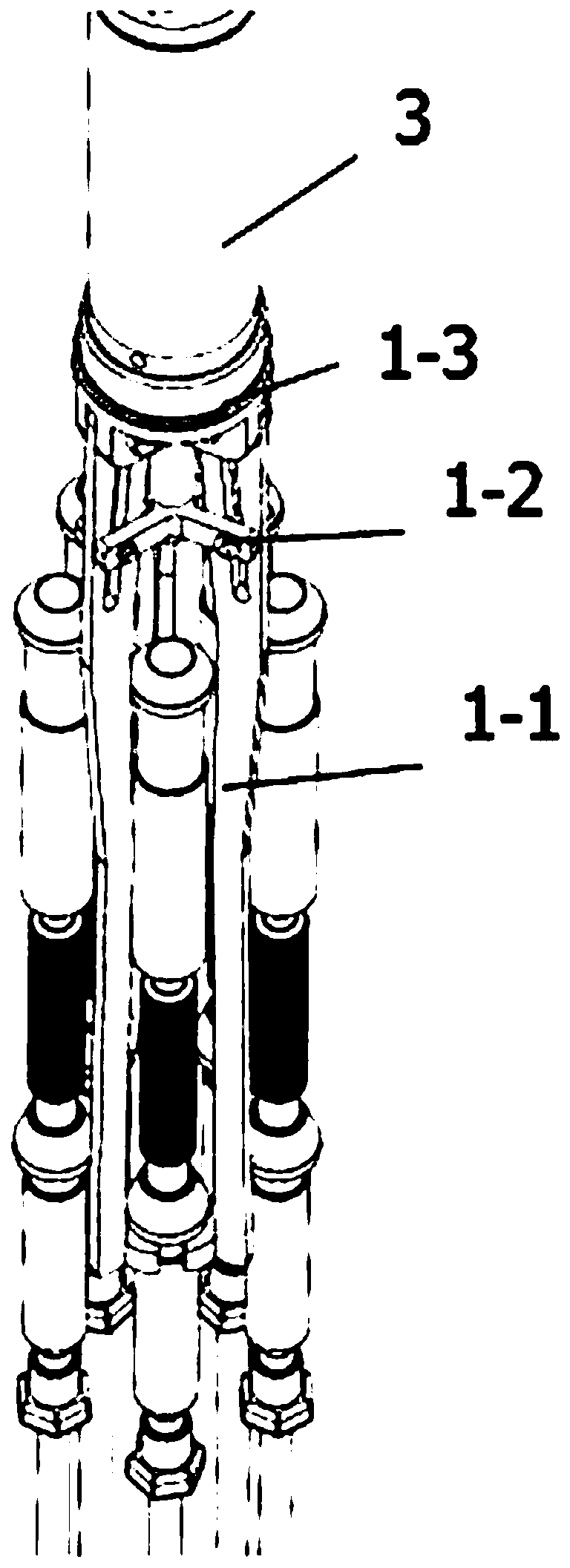

Underwater Pipeline Connection Robot

InactiveCN109159828AGuaranteed uptimePrevent rotationProgramme-controlled manipulatorGripping headsHydraulic cylinderUnderwater

The invention provides an underwater pipeline connection robot. The underwater pipeline connection robot mainly solves the problems of complicated connection system and various tools of the existing underwater pipeline connection robot. The utility model is characterized in that the robot adopts a frame structure of a triangular crawler, and the triangular crawler can be adapted to the complicatedterrain environment of the seafloor; Hydraulically driven mechanical jaws are installed on both sides to realize the clamping of the pipeline, The two pipelines can reach the same horizontal height by using the double-axis oil cylinder lifting mechanism, and the double-axis oil cylinder structure is more stable and can prevent the circumstance of rotation under water. The sliding rail mechanism and the hydraulic cylinder are used together to make the pipelines move to the left and the right for position adjustment. Make the two pipes to be connected face to face, and clamp connectors arrangedin the middle of the robot will lock the two pipes in alignment to realize the pipe connection function. The robot can accomplish underwater walking, pipe clamping, pipe alignment and pipe connection, and adopts hydraulic driving mode as a whole, which not only has high machine power, but also has higher stability.

