Patents

Literature

40results about How to "Solve the problem of infiltration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ecological restoration method for coal gangue dump

ActiveCN102251775ASolve the problem of infiltrationPromote growthUnderground miningSurface miningSedum alfrediiCoal gangue

The invention relates to an ecological restoration method for a coal gangue dump; according to the method, during the arrangement of a coal gangue dump and the arrangement of the dump body, annular plant ditches and longitudinal drainage ditches are disposed from top to bottom; clay is added onto gangue and is tamped; a mixture of dehydrated sludge and gangue is added onto the clay between ditches, and sedum alfredii hance are planted; a mixed substrate of gangue dump surface soil, fermented pig manure, and vermiculite is added into the plant ditches; and prostrate spurge, crape myrtle, and cucurbita pepo are planted orderly and repeatedly in the mixed substrate. The method effectively reduces the spontaneous combustion probability of coal gangue, shortens the restoration period, makes use of dehydrated activated sludge, changes wastes into valuables, and obtain certain economic benefits, environmental benefits, and social benefits.

Owner:ELION ECOLOGICAL RESTORATION +1

Method for improving fabric ink-jet printing performance by using quaternary ammonium chitosan

InactiveCN102071574AImprove inkjet printing performanceImprove finenessDyeing processVegetal fibresWater solublePulp and paper industry

The invention relates to a method for improving fabric ink-jet printing performance by using quaternary ammonium chitosan, belonging to the technical field of textile chemistry. The method is characterized by comprising the following steps of: respectively using dipping or padding manners to pre-process the fabric by using the water-soluble quaternary ammonium chitosan; then drying and jetting ink and printing. The improved pre-processing technique of the quaternary ammonium chitosan can obviously increase the ink-jet printing performance of the fabric, improve the fineness and color depth of the printing fabric, and increase printing color firming degree. Furthermore, the fabric has good hand feeling and antibacterial performance.

Owner:JIANGNAN UNIV

Processing technology for digital printing of silk fabric

InactiveCN108457101AImprove accuracyHigh precisionTypewritersDyeing processDigital printingEngineering

The invention provides a processing technology for digital printing of a silk fabric and belongs to the technical field of the digital printing, aiming at overcoming the disadvantages that a dyestuffruns, the clear degree of a decorative pattern is poor, the brightness is low and the color yield is not high and the like when an existing silk fabric is dyed. The processing technology for the digital printing of the silk fabric comprises the following steps: S1, preparing a textile; S2, washing and drying; S3, treating the textile; S4, printing and fixing color; S5, carrying out alkaline washing; S6, washing with de-ionized water; S7, drying; S8, checking. The processing technology has the advantages that the dyestuff does not run, the clear degree of the decorative pattern is good, the brightness is good and the color yield is relatively high.

Owner:HAINING GELIN FURNITURE

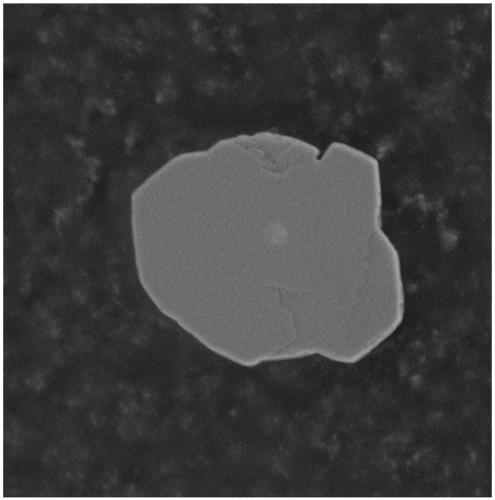

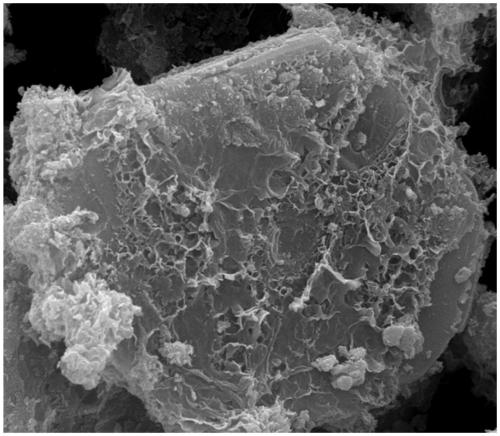

Preparation method of tungsten carbide composite powder

InactiveCN102978426ASimple processEasy to controlVacuum evaporation coatingSputtering coatingRadio frequencyDecarburization

The invention discloses a preparation method of tungsten carbide composite powder. The tungsten carbide composite powder is prepared by microparticle magnetron sputtering equipment. The preparation method is characterized in that tungsten carbide powder is used as a matrix; a coated metal is used as a target material; through direct current, radio frequency or pulsed sputtering, the metal of the target material is sputtered and deposited on surfaces of the tungsten carbide powder to form uniform and compact metal films; and the uniform and compact metal films closely coat tungsten carbide particles so that metal-coated tungsten carbide powder is obtained. The preparation method has the advantages that processes are simple; control is easy; stability is high; pollution on the environment is avoided; a compact and continuous film is obtained; adhesion is strong; through a change of components of the target material, coating by films having different components is realized; the problem of infiltration of interfaces between tungsten carbide particles and a metal is solved; and decarburization in tungsten carbide powder heating is inhibited.

