Macroporous strong alkaline carbon nanotube composite ion exchange resin and preparation method thereof

A carbon nanotube composite, ion exchange resin technology, applied in ion exchange, anion exchange, chemical instruments and methods, etc., can solve the problems of poor heat resistance and poor swelling resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

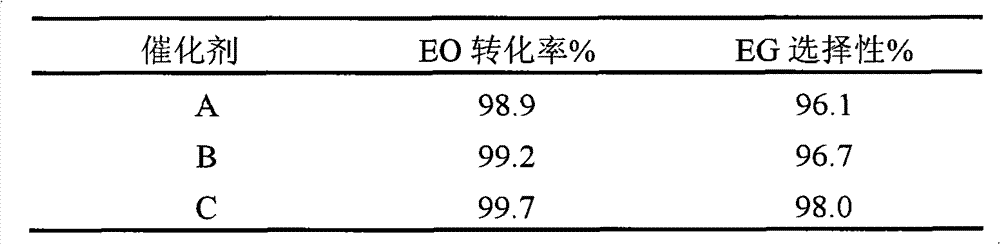

Embodiment 1

[0022] Add 38.0 grams of p-chloromethylstyrene, 8.0 grams of divinylbenzene, 0.6 grams of benzoyl peroxide initiator, and 35.0 grams of polystyrene in a 250 milliliter three-necked flask, and stir at 60 °C for 1.5 hours; then add 2.4 g of multi-walled carbon nanotubes were stirred for 1 hour for pre-polymerization. 130 mL of deionized water in which 1.3 g of polyvinyl alcohol had been dissolved was added. Adjust the stirring speed, while gradually raising the temperature to 80°C, and react for 5 hours; then raise the temperature to 90°C, react for 5 hours, and finally raise the temperature to 98°C, and react for 6 hours. After the reaction, pour out the upper layer liquid, extract the microspheres with a Soxhlet extractor for 5 hours, then wash the microspheres with hot water, filter, put them in an oven for drying at 80°C, and sieve to collect a particle size of 0.35 Composite microspheres A in the range of ~0.60 mm.

Embodiment 2

[0024] In a 500 ml three-neck flask, add 3.1 g of polyvinyl alcohol and 300 ml of deionized water, start stirring and raise the temperature to completely dissolve the polyvinyl alcohol. Stop stirring, add 80.0 grams of p-chloromethylstyrene, 9.0 grams of divinylbenzene and 1.5 grams of benzoyl peroxide initiator, 30.0 grams of polystyrene, and a mixed solution of 9.9 grams of multi-walled carbon nanotubes after cooling slightly . Adjust the stirring speed while gradually raising the temperature, and react at 80°C for 5 hours; then raise the temperature to 88°C, continue the reaction for 5 hours, and finally raise the temperature and react at 100°C for 6 hours. After the reaction, pour out the upper layer liquid, extract the microspheres with a Soxhlet extractor for 5 hours, then wash the microspheres with hot water, filter, put them in an oven for drying at 80°C, and sieve to collect a particle size of 0.35 Composite microspheres B in the range of ~0.60mm.

Embodiment 3

[0026]Add 140 grams of p-chloromethylstyrene, 8.5 grams of divinylbenzene and 3.9 grams of benzoyl peroxide initiator, 90.0 grams of polystyrene, and 12.4 grams of multi-walled carbon nanotubes in a 1000 milliliter three-necked flask, at 65 The mixture was stirred at °C for 1.5 hours to carry out prepolymerization. Then 500 ml of deionized water in which 5.0 g of polyvinyl alcohol had been dissolved was added. Adjust the stirring speed, raise the temperature to 80°C within one hour, and react continuously for 5 hours; then raise the temperature to 90°C, react for 5 hours, and finally raise the temperature to 98°C, and react for 6 hours. After the reaction, pour out the upper layer liquid, extract the microspheres with a Soxhlet extractor for 5 hours, then wash the microspheres with hot water, filter, put them in an oven for drying at 80°C, and sieve to collect a particle size of 0.35 Composite microspheres C in the range of ~0.60mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com