Quick anaerobic fermentation system of livestock and poultry liquid dung

An anaerobic fermentation, livestock and poultry manure technology, applied in anaerobic digestion treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Complete fermentation, efficient and fast processing, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

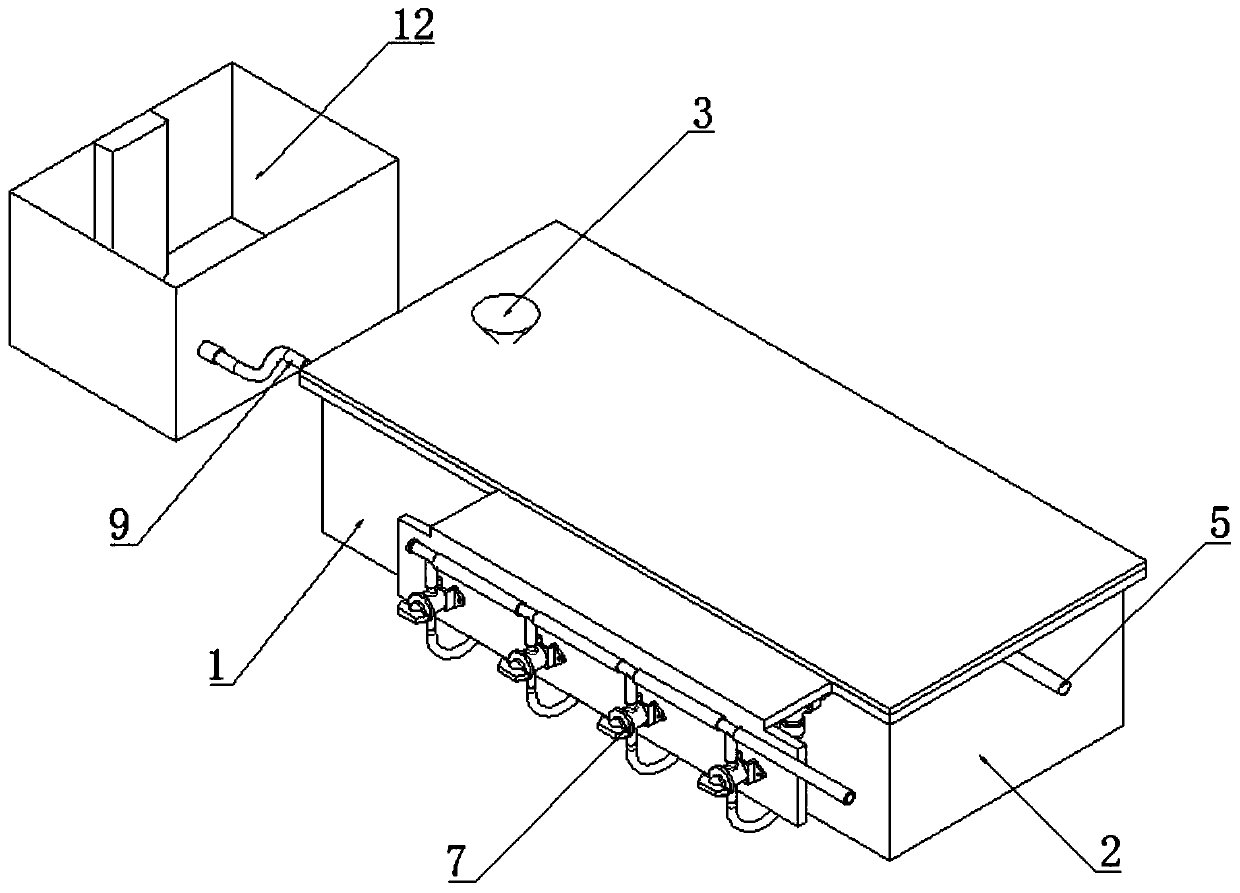

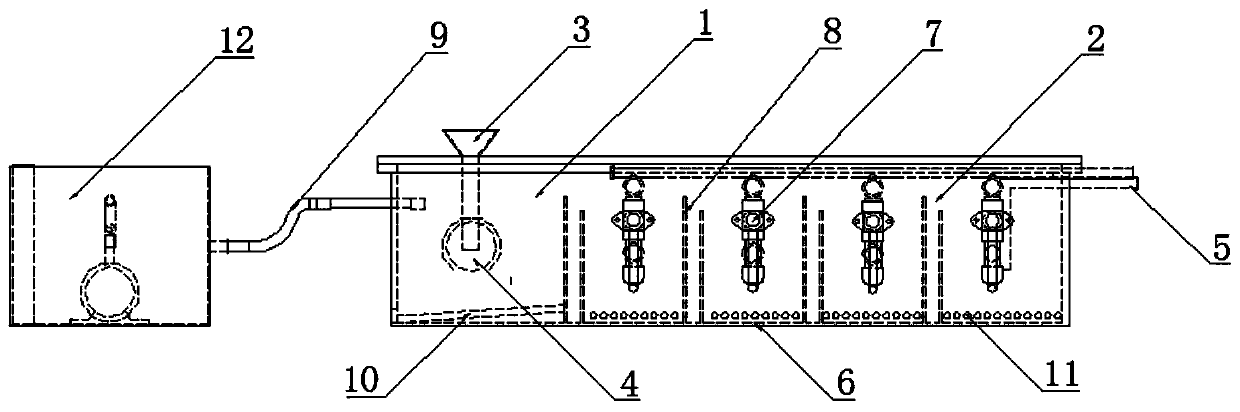

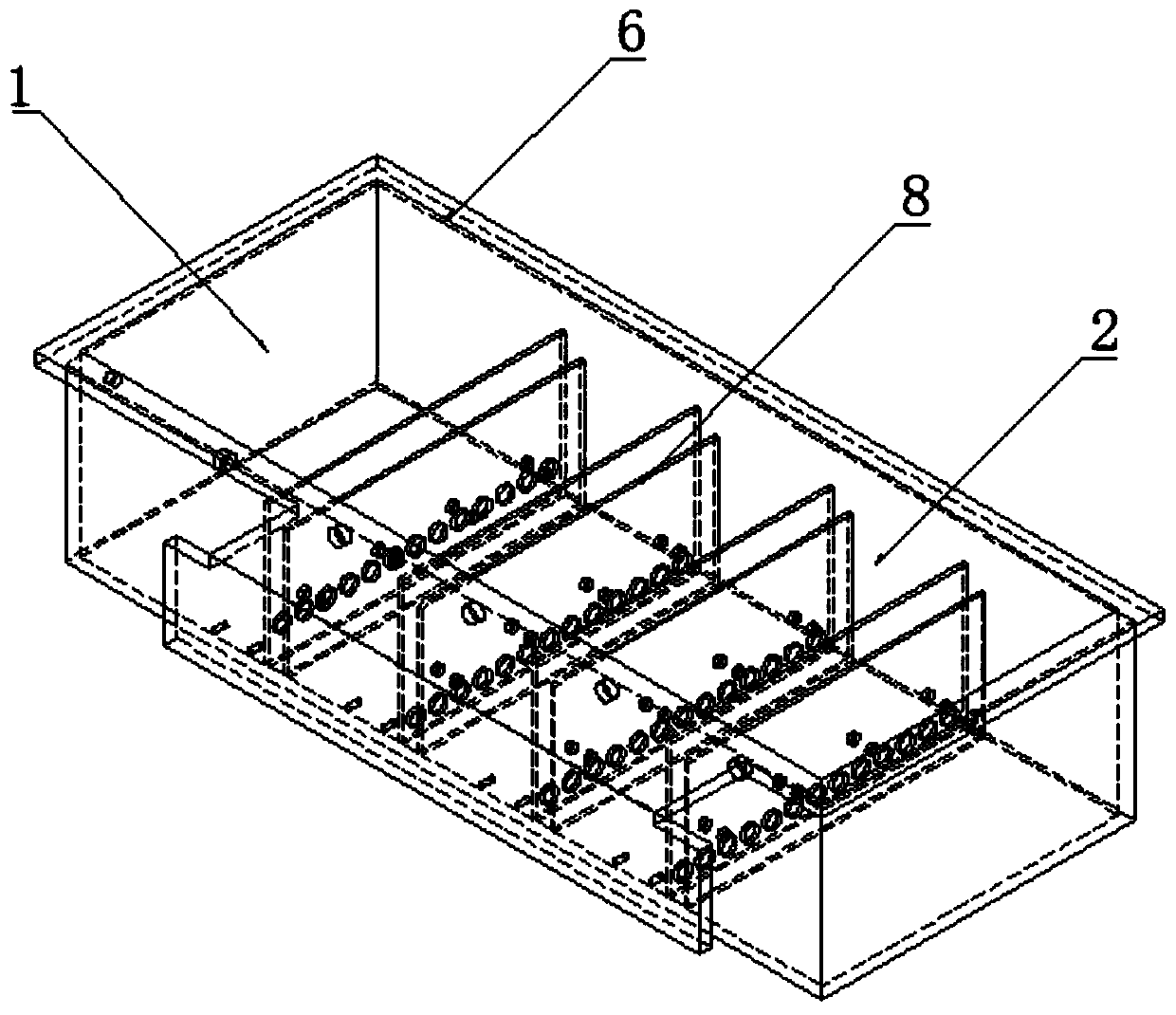

[0014] A rapid anaerobic fermentation system for livestock and poultry manure, comprising a filter tank 1, a fermentation tank 2 and a biogas tank 12, the filter tank 1 and the fermentation tank 2 are connected in parallel and connected by a partition, and the filter tank 1 and the fermentation tank 2 are connected by the same cover plate Covering, the cover plate is provided with a feed pipe 3 in the filter tank 1, a submersible pump 4 is arranged in the filter tank 1, and the bottom and sides of the filter tank 1 and the fermentation tank 2 are covered with a black film 6; the side wall of the fermentation tank 2 The upper end is provided with a discharge pipe 5, and the middle part is provided with 6 parallel flushing devices 7, each flushing device 7 includes a high-pressure pump and a ppr pipe connected to it, the ppr pipe extends into the fermentation tank 2, and the flushing device 7 There is a set of baffles 8, the height of the baffles 8 is lower than the side wall of ...

Embodiment 2

[0016] A rapid anaerobic fermentation system for livestock and poultry manure, comprising a filter tank 1, a fermentation tank 2 and a biogas tank 12, the filter tank 1 and the fermentation tank 2 are connected in parallel and connected by a partition, and the filter tank 1 and the fermentation tank 2 are connected by the same cover plate Covering, the cover plate is provided with a feed pipe 3 in the filter tank 1, and a submersible pump 4 is arranged in the filter tank 1, and the bottom and sides of the filter tank 1 and the fermentation tank 2 are covered with a black film 6; the side wall of the fermentation tank 2 The upper end is provided with a discharge pipe 5, and the middle part is provided with 4 parallel flushing devices 7, each flushing device 7 includes a high-pressure pump and a ppr pipe connected thereto, the ppr pipe extends into the fermentation tank 2, and the flushing device 7 is There is a set of baffles 8, the height of which is lower than the side wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com