Owner:CHINA NAT ACAD NANOTECH & ENG

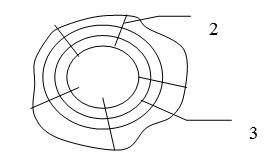

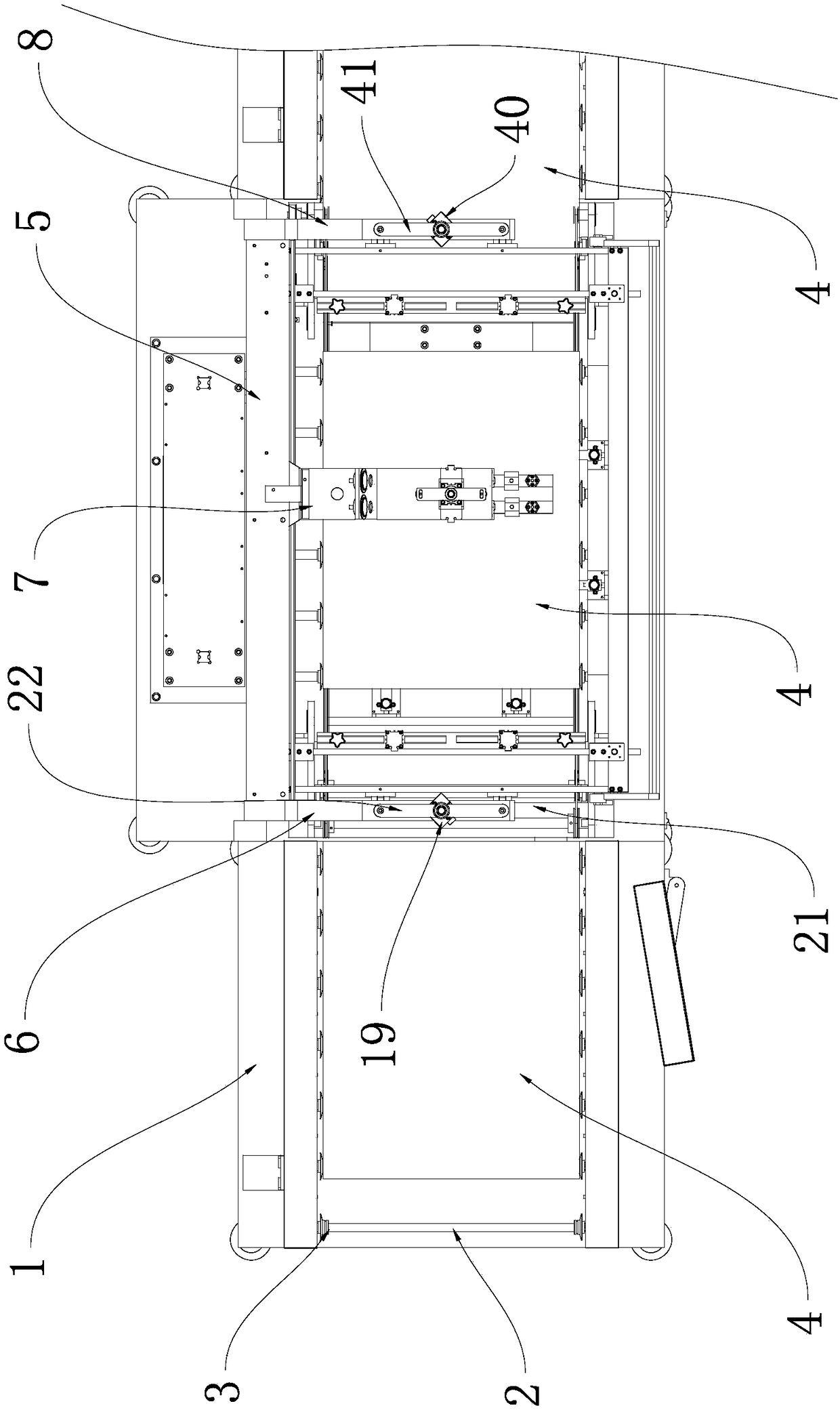

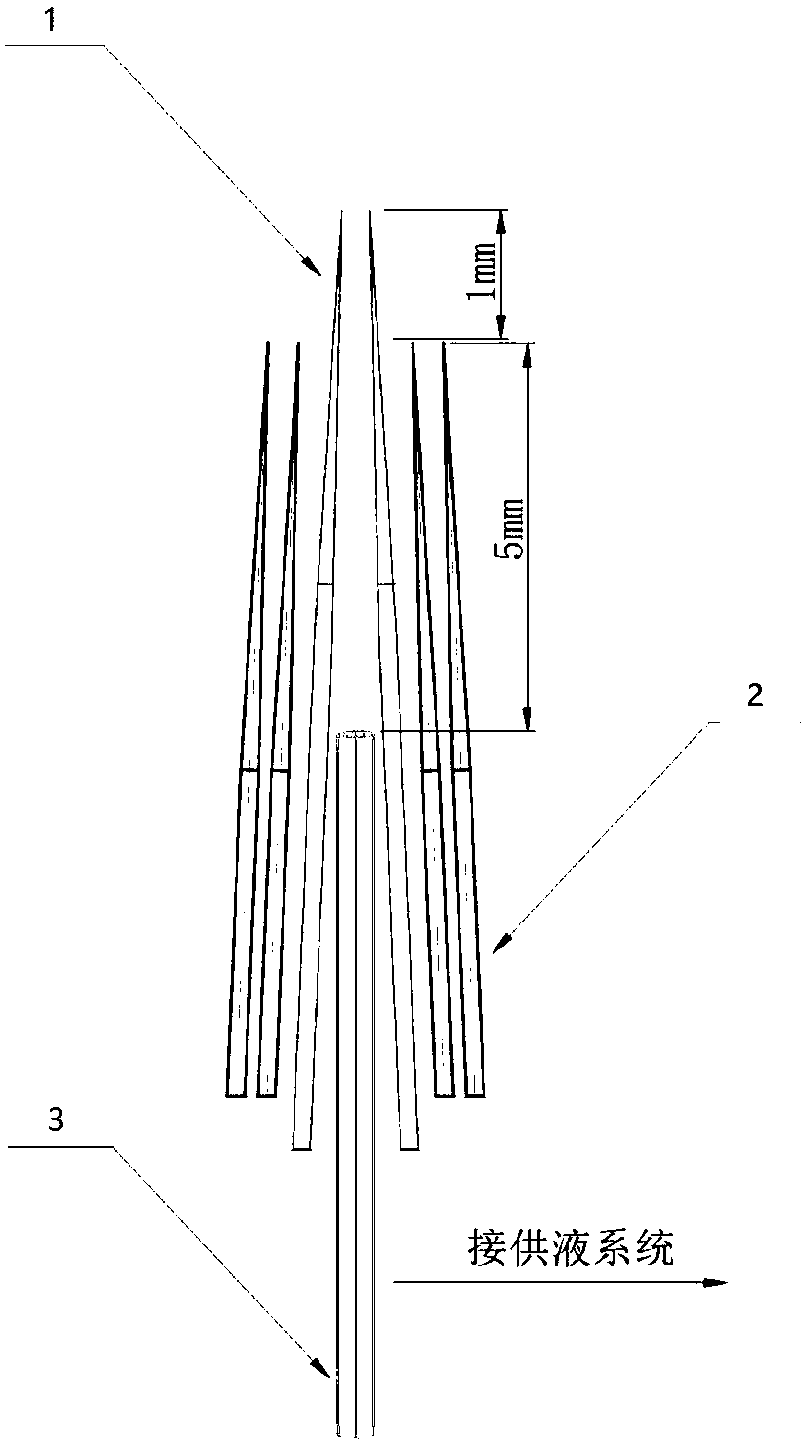

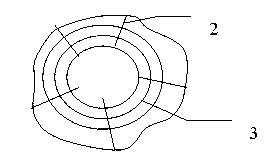

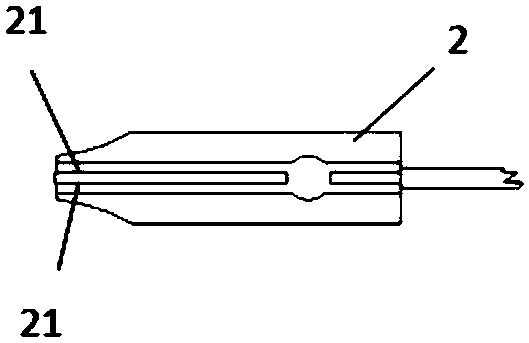

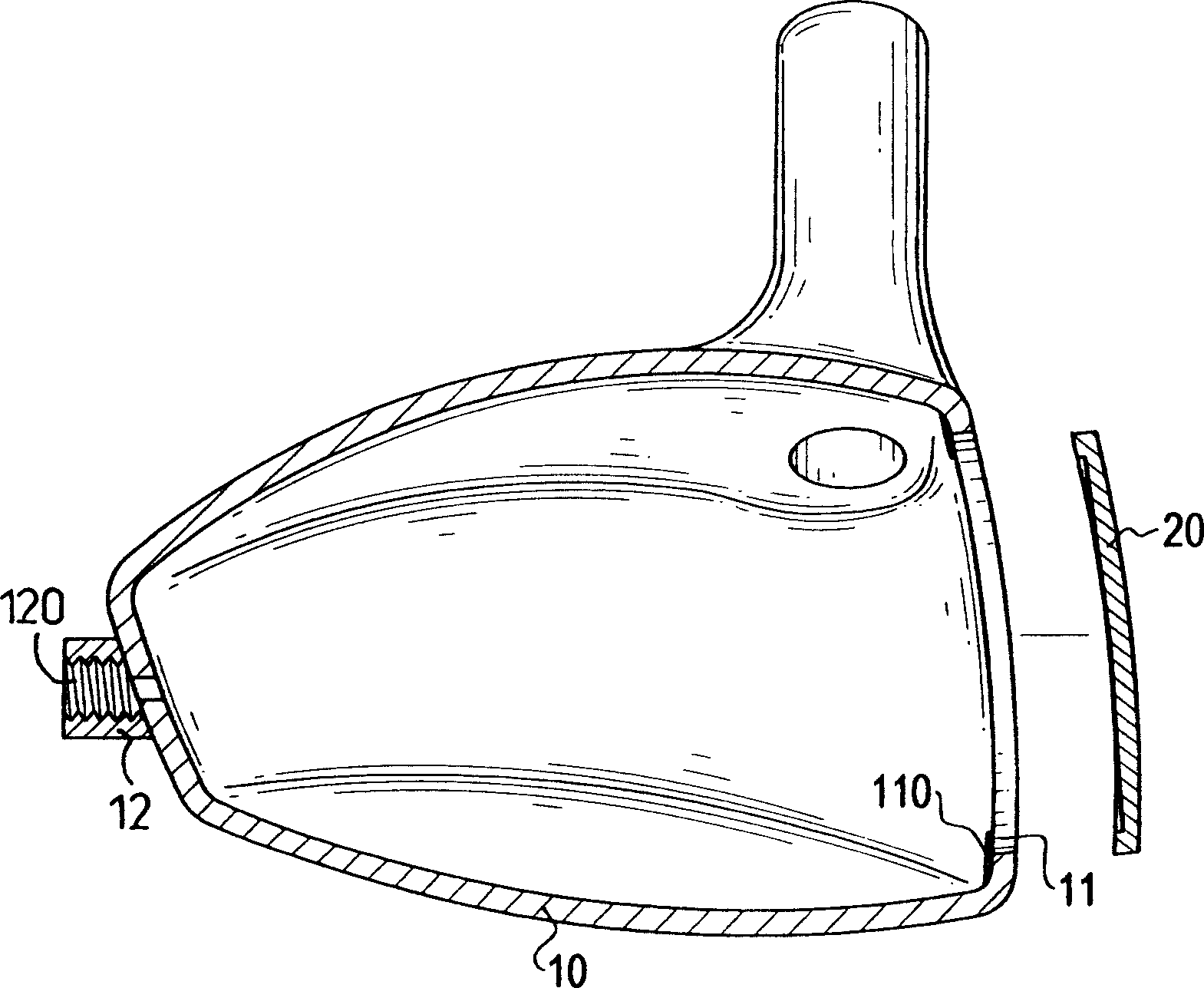

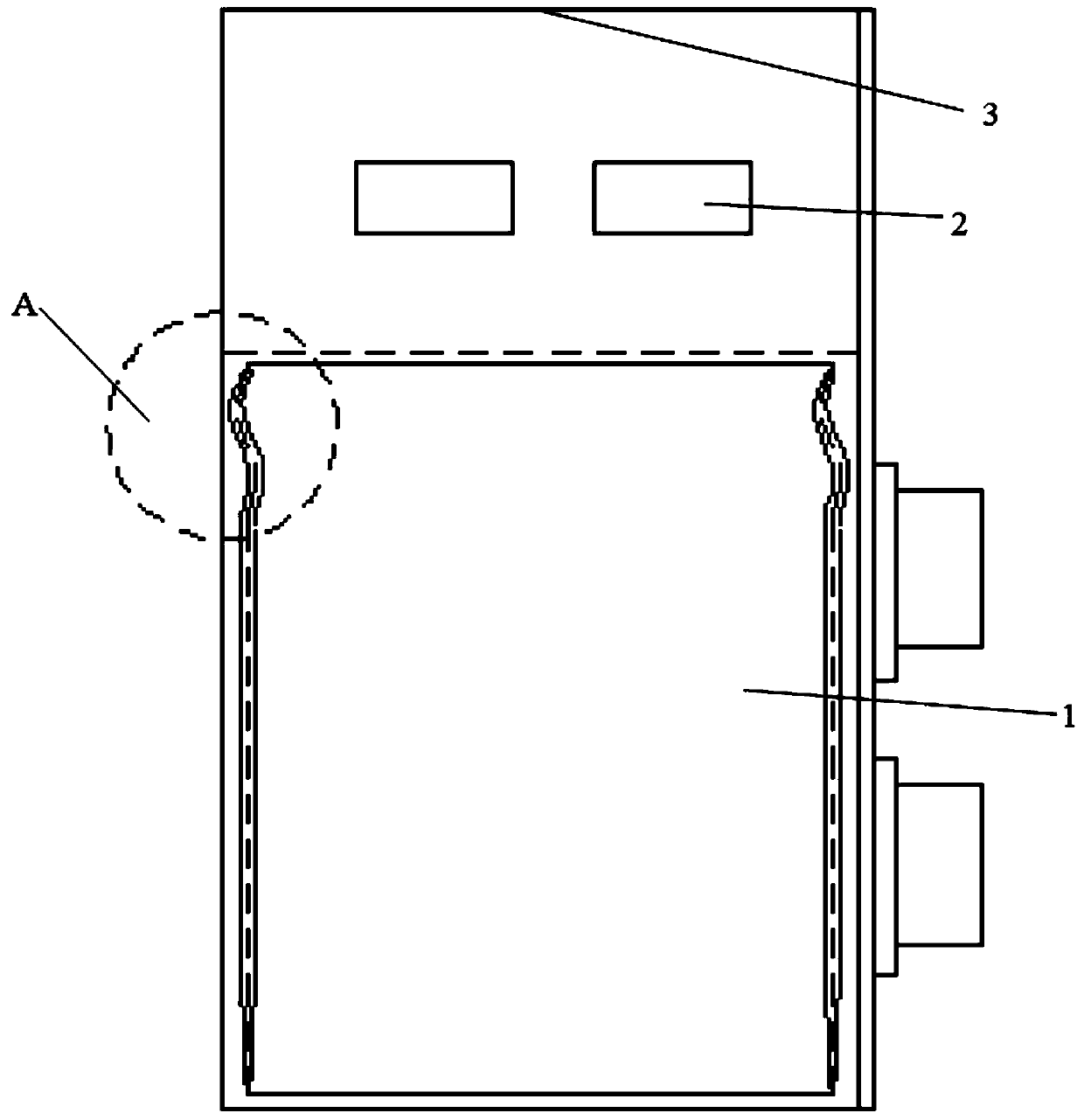

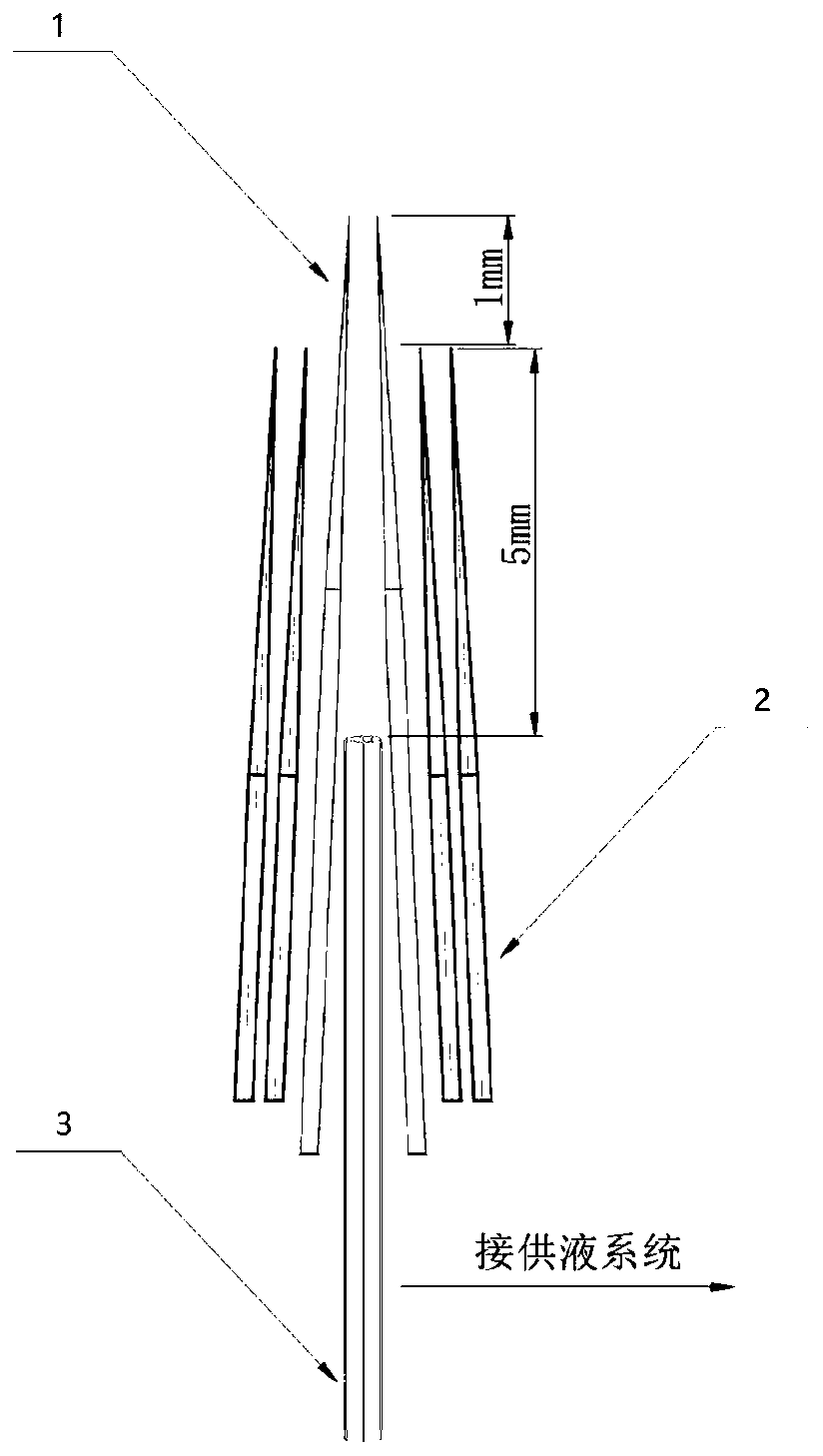

Writing brush type liquid guide infiltration device

ActiveCN108264017ASolve problems that require a dipSolve the problem of infiltrationNanostructure manufactureMicrostructural device manufactureFiberBristle

The invention relates to the field of micro-liquid infiltration devices, in particular to a writing brush type liquid guide infiltration device. The writing brush type liquid guide infiltration devicecomprises a micro-liquid guide pipe (3), wherein the periphery of the head part of one end of the micro-liquid guide pipe (3) is wrapped with a bundle of flush pen bristles (2), and a plurality of protruding pen bristles (1) are arranged on the innermost side of the flush pen bristles (2) along the periphery of the micro-liquid guide pipe at equal intervals; the vertical distance between the tipsof the flush pen bristles (2) and the head part of the micro-liquid guide pipe is 4-7 mm; the vertical distance between the tips of the protruding pen bristles (1) and the tips of the flush pen bristles (2) is 1-2 mm. By means of the device, micro-liquid can evenly infiltrate two fiber bristles, and an ultra-thin film with any length can be drawn on a plane. A method is simple in principle, easyto implement and capable of effectively solving the micro-liquid infiltration problem of a micro-liquid supply system.

Owner:BEIJING SCITECH NANOTECH CO LTD

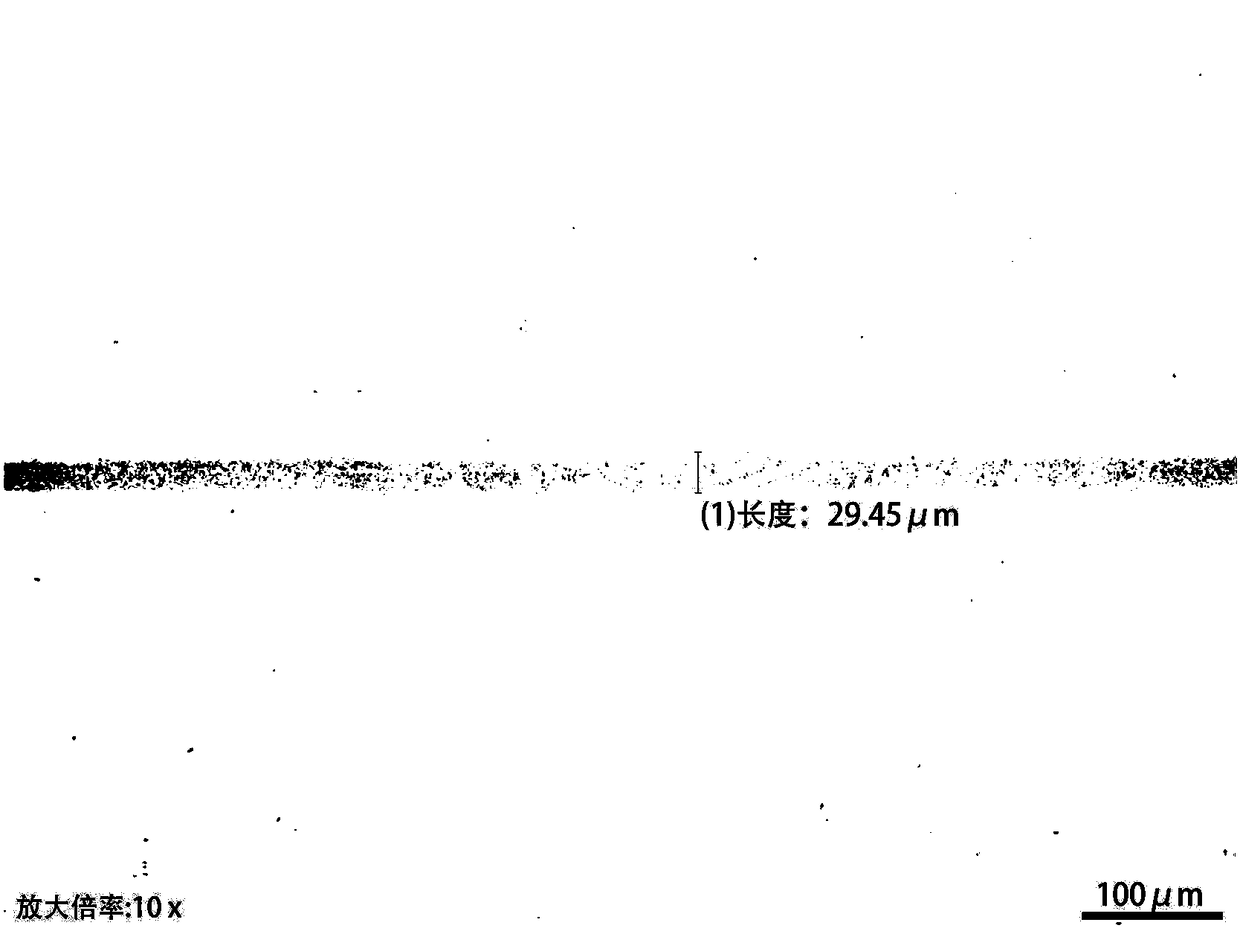

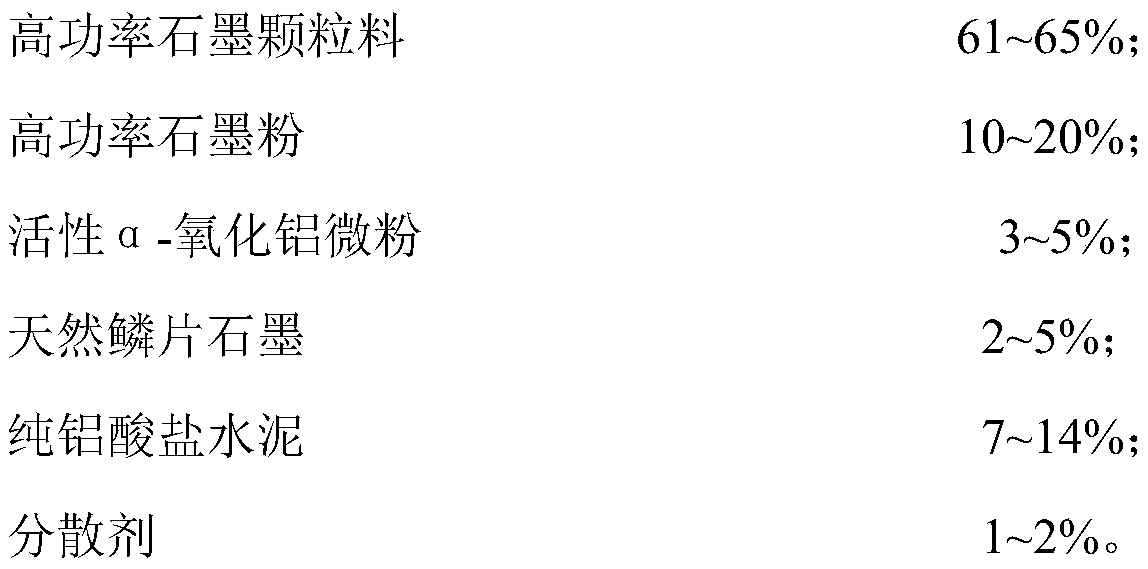

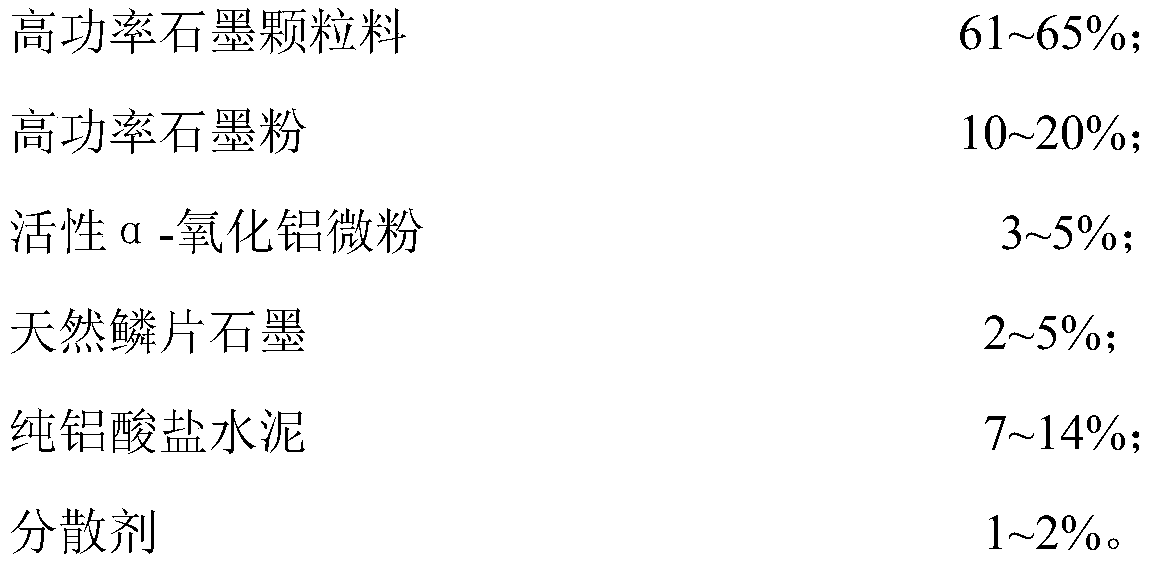

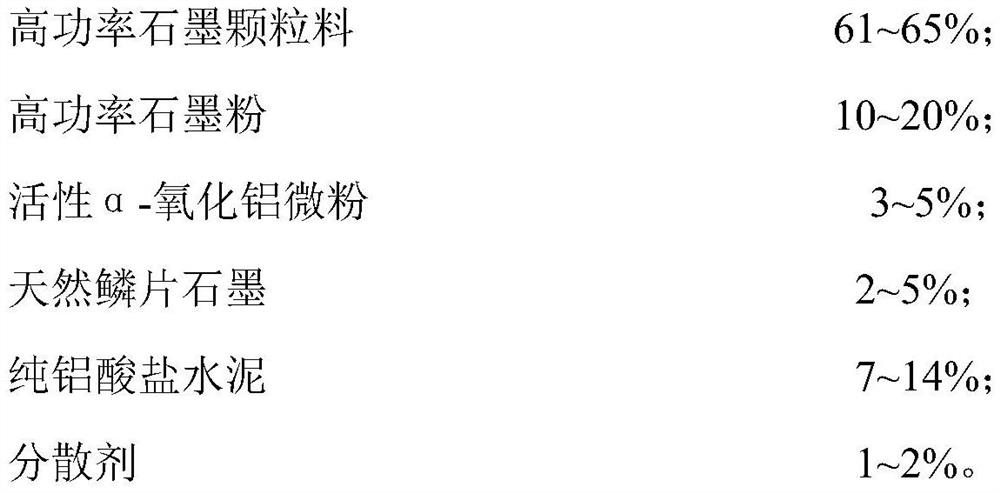

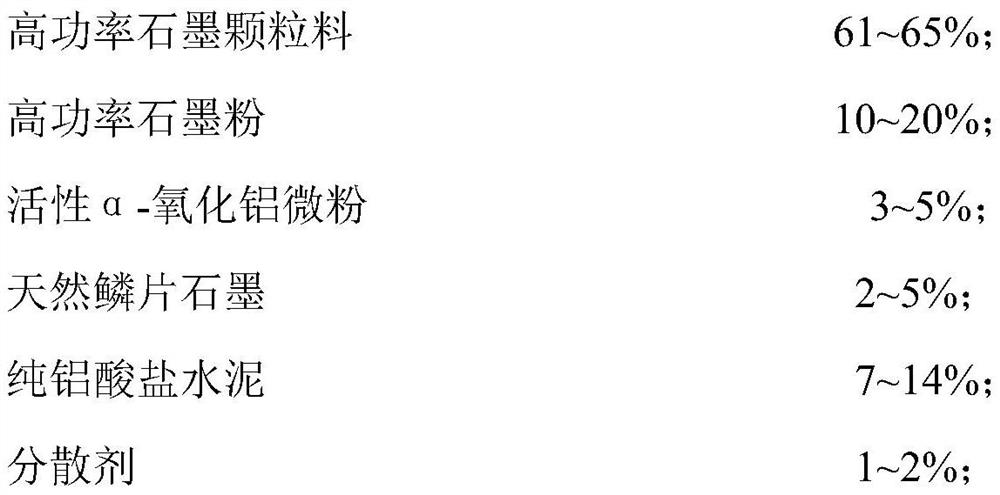

Flexible carbonaceous castable for furnace bottom leveling layer

The invention discloses flexible carbonaceous castable for a furnace bottom leveling layer. The flexible carbonaceous castable is prepared from the components in percentage by mass: 61 to 65 percent of high-power graphite granules, 10 to 20 percent of high-power graphite powder, 3 to 5 percent of activated alpha-aluminum oxide micro-powder, 2 to 5 percent of natural flake graphite, 7 to 14 percentof pure-aluminate cement and 1 to 2 percent of a dispersant. The flexible carbonaceous castable disclosed by the invention has the advantages of energy saving and environment protection; the flexiblecarbonaceous castable does not produce substances harmful to the environment, has no dangers to bodies of construction personnel and meets environment protection, energy saving and emission reductionrequirements advocated in China; compared with the prior art in the aspect of the environment protection, the flexible carbonaceous castable has relatively great advantages. The used materials are simple to construct and operate and have certain thixotropy; the materials can be rapidly leveled only if the flexible carbonaceous castable is vibrated and molded so that a construction period can be greatly saved.

