Zinc-alluminium-based wear-resistant alloy and production thereof

A wear-resistant alloy and alloy material technology, applied in the field of metal materials, can solve the problems of casting defects, affecting the fluidity of liquid metal pouring, etc., and achieve the effects of low production cost, easy industrial production, and stable and reliable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

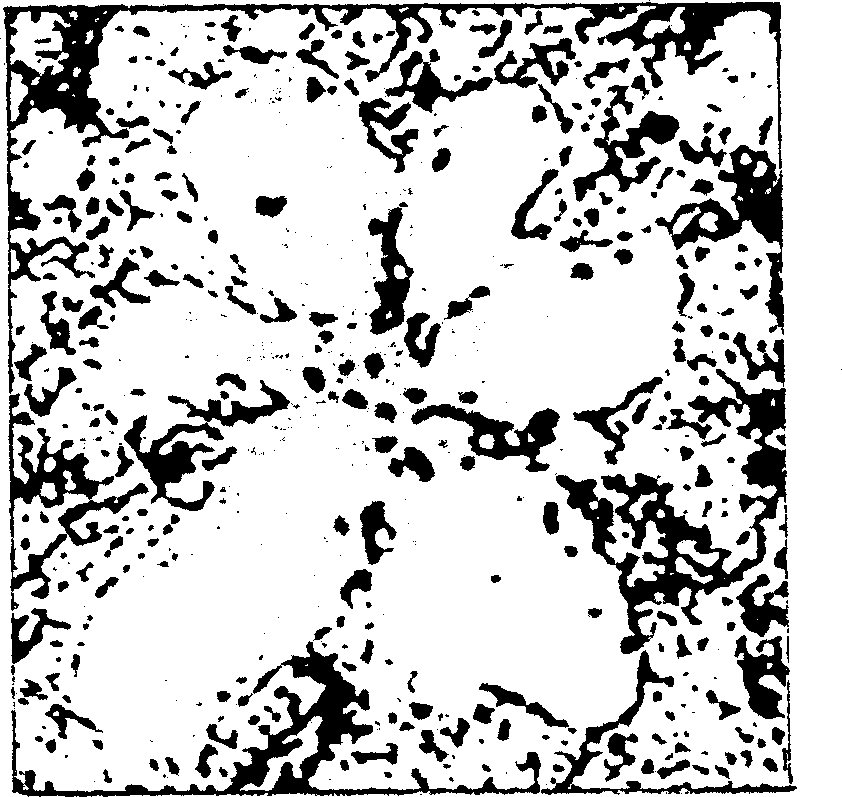

[0015] Melt 41% pure aluminum ingots, 57.8% pure zinc ingots, 1.2% crystalline silicon, and 0.025% tellurium metal, which account for the total weight of raw materials (the same below), to form zinc, aluminum, silicon, and tellurium alloy liquids; when the alloy liquid When heated to about 710°C, a metal salt composite treatment agent with a total weight of 1.0% of the raw material is pressed into the molten alloy liquid with a bell jar. The main components of the treatment agent are NaF, Na 3 AlF 6 and NaCl, the weight ratio of the three is 2:1.5:0.5. After adding the treatment agent, stir the alloy liquid properly and keep it warm for about 12 minutes. The angular and irregular silicon phase in the alloy will become a flowering silicon phase (such as figure 1 As shown), the wear-resistant enhanced phase is formed spontaneously in the alloy liquid, and after the treatment is completed, it is cast into the corresponding casting. The weight percent of the chemical composition...

Embodiment approach 2

[0017] Melt 50% pure aluminum ingots, 47.7% pure zinc ingots, 2.3% crystalline silicon, and 0.035% metal lanthanum, which account for the total weight of raw materials (the same below), to form zinc, aluminum, silicon, and lanthanum alloy liquids; when the alloy liquid When heated to about 750°C, a metal salt composite treatment agent with a total weight of 1.5% of the raw material is pressed into the molten alloy liquid with a bell jar. The main components of the treatment agent are NaF, Na 3 AlF 6 and NaCl, the weight ratio of the three is 3:1:1. After adding the treatment agent, stir the alloy liquid appropriately and keep it warm for 20 minutes. The angular and irregular silicon phase in the alloy turns into a flower-like silicon phase, and its wear-resistant enhanced phase is formed spontaneously in the alloy liquid. After the treatment, Cast into corresponding castings. The weight percent of the chemical composition of the treated zinc-aluminum-silicon-tellurium alloy ...

Embodiment approach 3

[0019] 48% pure aluminum ingots, 47% pure zinc ingots, 3.5% crystalline silicon, and 0.025% tellurium metal are melted to form zinc, aluminum, silicon, and tellurium alloy liquids; when the alloy liquids are When heated to about 740°C, a metal salt composite treatment agent with a total weight of 2.0% of the raw material is pressed into the molten alloy liquid with a bell jar. The main components of the treatment agent are NaF, NaF 3 AlF 6 and KCl, the weight ratio of the three is 4:0.5:1.5. After adding the treatment agent, stir the alloy liquid properly and keep it warm for 15 minutes. The angular and irregular silicon phase in the alloy turns into a flower-like silicon phase, and its wear-resistant enhanced phase is formed spontaneously in the alloy liquid. After the treatment, Cast into corresponding castings. The chemical composition of the treated zinc-aluminum-silicon-tellurium alloy material contains 48% of aluminum, 0.02% of tellurium, 3.0% of silicon and the rest i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com