Owner:NORTHEAST GASOLINEEUM UNIV

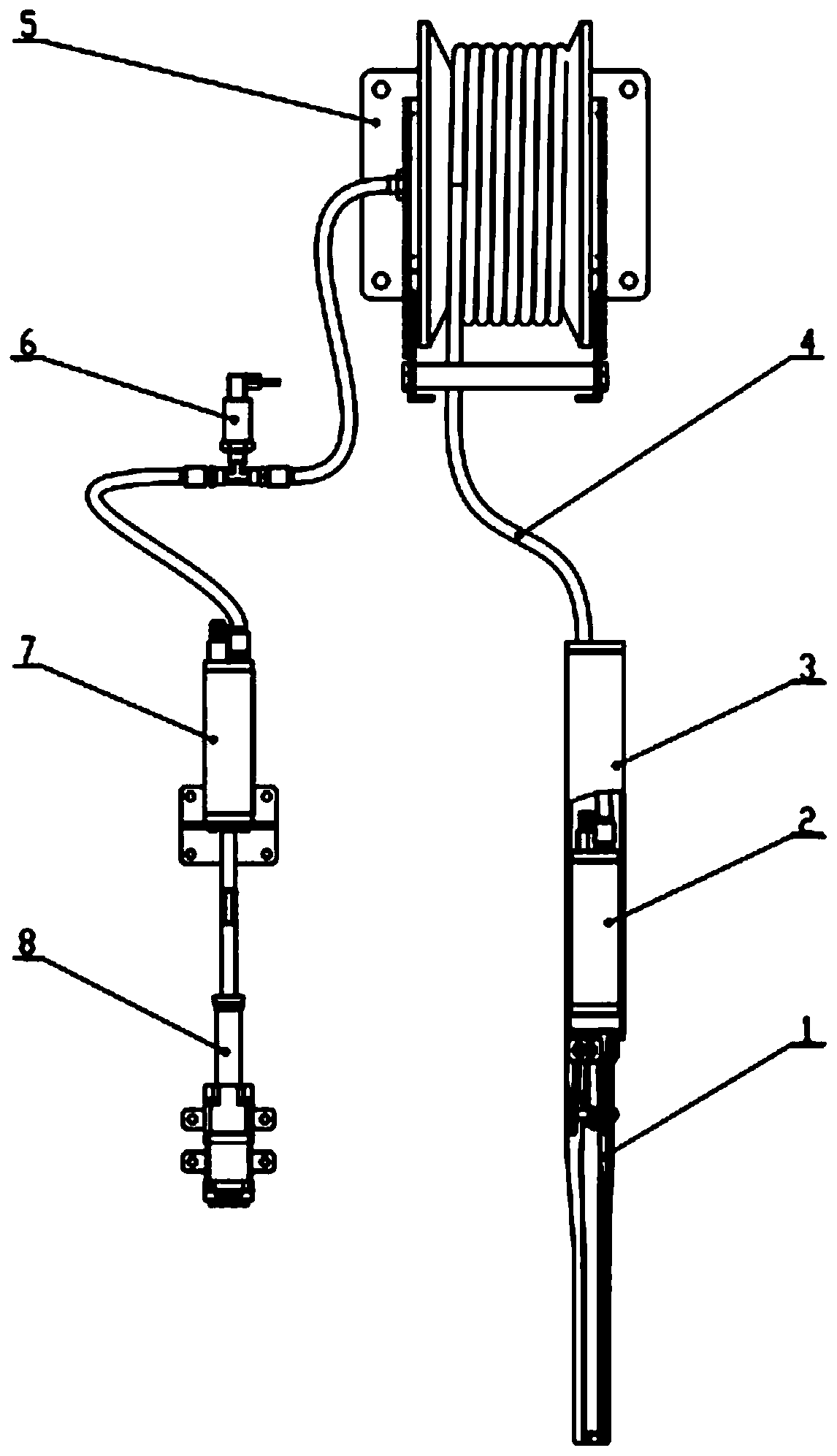

Pincer device used in water narrow space of nuclear power station

PendingCN109773805AReduce cumulative errorAchieve thong openProgramme-controlled manipulatorNuclear energy generationNuclear powerEngineering

