Movable heavy-load pallet based on clamping self-adaptive adjustment

A self-adaptive adjustment and pallet technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of potential safety hazards, vulnerable body, poor clamping accuracy, etc., and achieve low cost and ingenious structure. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

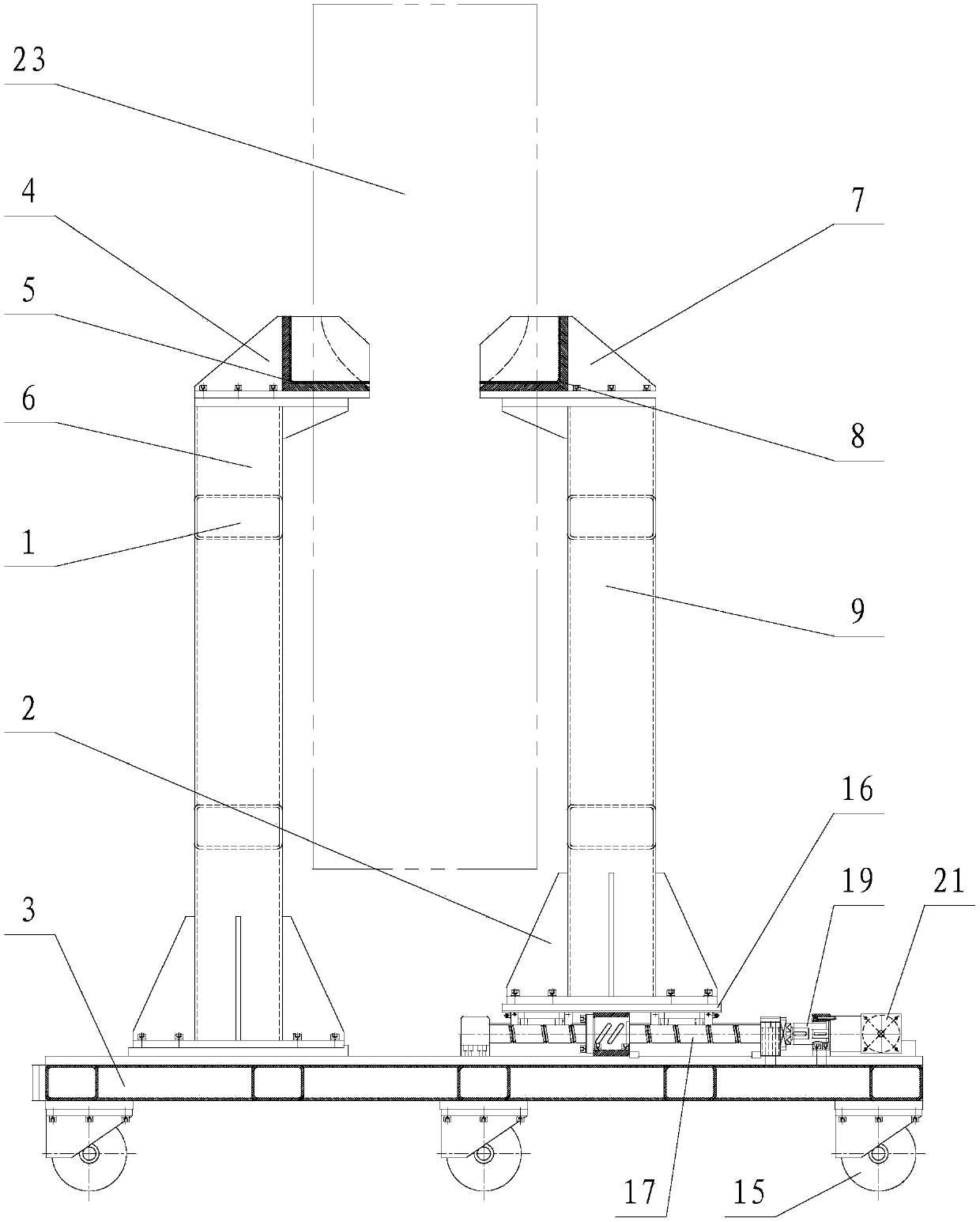

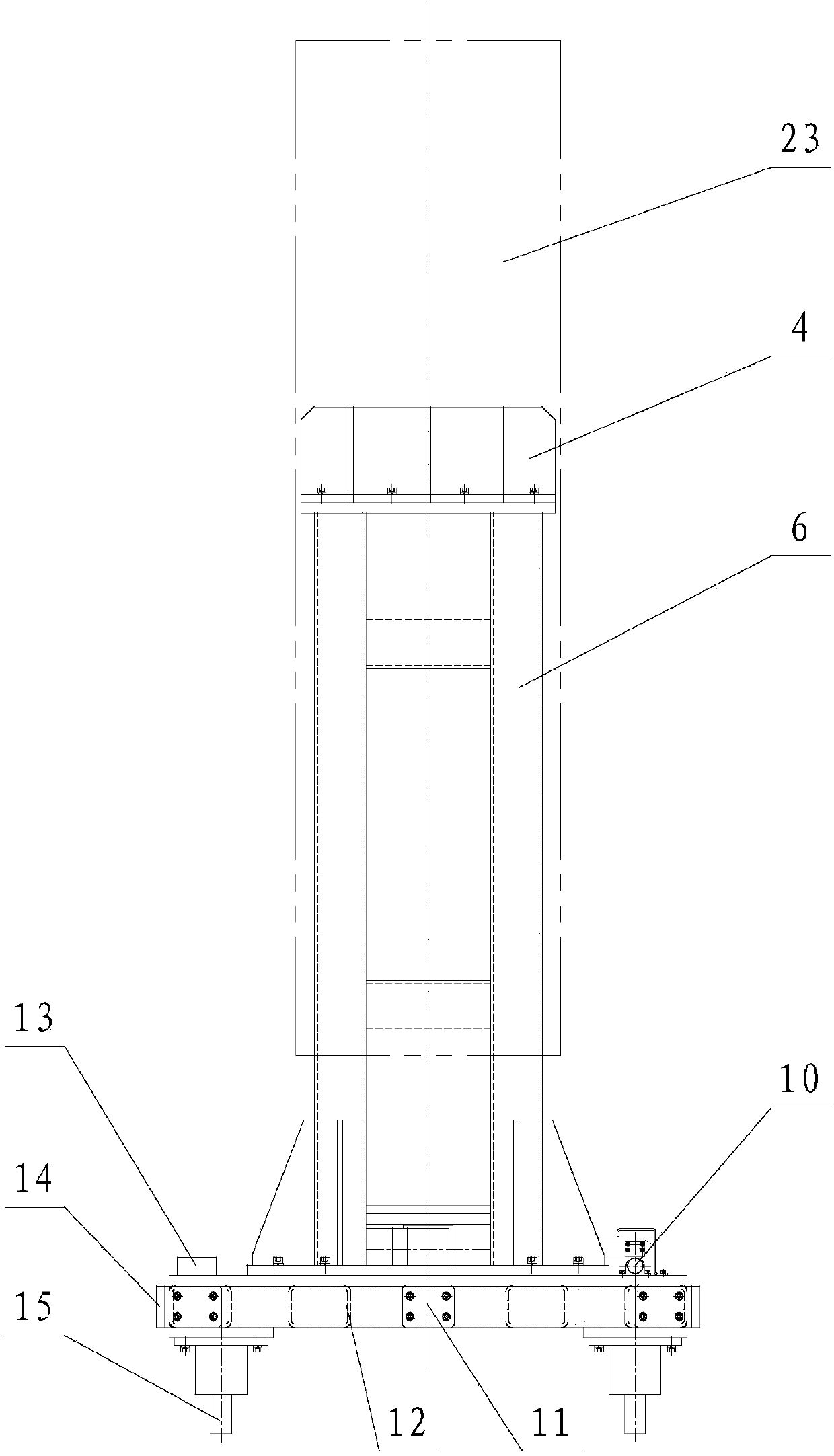

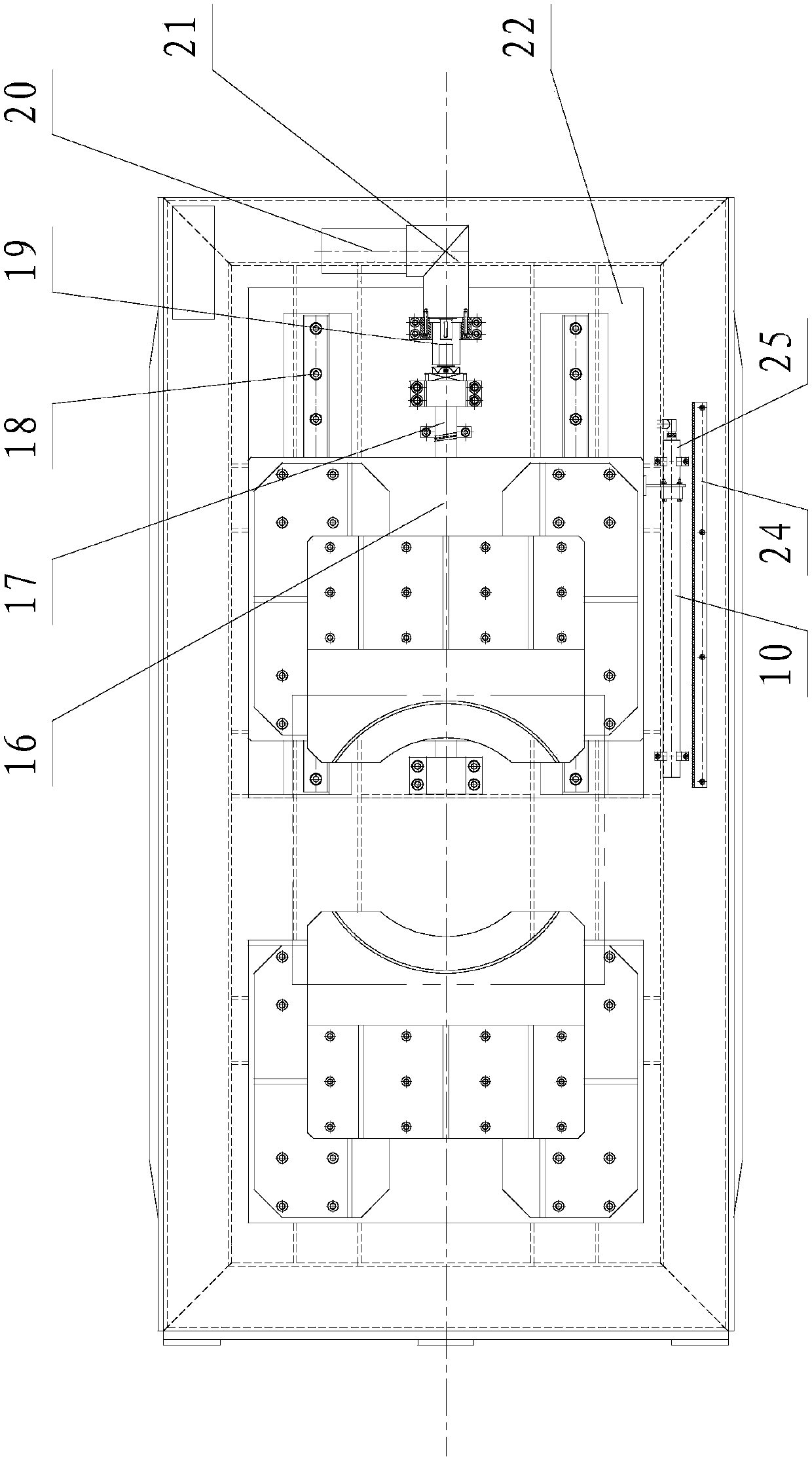

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] Such as Figure 1~3 As shown, the present invention includes a clamping and fixing part 1, a clamping and moving part 2 and a moving base part 3, wherein the clamping and fixing part 1 includes a fixed and clamped tooling 4, a fixed and clamped tooling pad 5 and a fixed and clamped bracket 6, The clamping and moving part 2 includes a mobile clamping tool 7, a mobile clamping tool pad 8, a mobile clamping bracket 9, a displacement sensor mechanism 10, a mobile base plate 16, a ball screw 17, a linear guide rail 18, a power output unit and a mobile base 22. The mobile base part 3 includes an X movement limiting block 11, a base 12, a power control quick change combination module 13, a Y movement limiting block 14 and a heavy-duty universal wheel 15.

[0024] The fixed clamping tooling pad 5 is fixed on the fixed clamping tooling 4 through screw connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com