Low-viscosity thermosetting polyimide resin as well as preparation method and application thereof

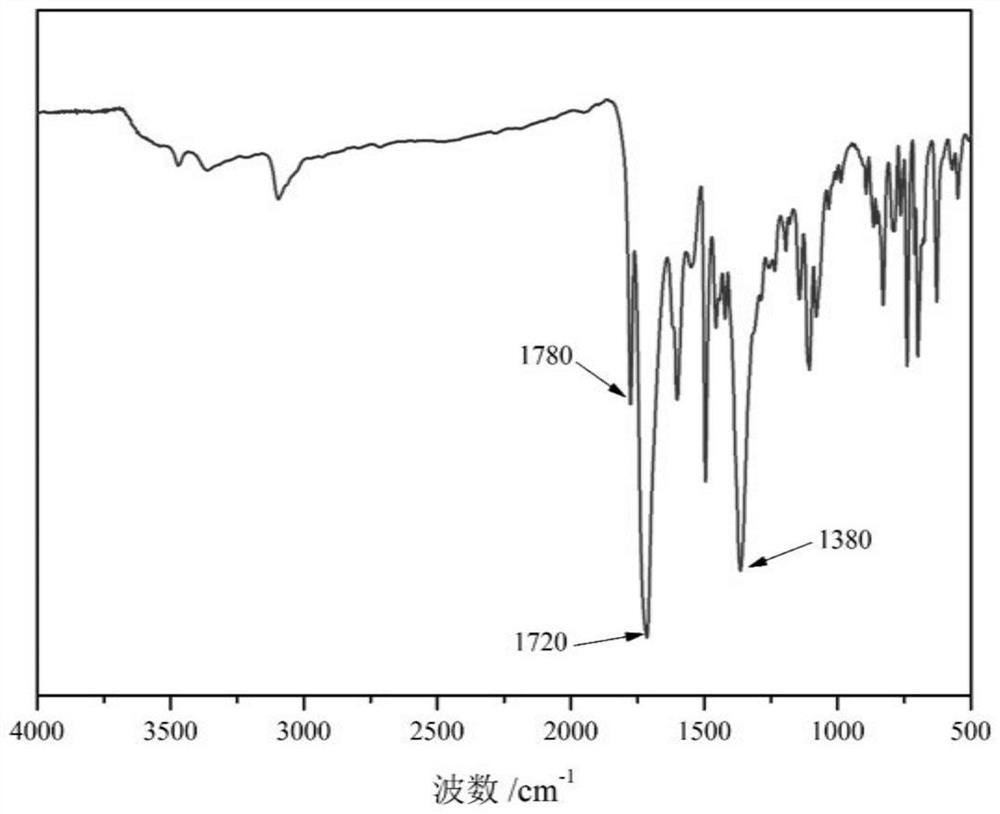

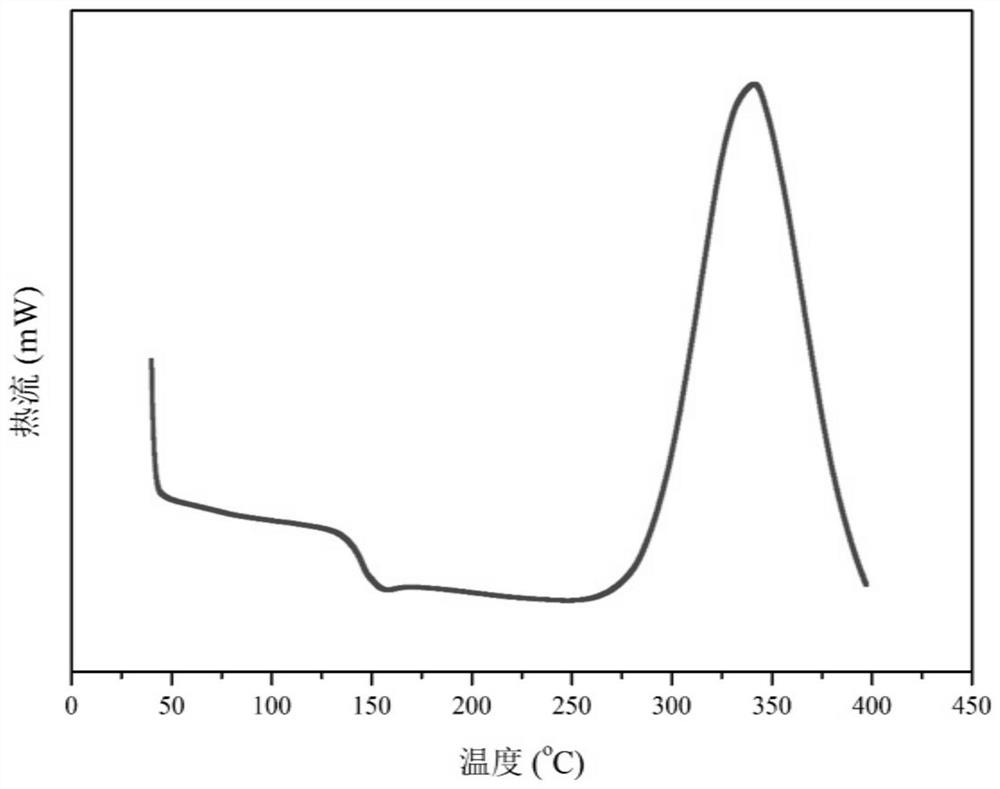

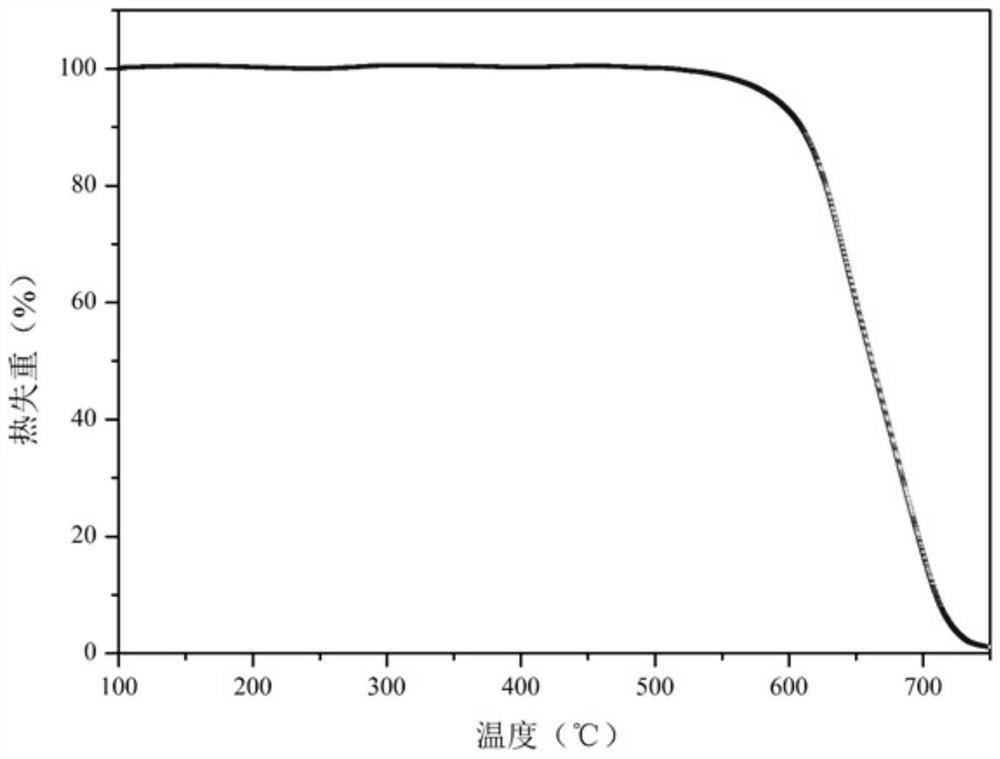

A polyimide resin and thermosetting technology, applied in the field of polymer materials, can solve the problems of poor manufacturability, high viscosity of thermosetting polyimide resin, limited application, etc., and achieve cheap price, good thermal stability and wide application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The preparation method of low-viscosity thermosetting polyimide resin of the present invention, step is as follows:

[0053] Step 1. Under the condition of maintaining the temperature at 10-15°C and continuous stirring, add the solvent containing the dibasic anhydride to the solvent containing the diamine dropwise. After the addition is completed, stir and react for 10-12 hours to obtain polyamide acid solution;

[0054] Step 2. Under the condition of maintaining the temperature at 20-25°C and continuous stirring, add the solvent dissolved in monobasic acid anhydride to the polyamic acid solution obtained in step 1. After the addition is completed, stir and react for 10-15 hours to obtain the active radical Group-terminated polyamic acid solution;

[0055] Step 3: Add a water-carrying agent to the active group-terminated polyamic acid solution prepared in Step 2, first heat the reaction system to 140-160°C for 6-8 hours, take out the excess water generated by the react...

Embodiment 1

[0067] Low viscosity thermosetting polyimide resin, the structural formula is as follows:

[0068]

[0069] Wherein, A is the following structure, or one of the isomers of the following structure:

[0070]