The invention provides a pincer device which can be used in water narrow space of radiation environment of a nuclear power station. The extraction force of the pincer device is larger than 2000 N. Thepincer device comprises a pincer mechanism, a first hydraulic cylinder, a cylinder body, a hose, a winding wheel, a pressure sensor, a second hydraulic cylinder and a control system. The control system provides power for the pincer mechanism. The first hydraulic cylinder synchronous with the second hydraulic cylinder achieves opening and closing while driving the pincer mechanism to do reciprocating linear motion. Due to multi-directionality of force vector for workpiece extracting of pincers and workpiece clamping of clamping toes, the pincer mechanism has good stability at the stroke limitposition of the clamping toes. By means of the design of the geometrical shape of the clamping toes, the bearing face can be enlarged, it is ensured that the clamping toes do not deform, and the clamping stability and safety are improved. The pincer device is a long-distance tail end execution mechanism, developed by integrating the characteristics of high radiation, narrow space, high flexibilityand capability of operating in water, of an irradiation-resistant robot and a mechanical arm.

Owner:中乌先楚核能科技有限公司

A counterweight device for towed line array and towed line array

ActiveCN104047994BRealize fixed depthImprove detection performanceWave based measurement systemsCounterweightsSEMI-CIRCLEHalf field

The present invention provides a counterweight device for a towed line array and a towed line array, comprising: a first semi-cylindrical counterweight and a second semi-cylindrical counterweight with a semi-circular section, Buckle type locking mechanism, first hinge; a contact surface of the first semi-cylindrical counterweight and the second semi-cylindrical counterweight is connected through the first hinge, when the first semi-cylindrical counterweight When the opening angle of the counterweight and the second semi-cylindrical counterweight is zero, the two counterweights cooperate with each other to form a hollow cylinder. When the first semi-cylindrical counterweight and the second semi-cylindrical counterweight are opened into It is used to place the towing cable to the hollow part of the above-mentioned cylinder when the angle is at an angle; A streamer placed closely on the hollow part; wherein, the cylinder ends of the first semi-cylindrical counterweight and the second semi-cylindrical counterweight are also provided with a first conical guide section.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

