Printing raw paste capable of improving reactive printing fineness of real silk fabrics

A technology of reactive printing and fineness, applied in dyeing, textile and papermaking, etc., can solve the problems of hindering the application of reactive dye printing, and achieve the effect of solving the problem of seepage and improving the fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Original printing paste formula:

[0051]

[0052] In the above formula, sodium hexametaphosphate is the water softener; anti-staining salt S is the anti-reducing agent; baking soda is the alkali agent.

[0053] Dissolve sodium hexametaphosphate, anti-staining salt S and baking soda in warm water according to the above formula, add LYOPRINT RD-HT 01 while stirring, after stirring at high speed for 30 minutes, add urea and cold water, and stir evenly.

[0054] The production process and production process of printing on fabrics are:

[0055] Mixing→printing→drying→steaming with saturated steam at 102°C for 8 minutes→soaping→drying

[0056] The details are as follows: Add 50 grams of reactive dye Norwich Black P-GR to the original paste, stir evenly, and prepare a black color paste; add 30 grams of reactive dye Norwich Yellow P-6GS to the original paste, stir evenly, and prepare a yellow color paste. Color paste. Printed on a flat screen printing machine. Print the...

Embodiment 2

[0059] Original printing paste formula:

[0060]

[0061] In the above formula, sodium hexametaphosphate is the water softener; anti-staining salt S is the anti-reducing agent; baking soda is the alkali agent.

[0062] Dissolve sodium hexametaphosphate, anti-staining salt S, and baking soda in warm water according to the above formula, add LYOPRINT RD-HT 01 while stirring, stir at high speed for 30 minutes, add urea and cold water, and stir evenly.

[0063] The production process and production process of printing on the fabric are the same as in Example 1.

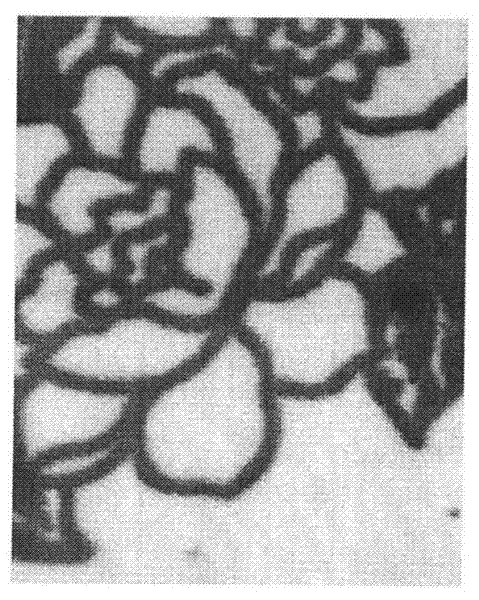

[0064] Figure 5 For the original paste printing effect of embodiment 2, by Figure 5 and image 3 By contrast, it can be found that the fineness of the original paste of sodium alginate in Example 2 is improved compared with the original paste of sodium alginate in the prior art. And by adding Figure 5 and Figure 4 By comparison, it can be found that the fineness of Example 2 is slightly improved compared with...

Embodiment 3

[0066] Original printing paste formula:

[0067]

[0068] In the above formula, sodium hexametaphosphate is the water softener; anti-staining salt S is the anti-reducing agent; baking soda is the alkali agent.

[0069] Dissolve sodium hexametaphosphate, anti-staining salt S, and baking soda in warm water according to the above formula, add LYOPRINT RD-HT 01 while stirring, stir at high speed for 30 minutes, add urea and cold water, and stir evenly.

[0070] The production process and production process of printing on the fabric are the same as in Example 1.

[0071] Figure 6 For embodiment 3 original paste printing effect, by Figure 6 and image 3 By contrast, it can be found that the fineness of the original paste of Example 3 is improved compared with the original paste of sodium alginate. And by adding Figure 6 and Figure 5 By comparison, it can be found that the fineness of Example 3 is slightly improved compared with that of Example 2, that is, the amount of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com