Method for preparing nanometer titanium dioxide

A technology of nano-titanium dioxide and propyl titanate, which is applied in the field of photocatalytic materials, can solve the problems of limited excellent performance, easy agglomeration of products, and high cost, and achieve the effects of inhibiting excessive growth, uniform particle size distribution, and reducing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

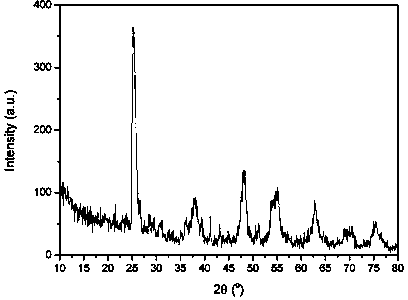

Image

Examples

Embodiment 1

[0022] a. Using butyl titanate as a raw material and ethanol as a solvent, slowly drop 10ml of butyl titanate into 30ml of ethanol under rapid stirring with a magnetic stirrer to prepare a butyl titanate solution;

[0023] b. Dissolve 1g of gelatin in 49g of deionized water at a temperature of 85°C to prepare a gelatin solution with a concentration of 1% by mass;

[0024] c. Slowly add 10ml of the gelatin solution into 40ml of butyl titanate solution, stir evenly, slowly drop 20% hydrochloric acid into the mixed solution, adjust the pH of the solution to 2.7, stir quickly until the solution loses fluidity, A pale yellow gel was obtained;

[0025] d. Dry the yellow gel in an oven at 50°C for 5 hours to obtain a uniformly dispersed white powder;

[0026] e. Boil the white powder in deionized water for 10 minutes, filter the precipitate, wash the precipitate 3 times with deionized water, then wash 3 times with ethanol, and dry naturally in the air (volatilize ethanol) to obtain ...

Embodiment 2

[0030] a. Using ethyl titanate as raw material and methanol as solvent, slowly drop 10ml of ethyl titanate into 50ml of ethanol under rapid stirring with a magnetic stirrer to prepare ethyl titanate solution;

[0031] b. Dissolve 0.25g of gelatin in 49.75g of deionized water at a temperature of 80°C to prepare a gelatin solution with a concentration of 0.5% by mass;

[0032] c. Slowly add 20ml of the gelatin solution into 60ml of ethyl titanate solution, stir evenly, slowly drop nitric acid with a mass percentage of 20% into the mixed solution, adjust the pH of the solution to 2.1, and stir rapidly until the solution loses fluidity, A pale yellow gel was obtained;

[0033] d. Dry the yellow gel in an oven at 45°C for 6 hours to obtain a uniformly dispersed white powder;

[0034] e. Put the white powder into deionized water and boil for 20 minutes, filter to collect the precipitate, wash the precipitate with deionized water, then wash with ethanol 3 times, and dry naturally in...

Embodiment 3

[0038] a. Using propyl titanate as raw material and propanol as solvent, slowly drop 10ml of propyl titanate into 20ml of ethanol under rapid stirring with a magnetic stirrer to prepare a propyl titanate solution;

[0039] b. Dissolve 0.75g of gelatin in 49.25g of deionized water at a temperature of 75°C to prepare a gelatin solution with a concentration of 1.5% by mass;

[0040] c. Slowly add 6ml of the gelatin solution into 30ml of propyl titanate solution, stir evenly, slowly drop 20% hydrochloric acid into the mixed solution, adjust the pH of the solution to 3.8, stir quickly until the solution loses fluidity, A pale yellow gel was obtained;

[0041] d. Dry the yellow gel in an oven at 50°C for 4 hours to obtain a uniformly dispersed white powder;

[0042] e. Boil the white powder in deionized water for 10 minutes, filter the precipitate, wash the precipitate with deionized water, and then wash with ethanol for 3 times, and dry naturally in the air (volatilize ethanol) to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com