Device for separating positive and negative ions, film forming equipment and chamber cleaning method

A technology of positive and negative ions and film-forming equipment, which is applied in the direction of circuits, discharge tubes, electrical components, etc., can solve problems such as energy waste, low ions, and complicated equipment structure, so as to improve cleaning effect, improve cleaning efficiency, and avoid composite problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

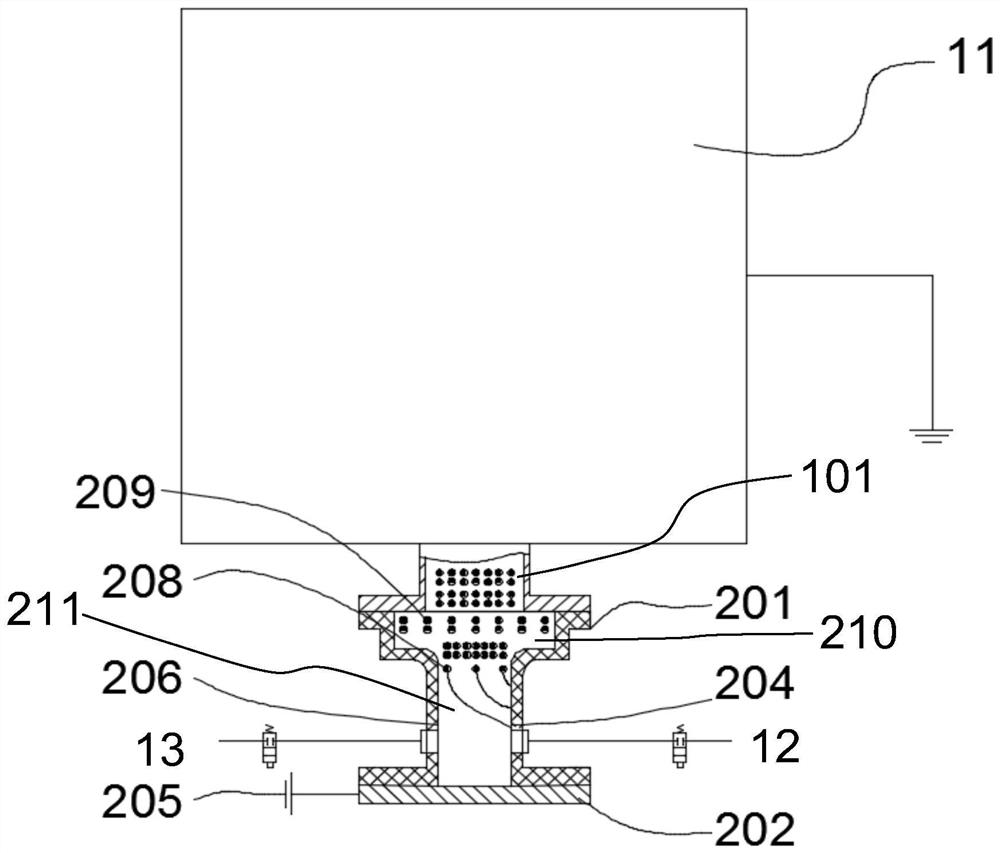

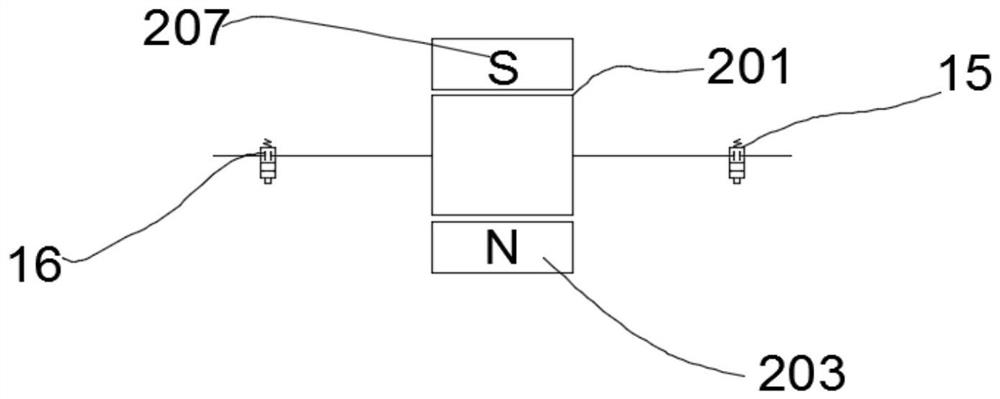

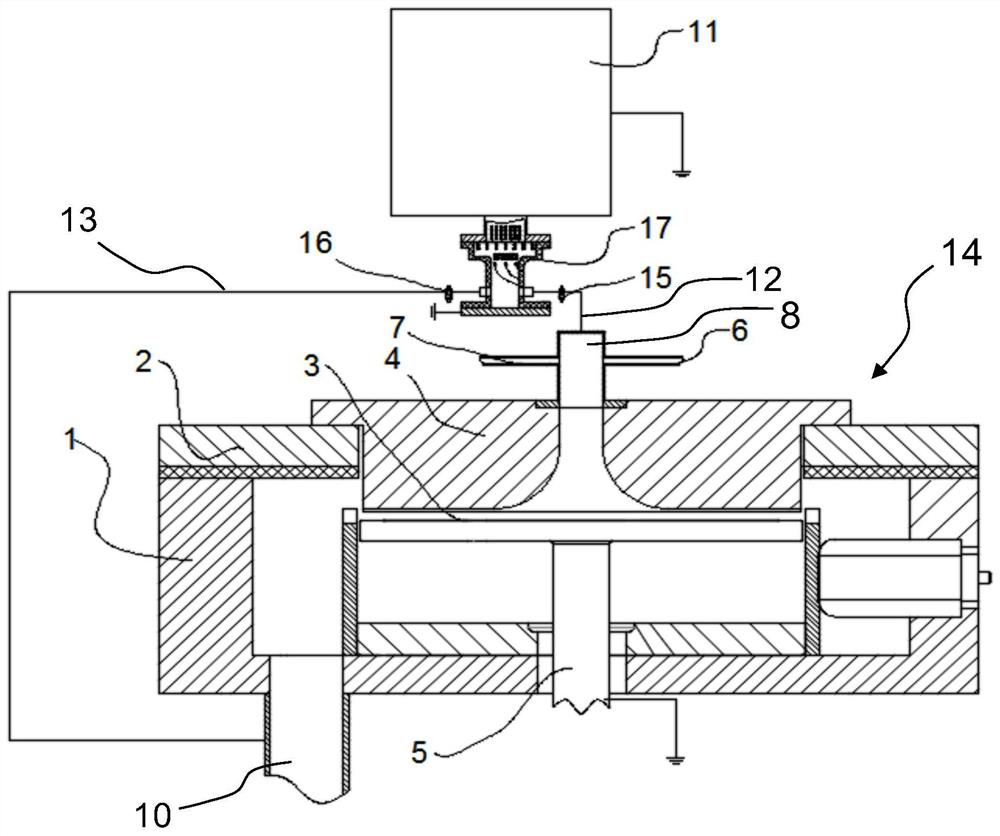

[0040] The purpose of the present invention is to solve the problems of low cleaning efficiency and poor cleaning effect during in-situ cleaning of remote ion sources, and to provide a device for separating positive and negative ions, a film-forming device equipped with a device for separating positive and negative ions, and a chamber cleaning method , and because of its simple structure and commonly used materials, the production cost is greatly reduced. According to the principle that the Lorentz force can change the direction of movement of ions in a magnetic field and the electric field can separate positive and negative ions, the present invention designs the following device for separating positive and negative ions and the film forming equipment provided with the device for separating positive and negative ions. After the positive ions are separated from the negative ions, the required negative ions can enter the chamber for cleaning, and the unnecessary positive ions ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com