Macroporous strong alkaline carbon nanotube composite ion exchange resin and preparation method thereof

A carbon nanotube composite and ion exchange resin technology, which is applied in ion exchange, anion exchange, chemical instruments and methods, etc., can solve the problems of poor swelling resistance and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

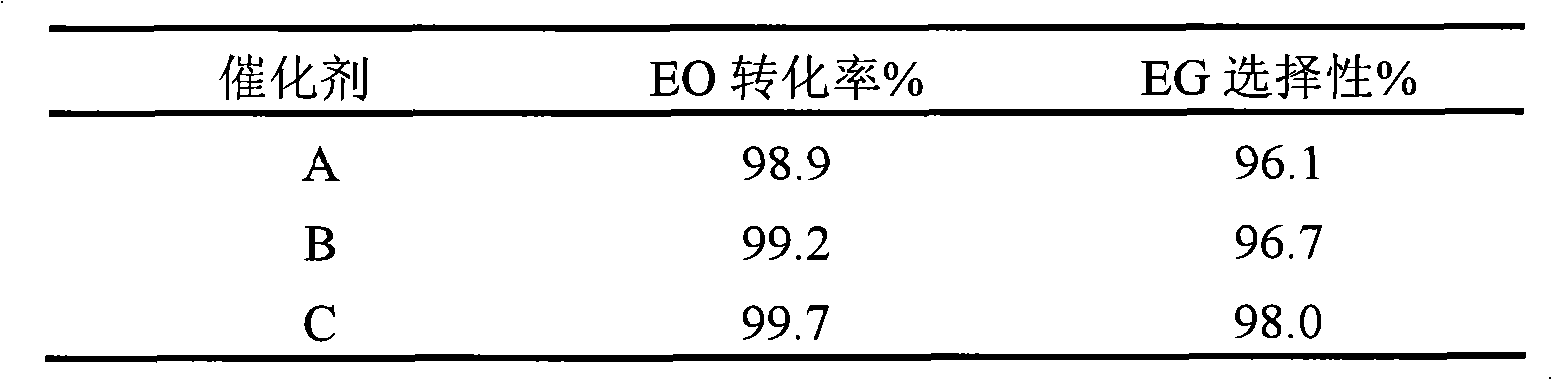

Embodiment 1

[0022] Add 38.0 grams of p-chloromethylstyrene, 8.0 grams of divinylbenzene, 0.6 grams of benzoyl peroxide initiator, and 35.0 grams of polystyrene in a 250 milliliter three-necked flask, and stir at 60 °C for 1.5 hours; then add 2.4 g of multi-walled carbon nanotubes were stirred for 1 hour for pre-polymerization. 130 mL of deionized water in which 1.3 g of polyvinyl alcohol had been dissolved was added. Adjust the stirring speed while gradually raising the temperature to 80°C and react for 5 hours; then raise the temperature to 90°C and react for 5 hours; finally raise the temperature to 98°C and react for 6 hours. After the reaction, pour out the upper layer liquid, extract the microspheres with a Soxhlet extractor for 5 hours, then wash the microspheres with hot water, filter, put them in an oven for drying at 80°C, and sieve to collect a particle size of 0.35 Composite microspheres A in the range of ~0.60 mm.

Embodiment 2

[0024] In a 500 ml three-necked flask, add 3.1 g of polyvinyl alcohol and 300 ml of deionized water, start stirring and raise the temperature to completely dissolve the polyvinyl alcohol. Stop stirring, add 80.0 grams of p-chloromethylstyrene, 9.0 grams of divinylbenzene and 1.5 grams of benzoyl peroxide initiator, 30.0 grams of polystyrene, and a mixed solution of 9.9 grams of multi-walled carbon nanotubes after cooling slightly . Adjust the stirring speed while gradually raising the temperature, and react at 80°C for 5 hours; then raise the temperature to 88°C, continue the reaction for 5 hours, and finally raise the temperature and react at 100°C for 6 hours. After the reaction, pour out the upper layer liquid, extract the microspheres with a Soxhlet extractor for 5 hours, then wash the microspheres with hot water, filter, put them in an oven for drying at 80°C, and sieve to collect a particle size of 0.35 Composite microspheres B in the range of ~0.60 mm.

Embodiment 3

[0026]Add 140 grams of p-chloromethylstyrene, 8.5 grams of divinylbenzene and 3.9 grams of benzoyl peroxide initiator, 90.0 grams of polystyrene, and 12.4 grams of multi-walled carbon nanotubes in a 1000 milliliter three-necked flask, at 65 The mixture was stirred at °C for 1.5 hours to carry out prepolymerization. Then 500 ml of deionized water in which 5.0 g of polyvinyl alcohol had been dissolved was added. Adjust the stirring speed, raise the temperature to 80°C within one hour, and react continuously for 5 hours; then raise the temperature to 90°C, react for 5 hours, and finally raise the temperature to 98°C, and react for 6 hours. After the reaction, pour out the upper layer liquid, extract the microspheres with a Soxhlet extractor for 5 hours, then wash the microspheres with hot water, filter, put them in an oven for drying at 80°C, and sieve to collect a particle size of 0.35 Composite microspheres C in the range of ~0.60 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com