High-resistance resistor magnetron sputtering target material and preparation method thereof

A technology of magnetron sputtering and resistance, applied in the field of material science, can solve problems such as large temperature coefficient and voltage coefficient, poor moisture resistance stability, unsatisfactory voltage coefficient and current noise, etc., and achieve small temperature coefficient of resistivity and high bonding strength Good effect of prevention and electrical performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Such as figure 1 As shown, in the embodiment of the present invention, the following steps are included:

[0025] (1) batching, batching is carried out according to the following components: Si 50wt%, Cr 40wt%, Ni remainder;

[0026] (2) Place the graphite magnesia composite crucible in vacuum induction melting for preheating, the preheating temperature is 850°C, then put Cr and Ni into the graphite magnesia composite crucible for further heating, and heat it to 1400°C to make it preliminary melt;

[0027] (3) Preheat Si to 850°C first, then keep it warm for 2.5 hours, then continue to put it into the graphite magnesium oxide composite crucible, and then continue to heat up to 2100°C until it is completely mixed and melted. During this process, Cr and Si are melted CrSi is partially formed in the liquid 2 Compounded components;

[0028] (4) Cool down the melt to 1800-1850°C, the cooling time is 2 hours, and continue to form more CrSi 2 Compounded components;

[00...

Embodiment 2

[0034] In the embodiment of the present invention, the following steps are included:

[0035] (1) batching, batching is carried out according to the following components: Si 57wt%, Cr 42wt%, Ni remainder;

[0036] (2) Place the graphite magnesia composite crucible in vacuum induction melting for preheating, the preheating temperature is 850°C, then put Cr and Ni into the graphite magnesia composite crucible for further heating, and heat it to 1400°C to make it preliminary melt;

[0037] (3) Preheat Si to 850°C first, then keep it warm for 4 hours, then continue to put it into the graphite magnesium oxide composite crucible, and then continue to heat up to 2100°C until it is completely mixed and melted. During this process, Cr and Si are melted CrSi is partially formed in the liquid system 2 Compounded components;

[0038] (4) Cool down the melt to 1800-1850°C, the cooling time is 4 hours, and continue to form more CrSi 2 Compounded components;

[0039] (5) Casting and coo...

Embodiment 3

[0044] In the embodiment of the present invention, the following steps are included:

[0045] (1) batching, batching is carried out according to the following components: Si 54wt%, Cr 41wt%, Ni remainder;

[0046](2) Place the graphite magnesia composite crucible in vacuum induction melting for preheating, the preheating temperature is 850°C, then put Cr and Ni into the graphite magnesia composite crucible for further heating, and heat it to 1400°C to make it preliminary melt;

[0047] (3) Preheat Si to 850°C first, then keep it warm for 3 hours, then continue to put it into the graphite magnesium oxide composite crucible, and then continue to heat up to 2100°C until it is completely mixed and melted. During this process, Cr and Si are melted CrSi is partially formed in the liquid system 2 Compounded components;

[0048] (4) Cool down the melt to 1800-1850°C for 3 hours to continue to form more CrSi 2 Compounded components;

[0049] (5) Casting and cooling molding, the me...

PUM

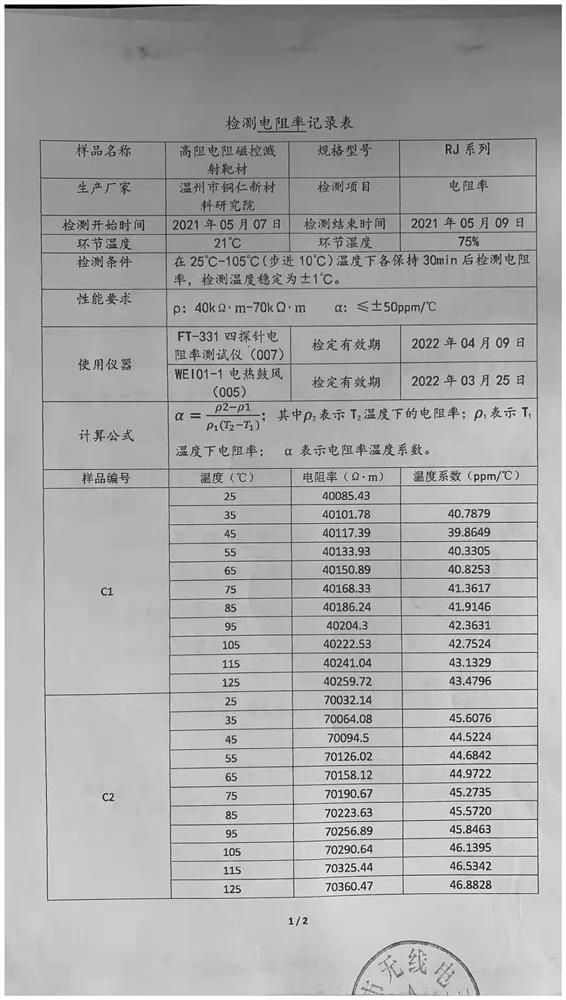

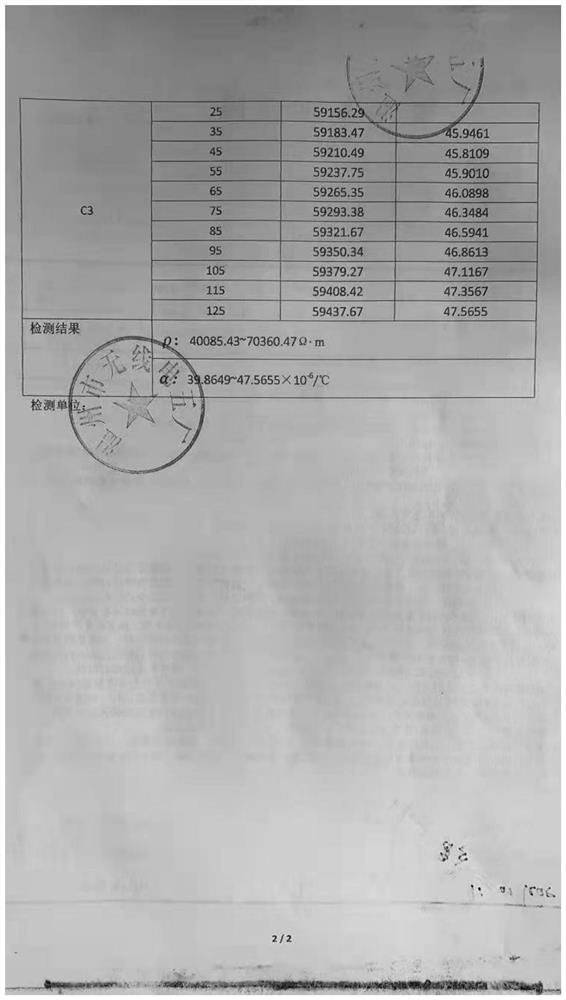

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com