Owner:中冶武汉冶金建筑研究院有限公司

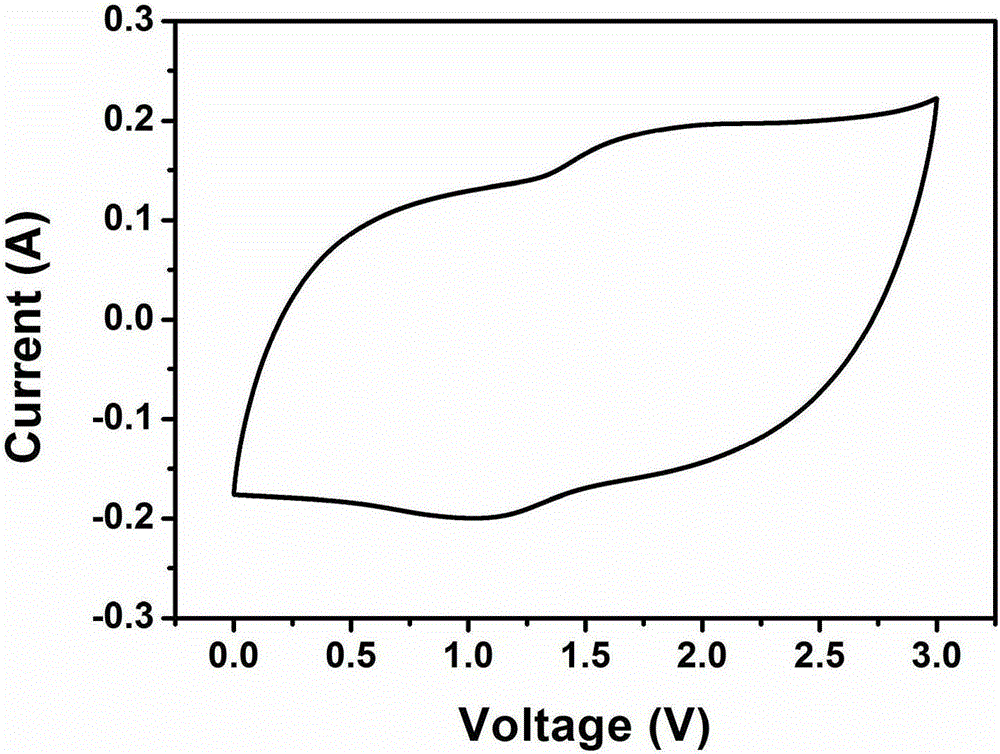

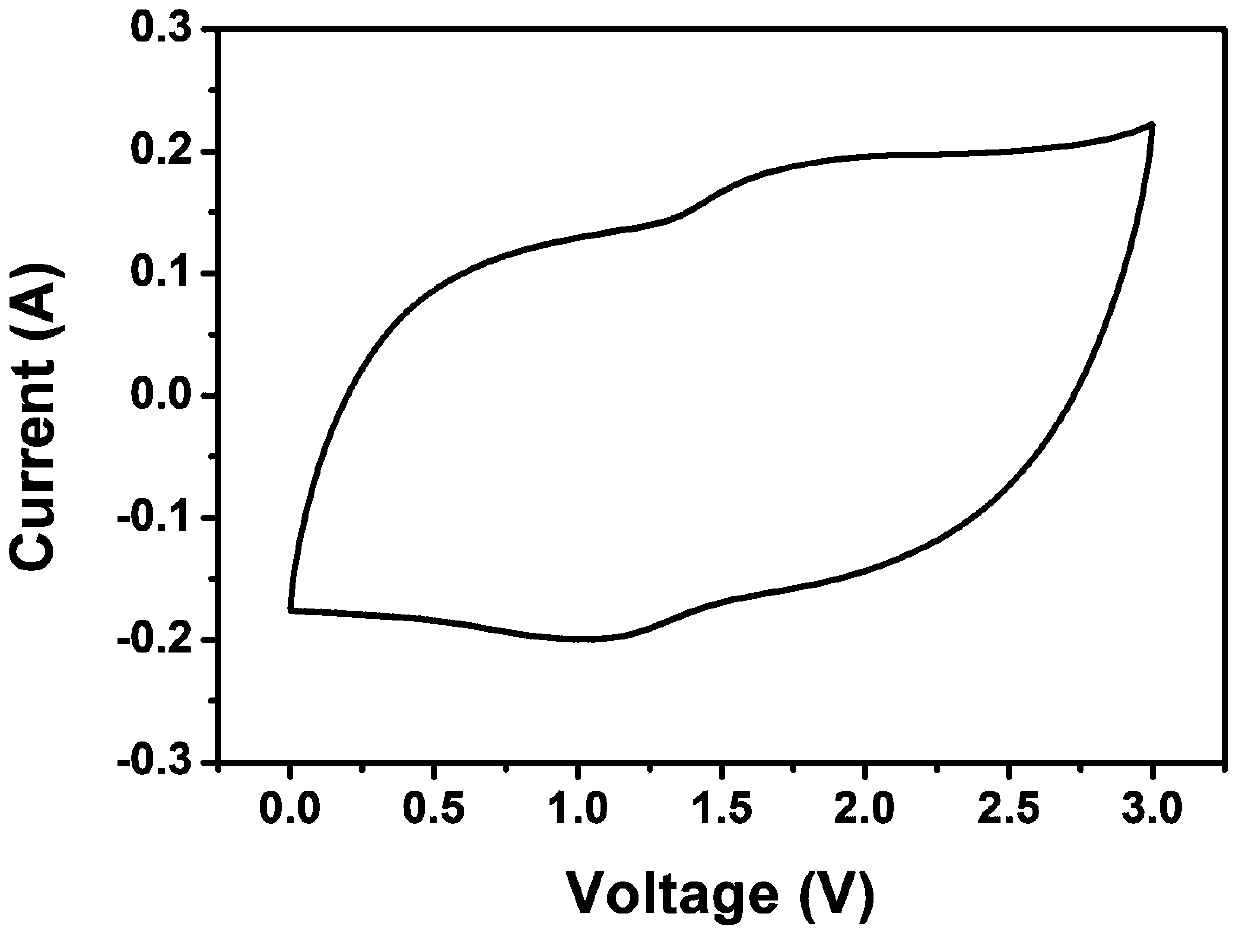

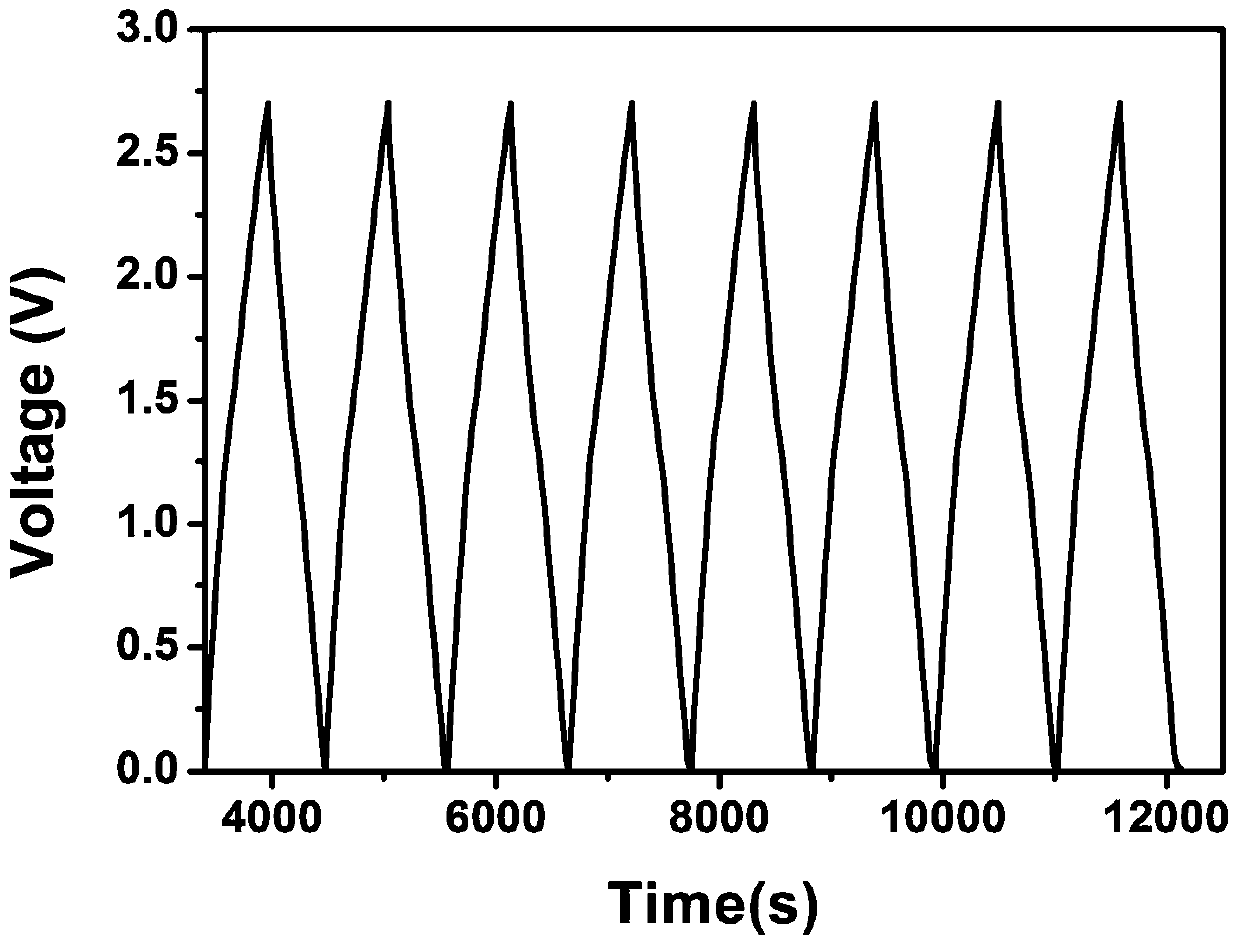

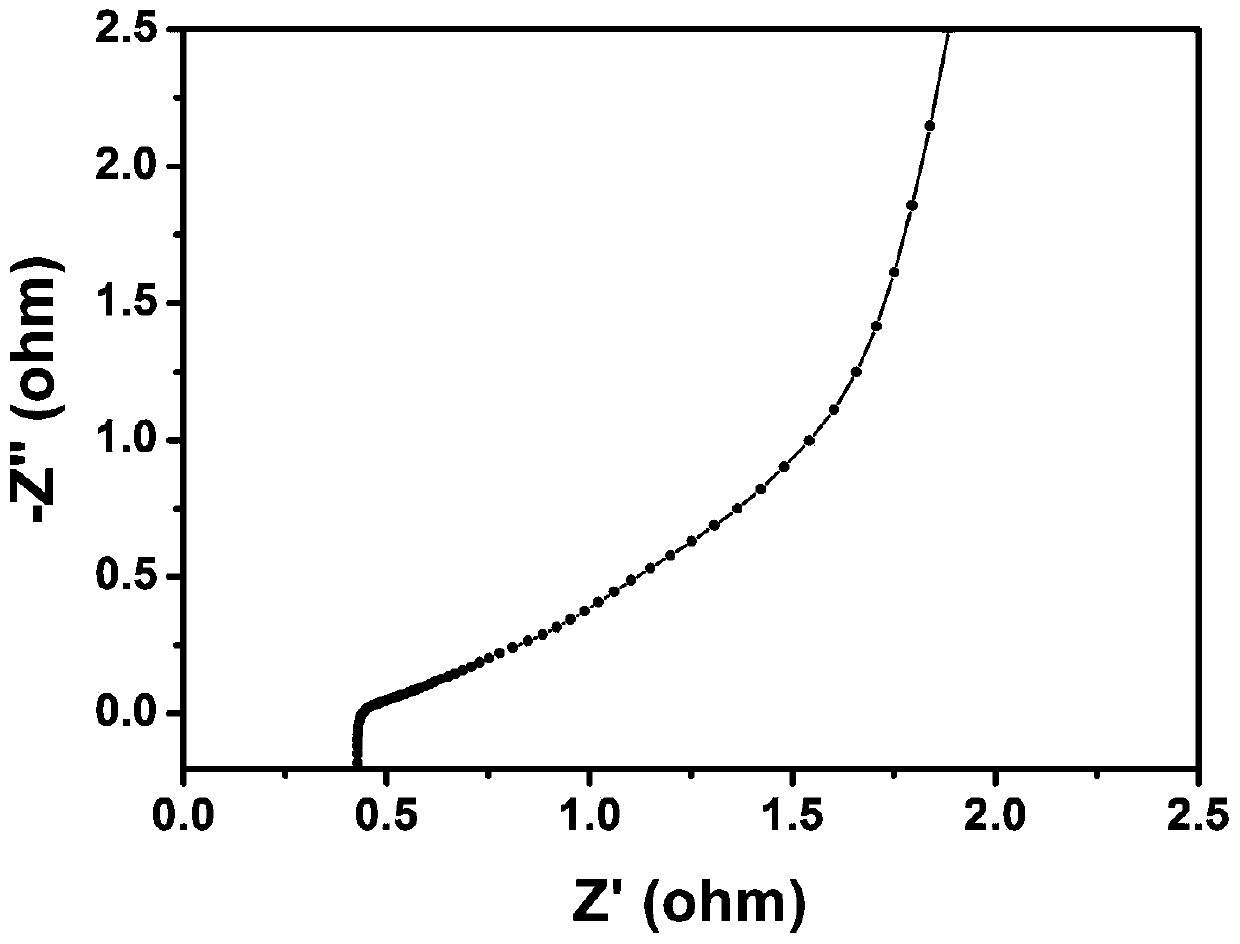

Ternary mixed ionic liquid electrolyte and preparation method and application thereof

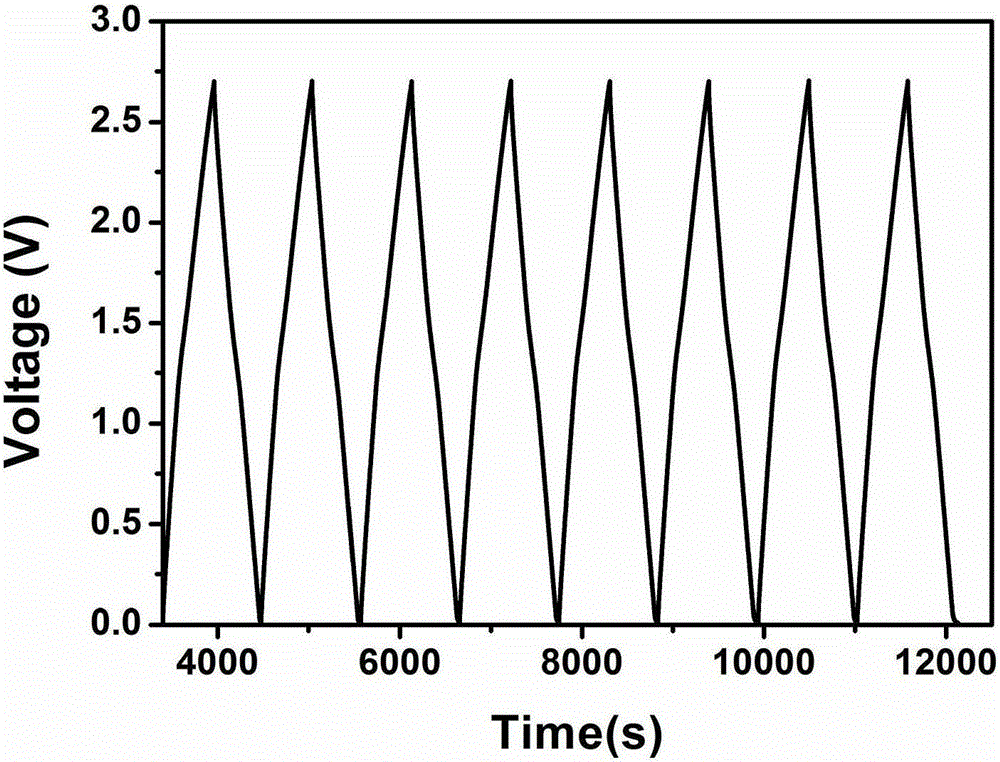

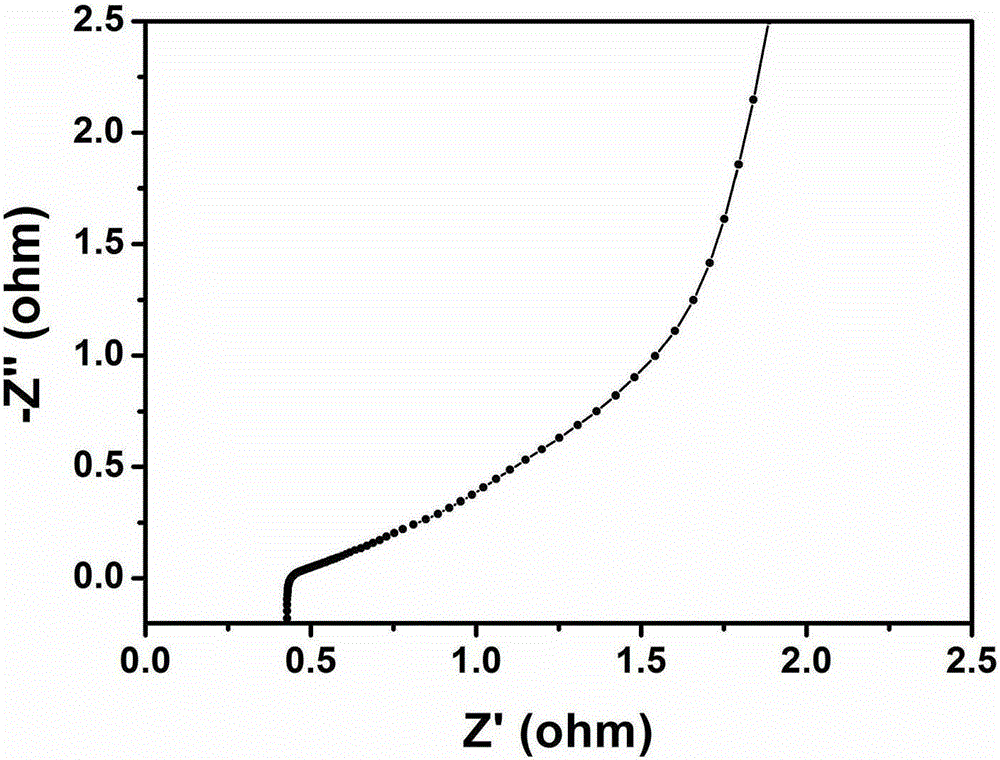

InactiveCN105304353AWide electrochemical windowImprove conductivityHybrid capacitor electrolytesTetrafluoroborateInternal resistance

The invention relates to a ternary mixed ionic liquid electrolyte and a preparation method and application thereof. Tetraethylammonium tetrafluoroborate (C<8>H<20>BF<4>N) and [Bmim]BF<4> ionic liquid are mixed according to a mol ratio of 0.02 - 0.06 : 1. Under the protection of nitrogen, the mixture is stirred at the room temperature for 40 to 50 hours and prepared into a mixed liquid. The mixed liquid is vacuum-dried until the water content is less than 0.06%, and a C<8>H<20>BF<4>N / [Bmim]BF<4> mixed liquid is obtained. With C<8>H<20>BF<4>N / [Bmim]BF<4> as solute and propylene carbonate as solvent, an electrolyte with a concentration of 0.5 - 1.5 mol * L<-1> is prepared. The electrolyte has a wide electrochemical window, a high conductive rate, low internal resistance, and other advantages. The preparation method is simple. Compared with a commercial electrolyte, the mixed electrolyte is cheaper in price and better in performance, and thus has great potential in application as a super capacitor electrolyte.

Owner:BOHAI UNIV

Metal-based composite reinforcement phase casting technique

InactiveCN104550857ASolve the problem of infiltrationSolve compound problemsLiquid metalMetal particle

The invention relates to a metal-based composite reinforcement phase casting technique. The casting technique comprises the steps of infiltrating and combining reinforcement phase metal in a quick-wearing part of a metal part, mixing and pressing reinforcement phase metal particles, powder and a binding agent into pellets, pre-sintering the pellets, fixing the pellets on the surface of the metal part, casting liquid metal on the pellets, infiltrating molten metal to the pellets to soak and combine with the reinforcement phase metal by virtue of static pressure and capillary force, and forming metal and a reinforcement phase composite layer when a casting is formed. The casting process provided by the invention is convenient in production process and low in cost; furthermore, the infiltration and combination between the prefabricate pellets and a casting body can be solved, therefore the pellets and a matrix are fused together without any obvious limit.

Owner:北京金煤创业科技股份有限公司

Antimicrobial composition

ActiveCN101772356ANo complaintsSolve the problem of infiltrationAntibacterial agentsBiocideMedicineSilicon dioxide

A complex antimicrobial sorption composition possessing the necrolytic effect for treating the purulent wounds, the trophic ulcers, the wounds, and the infiltrates with the significant necrotic and exudative components represents the silica sorbent with the immobilized drug. Aerosil is used as a siliceous sorbent, and seratiopeptidase as a drug.

Owner:亚历山大·A·戈卢布

Ecological restoration method for coal gangue dump

ActiveCN102251775BSolve the problem of infiltrationPromote growthUnderground miningSurface miningActivated sludgeSpontaneous combustion

The invention relates to an ecological restoration method for a coal gangue dump; according to the method, during the arrangement of a coal gangue dump and the arrangement of the dump body, annular plant ditches and longitudinal drainage ditches are disposed from top to bottom; clay is added onto gangue and is tamped; a mixture of dehydrated sludge and gangue is added onto the clay between ditches, and sedum alfredii hance are planted; a mixed substrate of gangue dump surface soil, fermented pig manure, and vermiculite is added into the plant ditches; and prostrate spurge, crape myrtle, and cucurbita pepo are planted orderly and repeatedly in the mixed substrate. The method effectively reduces the spontaneous combustion probability of coal gangue, shortens the restoration period, makes use of dehydrated activated sludge, changes wastes into valuables, and obtain certain economic benefits, environmental benefits, and social benefits.

