Inorganic conditioning based integrated sludge deep dehydration treatment process

A technology of deep dewatering and treatment process, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of sludge dewatering treatment effect and unsatisfactory cost, and achieve the goal of eliminating secondary pollution, clean production site and technical safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

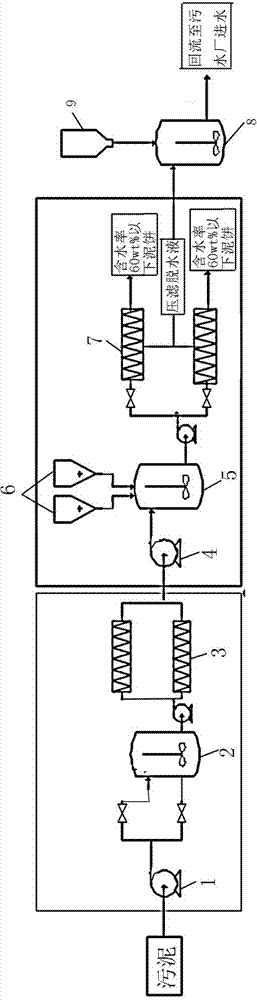

[0046] The technical scheme of the present invention comprises following processing steps:

[0047] Step 1, preliminary dehydration; the sludge with a water content of 99.7wt% in the sludge homogenization tank is transported to the mixing tank I 2 through the sludge delivery pump I 1, and at the same time, the compound conditioner is put into the mixing tank I through the dosing pump, and the sludge The ratio of parts by weight to the composite conditioner is: dry sludge: composite conditioner=100:5; the sludge and the composite conditioner are fully stirred and mixed by the mixer in the mixing tank I; the fully stirred and mixed sludge is transported Concentrate to the concentrating screw stacker 3; concentrate until the moisture content of the sludge is 93-95wt%.

[0048] Step 2, deep dehydration; the concentrated sludge is transported to the mixing tank II 5 through the sludge delivery pump II 4, and at the same time, the composite conditioner is put into the mixing tank II...

Embodiment 2

[0056] In the step 1, the moisture content of pretreated sludge is 99.0wt%; absolute dry sludge: composite conditioner=100:2;

[0057] In the described step 2, absolute dry sludge: composite conditioner=100:13;

[0058] In the described step 3, the acid in the acid tank is sulfuric acid.

[0059] The composite conditioner is prepared from the following raw materials in parts by weight, fly ash: quicklime: polyferrous sulfate / attapulgite = 70:10:2.

