A new process for re-election of iron tailings

A technology of iron tailings and a new process, which is applied to the comprehensive utilization of resources and iron tailings re-election process, which can solve the problems of low recovery index and complicated process flow, and achieve the improvement of concentrate grade, simple process and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The raw ore (original iron tailings) is taken from the iron ore tailings pool of Shangchang Iron and Steel Group of Kunming Iron and Steel Group, containing 18.79% Fe, which belongs to low-grade, fine-grained and refractory red limonite tailings.

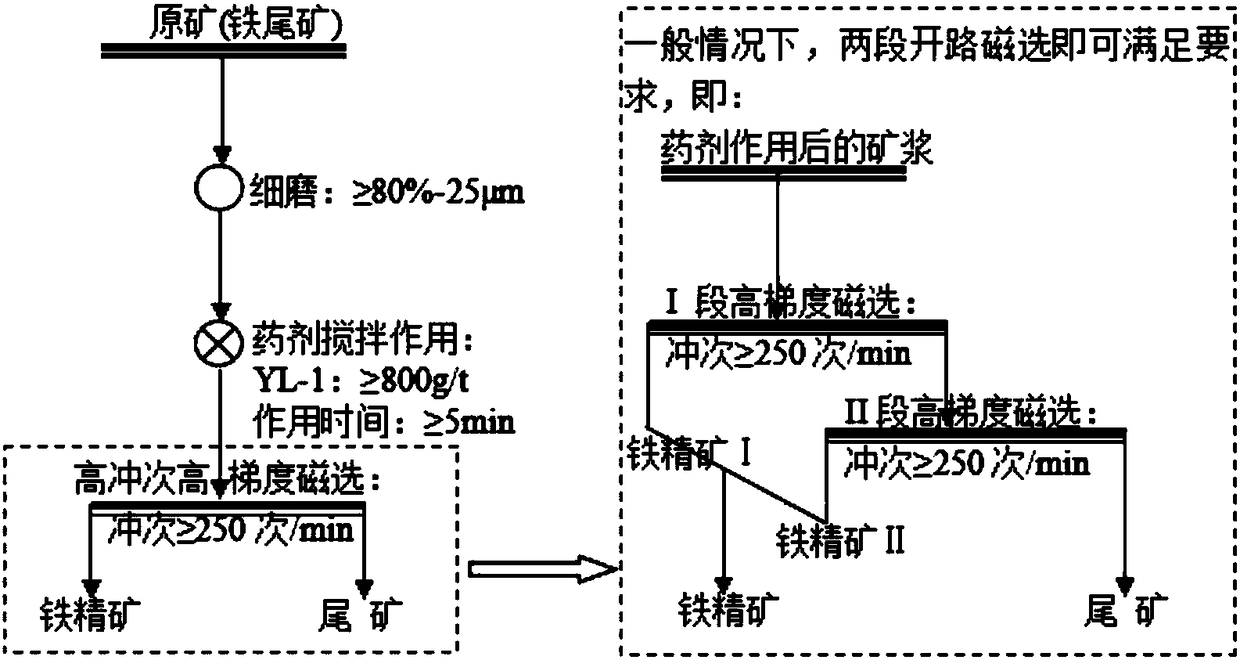

[0030] use as figure 1 In the process flow shown, firstly, the raw ore (iron tailings as it is) is finely ground, and the fineness of the ground product is -25 μm, accounting for 95%.

[0031] The ore grinding product (finely ground pulp) enters the mixing tank, and the agent YL-1 is added in an amount of 1500g / (t raw ore), and interacts in the mixing tank for 10 minutes.

[0032] The ore pulp after the chemical action is fed into the high-gradient strong magnetic separator, and the magnetic separation is carried out under the condition of high stroke frequency. The magnetic separation adopts two open-circuit processes, and the first and second magnetic separation iron concentrates are combined as the final iron concentrate. ...

Embodiment 2

[0035] The raw ore (iron tailings as it is) is taken from the root iron ore tailings pool of Kunming Iron and Steel Co., Ltd., containing 23% Fe, which belongs to low-grade, fine-grained and refractory hematite tailings.

[0036] use as figure 1 In the process flow shown, the raw ore (iron tailings as it is) is further finely ground, and the fineness of the ground product is -25 μm, accounting for 90%.

[0037] The ore grinding product (finely ground pulp) enters the mixing tank, and the drug YL-1 is added at a dosage of 1000g / (t raw ore), and interacts in the mixing tank for 8 minutes.

[0038] The ore pulp after the chemical action is fed into the high-gradient strong magnetic separator, and the magnetic separation is carried out under the condition of high stroke frequency. The magnetic separation adopts two open-circuit processes, and the first and second magnetic separation iron concentrates are combined as the final iron concentrate. mine.

[0039]In stage I high gradi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com