Owner:ELION ECOLOGICAL RESTORATION +1

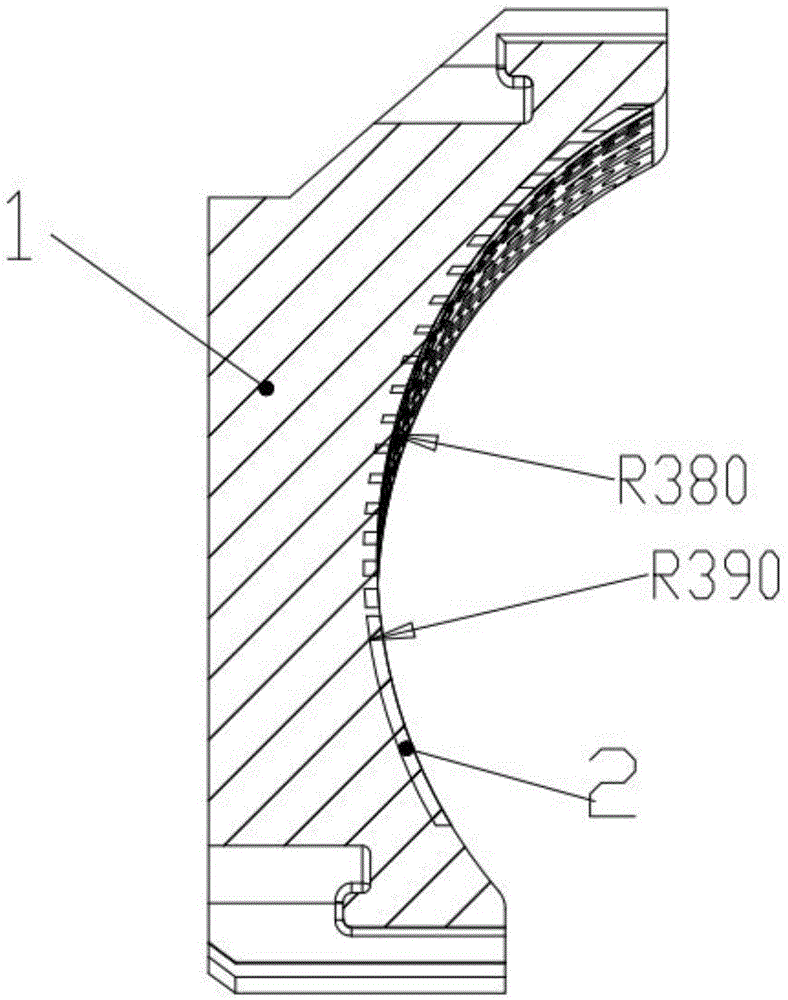

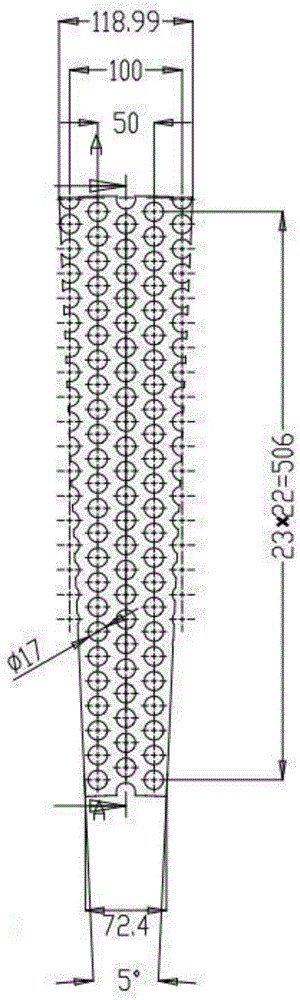

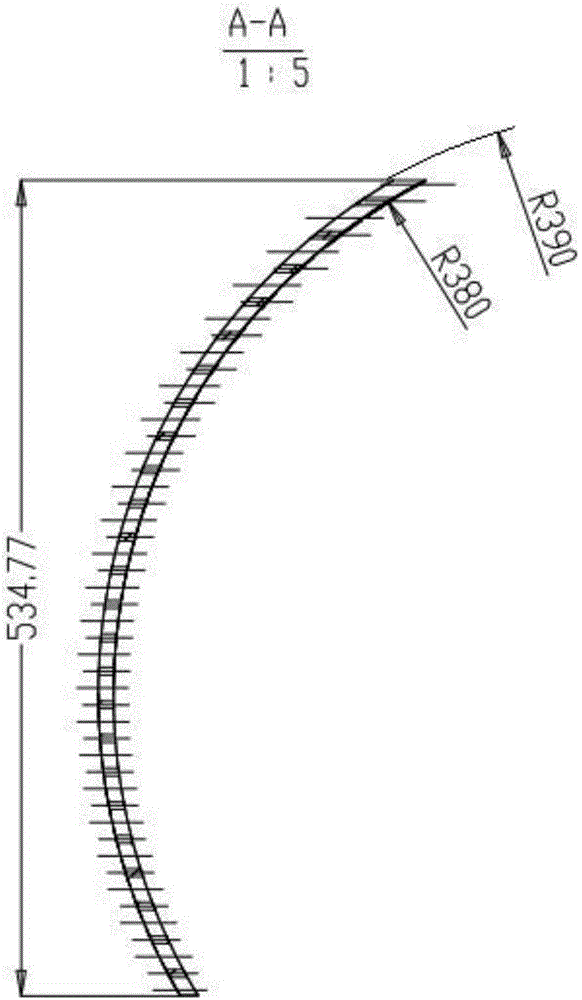

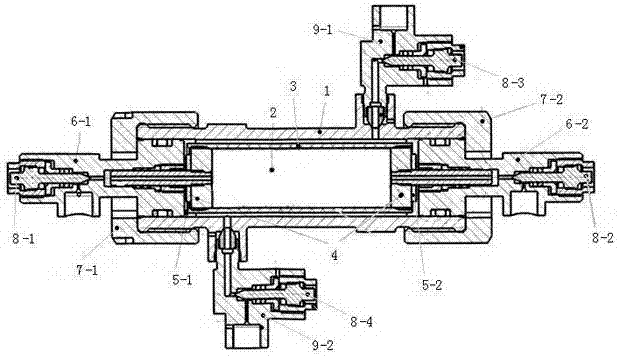

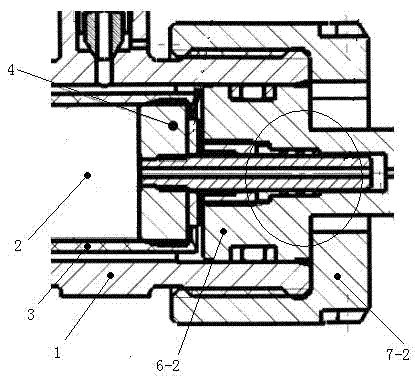

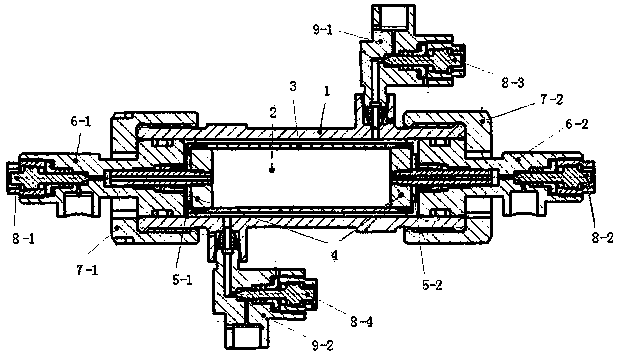

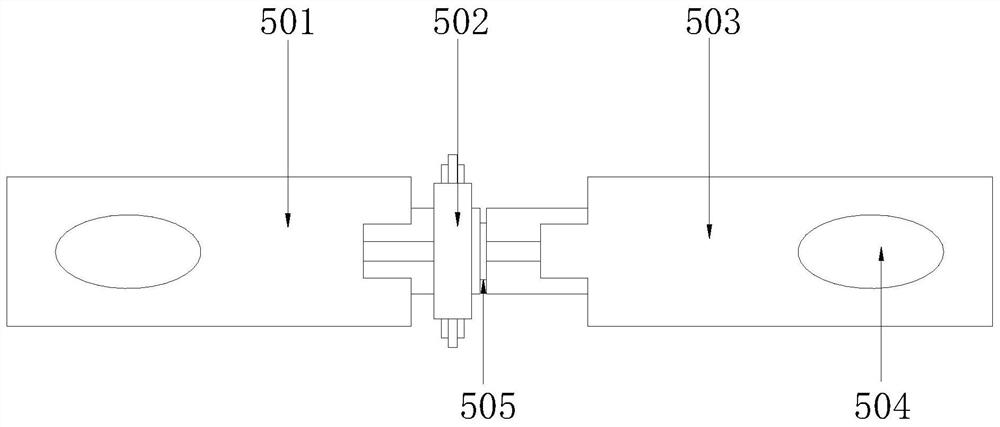

Ultrahigh pressure and high temperature core holder

ActiveCN102778417AAchieve precision weighingReduce quality problemsFlow propertiesEngineeringTitanium alloy

The invention relates to an ultrahigh pressure and high temperature core holder, which comprises a core cabin, and a left seal plug and a right seal plug positioned at two ends of a core cabin cylindrical space and screwed tightly as well as sealed by a left compaction nut and a right compaction nut. The outer ends of the left seal plug and the right seal plug are respectively equipped with a left built-in needle valve and a right built-in needle valve. The inside of the core cabin 1 cylindrical space includes a core, choke plugs and a sleeve. Two sides of the core are respectively equipped with a choke plug. The choke plugs are in close contact with the core, and they are placed in a cylindrical sleeve inside the core cabin together. The outer wall of the core cabin is equipped with an upper built-in needle valve and a lower built-in needle valve. The holder core cabin, the choke plugs, the seal plugs, the compaction nuts, the built-in needle valves and valve accessories all employ a titanium alloy material, and the sleeve adopts polyetheretherketone. The core holder has the characteristics of ultrahigh pressure and high temperature, as well as light mass. With a highest bearable pressure of 200MPa, a highest temperature of 250DEG C, and an overall mass of 2600g, the core holder can realize precise weighing in a precision balance, thus providing a reliable guarantee for core flow experiments under ultrahigh pressure and high temperature conditions.

Owner:CHINA PETROLEUM & CHEM CORP +1

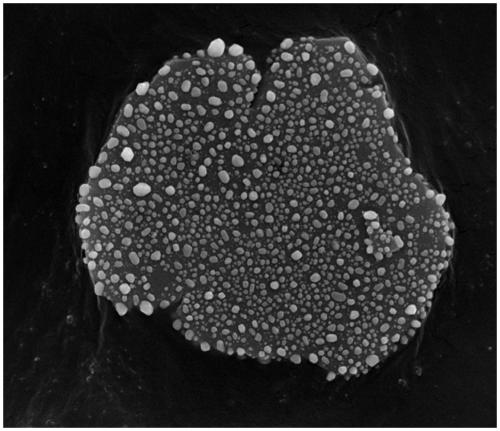

Preparation method of bionic shell structure ceramic and metal composite material

ActiveCN110004347AHigh Temperature Performance ImprovementsImproves Strength and ToughnessHot pressingElectroless nickel plating

The invention discloses a preparation method of a bionic shell structure ceramic and metal composite material. The preparation method comprises the following steps that an ammonium bicarbonate solution and a nickel sulfate solution are correspondingly prepared for later use, chemical nickel plating is carried out on the surface of an alumina wafer layer by virtue of the prepared ammonium bicarbonate solution and the nickel sulfate solution, a nickel-coated alumina wafer layer block body is obtained by means of the metal nickel which is obtained after being subjected to chemical nickel plating,and hot-pressing sintering is carried out to obtain the bionic shell structure ceramic and metal composite material. The prepared bionic shell structure ceramic and metal composite material has highperformance.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

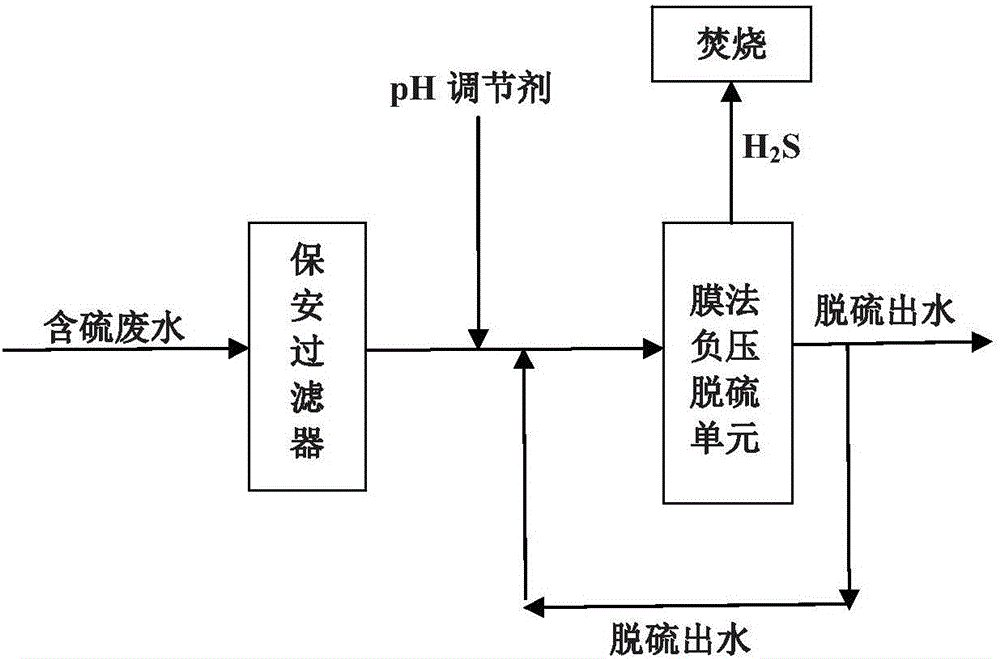

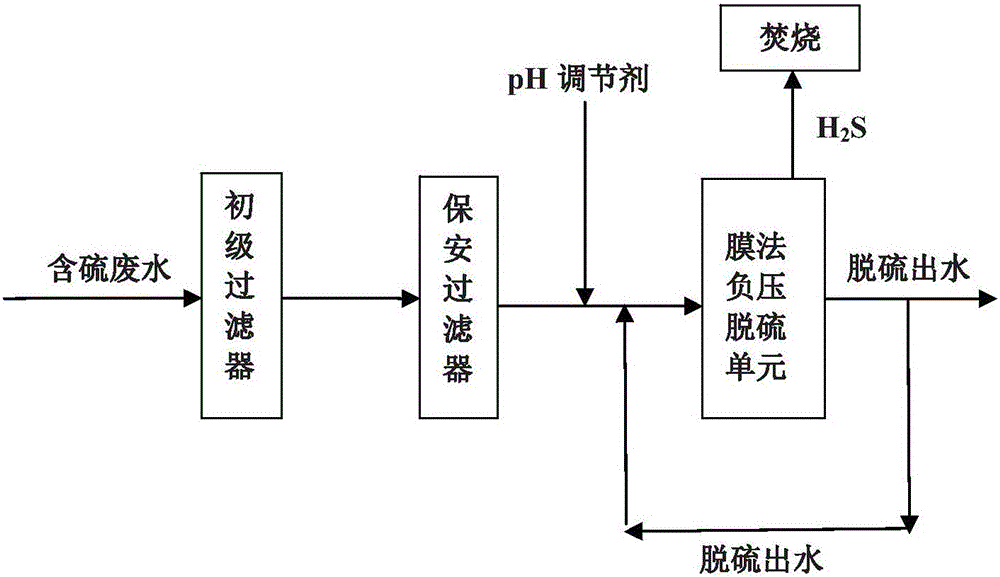

Method for processing sulfur-containing waste water

InactiveCN106256783AAchieve absorptionAchieving Wetting of the Hydrophobic MembraneMultistage water/sewage treatmentMembrane methodIndustrial waste water

The invention relates to the field of industrial waste water processing, and especially relates to a method for processing sulfur-containing waste water. The method comprises the following steps: 1) adjusting the pH value of the sulfur-containing waste water to 4-6 by employing a pH conditioning agent; and 2) inputting the sulfur-containing waste water after pH regulation into a membrane method negative pressure desulfurization unit for desulphurization processing. The method by employing the membrane method negative pressure desulfurization technology for processing sulfur-containing waste water has the advantages of simple equipment, high automation degree, easy operation maintenance, strong environmental adaptability, less land occupation, and high desulphurization efficiency, can realize the skid-mounted processing, and greatly reduces the operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

