Preparation method of bionic shell structure ceramic and metal composite material

A technology of metal composite materials and shells, which is applied in the field of composite materials, can solve the problems of not being too thick, reducing, and not being able to replicate the fine structure of natural materials, and achieve the effects of improving high temperature performance, increasing strength and toughness, and good synergistic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

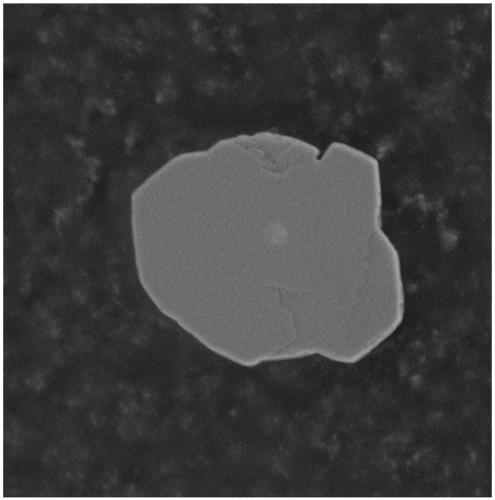

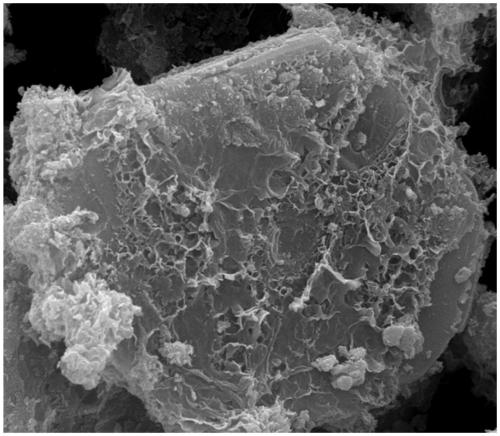

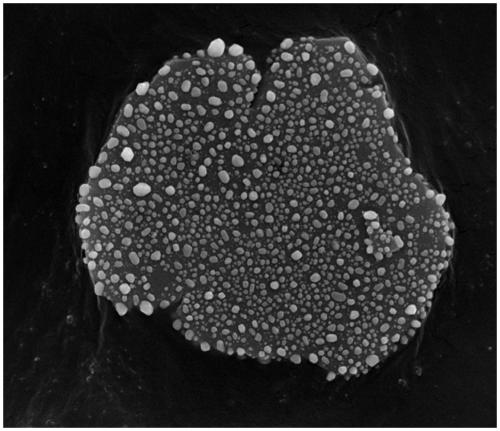

[0042] like Figure 1-Figure 8 A preparation method of a bionic shell structure ceramic and metal composite material shown, comprising the following steps:

[0043] Step 1, preparing ammonium bicarbonate solution and nickel sulfate solution respectively for subsequent use;

[0044] Step 2: Add 500ml of deionized water and 20g of alumina flakes into a 1L beaker, ultrasonically clean for 20 minutes, then let stand for 30 minutes, remove the supernatant, then add 500ml of deionized water, continue ultrasonic cleaning, repeat the above cleaning process 3 times before adding Deionized water to 500ml, add a magnetic stirrer, place on a magnetic stirrer and continue stirring;

[0045] Step 3. Dissolve the ammonium bicarbonate prepared in step 1 and transfer the nickel sulfate solution to a 500ml separatory funnel, drop the aluminum oxide f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com