Antifogging agent, preparation method and application thereof

An anti-fogging agent and surfactant technology, applied in the field of anti-fogging agent and its preparation, can solve the problems of inconvenience of goggles, loss of anti-fogging effect, unsuitable for use in epidemic areas, etc., so as to improve the anti-fogging effect and satisfy the Performance requirements, the effect of improving transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of antifogging agent of the present invention and test method thereof are as follows:

[0025] (1) Concentrate preparation: mix surfactant, titanium dioxide, polyvinyl alcohol, tartaric acid, potassium tetraborate, and glycerin according to the corresponding ratio;

[0026] (2) Dilute the concentrated solution: dilute the concentrated solution with deionized water to 35 ml of aqueous solutions with concentrations of 0.01%, 0.05%, and 0.1%.

[0027] (3) Adjusting the pH value: the above solution was adjusted to pH = 10 with sodium hydroxide, and stirred at an ambient temperature of 20° C. for 30 minutes.

[0028] (4) Smear and measure the contact angle: Spin-coat the prepared solution onto a glass sheet with a coater, place the glass sheet with an anti-fog coating on the surface in an oven at 45°C for 2 hours, and measure it with a contact angle meter Contact angle.

Embodiment 1

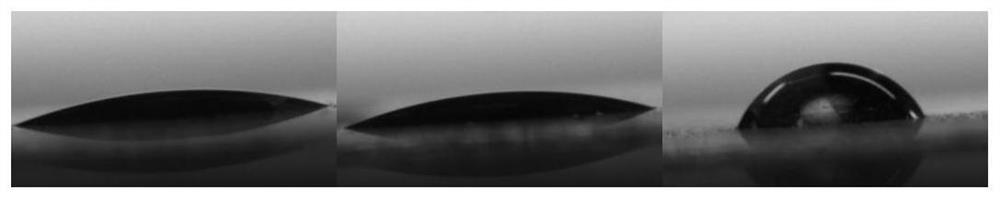

[0029] Embodiment 1: concentrate, according to the formula in Table 1, surfactant, titanium dioxide, polyvinyl alcohol, tartaric acid, potassium tetraborate, glycerin are mixed according to the corresponding proportion. The concentrated solution was diluted with deionized water to 35 ml of an aqueous solution with a concentration of 0.01%, 0.05%, and 0.1%. The above solution was adjusted to pH=10 with sodium hydroxide and stirred at ambient temperature of 20° C. for 30 minutes. Spin-coat the prepared solution onto a glass sheet with a coater, place the glass sheet with an anti-fog coating on the surface in an oven at 45°C for 2 hours, and then measure the contact angle with a contact angle meter. The results are shown in figure 1 .

Embodiment 2

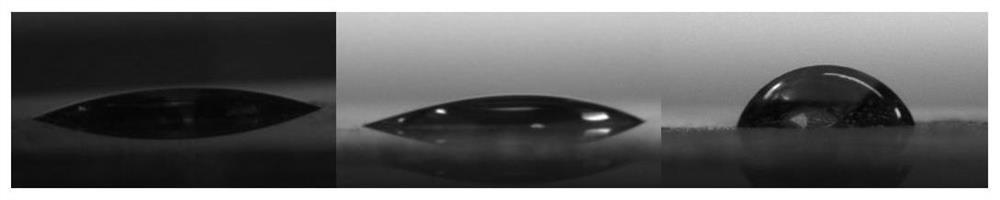

[0030] Embodiment 2: concentrate, according to the formula in Table 1, surfactant, titanium dioxide, polyvinyl alcohol, tartaric acid, potassium tetraborate, glycerin are mixed according to the corresponding proportion. The concentrated solution was diluted with deionized water to 35 ml of an aqueous solution with a concentration of 0.01%, 0.05%, and 0.1%. The above solution was adjusted to pH=10 with sodium hydroxide and stirred at ambient temperature of 20° C. for 30 minutes. Spin-coat the prepared solution onto a glass sheet with a coater, place the glass sheet with an anti-fog coating on the surface in an oven at 45°C for 2 hours, and then measure the contact angle with a contact angle meter. The results are shown in figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com