High-temperature pressure and temperature integrated composite sensor

A composite sensor, pressure and temperature technology, applied to thermometers, measurement of properties and forces using piezoelectric devices, instruments, etc., can solve the problems of large volume, poor compatibility, and inability to meet large-range pressure measurement, etc., to achieve small size, assembly The process is simple and the effect of solving the composite problem of pressure and temperature sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

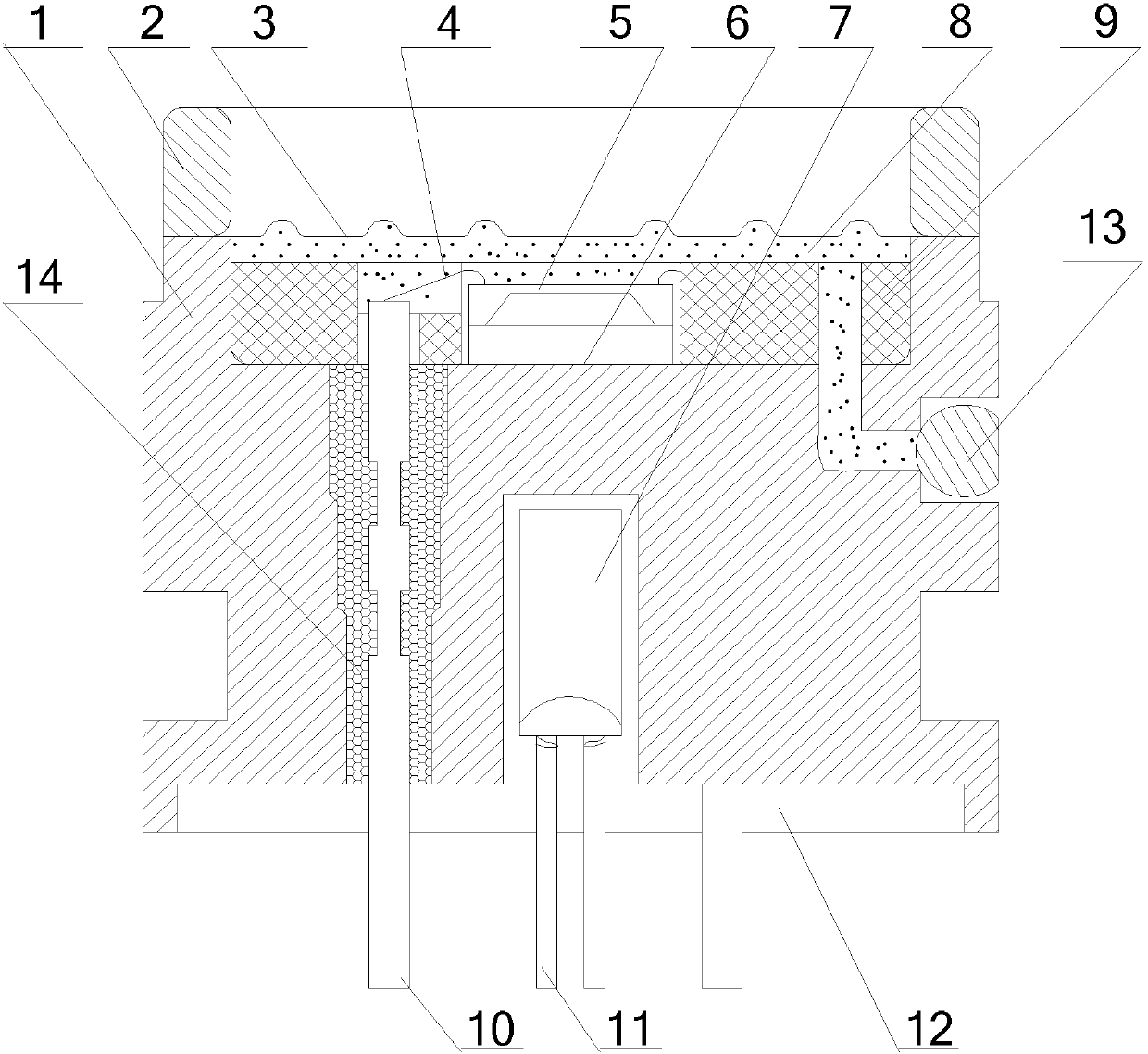

[0021] Specific implementation mode one: refer to figure 1 and 2 Describe this embodiment in detail. The high temperature, pressure and temperature integrated composite sensor described in this embodiment includes: a tube base 1, a pressure ring 2, a corrugated diaphragm 3, a pressure sensitive chip 5, a temperature sensitive chip 7, a ceramic ring 9, a pressure lead Line post 10 and temperature lead-out line post 11;

