A magnetic ball mill for magnetite

A ball mill and magnetite technology, applied in grain processing and other directions, can solve the problems affecting the continuous operation of the ball mill, increase the load of the ball mill, increase the power consumption of the ball mill, etc., and achieve the effects of improving the grinding efficiency, increasing the effective collision, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

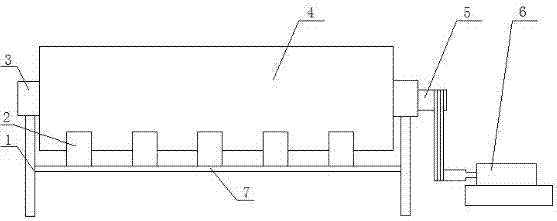

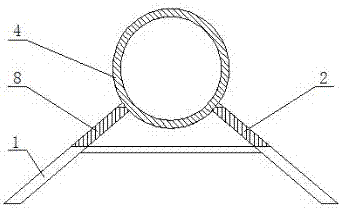

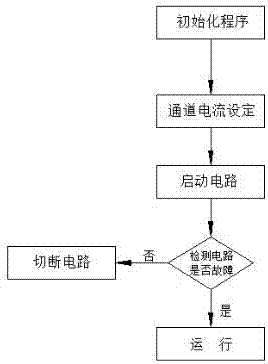

[0029] A magnetic ball mill for magnetite. Such as figure 1 and figure 2 As shown, the ball mill includes a support 1 , a first row of magnetic coils 2 , a second row of magnetic coils 8 , a cylindrical barrel 4 , a hollow shaft 5 and a programmable constant current source 9 . The two ends of the cylindrical body 4 are coaxially fixed with a hollow shaft 5, and the hollow shafts 5 at both ends are movably connected to the corresponding bracket 1 through their respective bearings 3, and one end of the hollow shaft 5 passes through the bracket 1 and is connected to the motor 6 through a belt. . The first row of magnetic coils 2 and the second row of magnetic coils 8 are correspondingly arranged on both sides of the vertical center line of the cylindrical shell 4, and the lower ends of the first row of magnetic coils 2 and the second row of magnetic coils 8 are evenly fixed on the On the corresponding horizontal beam 7, the upper ends of the first row of magnetic coils 2 and ...

Embodiment 2

[0040]A magnetic ball mill for magnetite. Except following technical parameter, all the other are with embodiment 1:

[0041] There are 6-10 magnetic coils 2 in the first row and 8 in the second row.

[0042] Compared with the prior art, this specific embodiment has the following positive effects:

[0043] 1. The first row of magnetic coils 2 and the second row of magnetic coils 8 are correspondingly arranged on both sides of the vertical centerline of the cylindrical body 4, and the lower ends of the first row of magnetic coils and the second row of magnetic coils 8 are evenly fixed On the corresponding horizontal beam 7, the upper ends of the first row of magnetic coils 2 and the second row of magnetic coils 8 are close to the cylindrical shell 4, and the first row of magnetic coils 2 and the second row of magnetic coils 8 are arranged symmetrically, both of which are 5~ 10 magnetic coils. Compared with the "ball mill magnetic liner" CN 102806123 A patent technology, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com