Packaging electrolyte injection method for improving pole piece infiltration and side deformation of pouch cell

A technology for soft packs and batteries, which is applied to secondary batteries, battery pack components, circuits, etc., which can solve problems such as increased battery interface impedance, pole piece deformation, and longer ion transmission paths, so as to reduce side force situation, improvement of safety performance, and solution to the effect of poor infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

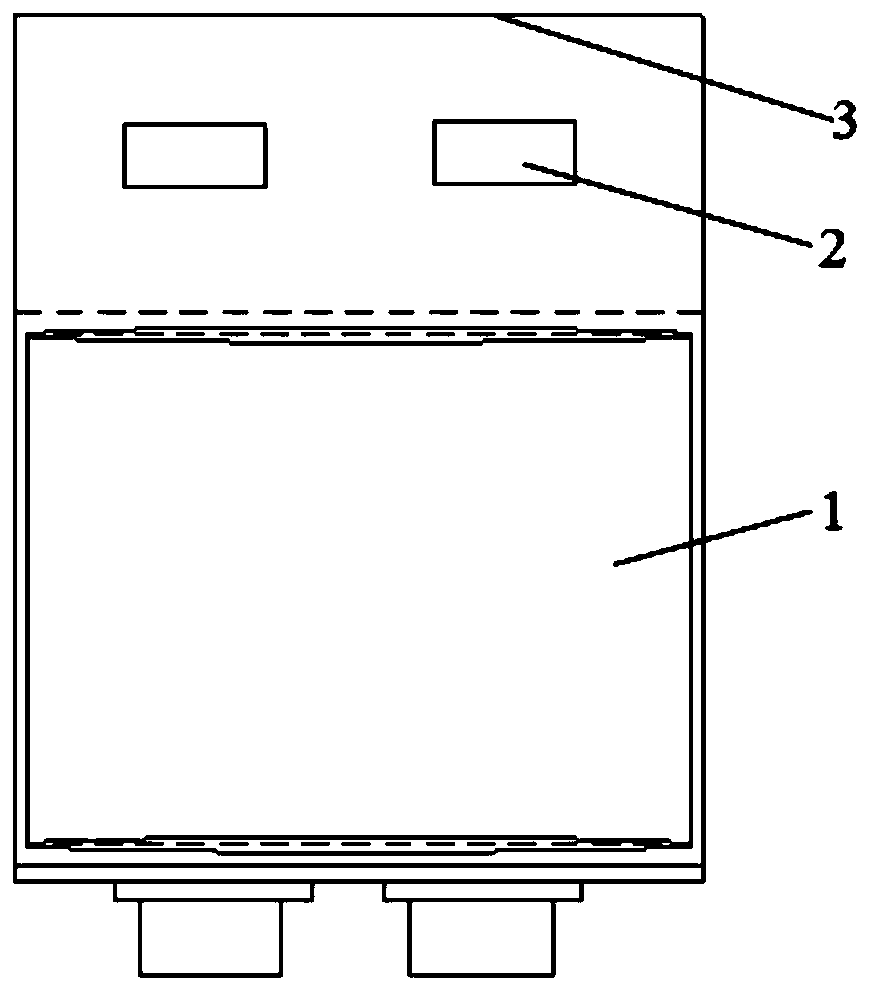

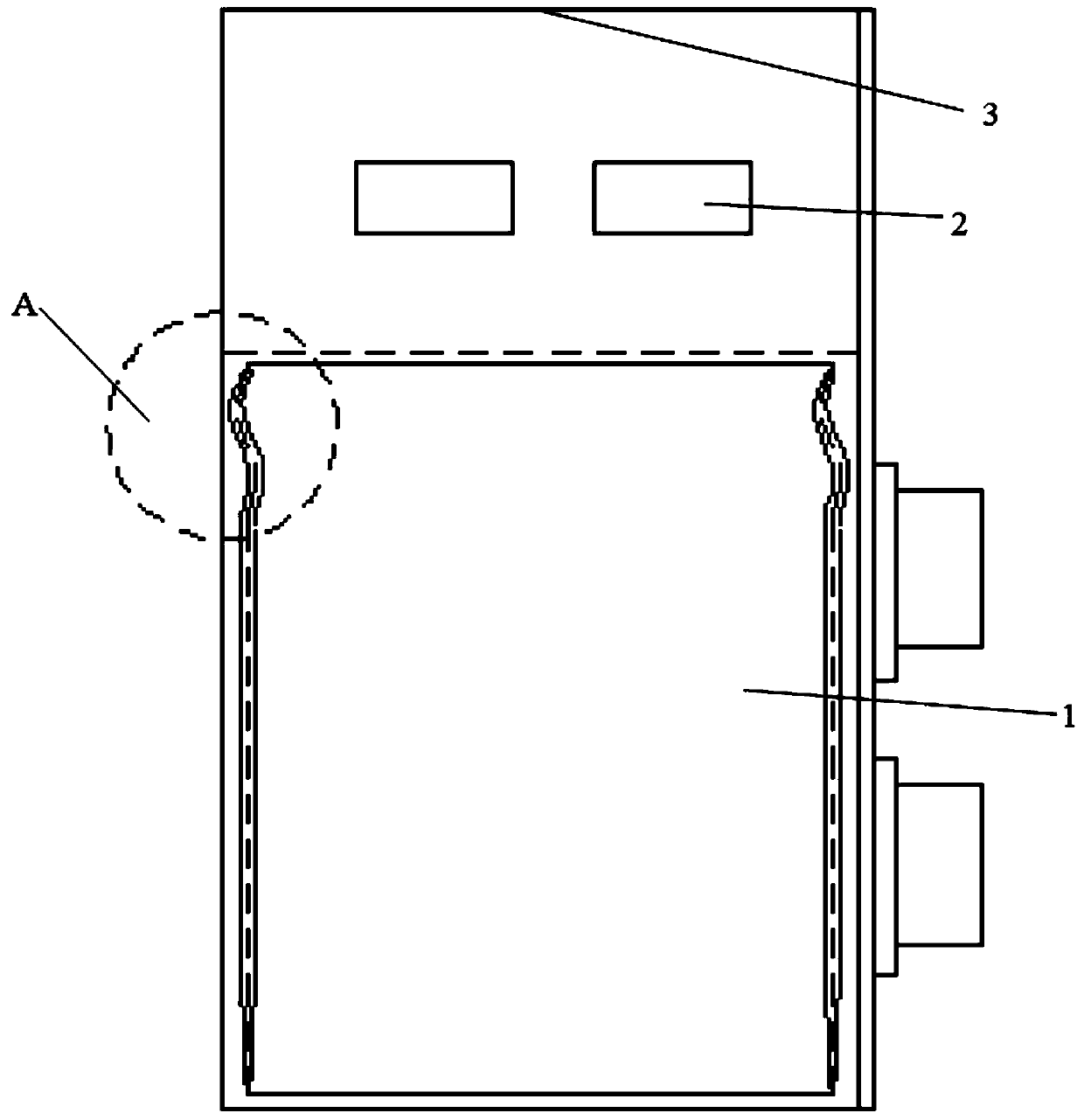

[0034] The schematic diagram of the structure of the soft package winding battery described in this embodiment is as follows figure 1 As shown, it can be seen from the figure that the soft package winding battery includes a winding core, the winding core has been top-sealed and side-sealed, and an air bag is reserved at the bottom of the winding core as a liquid injection port.

[0035] Injection method for packaging of soft-wound batteries:

[0036] (1) Use two pieces of aluminum-plastic film to seal the top and side of the core, leave an air bag at the bottom of the core as a liquid injection port, the length of the air bag is 47mm, and the model of the core is 3810980 (thickness 3.8mm , width 109mm, length 80mm).