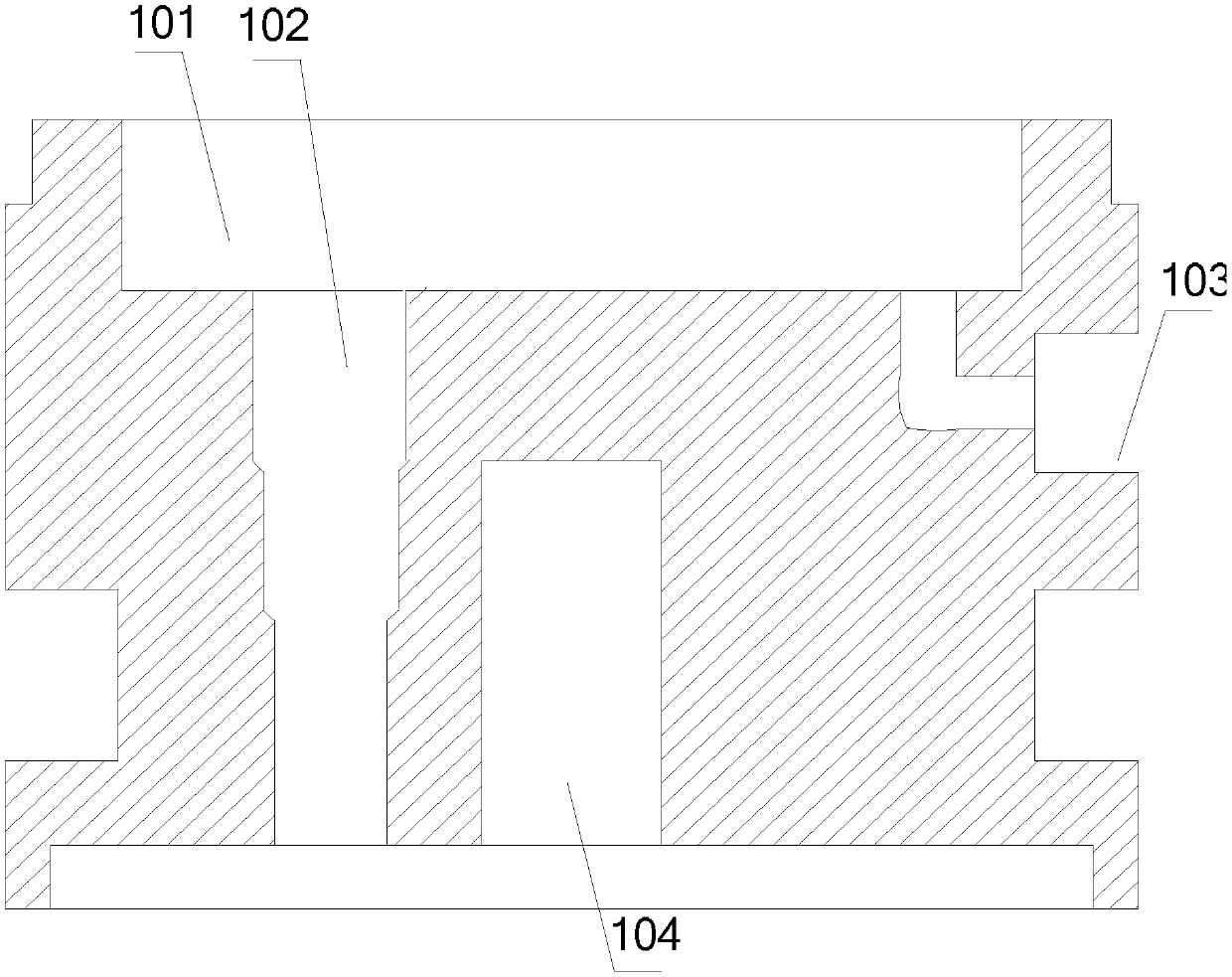

[0022] The tube base 1 is cylindrical, and the top of the tube base 1 has a large circular groove 101, the ceramic ring 9 is located in the circular large groove 101, and the pressure sensitive chip 5 is located in the ring of the ceramic ring 9, and through the eutectic Welding 6 is welded in the center of the bottom of the large circular groove 101, the corrugated diaphragm 3 covers the opening end of the large circular groove 101, the gap between the corrugated diaphragm 3 and the pressure sensitive chip 5 is filled with high temperature silicone oil 8, the...

specific Embodiment approach 2

[0034] Embodiment 2: This embodiment is a further description of the high-temperature pressure-temperature integrated composite sensor described in Embodiment 1. In this embodiment, the pressure sensitive chip 5 is an SOI pressure sensitive chip.

[0035] The pressure-sensitive chip 5 uses an SOI substrate as a substrate material, and the silicon micro-piezoresistive principle is pressure-sensitive. The chip uses the upper layer of single crystal silicon as the material for pressure-sensitive resistors, and four pressure-sensitive resistors are produced. The circuit is connected as a Wheatstone bridge to sense the pressure signal. The pressure-sensitive resistor and the substrate are implanted through MEMS technology and high-energy oxygen ions technology to form SiO 2 The isolation layer, which removes the PN isolation junction in the traditional diffused silicon piezoresistive sensitive chip, is made of SiO 2 The layer realizes the full dielectric isolation of the device an...

specific Embodiment approach 3

[0036]Embodiment 3: This embodiment is a further description of the high temperature, pressure and temperature integrated composite sensor described in Embodiment 1. In this embodiment, the temperature sensitive chip 7 is a Pt1000 temperature sensitive chip.

[0037] The temperature sensitive chip 7 uses a platinum thin film resistor for temperature testing. The chip is designed as a three-layer structure of ceramic substrate, platinum film and surface encapsulation, and the platinum film is tightly attached between the substrate and the encapsulation layer. The thermal properties of the three-layer materials of the temperature-sensitive chip are consistent, so that the compressive strain of the substrate on the platinum film and the compressive strain caused by the encapsulation layer cancel each other out, which not only broadens the operating temperature of the platinum film thermistor, but also improves its reliability. , stability and repeatability. A standard Pt1000 res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com