rGO/silver silicate composite and preparation method and application thereof

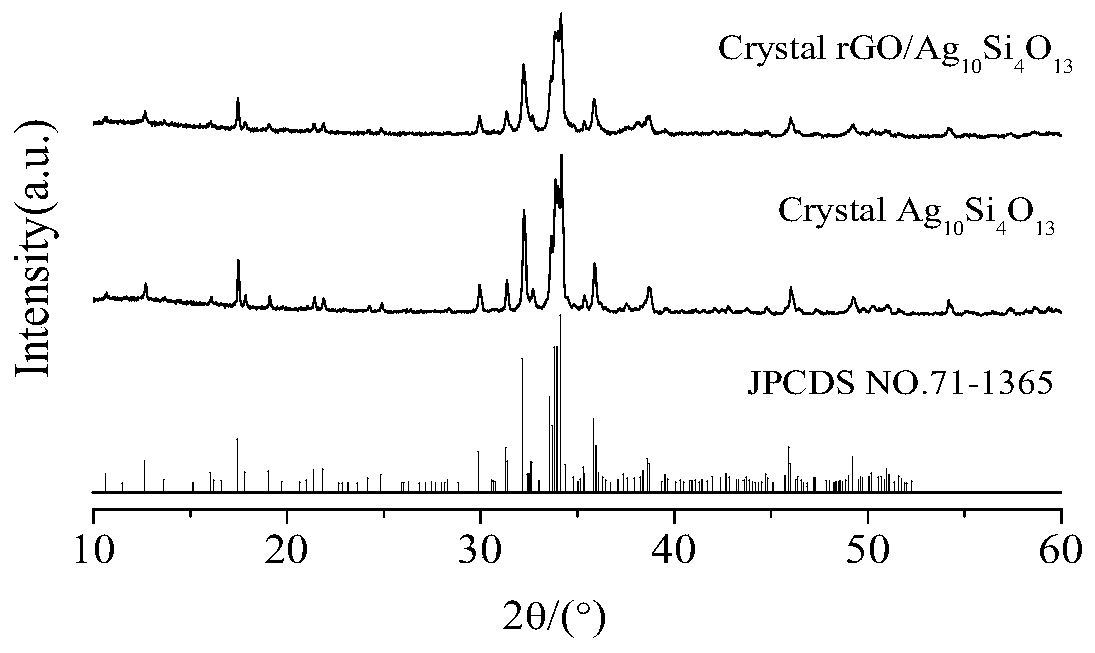

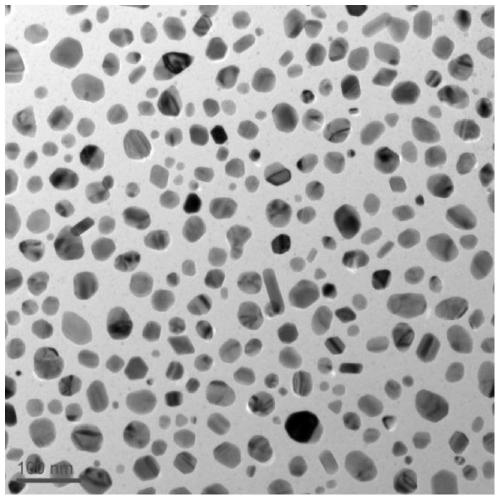

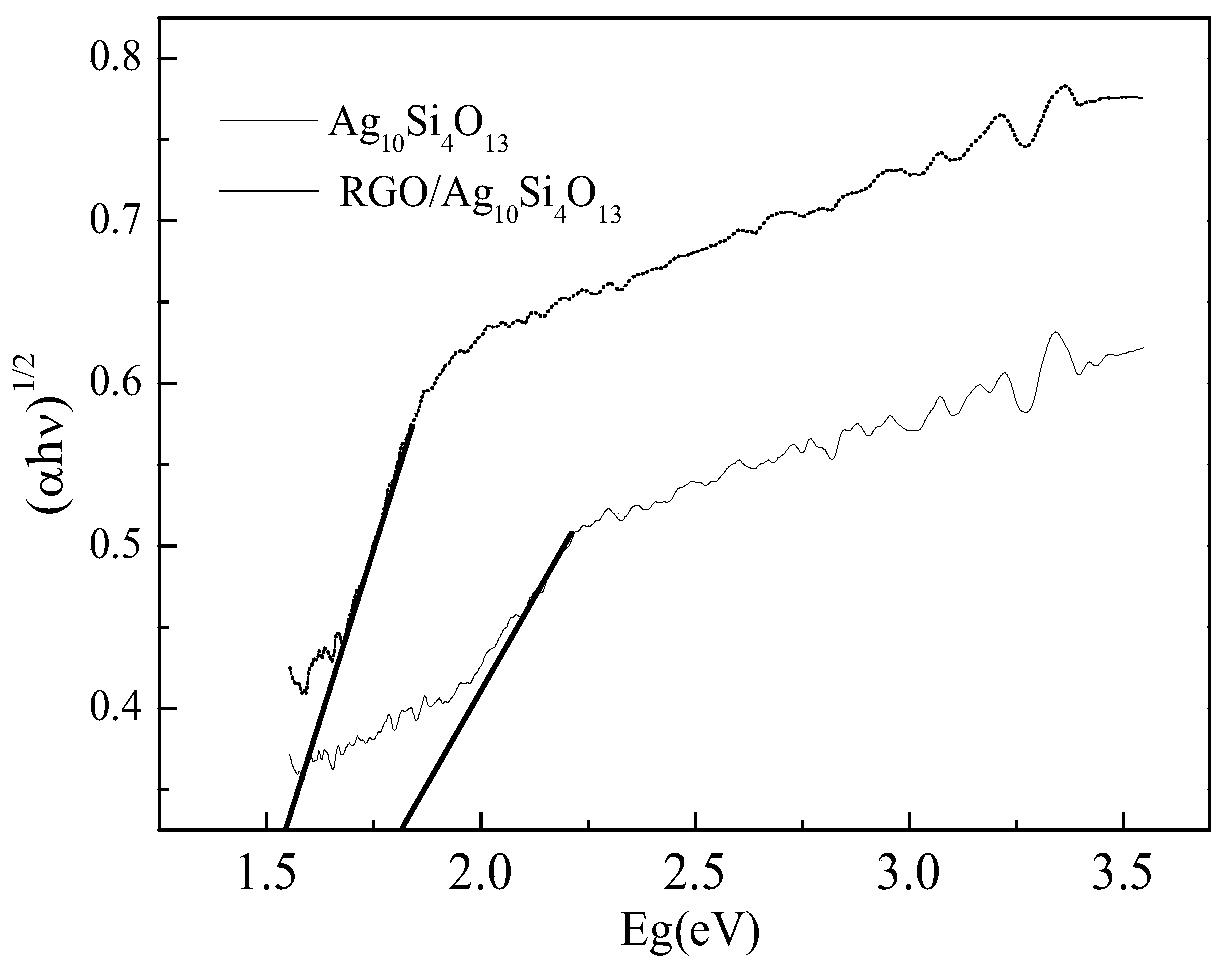

A technology of composite materials and silicic acid sol, which is applied in the field of photocatalytic materials, can solve the problems of high recombination rate of photogenerated carriers, low utilization efficiency of visible light, and narrow light absorption range, so as to improve photocatalytic efficiency and avoid photocorrosion problems , the effect of uniform grain distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a rGO / Ag 10 Si 4 o 13 The preparation method of composite material, comprises the following steps:

[0031] (1) Mix citric acid, dehydrated alcohol and ethyl orthosilicate to obtain a mixed solution;

[0032] (2) adding water dropwise to the mixed solution obtained in the step (1), and aging after stirring to obtain silicic acid sol;

[0033] (3) graphene hydrosol is mixed with silicic acid sol, obtains graphene-silicic acid sol;

[0034] (4) drip silver nitrate solution in the graphene-silicic acid sol that described step (3) obtains, carry out complexation reaction, dry after leaving standstill, obtain precursor;

[0035] (5) heat-treating the precursor obtained in step (4) to obtain GO / Ag 10 Si 4 o 13 Material;

[0036] (6) the GO / Ag obtained in the step (5) 10 Si 4 o 13 Material reduction treatment to obtain the rGO / Ag 10 Si 4 o 13 composite material.

[0037] The invention mixes citric acid, absolute ethanol and ethyl orthosili...

Embodiment 1

[0059] (1) Mix 0.43g of citric acid with 5.2mL of absolute ethanol and stir until completely dissolved; add 1mL of tetraethyl orthosilicate to the above solution and stir to obtain a mixed solution;

