Steel for oil casing pipe, oil casing pipe and manufacturing methods thereof

A technology for oil casing and its manufacturing method, which is applied in the field of ultra-high-strength and high-toughness oil casing and its manufacturing, which can solve the problems of reducing toughness, etc., and achieve the effect of improving strength and toughness, high strength and good toughness, and low alloy cost

Inactive Publication Date: 2012-04-11

BAOSHAN IRON & STEEL CO LTD

View PDF5 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The design components mentioned in this patent are characterized by high carbon and high silicon. These two components can signific

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

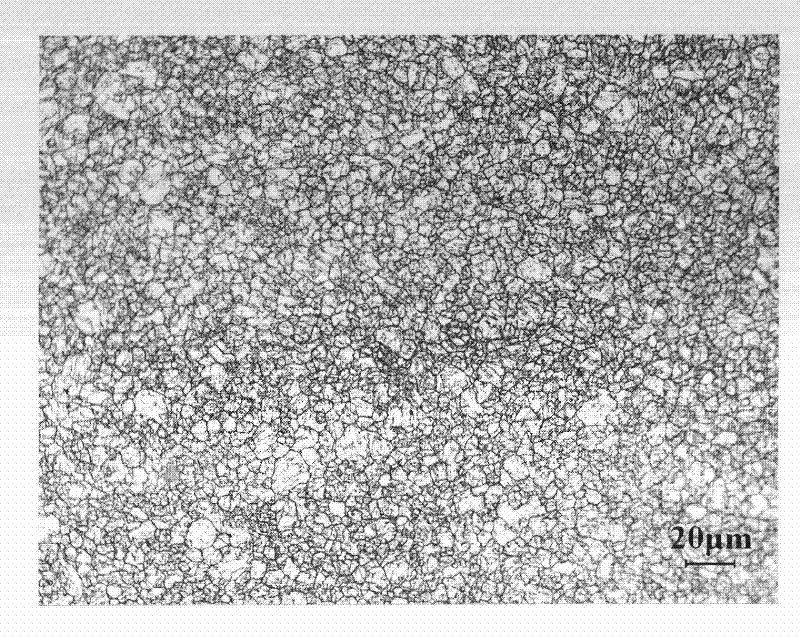

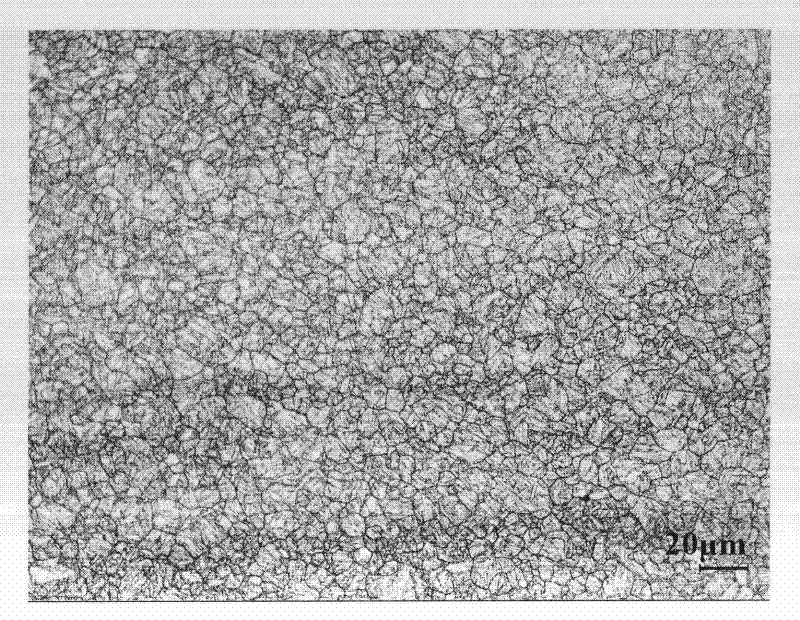

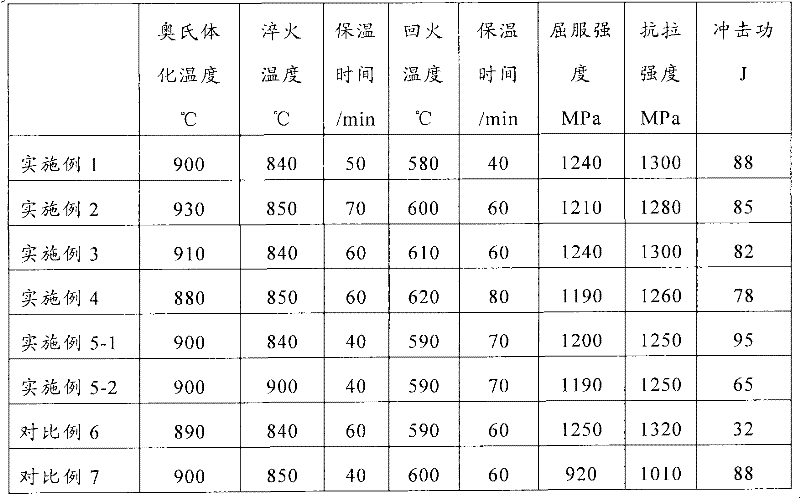

The invention relates to steel for an oil casing pipe. The steel comprises the following chemical components by weight percent: 0.25-0.35% of C, 0.1-0.6% of Si, 0.8-1.5% of Mn, not more than 0.015% of P, not more than 0.003% of S, 1-1.5% of Cr, 1-1.5% of Mo, 0.05-0.12% of V, 0.02-0.04% of Nb, 0.01-0.04% of Ti, 0.01-0.08% of Al, 0.0005-0.005% of Ca and the balance of Fe and inevitable impurities. A steel pipe which is obtained through smelting, continuously casting, perforating and hot-rolling by using the components is insulated for 30-60 minutes at an austenitizing temperature of 880-930 DEG C, is cooled with air to 830-850 DEG C after discharged and undergoes water quenching, undergoes high-temperature tempering at 580-620 DEG C and is insulated for 40-80 minutes to obtain the oil casing pipe. The steel grade of the obtained oil casing pipe can be above 160ksi and the impact energy is above 70J. The obtained oil casing pipe has high strength and toughness.

Description

technical field [0001] The invention relates to an ultra-high-strength and high-toughness oil casing and a manufacturing method thereof, in particular to an ultra-high-strength and high-toughness oil casing above 160 ksi and a manufacturing method thereof. Background technique [0002] Casing is an indispensable special pipe suitable for oil and gas well completion operations such as deep wells and ultra-deep wells. Guarantee the function of drilling in various complex formations. In the next 10 years, the western oil fields will be one of the focuses of China's oil development. Western oilfield resources are buried extremely deep, with complex formations, usually several thousand meters in length, and the deepest well currently exceeds 8,000m. With the advancement of drilling technology, the pressure on bit and rotational speed have increased significantly, enhanced drilling technology has become more and more popular, and the production conditions such as thermal recover...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/28C21D8/10E21B17/01

Inventor 董晓明田青超

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com