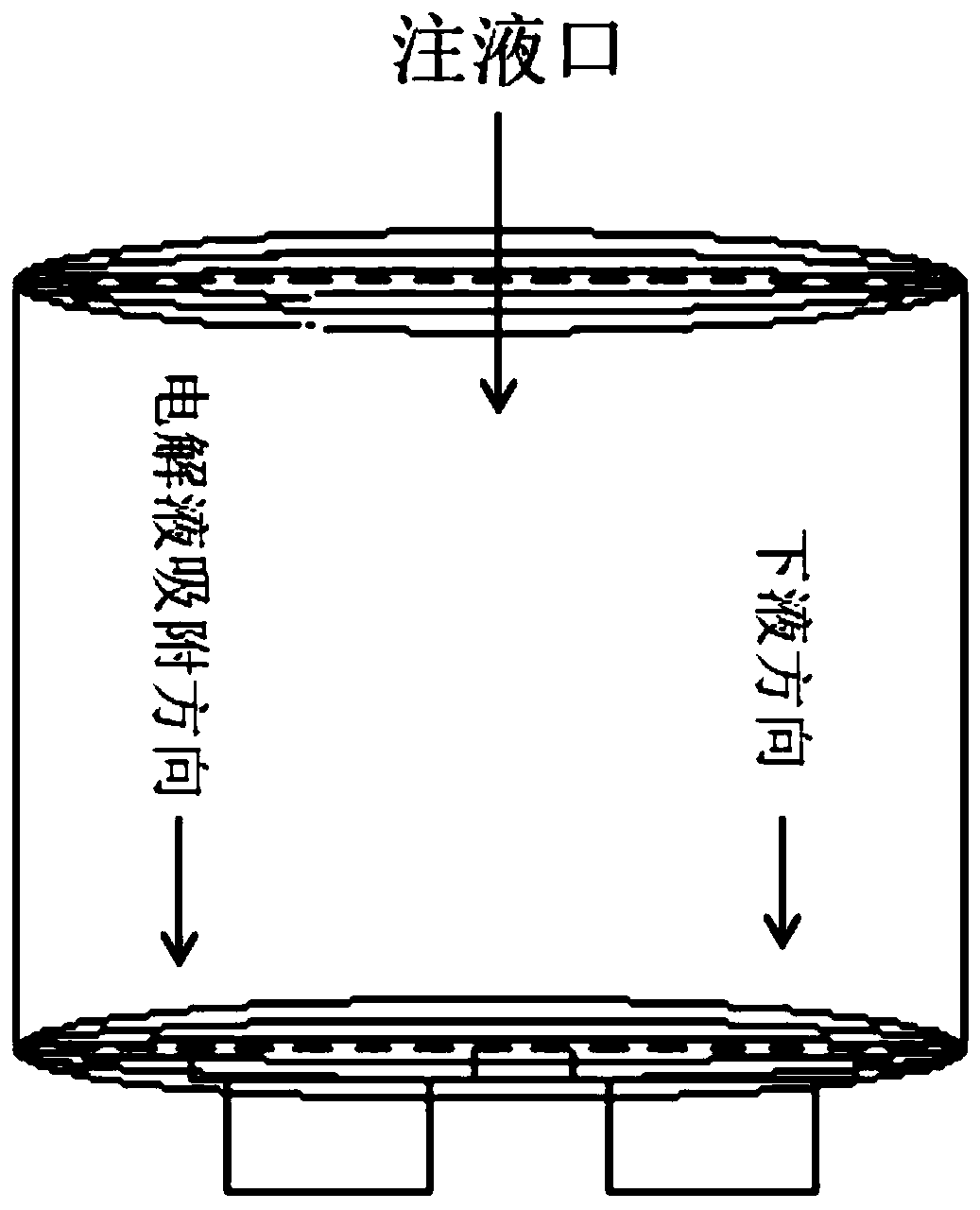

[0037] (2) Place the head of the winding core vertically downward, inject liquid from the liquid injection port at the bottom of the winding core, and then perform bottom sealing to obtain a soft-pack wound battery.

[0038] In the liquid injection process of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com