[0060] (2) Add 0.33mL of distilled water dropwise (dropping rate is 0.04mL / s) into the obtained mixed solution, stir for 1h, seal and store for 15 days to obtain silicic acid sol;

[0061] (3) Mix 4.394g of graphene sol (solid-to-liquid ratio is 0.003564) and 6.53mL of silicic acid sol, stir for 1h to make it evenly distributed, and then ultrasonicate for 6h to obtain graphene-silicate sol;

[0062] (4) 1.9g AgNO 3 Mix with 5mL of distilled water to obtain a silver nitrate solution; add the gained silver nitrate solution dropwise (a drop rate of 0.04mL / s) into the graphene-silicic acid sol, carry out complexation reaction for 2h under stirring conditions, and let it stand 12h, put it into a 100°C oven to dry and grind to obtain the precursor;

[0063] (5) The precursor was heat-t...

Embodiment 2

[0067] (1) Mix 0.086g of citric acid with 5.2mL of absolute ethanol and stir until completely dissolved; add 1mL of ethyl orthosilicate to the above solution and stir to obtain a mixed solution;

[0068] (2) Add 0.33mL of distilled water dropwise into the obtained mixed solution (the dropping rate is 0.04mL / s), stir for 1h, seal and age for 15 days to obtain silicic acid sol;

[0069] (3) Mix 4.394g of graphene sol (solid-to-liquid ratio is 0.003564) with 6.53mL of silicic acid sol, stir for 1h to make it evenly distributed, and then ultrasonicate for 6h to obtain graphene-silicic acid sol;

[0070] (4) 1.9g AgNO 3 Mix with 5mL of distilled water to obtain a silver nitrate solution; add the obtained silver nitrate solution dropwise (the drop rate is 0.04mL / s) to the obtained graphene-silicic acid sol, and carry out the complexation reaction for 2h under the condition of stirring, after standing for 12h , placed in a 100°C oven for drying and grinding to obtain the precursor; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com