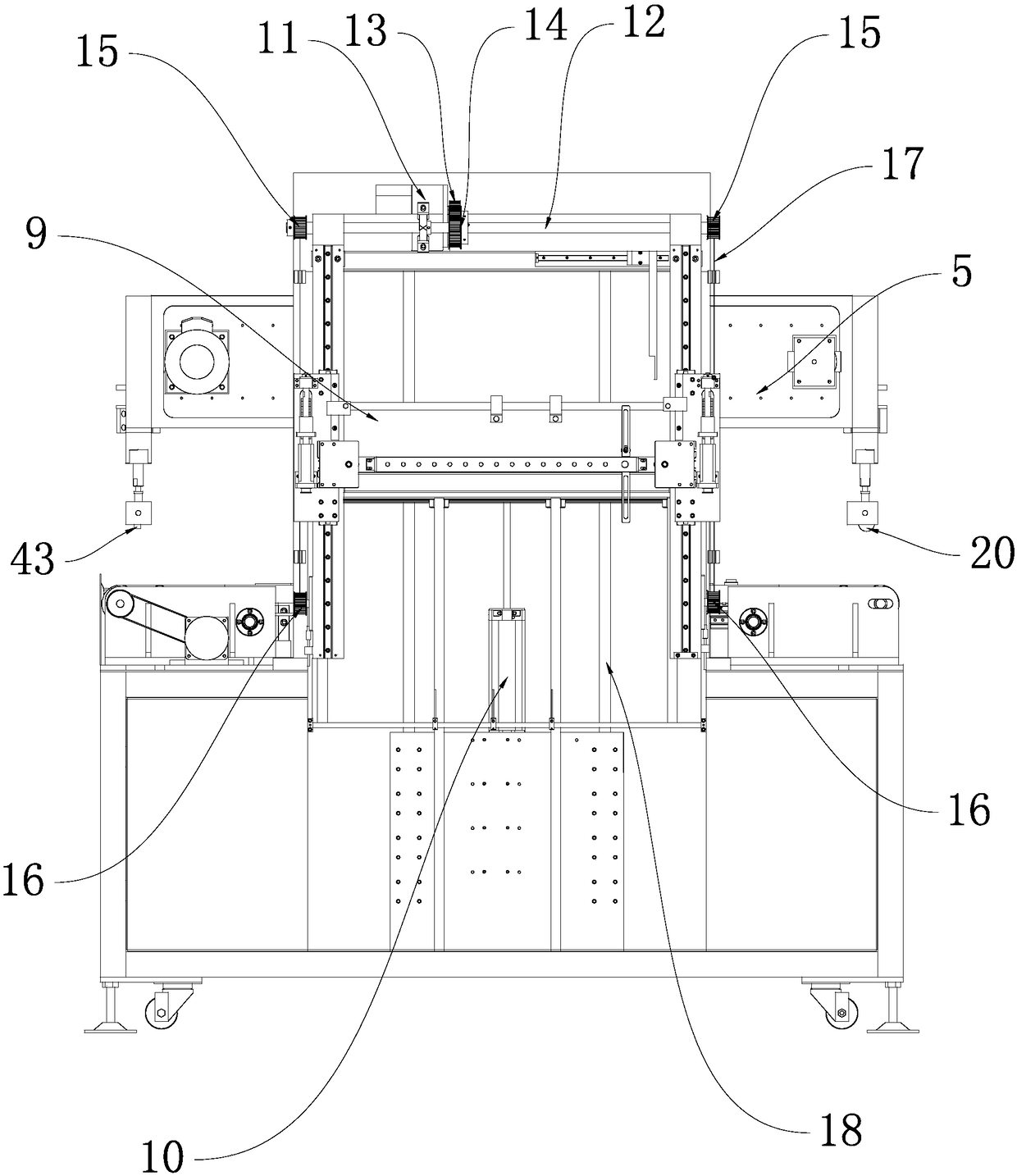

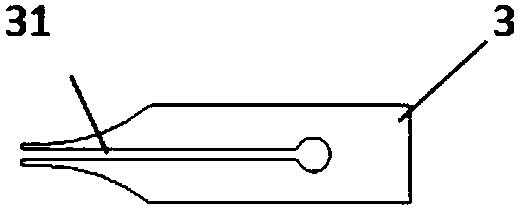

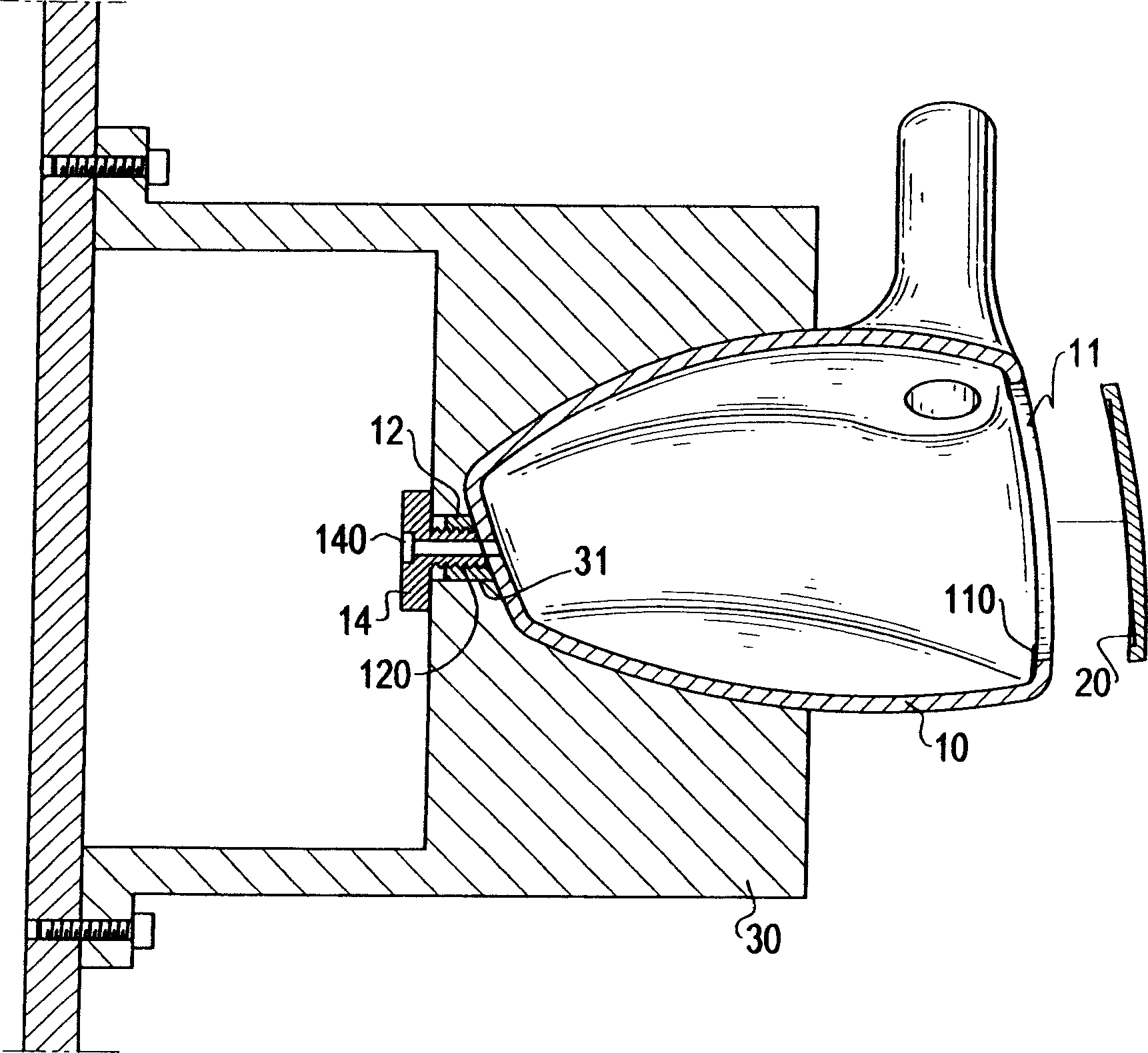

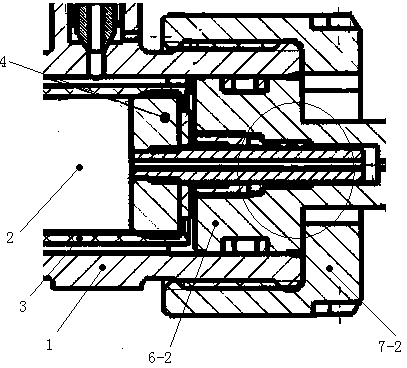

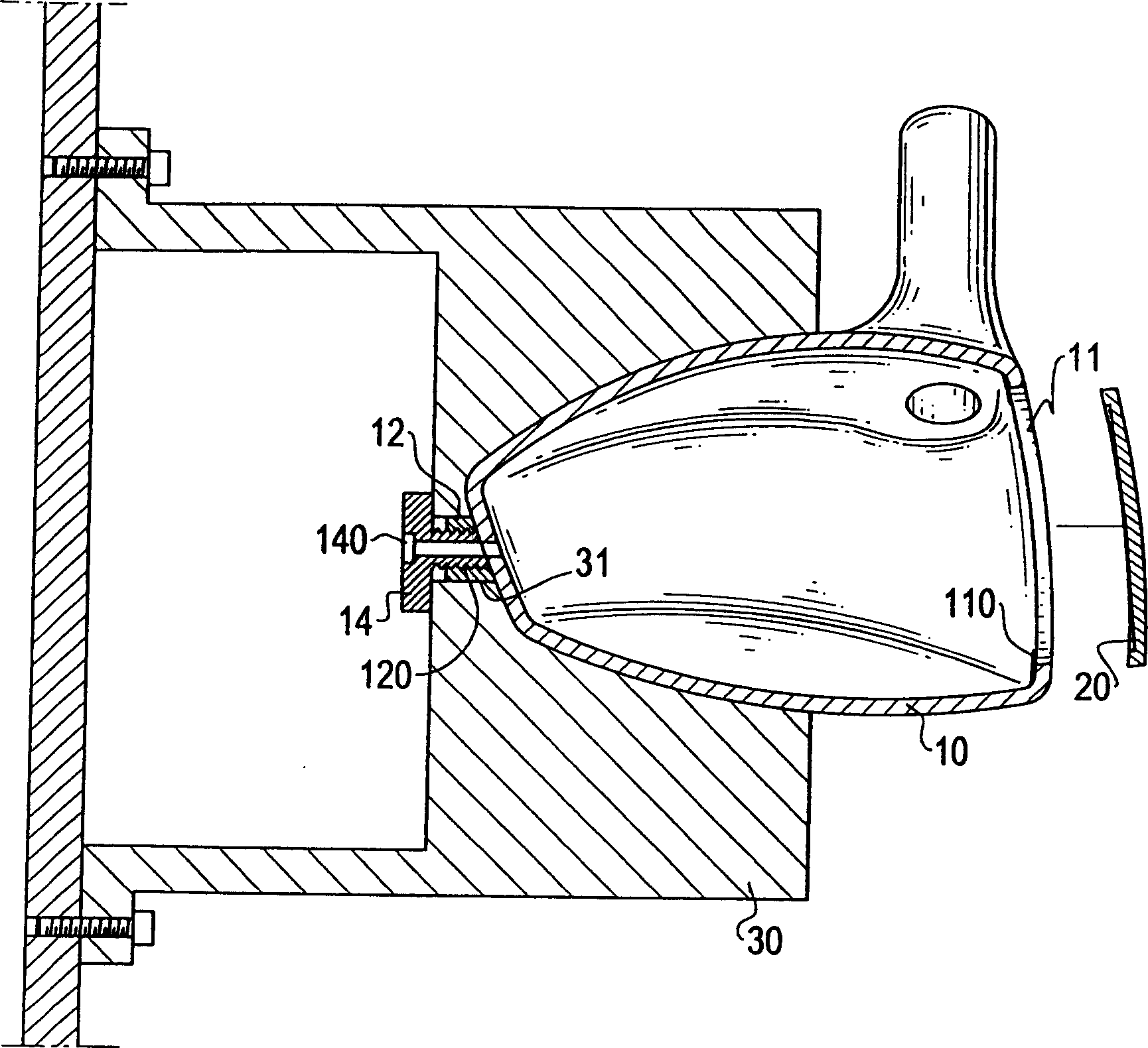

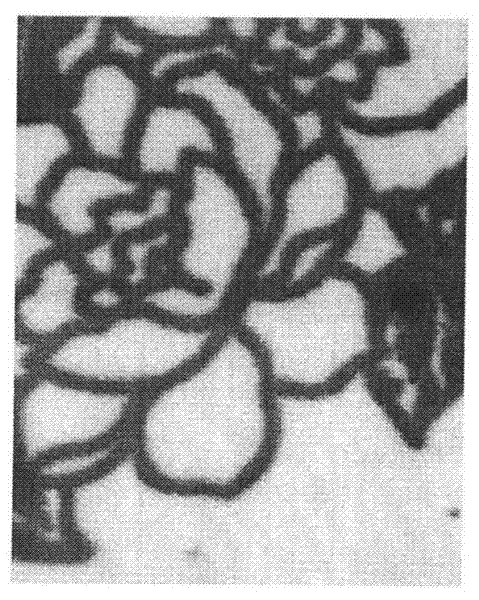

Pen type liquid guiding and infiltration device

ActiveCN108297569ATroubleshoot drawing linesSolve the problem of infiltrationInk reservoir pensNibsFiberEngineering

The invention relates to the field of microscale liquid infiltration device, in particular to a pen type liquid guiding and infiltration device. The pen type liquid guiding and infiltration device comprises a water supplying pipe (1), a pen inner tongue liquid transfer pipe (2), a circular hoop type pen head (3) and fiber brush needles (4), wherein two circular-arc-shaped grooves (21) are formed in the pen inner tongue liquid transfer pipe (2) in the periphery, and the fiber brush needles (4) are fixed in the circular-arc-shaped grooves (21) at the liquid discharging end of the pen inner tongue infusion pipe (2); the pen inner tongue liquid transfer pipe (2) penetrates through the circular hoop type pen head (3), and side wall openings of the circular-arc-shaped grooves (21) face a liquidguiding groove (31) of the inner wall of the circular hoop type pen head (3).The pen type liquid guiding and infiltration device is simple in the principle, easy to realize, capable of effectively solving infiltration problem of the microscale liquid in a microscale liquid supplying system, and is of great importance in the development of the research and production of novel ultrathin films with high-quality.

Owner:BEIJING SCITECH NANOTECH CO LTD

Water-based pigment ink used for a high-speed ink-jet printer and a preparing method thereof

The invention relates to water-based pigment ink used for a high-speed ink-jet printer and a preparing method thereof. The water-based pigment ink includes 5-15 parts of pigment, 0.3-1 part of a defoamer, 1-3 parts of a dispersant, 39.6-67.6 parts of purified water and 26.1-38.4 parts of a waterborne solvent. The method includes (1) preparing the purified water; (2) adding the purified water, thepigment, the dispersant and the waterborne solvent according to a mass ratio into a dispersing machine, and dispersing the materials to obtain a mixture; (3) grinding the mixture until the particle size is less than 500 nm; and (4) adding the mixture into a stirrer, adding a pH adjusting agent, the defoamer, a humectant, an aseptic and a surfactant according to a ratio, and fully stirring the mixture to obtain the ink.

Owner:ZHONGJI OIL COLTHING BEIJING TECH CO LTD

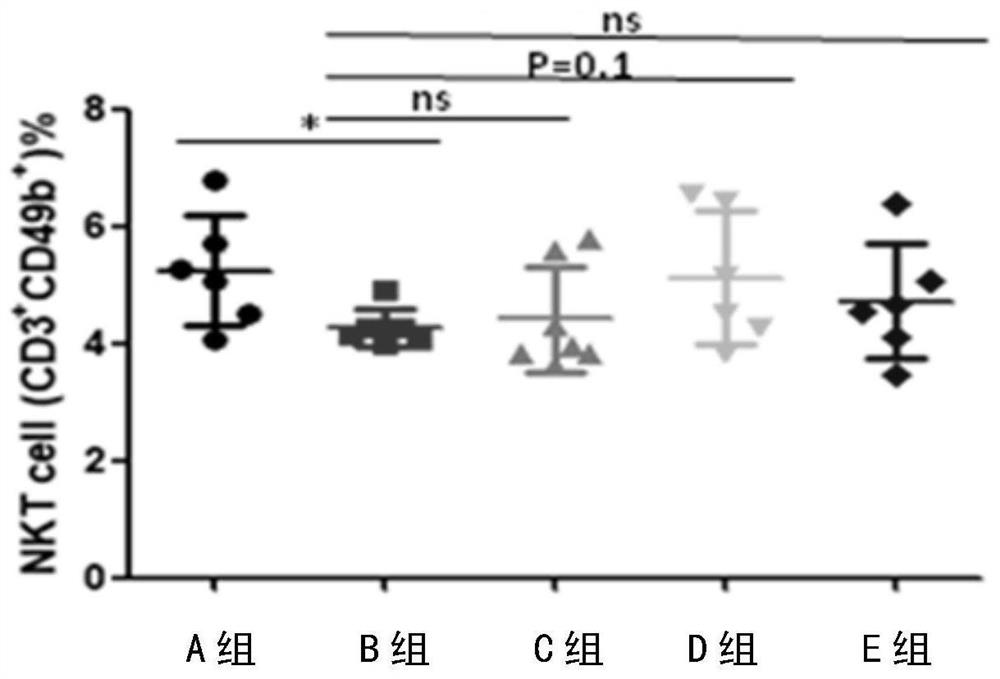

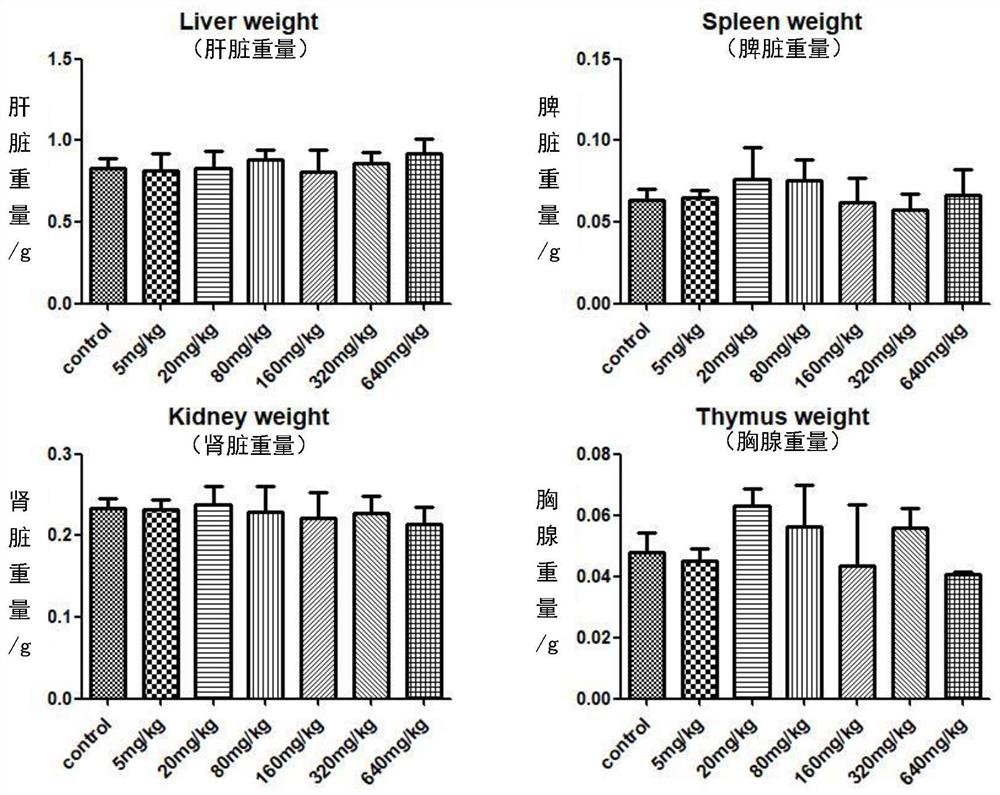

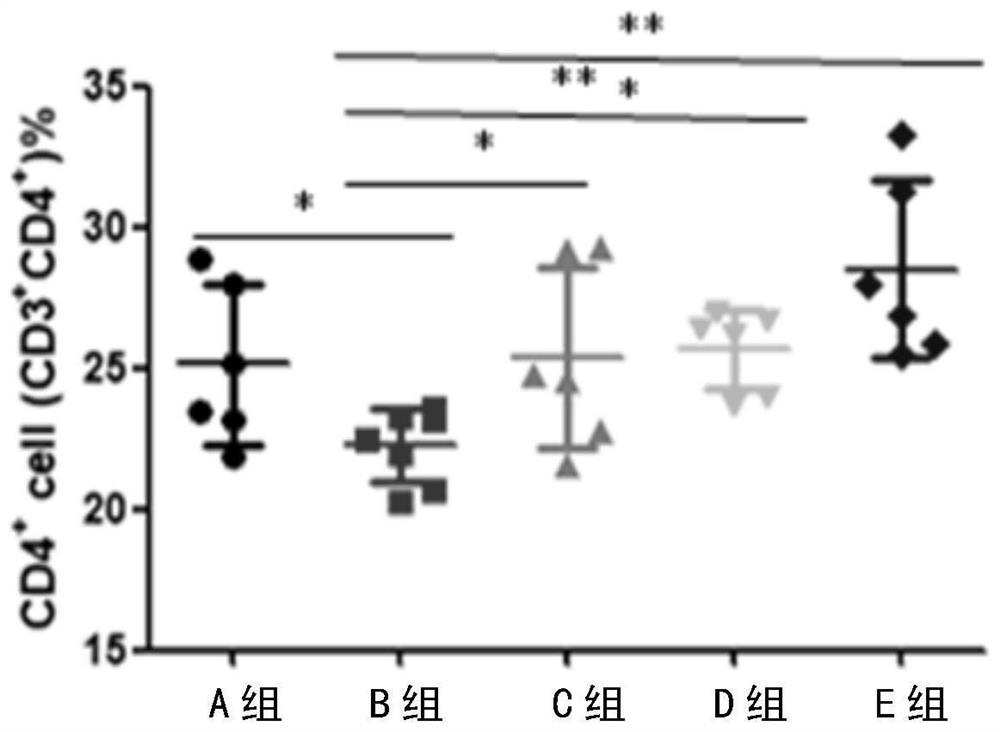

Natural immunity activator, application thereof, natural TIL cell accelerant and application of natural TIL cell accelerant

PendingCN111700900AActivate the immune systemRaise the ratioOrganic active ingredientsImmunological disordersImmunityCellular infiltration

The invention discloses a natural immunity activator and a natural TIL cell accelerant which comprise icariside I. The natural immunity activator can increase the proportion of varied immunity cell subsets in peripheral blood, besides, can increase the CD8+ / CD4+ ratio in the peripheral blood, and can activate an immune system; and the natural TIL cell accelerant can promote immunocyte in the peripheral blood to perform infiltration on tumor tissue, the proportion of the TIL cells in tumors can be increased, particularly infiltration of CD8+ cells in the tumor tissue is increased, the CD8+ / CD4+ratio is increased, and T cells are increased to restrain growth of the tumors. The invention further discloses an application of the natural immunity activator and the natural TIL cell accelerant totumor immunotherapy, the content of the immunocyte in patients suffering from tumors can be increased, the difficult problem that during present tumor immunotherapy, infiltration and / or accumulationof the CD8+ cells in tumor microenvironment is deficient can be solved, and the curative effect of the tumor immunotherapy can be increased.

Owner:FOSHAN GOLDEN HEALTH TECH CO LTD

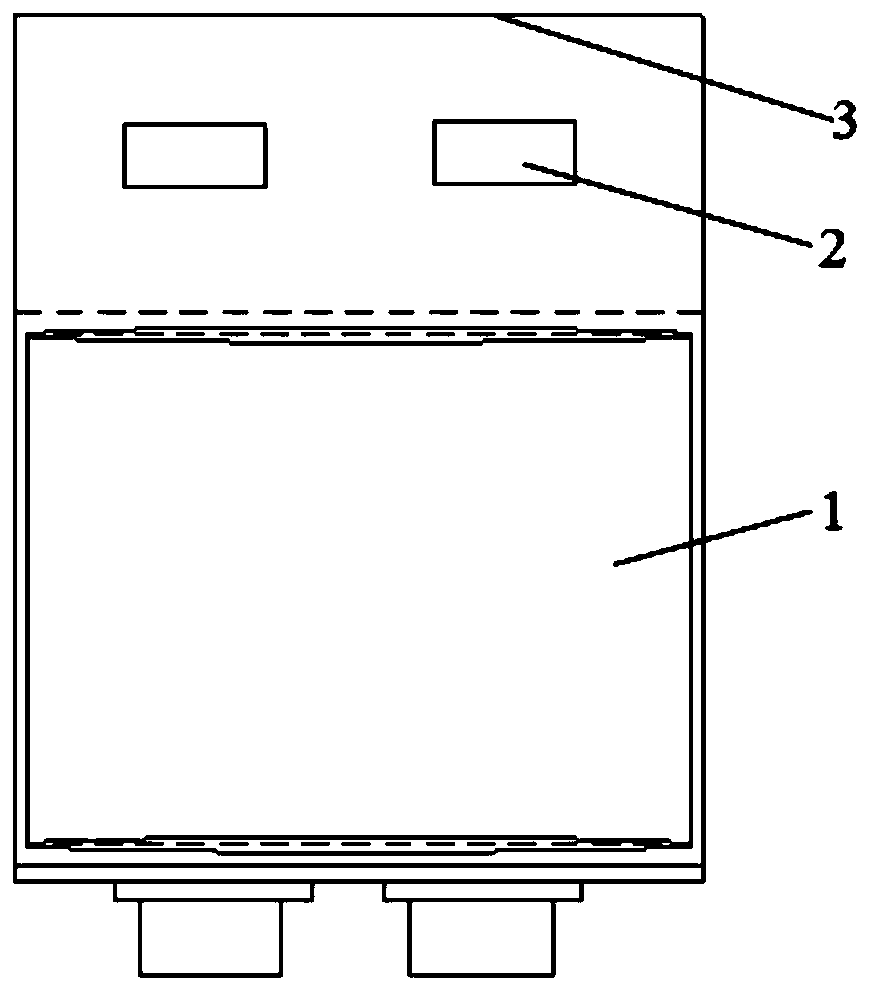

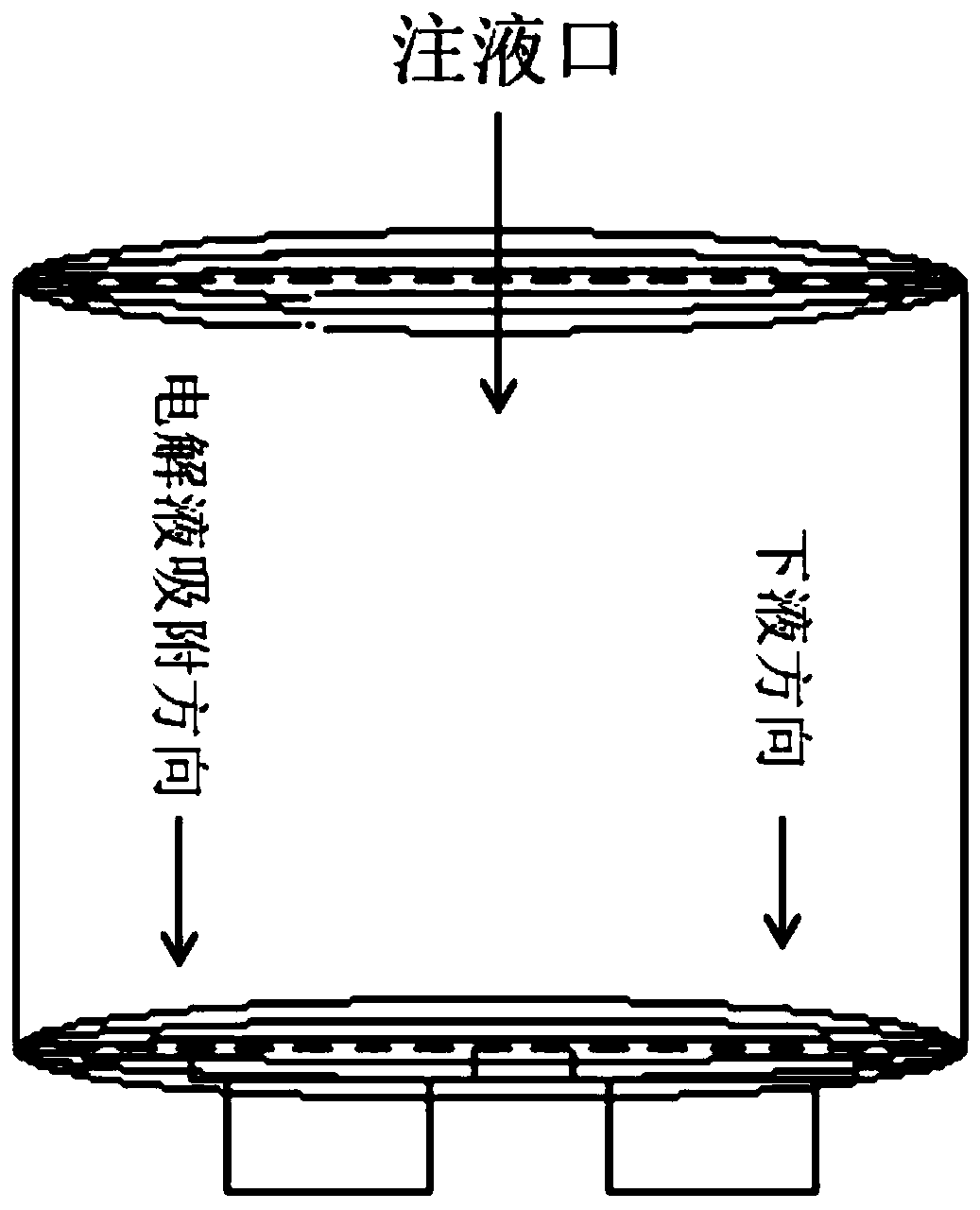

Lithium ion battery liquid injection method adopting polygonal double-hole liquid injection mode