[0071] B is the following structure, or one of the isomers of the following structure:

[0072]

[0073] C is the following structure, or one of the isomers of the following structure:

[0074]

[0075] The preparation method of above-mentioned low-viscosity thermosetting polyimide resin:

[0076] Step 1. Dissolve 0.2mol of 4,4'-diaminodiphenyl ether in 160mL of dimethylacetamide in the reaction device, keep the temperature at 12°C and keep stirring at 40rpm, and add to the reaction device at a rate of 10mL / min Add dropwise a mixed solution of 0.1mol 3,3',4,4'-biphenyltetracarboxylic dianhydride and 120mL dimethylacetamide, after the dropwise addition, stir and react for 12 hours to obtain a polyamic acid solution;

[0077] Step 2. Fully dissolve 0.2 mol of ...

Embodiment 2

[0085] Low viscosity thermosetting polyimide resin, the structural formula is as follows:

[0086]

[0087] Wherein, A is the following structure, or one of the isomers of the following structure:

[0088]

[0089] B is the following structure, or one of the isomers of the following structure:

[0090]

[0091] C is the following structure, or one of the isomers of the following structure:

[0092]

[0093] The preparation method of above-mentioned low-viscosity thermosetting polyimide resin:

[0094] Step 1. Dissolve 0.2mol of 4,4'-diaminodiphenylmethane in 160mL of dimethylacetamide in the reaction device, keep the temperature at 12°C and keep stirring at 40rpm, and proceed to the reaction at a rate of 10mL / min Add dropwise a mixed solution of 0.1mol pyromellitic dianhydride and 120mL dimethylacetamide into the device, after the dropwise addition is completed, stir and react for 12 hours to obtain a polyamic acid solution;

[0095] Step 2. Fully dissolve 0.2 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com