A flexible carbon castable for furnace bottom screed

A technology of leveling layer and castable, applied in the field of materials, can solve the problems of unsuitable leveling, low thermal conductivity, impact on the service life of blast furnace, etc., and achieve the effect of easy grinding and leveling, simple construction operation and saving construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

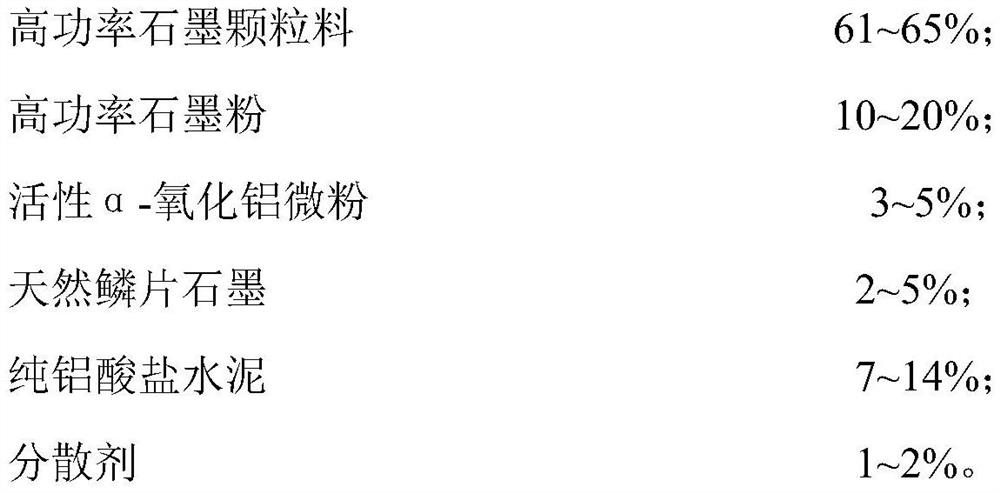

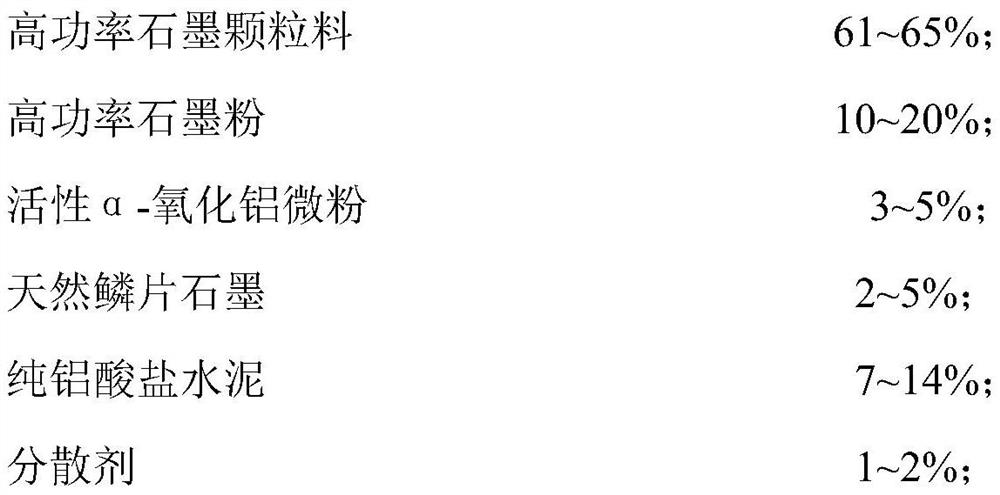

Method used

Image

Examples

Embodiment 1

[0024] Put 63.5% of high-power graphite granular material, 13% of high-power graphite powder, 4% of natural flake graphite, 15% of pure aluminate cement, 3% of active α-alumina micropowder, and 1.5% of dispersant into the mixer by mass percentage Stir evenly, add an appropriate amount of water and stir to form a pourable state, then place it in a mold for vibration molding, and demould after the sample is hardened.

[0025] After demoulding, put the test piece in an oven at 110°C to dry for 24 hours, then take it out to test its thermal conductivity.

[0026] Make a mold with a steel plate, the specific size is that the bottom plate is a square with a side length of 1m, the side wall size is a side length of 1m, and a height of 0.1m. After the production is completed, the top surface of the mold side wall is washed and polished, and the horizontal accuracy reaches ≤1.6um.

[0027] Weigh 200kg of powder according to the ratio of this example, add an appropriate amount of water...

Embodiment 2

[0030] Put 65% of high-power graphite granules, 13% of high-power graphite powder, 3% of natural flake graphite, 13% of pure aluminate cement, 4% of active α-alumina micropowder, and 2% of dispersant into the mixer and stir evenly, adding Stir an appropriate amount of water into a pourable state, place it in a mold for vibration molding, and release the mold after the sample hardens.

[0031] After demoulding, put the test piece in an oven at 110°C to dry for 24 hours, then take it out to test its thermal conductivity.

[0032] Make a mold with a steel plate, the specific size is that the bottom plate is a square with a side length of 1m, the side wall size is a side length of 1m, and a height of 0.1m. After the production is completed, the top surface of the mold side wall is washed and polished, and the horizontal accuracy reaches ≤1.6um.

[0033] Weigh 200kg of powder according to the material ratio of this example, add an appropriate amount of water and stir evenly, pour ...

Embodiment 3

[0036] Put 62% of high-power graphite granules, 17% of high-power graphite powder, 4% of natural flake graphite, 12% of pure aluminate cement, 3% of active α-alumina micropowder, and 2% of dispersant into a mixer and stir evenly, adding Stir an appropriate amount of water into a pourable state, place it in a mold for vibration molding, and release the mold after the sample hardens.

[0037] After demoulding, put the test piece in an oven at 110°C to dry for 24 hours, then take it out to test its thermal conductivity.

[0038] Make a mold with a steel plate, the specific size is that the bottom plate is a square with a side length of 1m, the side wall size is a side length of 1m, and a height of 0.1m. After the production is completed, the top surface of the mold side wall is washed and polished, and the horizontal accuracy reaches ≤1.6um.

[0039] Weigh 200kg of powder according to the material ratio of this example, add an appropriate amount of water and stir evenly, pour th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com