PendingCN114204233ABreak surface tensionSolve the problem of infiltrationVent arrangementsElectrolytic agentEngineering

The invention relates to a lithium ion battery liquid injection method adopting a polygonal double-hole liquid injection mode, which is characterized in that an exhaust hole and a liquid injection hole are arranged on a battery cover, the exhaust hole is hermetically connected with a vacuumizing device, and the liquid injection hole is hermetically connected with an electrolyte tank to form a vacuum negative-pressure electrolyte injection channel with double communicated holes; the vacuum value is adjusted in the liquid injection process, so that the battery always keeps stable negative pressure. The device has the beneficial effects that the surface tension of electrolyte can be effectively broken through by adopting the polygonal liquid inlet holes, and the problem that the electrolyte is difficult to inject and infiltrate is solved; and the exhaust hole is used as a vacuum hole, so that stable negative pressure in the battery can be always kept in the liquid injection process, and the liquid injection efficiency is remarkably improved. The method is simple in required condition, good in repeatability, wide in application range, high in controllability and simple to operate; according to the method, adjustable vacuum values can be set according to different batteries, so that stable and rapid liquid injection is ensured.

Owner:TIANJIN LISHEN BATTERY

Lithium iron phosphate battery cell, high-energy-density lithium iron phosphate battery and preparation method of battery

InactiveCN111244371AEnsure safetyIncrease energy densityPhosphatesFinal product manufactureLithium iron phosphateHigh energy

The invention discloses a lithium iron phosphate battery cell, a high-energy-density lithium iron phosphate battery and a preparation method of the battery, wherein the lithium iron phosphate batterycell is prepared by sequentially overlapping and winding a positive pole piece, a first diaphragm, a negative pole piece and a second diaphragm, the positive pole piece comprises a positive current collector and a positive coating coated on the surface of the positive current collector, and the negative pole piece comprises a negative current collector and a negative coating coated on the surfaceof the negative current collector. According to the invention, the monomer energy density of the lithium iron phosphate battery is improved to 190-195 Wh / kg, and the energy density of the system aftergrouping exceeds 140 Wh / kg, so that the endurance requirement of a passenger vehicle of more than 400 km is met, and a solution is provided for the wide application of the lithium iron phosphate battery in the field of passenger vehicles.

Owner:QINGDAO GUOXUAN BATTERY CO LTD

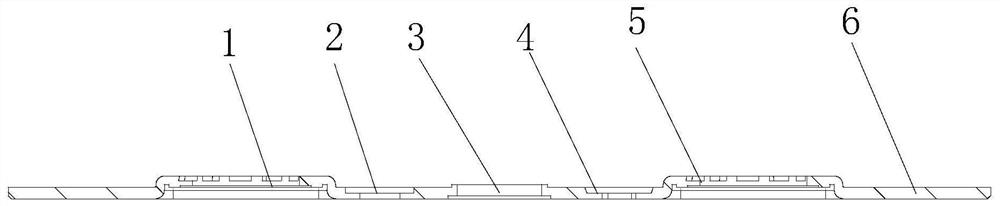

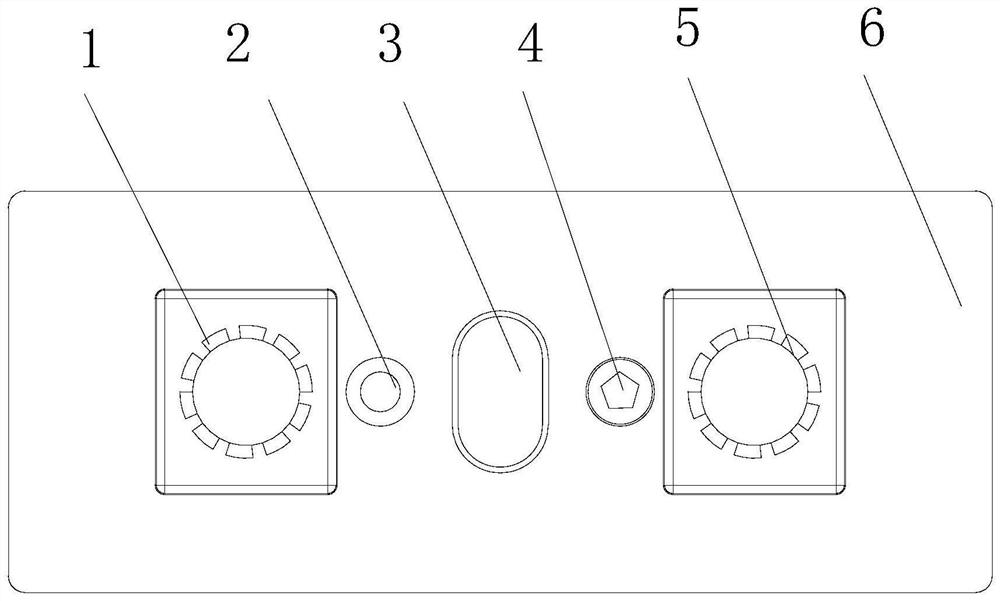

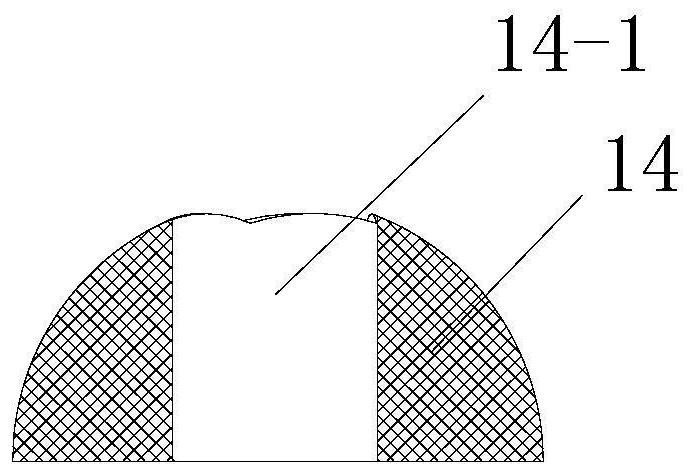

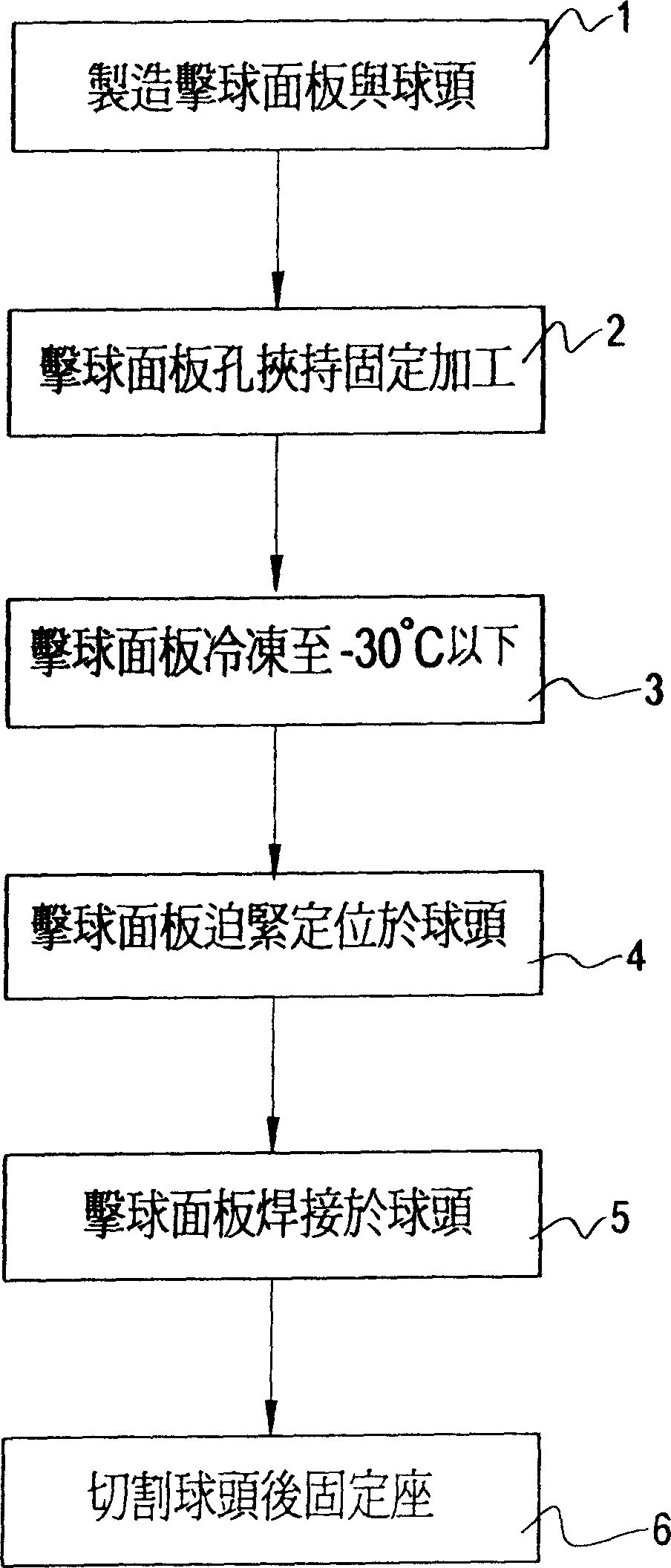

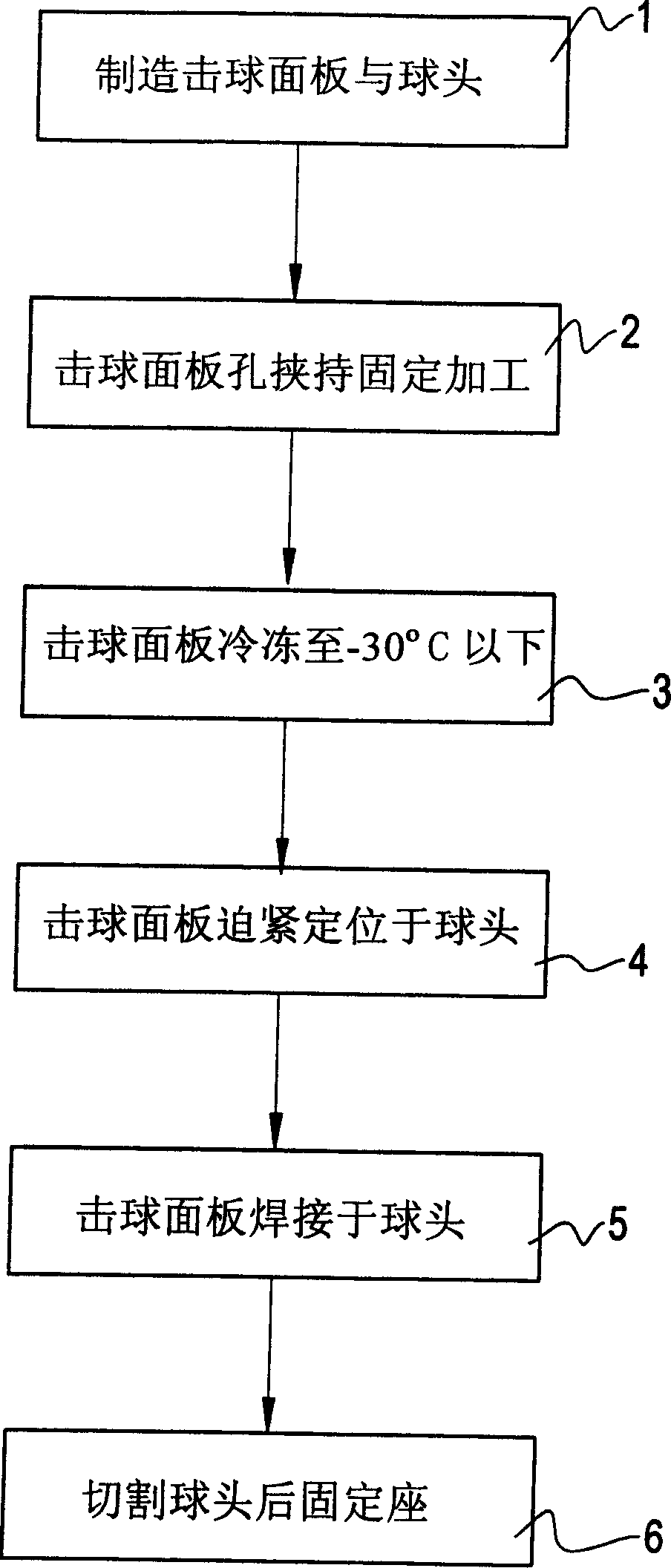

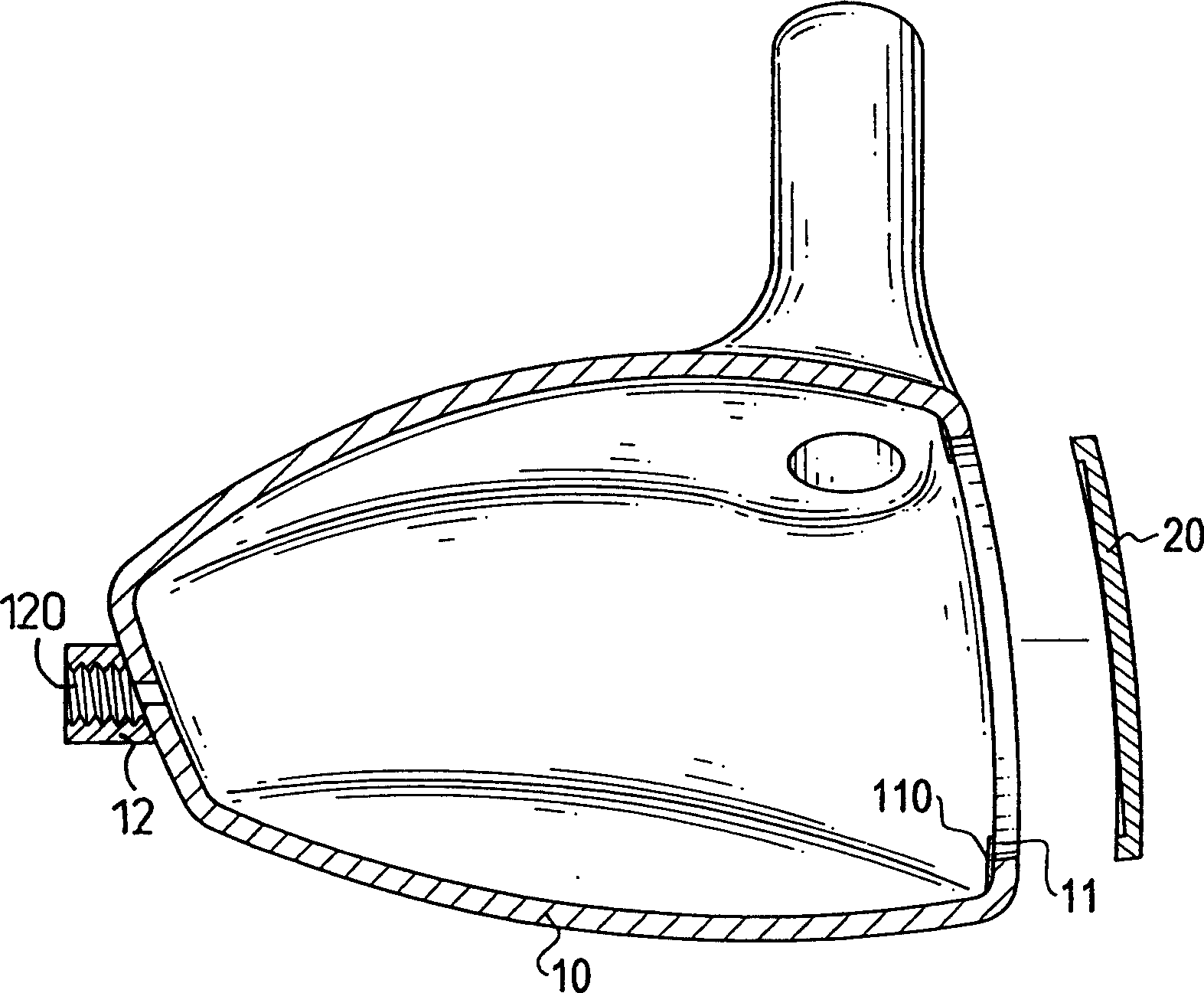

Golf head and connecting method of its surface plate

A technology for welding the golf head with its panel without the welded seam projected inward, which can cause weight nonuniformity and gravitational center shift includes such steps as manufacturing the golf head with a recess for the panel and the panel, fixing the head, freezing the panel, assembling the panel to said recess, naturally restoring the temp of panel for tight match between head and panel, and plasma welding or laser welding.

Owner:李孔文 +1

Packaging electrolyte injection method for improving pole piece infiltration and side deformation of pouch cell

InactiveCN110690406ASolve the problem of infiltrationImprove cycle lifeSecondary cellsCell component detailsElectrolytic agentEngineering

The invention relates to a packaging electrolyte injection method for improving the pole piece infiltration and side deformation of a pouch cell. The method includes disposing an electrolyte-injectionport at the bottom of the core of a pouch cell; orienting the head of the core of the pouch cell to the vertically downward direction. On the one hand, the electrolyte flows from the bottom of the core to the head of the core along a gap between the pole pieces of the core or a gap between the pole pieces and a diaphragm during an electrolyte injection process, thereby contributing to the uniforminfiltration of the pole pieces of the core. On the other hand, during the electrolyte injection process, the head of the core is oriented downward so as to help to increase the ring-rush strength ofthe core, avoid the deformation of the core, and further help to prolong the cycle life of the pouch cell.