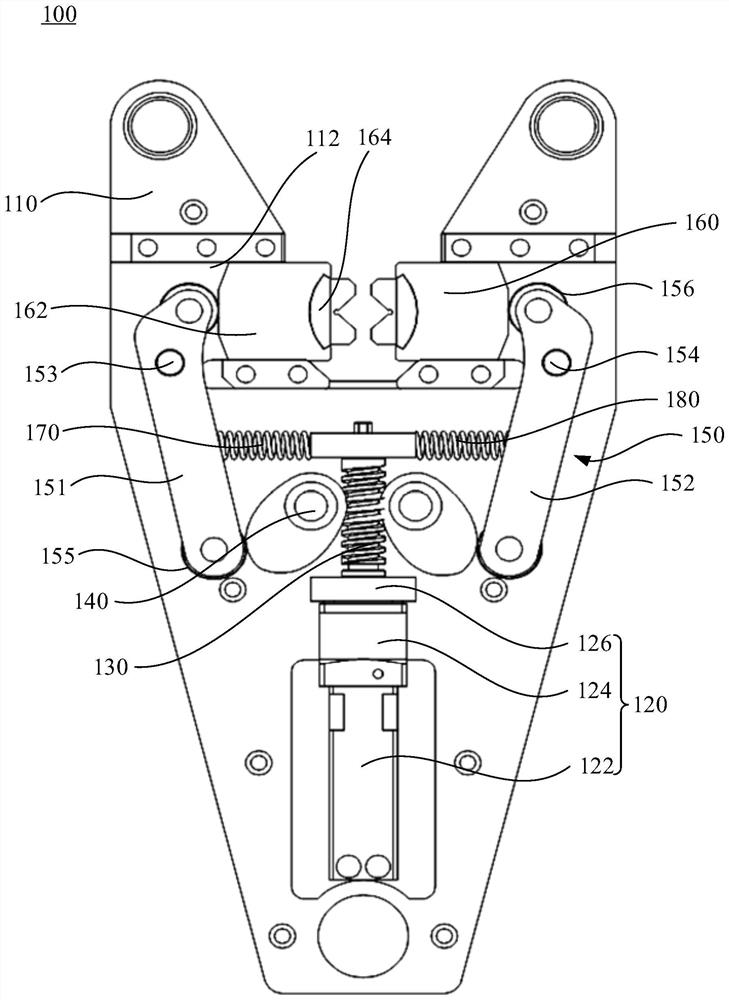

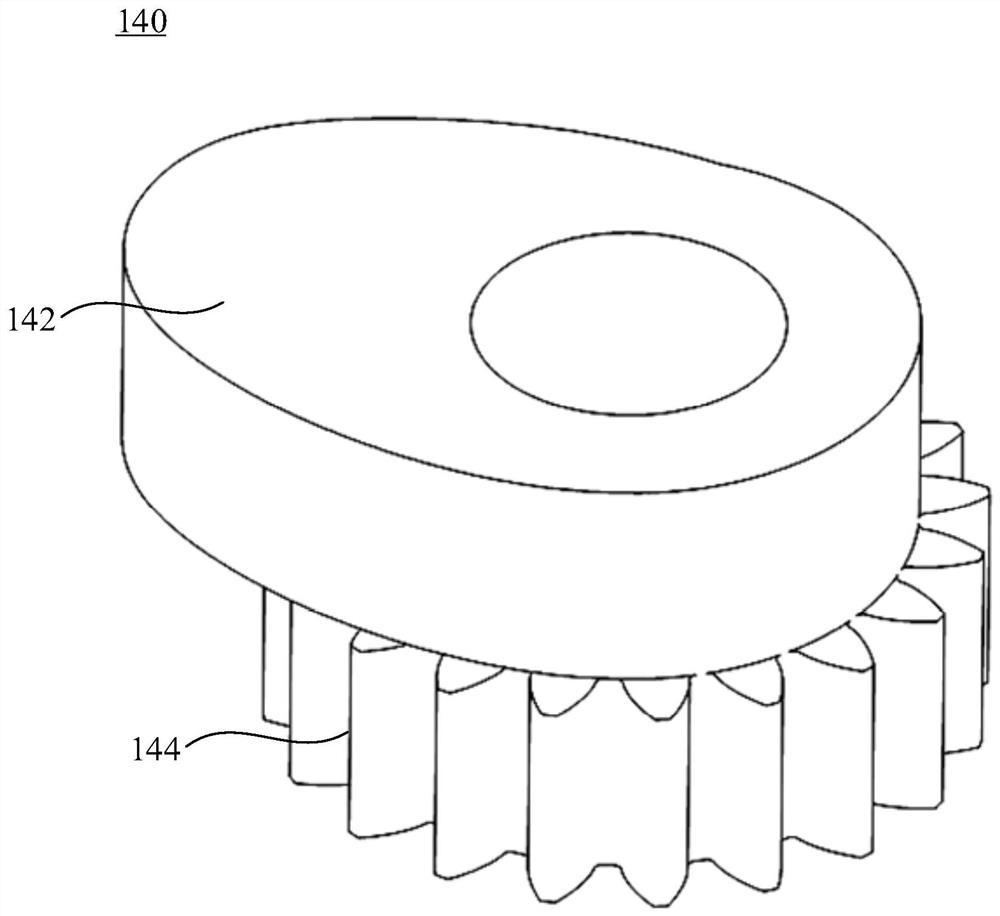

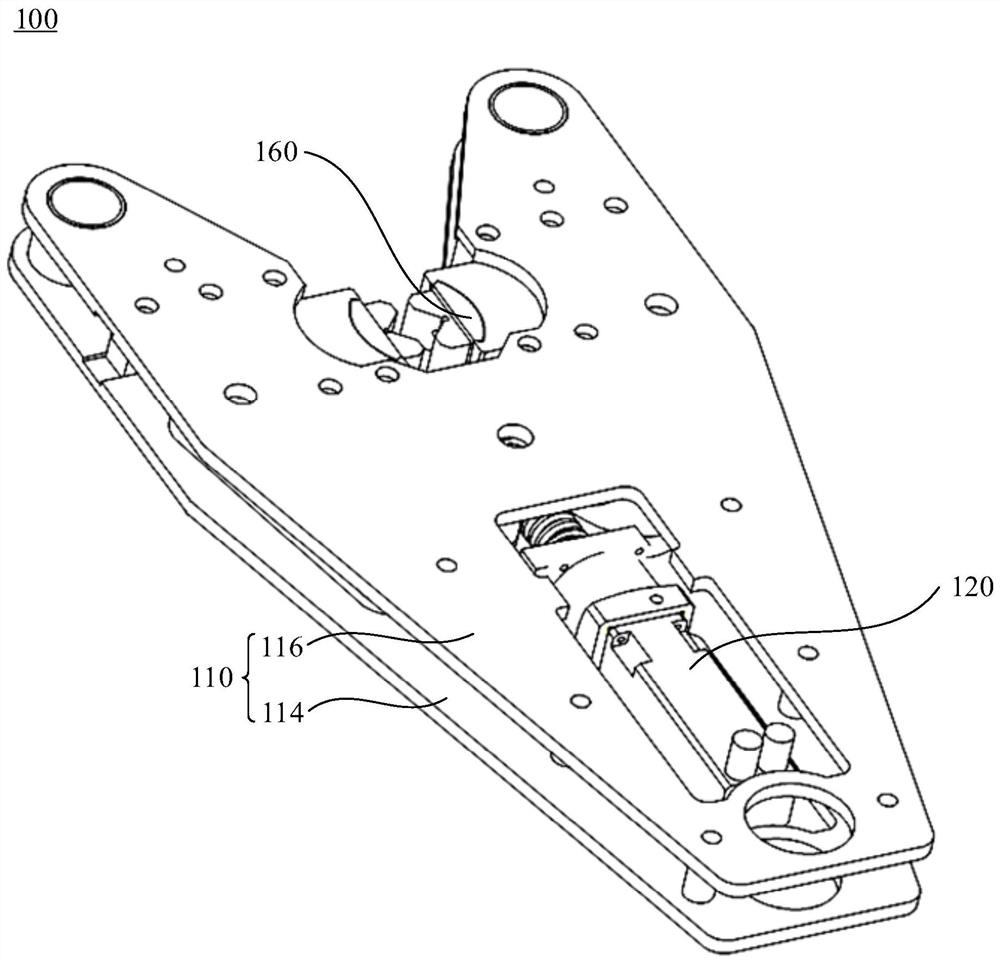

Back-up wrench clamping device and power tongs

PendingCN111608601AControl clamping forceNo need to worry about oil leakage and other issuesDrilling rodsDrilling casingsElectric driveWrench

The invention discloses a back-up wrench clamping device and power tongs, and relates to the technical field of maintenance auxiliary tools. The device comprises a mounting plate and an electric drivemechanism fixedly connected to the mounting plate, wherein the output end of the electric drive mechanism is fixedly connected to a worm; the worm is in transmission connection with a cam transmission mechanism; the cam transmission mechanism is in transmission connection with a link drive mechanism arranged on the mounting plate; two clamping heads slidably connected to the mounting plate are further arranged on the mounting plate; the two clamping heads are oppositely arranged; the two clamping heads are respectively connected to the link drive mechanism; the electric drive mechanism drivesthe worm to rotate; and the link drive mechanism drives the two clamping heads to approach each other. The connection form can be simplified and the clamping reliability is improved.

Owner:HUNAN SANY PETROLEUM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com