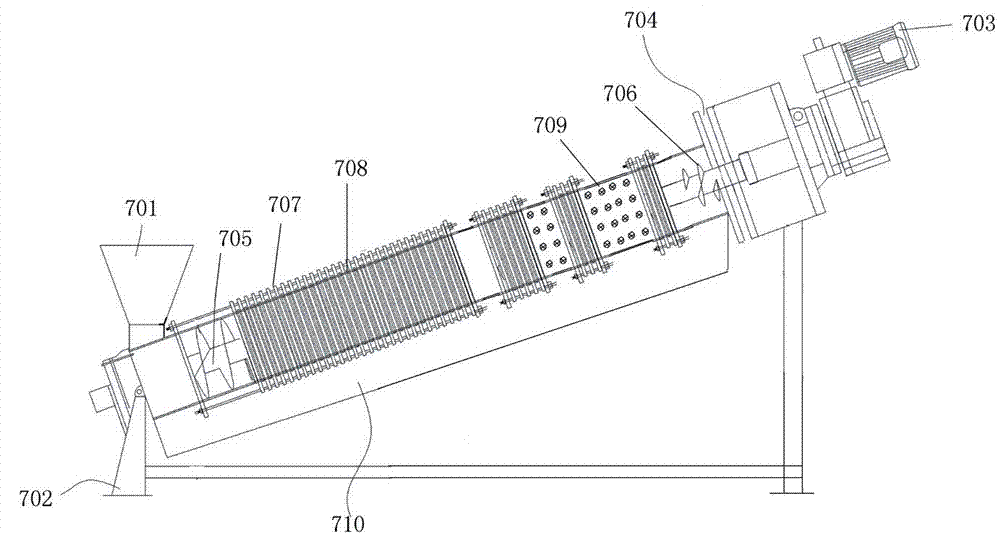

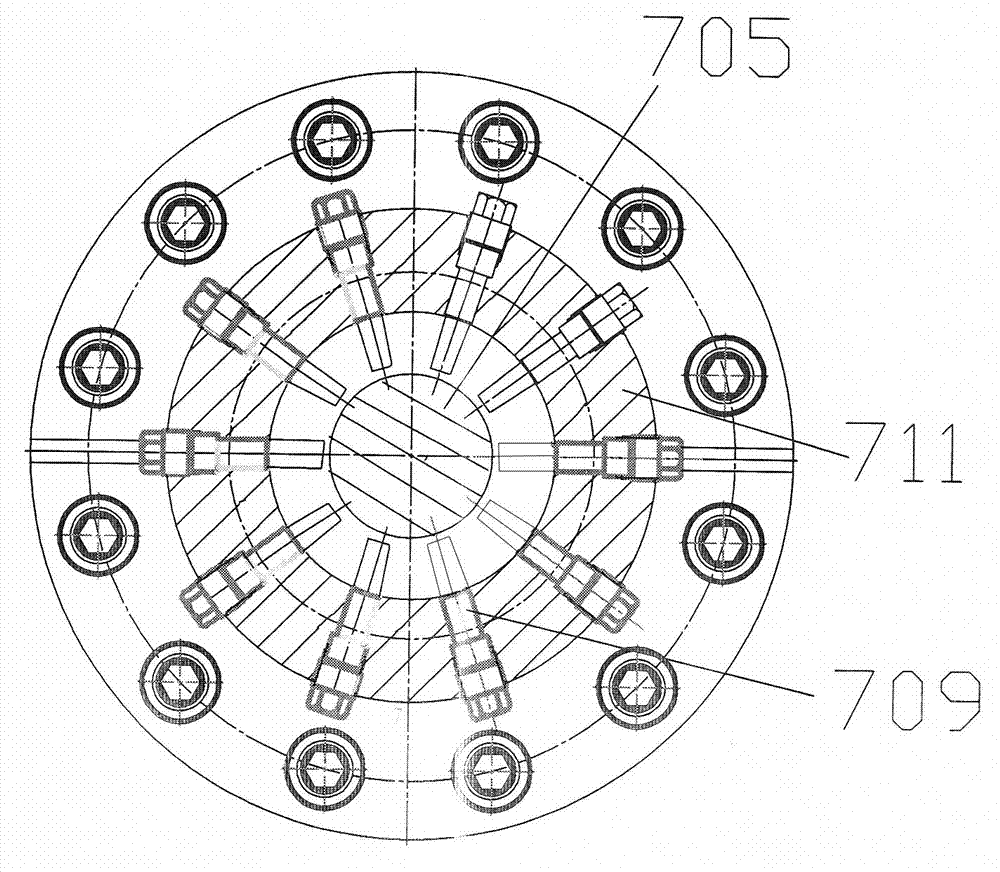

[0060] The structure of the pin screw stacking machine is that the length ratio of the pre-sequence section to the post-sequence section is, L front: L rear = 1:1; the inclination angle of the screw axis is 20 degrees from the horizontal plane; Set a pin 709 at 30 degrees for at least three weeks.

[0061] Other steps and structure are with embodiment 1.

Embodiment 3

[0063] In the described step 1, the moisture content of the pretreated sludge is 99.8wt%; absolute dry sludge: composite conditioner=100:6;

[0064] In the described step 2, absolute dry sludge: composite conditioner=100:5;

[0065] In the described step 3, the acid in the acid tank is acetic acid.

[0066] The composite conditioner is prepared from the following raw materials in parts by weight, fly ash: quicklime: polymerized ferrous sulfate / attapulgite = 90:20:10.

[0067] The structure of the pin screw stacking machine is that the length ratio of the pre-sequence section to the subsequent section is: L front: L rear = 3:1; the inclination angle of the screw axis is 10 degrees from the horizontal plane; the screw axis is at intervals of 18 degrees along the circumference. Set one pin 709 at least once for at least one week.

[0068] Other steps and structure are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com