Owner:东莞维科电池有限公司

Ultrahigh pressure and high temperature core holder

ActiveCN102778417BReduce quality problemsWith high pressure and high temperature resistanceFlow propertiesUltra high pressureEngineering

The invention relates to an ultrahigh pressure and high temperature core holder, which comprises a core cabin, and a left seal plug and a right seal plug positioned at two ends of a core cabin cylindrical space and screwed tightly as well as sealed by a left compaction nut and a right compaction nut. The outer ends of the left seal plug and the right seal plug are respectively equipped with a left built-in needle valve and a right built-in needle valve. The inside of the core cabin 1 cylindrical space includes a core, choke plugs and a sleeve. Two sides of the core are respectively equipped with a choke plug. The choke plugs are in close contact with the core, and they are placed in a cylindrical sleeve inside the core cabin together. The outer wall of the core cabin is equipped with an upper built-in needle valve and a lower built-in needle valve. The holder core cabin, the choke plugs, the seal plugs, the compaction nuts, the built-in needle valves and valve accessories all employ a titanium alloy material, and the sleeve adopts polyetheretherketone. The core holder has the characteristics of ultrahigh pressure and high temperature, as well as light mass. With a highest bearable pressure of 200MPa, a highest temperature of 250DEG C, and an overall mass of 2600g, the core holder can realize precise weighing in a precision balance, thus providing a reliable guarantee for core flow experiments under ultrahigh pressure and high temperature conditions.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of ternary mixed type ionic liquid electrolyte and its preparation method and application

InactiveCN105304353BWide electrochemical windowImprove conductivityHybrid capacitor electrolytesElectrochemical windowSolvent

The invention relates to a ternary mixed ionic liquid electrolyte and a preparation method and application thereof. Mix tetraethylammonium tetrafluoroborate and 1-butyl-3-methylimidazolium tetrafluoroborate ionic liquid at a molar ratio of 0.02-0.06:1, and stir at room temperature for 40-50 hours under nitrogen protection to prepare The mixed solution is vacuum-dried to make the water content less than 0.06% to obtain a C8H20BF4N / [Bmim]BF4 mixed solution. Using C8H20BF4N / [Bmim]BF4 as the solute and propylene carbonate as the solvent, a 0.5-1.5mol L-1 electrolyte solution was prepared. The ternary mixed ionic liquid electrolyte of the present invention has the advantages of wide electrochemical window, high electrical conductivity, small internal resistance, etc., and the preparation method is simple. Compared with commercial electrolytes, the mixed electrolyte is cheaper and has better performance. It is more prominent and has great potential in the application as supercapacitor electrolyte.

Owner:BOHAI UNIV

Golf head and connecting method of its surface plate

InactiveCN1239217CSolve the problem of infiltrationGolf clubsRacket sportsCenter shiftThermal expansion

A technology for welding the golf head with its panel without the welded seam projected inward, which can cause weight nonuniformity and gravitational center shift includes such steps as manufacturing the golf head with a recess for the panel and the panel, fixing the head, freezing the panel, assembling the panel to said recess, naturally restoring the temp of panel for tight match between head and panel, and plasma welding or laser welding.

Owner:李孔文 +1

A flexible carbon castable for furnace bottom screed

The invention discloses a flexible carbon castable for furnace bottom leveling layer, the composition of which is as follows in terms of mass percentage: 61-65% of high-power graphite granules; 10-20% of high-power graphite powder; active α-oxidation Aluminum powder 3-5%; natural flake graphite 2-5%; pure aluminate cement 7-14%; dispersant 1-2%. The invention is energy-saving and environment-friendly, does not produce substances harmful to the environment, does not cause any harm to construction workers, meets the requirements of the state for environmental protection and energy-saving emission reduction, and has greater advantages compared with the prior art in terms of environmental protection. The construction operation of the materials used is simple and has certain thixotropy. It only needs to be repaired in time and quickly after vibration forming, which can save a lot of construction time.

Owner:中冶武汉冶金建筑研究院有限公司

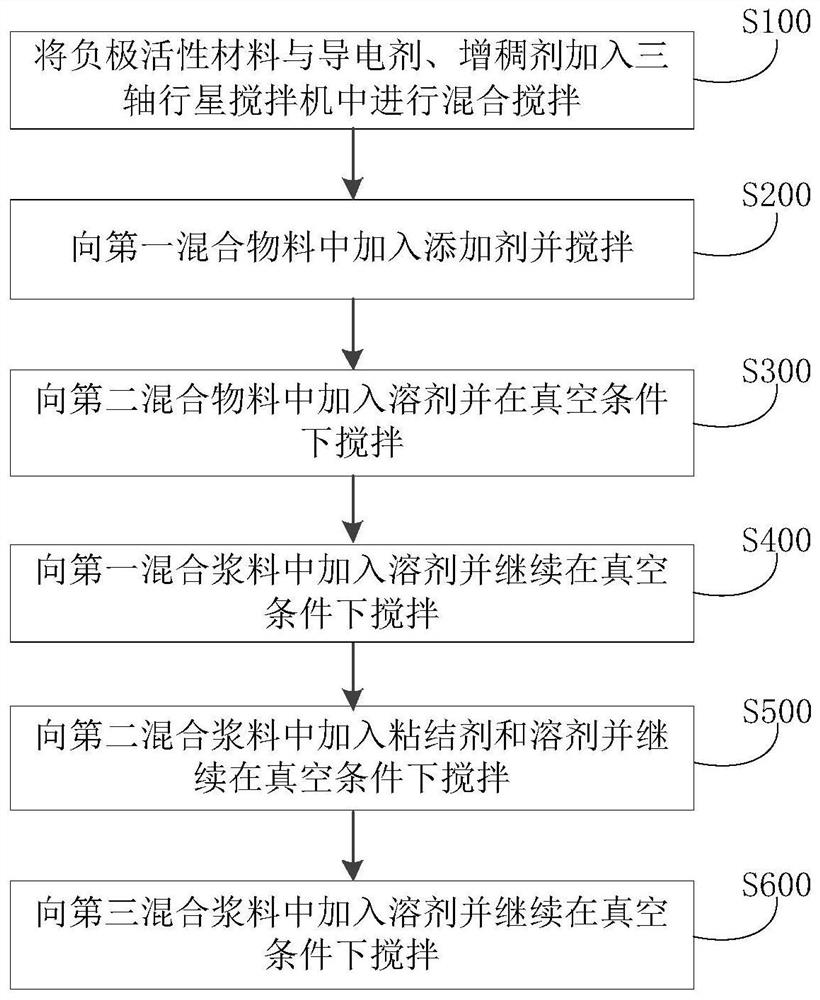

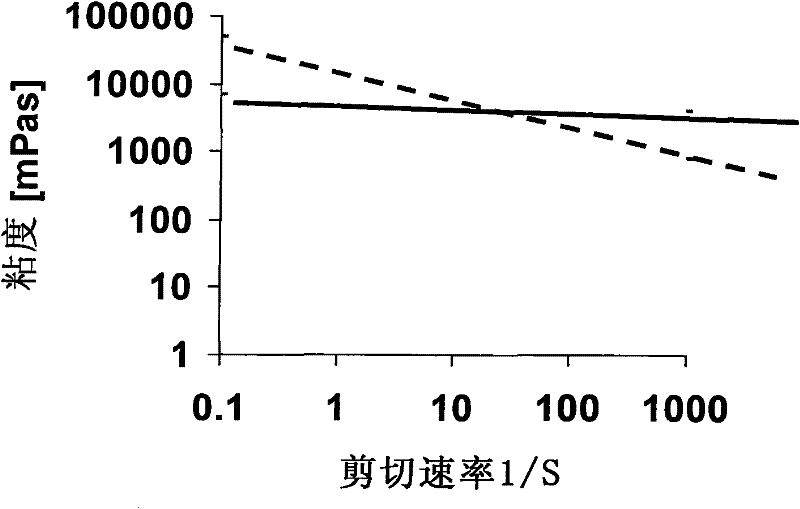

Negative electrode slurry and its preparation method and application

ActiveCN110071288BImprove stabilityIncreased shear frictionSecondary cellsNegative electrodesBLENDER/MIXERPhysical chemistry

The invention discloses a negative electrode slurry and its preparation method and application. The method comprises: adding a negative electrode active material, a conductive agent and a thickener into a three-axis planetary mixer for mixing and stirring to obtain a first mixed material; Adding additives to the mixed material and stirring to obtain a second mixed material; adding a solvent to the second mixed material and stirring under vacuum conditions to obtain a first mixed slurry with a solid content of 80wt% to 90wt%; adding to the first mixed slurry Add a solvent to the material and continue to stir under vacuum conditions to obtain a second mixed slurry with a solid content of 60wt% to 72wt%; add a binder and a solvent to the second mixed slurry and continue to stir under vacuum conditions to obtain A third mixed slurry with a solid content of 53wt%-58wt%, adding a solvent to the third mixed slurry and continuing to stir under vacuum to obtain a negative electrode slurry with a viscosity of 3000-8000mPa·s. The method can effectively solve the infiltration problem of the negative electrode active material and the solvent at the initial stage of stirring, shorten the stirring time of the slurry, and improve the viscosity consistency of the slurry.

Owner:昆山聚创新能源科技有限公司

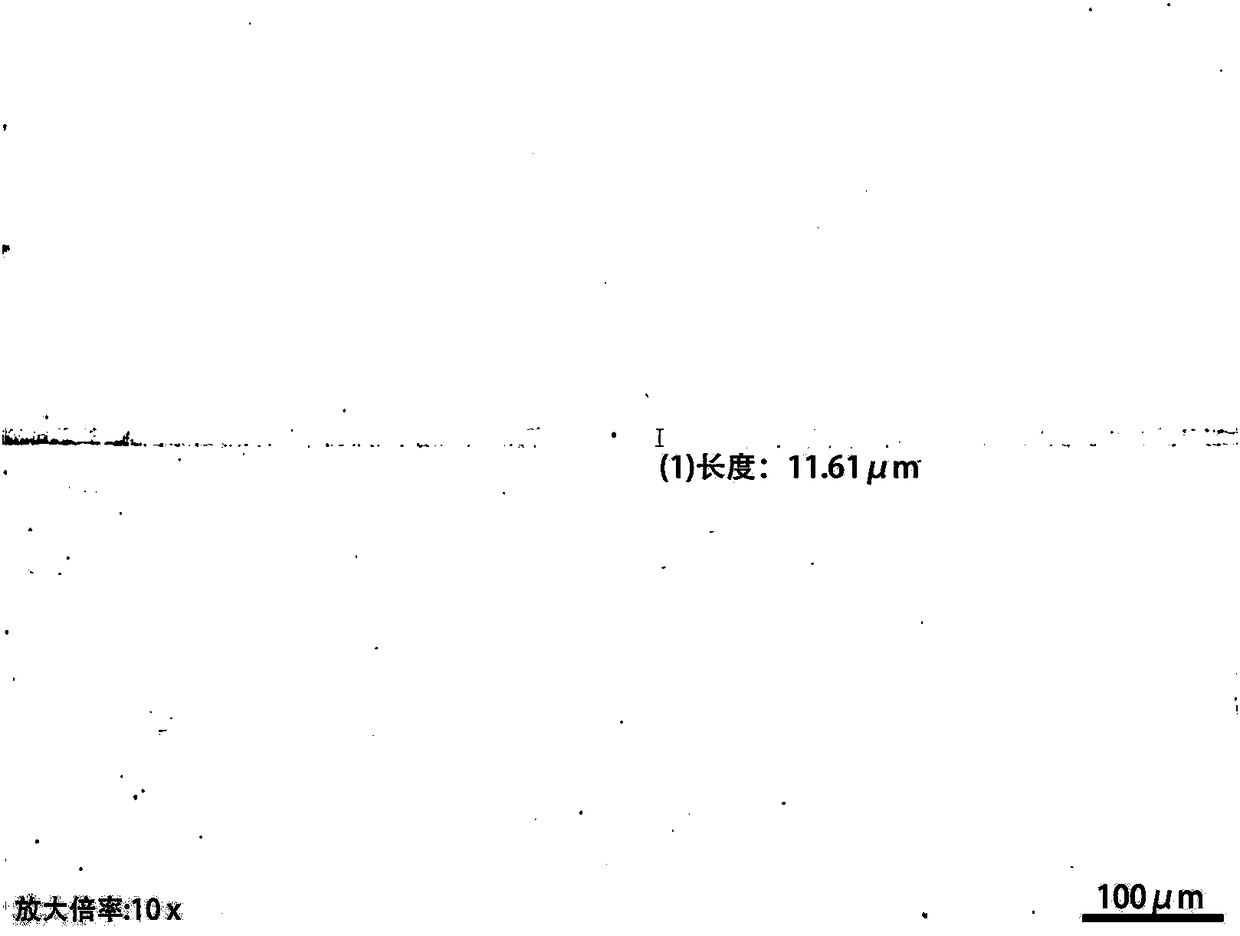

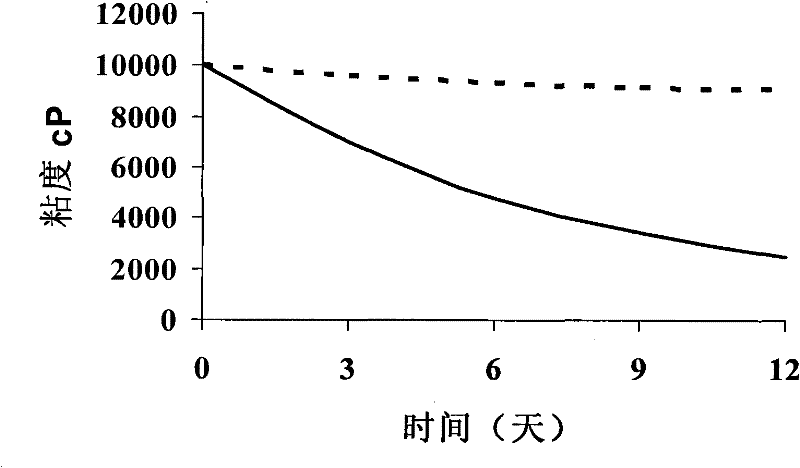

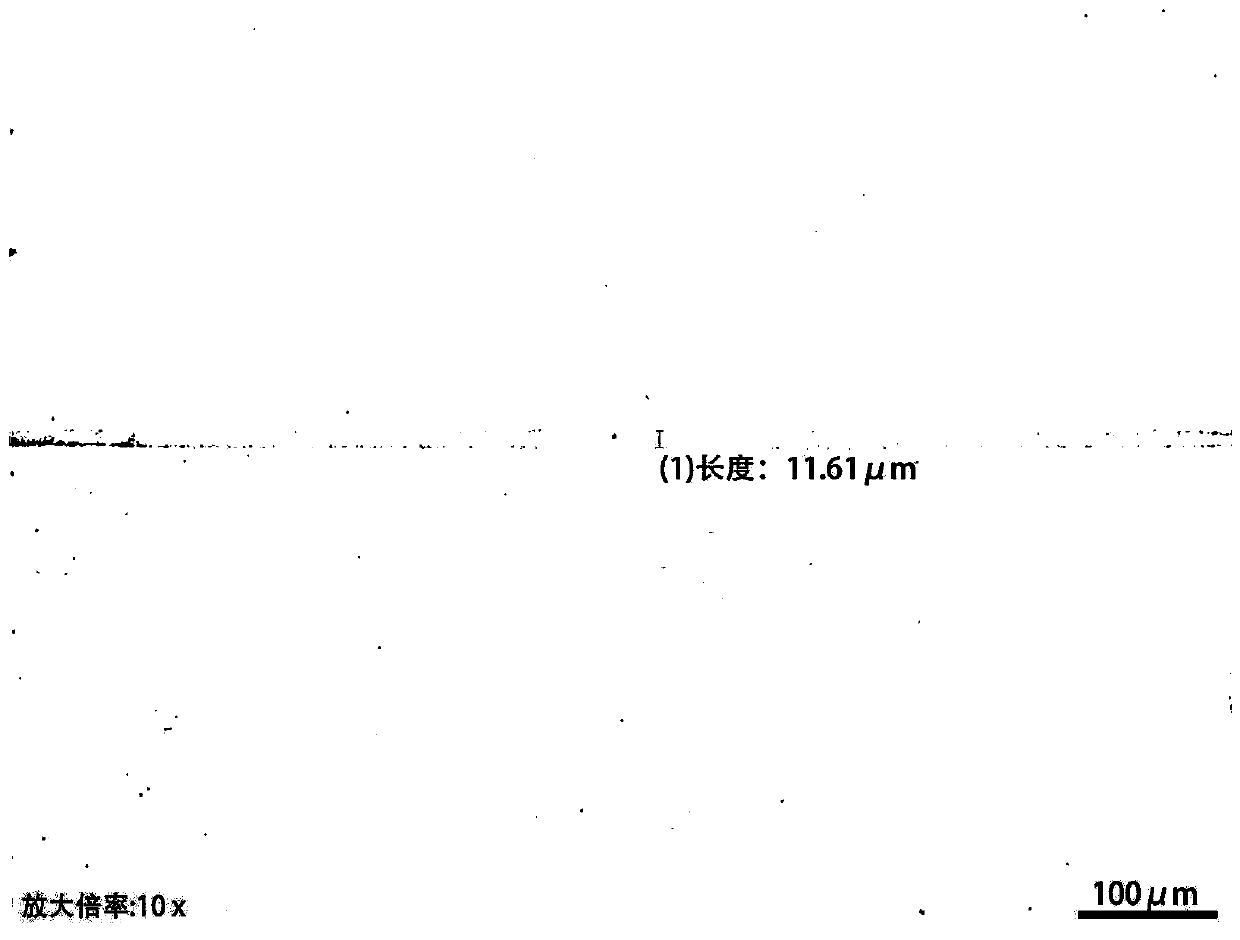

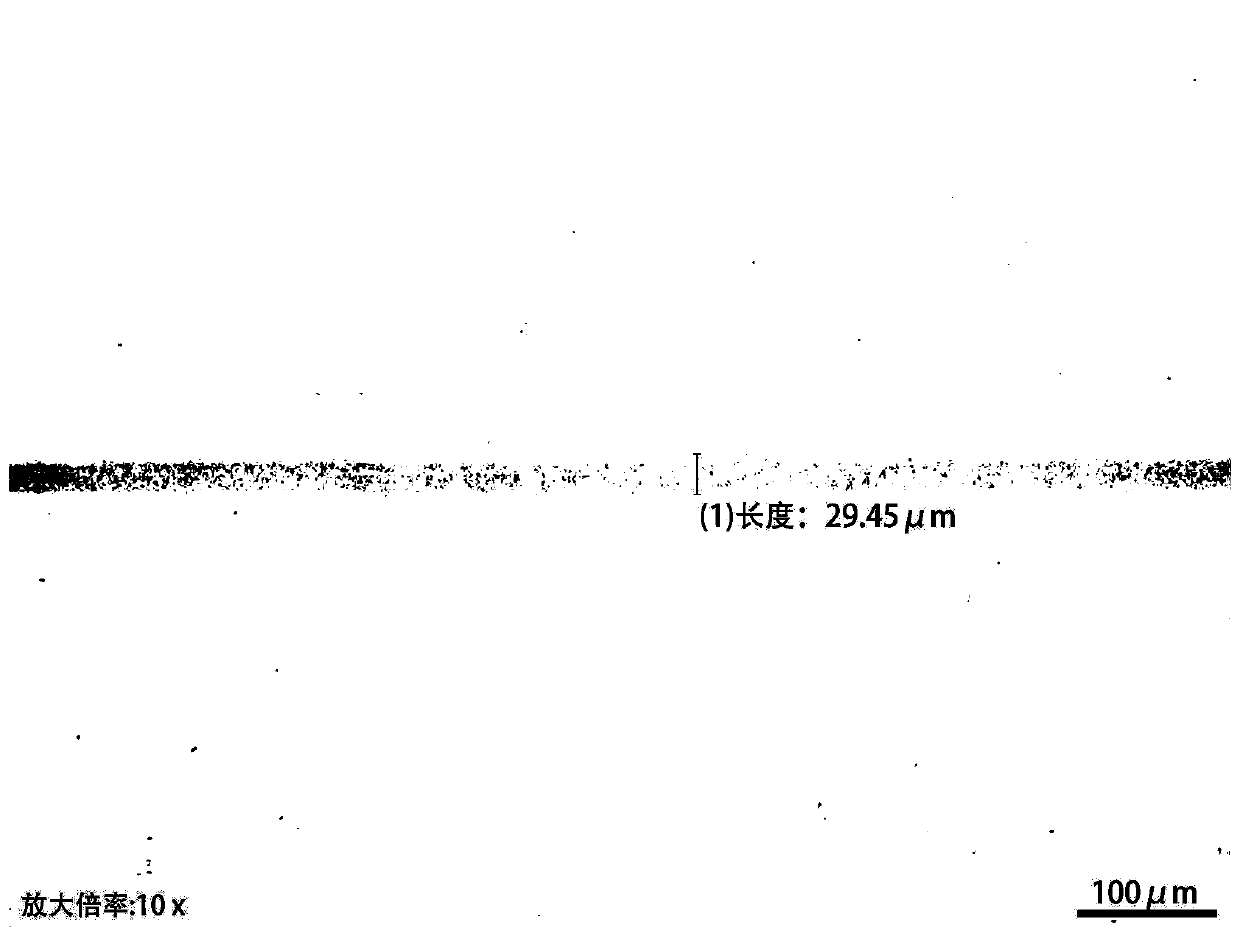

Printing raw paste capable of improving reactive printing fineness of real silk fabrics

InactiveCN101962917BImprove finenessSolve the problem of infiltrationDyeing processBiochemical engineeringReducing agent

The invention discloses a printing raw paste capable of improving reactive printing fineness of real silk fabrics, belonging to the technical field of reactive dye printing of the real silk fabrics. The printing raw paste comprises water, a waster softening agent, an antireducer, urea and an alkali agent. The printing raw paste is characterized by comprising a composite paste, wherein the mass percent of the composite paste is 4-5 percent and the mass percent of the urea is 2-5 percent. By changing the traditional sodium alga acid reactive printing system, the invention obviously improves thefineness of the reactive printing of the real silk fabrics, and thoroughly solves the problem of dispersion of the reactive printing of real silks and blending or interweaving fabrics thereof. It hasbeen found that the invention solves the technical difficulty of puzzling the industry for many years.

