Quality improvement and impurity reduction mineral separation method and device for low-grade micro-fine particle inlaid magnetite

A beneficiation method and fine-grained technology, which is applied in the field of low-grade fine-grained magnetite-improving and impurity-reducing mineral processing methods and devices, can solve the problems of large grinding volume, high operating cost, and high energy consumption, and achieve the goal of improving the overall Iron grade, improved processing capacity, and strong process adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

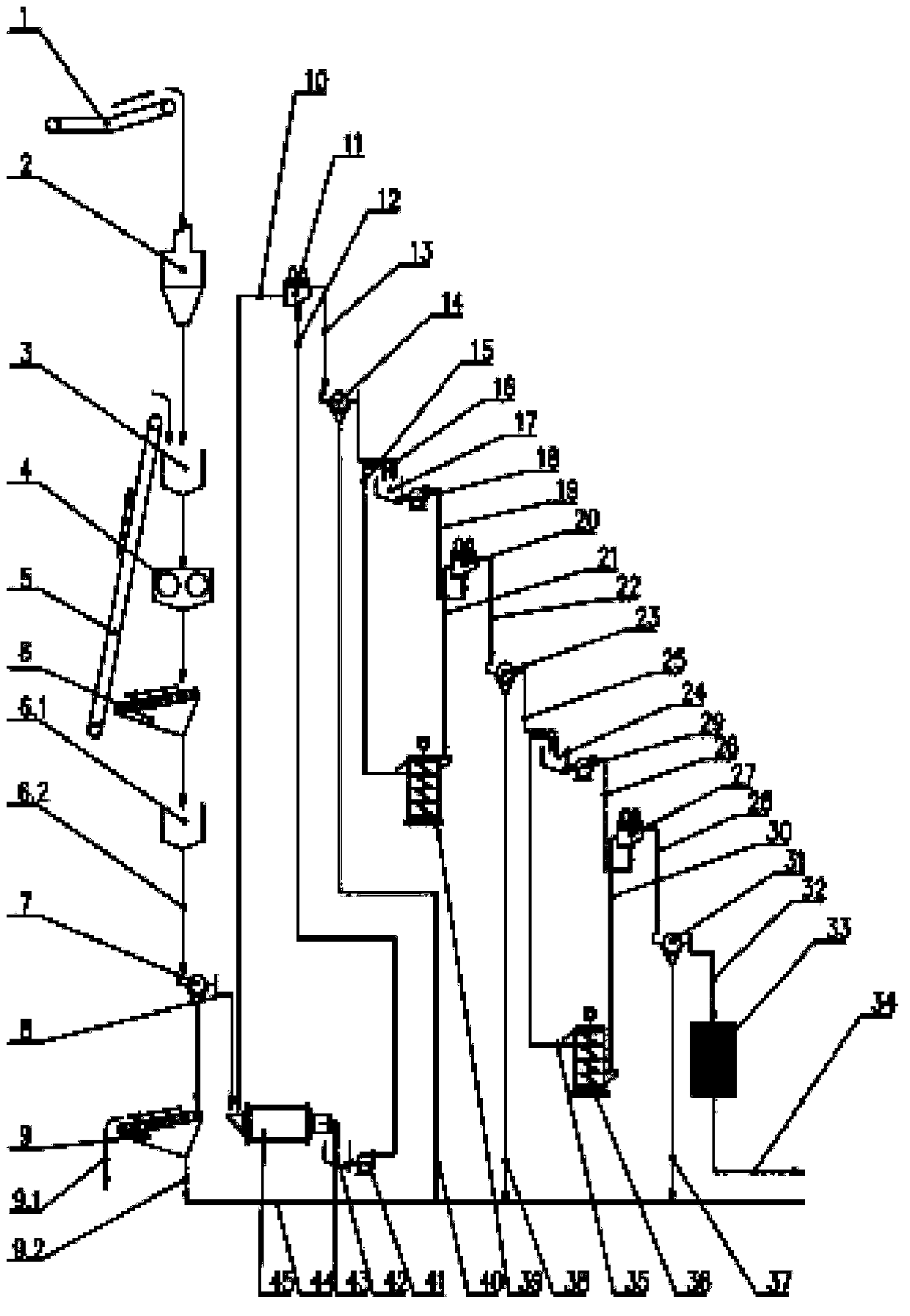

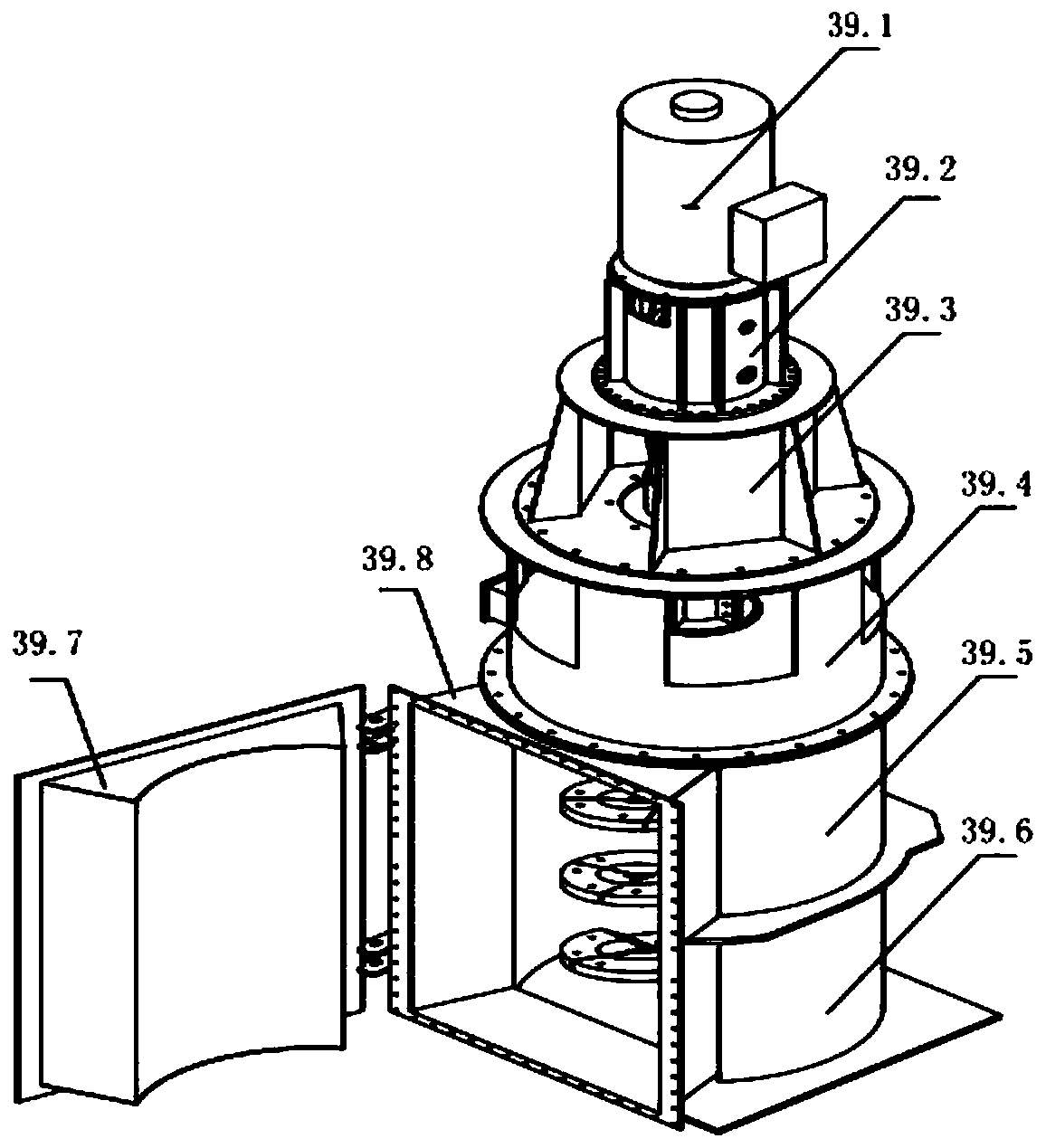

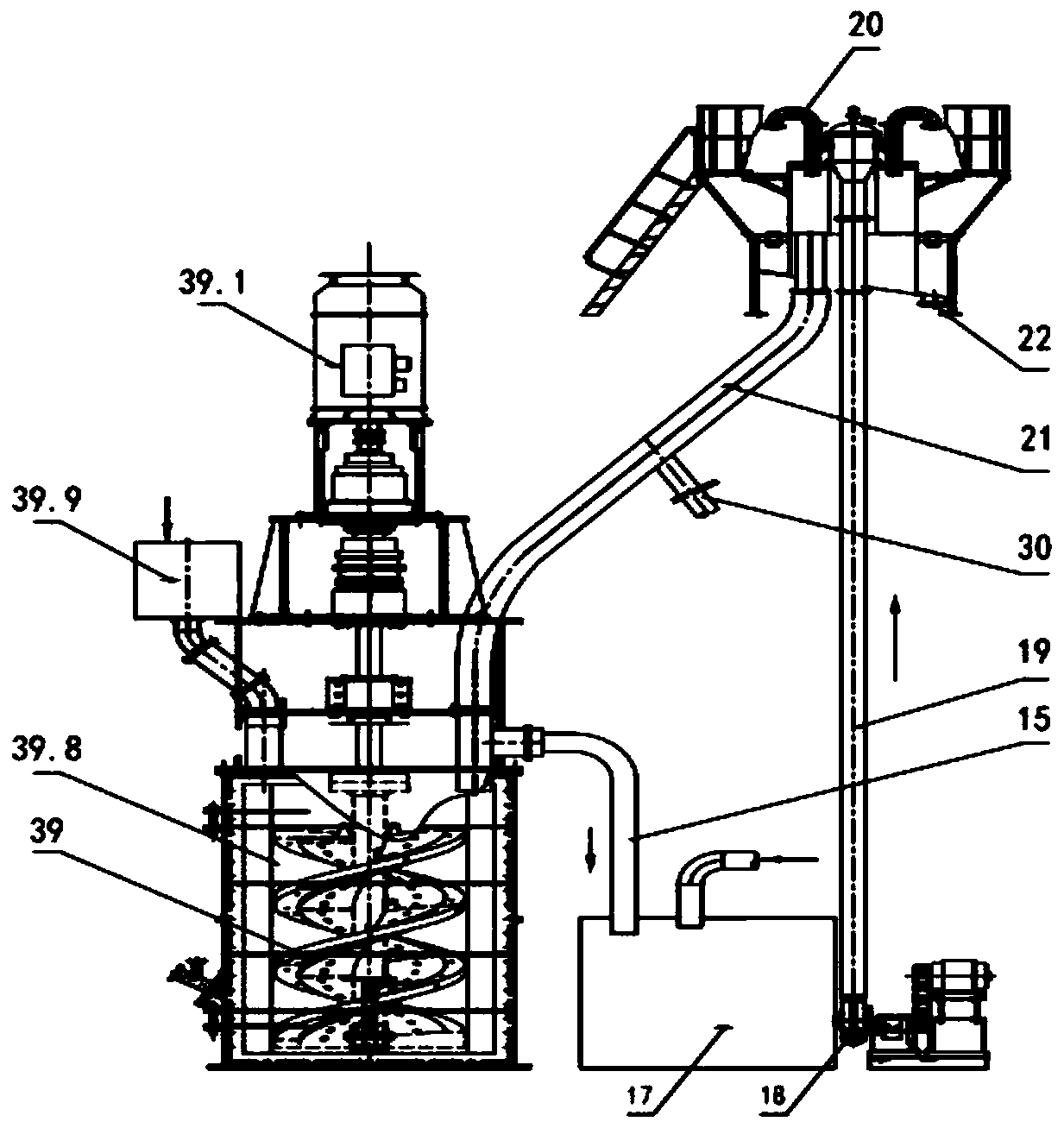

[0048] In order to facilitate the understanding of the present invention, the present invention will be described more comprehensively and in detail with reference to the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

[0049] The typical fine-grained magnetite ore processed in this implementation case has a fine crystal grain size and a complex structure. The main iron mineral is magnetite, followed by red (brown) iron ore, iron carbonate and iron silicate, gangue minerals are mainly silicon oxide and iron silicate minerals, a small amount of carbonate and calcium magnesium silicon salt minerals. The statistical results of the embedded particle size measurement of the magnetite under the electron microscope show that the magnetite (maghemite-containing) particle size is relatively fine, about 54.38% are distributed at -0.038mm, and the content of -0.074mm is 76.41%. Sider...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com