Owner:武丰才

A cable with multiple moisture-proof devices based on the principle of two-way glue leveling

The invention discloses a cable with multiple moisture-proof devices based on a bidirectional glue coating principle The structure of the cable comprises a cable main body, a splice groove, a coilingwheel, a fastening handle and wiring mechanisms, wherein the middle part of the cable main body is connected with the coiling wheel in a winding mode; the fastening handle is installed at the middle part of the coiling wheel in a penetrated mode; and the two wiring mechanisms are connected with two ends of the cable main body in an overlapping mode. According to the cable, when the wiring mechanisms are used for fixedly connecting the cable main body, a moisture-proof fluid is guided into an internal glue groove through an injection port, a pressurizing mechanism is controlled for driving a moisture-proof mechanism to move, and the moisture-proof fluid can be uniformly adhered to the thinned position of the cable main body and a wiring port, so that a sealing moisture-proof effect for theskin at the joint and a cable core is achieved, the problem of water infiltration is solved, secondary maintenance protection also can be carried out in later period, and the cable is more convenientto use.

Owner:泉州惠安泉创文化用品有限公司

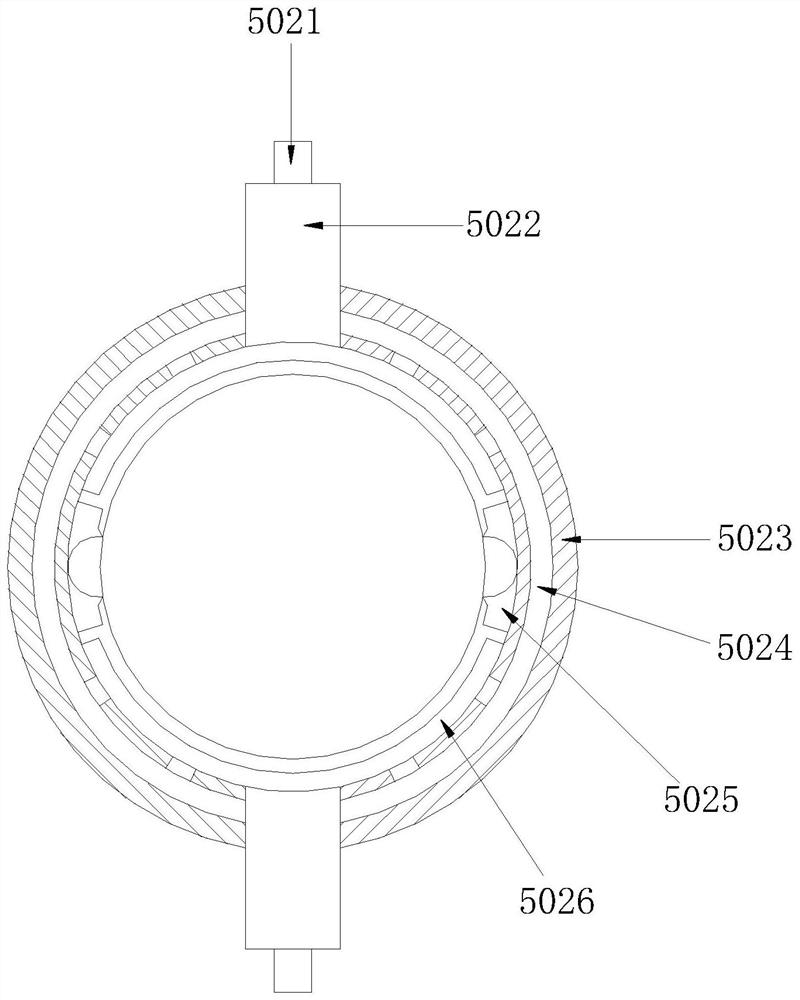

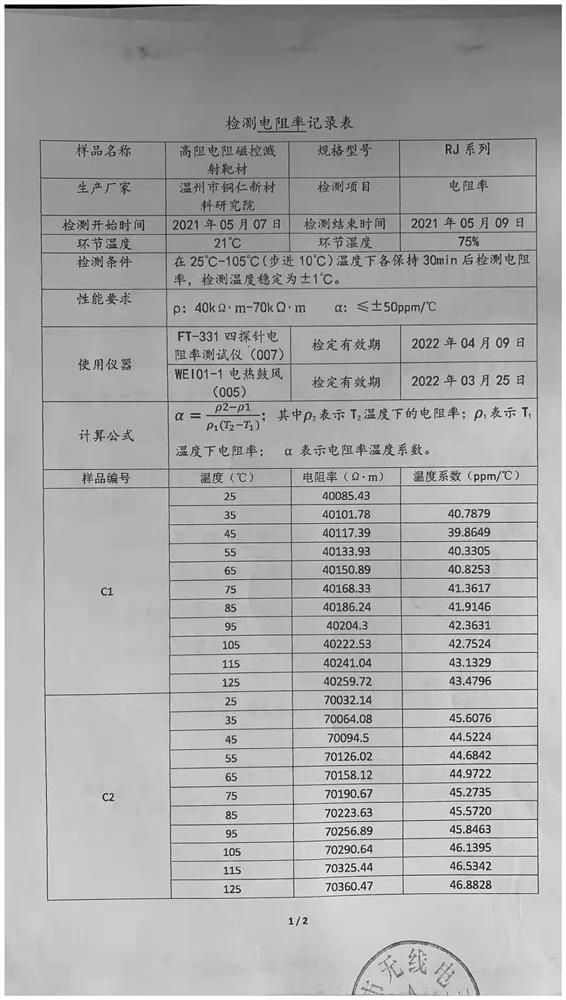

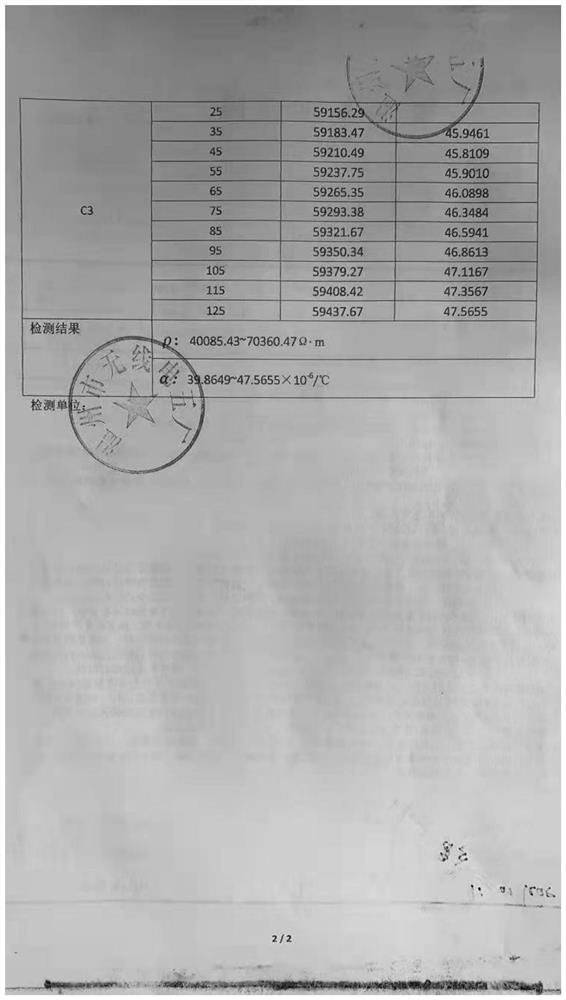

High-resistance resistor magnetron sputtering target material and preparation method thereof

InactiveCN114015921AHigh resistivityLow resistivityVacuum evaporation coatingSputtering coatingElectrical resistance and conductanceCrucible

The invention discloses a high-resistance resistor magnetron sputtering target material and a preparation method thereof. The preparation method comprises the steps of (1) conducting burdening, specifically, burdening according to the following components: 50-57 wt% of Si, 40-42 wt% of Cr and the balance of Ni; (2) placing the graphite and magnesium oxide composite crucible in vacuum induction melting for preheating with the preheating temperature being 850 DEG C, and then putting Cr and Ni into the graphite and magnesium oxide composite crucible for further heating to 1400 DEG C; (3) preheating Si to 850 DEG C, preserving heat for 2.5-4 hours, continuously putting the Si into the graphite magnesium oxide composite crucible, and continuously heating to 2100 DEG C until the Si is completely mixed and melted; (4) reducing the temperature to 1800 DEG C to 1850 DEG C; (5) conducting casting, cooling and molding; (6) conducting machining, specifically, machining the surface of the high-resistance resistor magnetron sputtering target blank to enable the surface to be flat and smooth; and (7) welding to form a finished product of the high-resistance resistor magnetron sputtering target material. The preparation method has the advantages of high resistivity, low resistivity temperature coefficient and the like.

Owner:温州市铜仁新材料研究院 +1

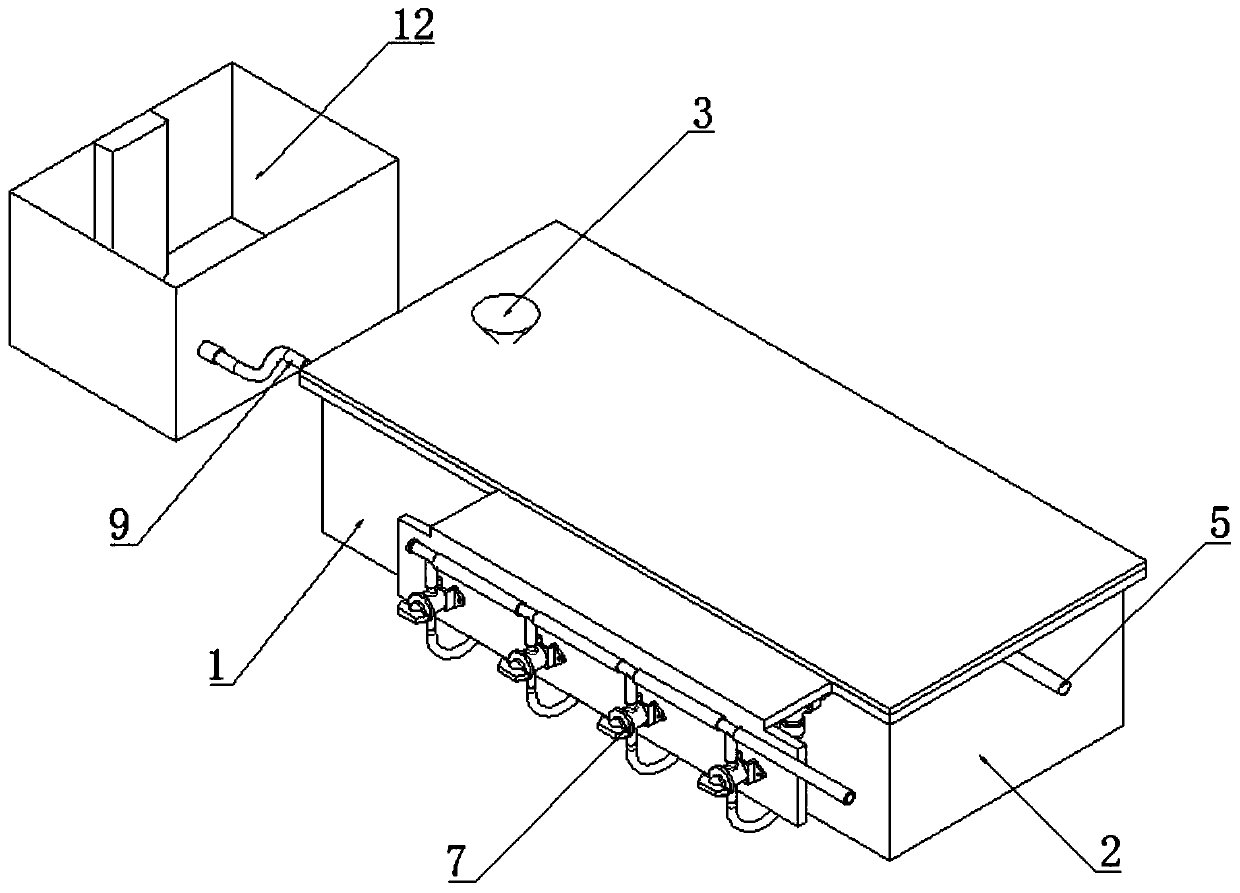

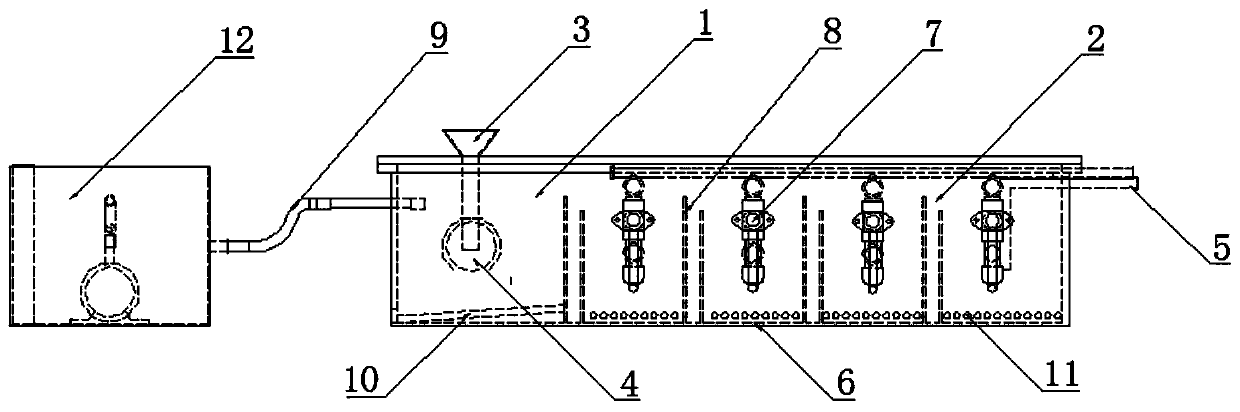

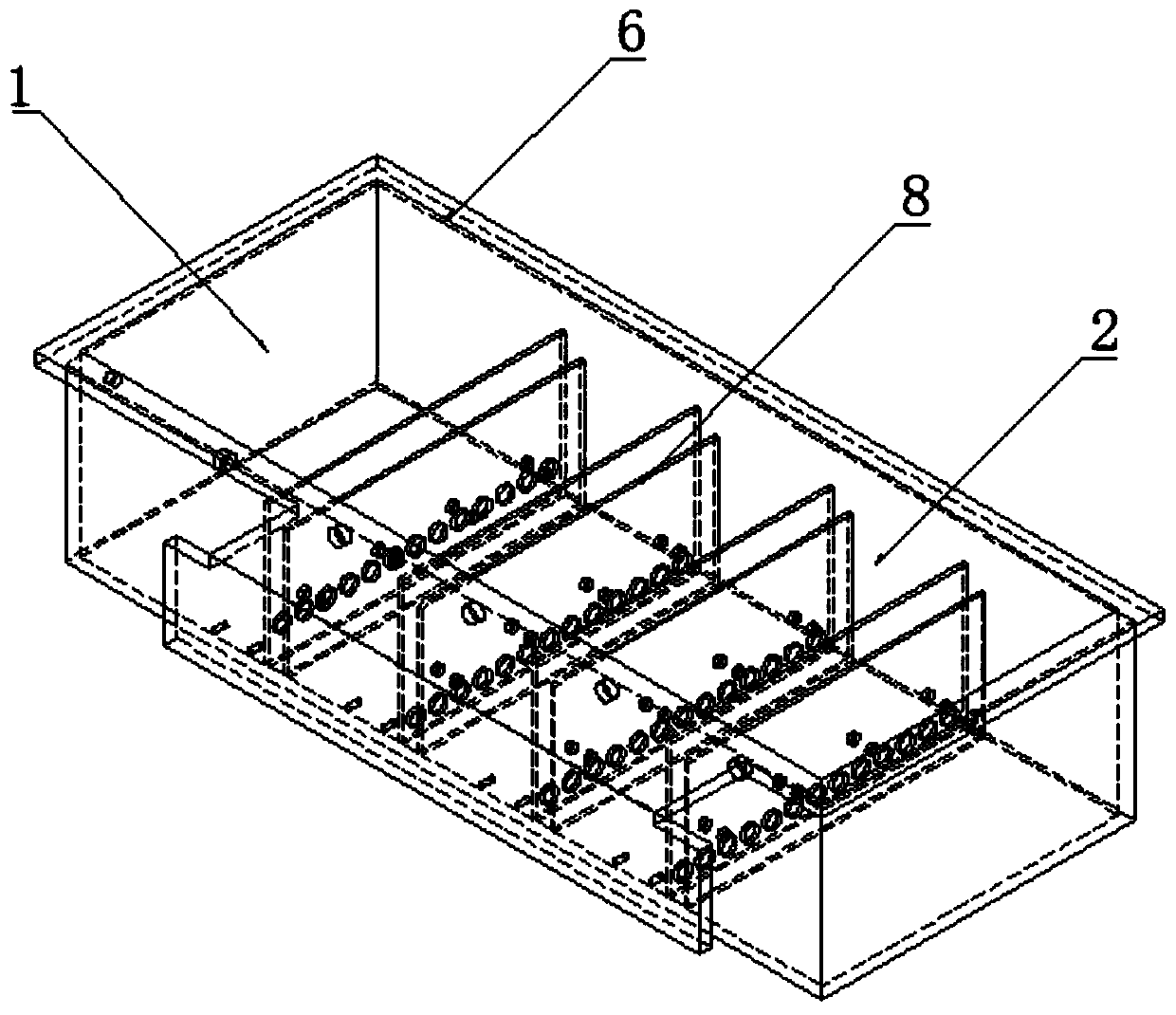

Quick anaerobic fermentation system of livestock and poultry liquid dung

PendingCN110028204AEfficient processingFully fermentedTreatment involving filtrationTreatment with anaerobic digestion processesRebarLivestock

The invention discloses a quick anaerobic fermentation system of livestock and poultry liquid dung. The system comprises a filter pool, a fermentation pool and a methane tank, wherein the filter poolis connected in parallel with the fermentation pool through a partition; the filter pool and the fermentation pool are covered with a single cover plate; the bottoms and the side faces of the filter pool and the fermentation pool are covered with black membranes; a discharge pipe is arranged at the upper end of a side wall of the fermentation pool; a plurality of parallel flushing devices are arranged in the middle of the fermentation pool; a heating coil is arranged at the bottom of the fermentation pool; the bottom of the filter pool is connected with the bottom of the fermentation pool through a deslagging pipe; an exhaust pipe is arranged at the upper part of a side wall of the filter pool; and the other end of the exhaust pipe is connected with the methane tank. The black membranes are laid; the problem of infiltration of the traditional methane system is solved; a shrinkage situation of reinforced concrete is avoided; with the adoption of the flushing devices and baffles, the problems of crusting on an upper layer of a reaction material in the anaerobic fermentation pool and depositing of a solid sand layer at the bottom of the fermentation pool are solved; the system can achieve efficient and quick treatment of livestock and poultry excrement; hydraulic retention time does not exceed 5 days; and the fermentation is thorough and high in efficiency.

Owner:中国农业大学烟台研究院

A brush type liquid guiding and infiltrating device

ActiveCN108264017BSolve problems that require a dipSolve the problem of infiltrationNanostructure manufactureMicrostructural device manufactureFiberBristle

A liquid guiding and infiltrating device utilized in an ink brush comprises : a micro-liquid guiding pipe (3) comprising an end portion surrounded at the periphery thereof by a plurality of pen bristles (2) aligned so as to be mutually level. A plurality of protruding pen bristles (1) are arranged at the innermost portion of the mutually level pen bristles (2) and at intervals around the periphery of the micro-liquid guiding pipe (3). A vertical distance from a bristle tip of the mutually level pen bristles (2) to the end portion of the micro-liquid guiding pipe (3) is 4-7 mm. A vertical distance from a bristle tip of the protruding pen bristles (1) to the bristle tip of the mutually level pen bristles (2) is 1-2 mm. The device can uniformly infiltrate a micro-volume of a liquid onto two fibers completely, and can be used to draw on a plane an effective device comprising a super-fine and super-thin film having an arbitrary length. The device is simple in the operating principle and method and easy to implement, and can effectively resolve an issue of infiltration of a micro-volume of a liquid in a micro-liquid supply system.

Owner:BEIJING SCITECH NANOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com