High-conductivity intermediate strength aluminum alloy and preparation method thereof

A medium-strength aluminum alloy, high-conductivity technology, applied in conductive materials, conductive materials, metal/alloy conductors, etc., can solve the problem of high price of Sc, achieve good comprehensive mechanical properties, improve strength and fracture toughness, and improve strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

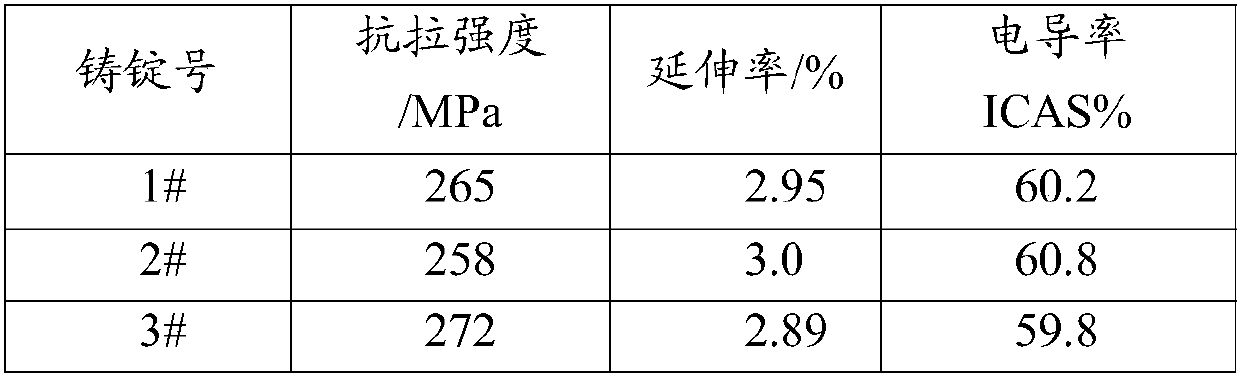

[0020] Table 1 shows the components and weight percentages of high-conductivity and medium-strength aluminum alloys.

[0021] Table 1

[0022] Ingot No.

Mg

Zn

Cu

Zr

Er

B

Fe

Si

Al

1#

0.38

0.90

0.30

0.45

0.25

0.03

<0.15

<0.10

margin

2#

0.55

0.7

0.35

0.5

0.225

0.05

<0.15

<0.10

margin

3#

0.63

0.60

0.24

0.35

0.30

0.06

<0.15

<0.10

margin

[0023] The preparation process is:

[0024] (1) Carry out raw material batching according to component composition and weight percent shown in Table 1;

[0025] (2) Melting: Under the temperature condition of 760°C, first melt the high-purity aluminum ingot, then add Al-Zr, Al-Er, Al-Cu, Al-B master alloys, after the master alloys are melted, add pure zinc, Pure magnesium and covering agent;

[0026] (3) Refining: add hexachloroethane to the molten alloy for degassing treatment, and fully stir. Durin...

Embodiment 2

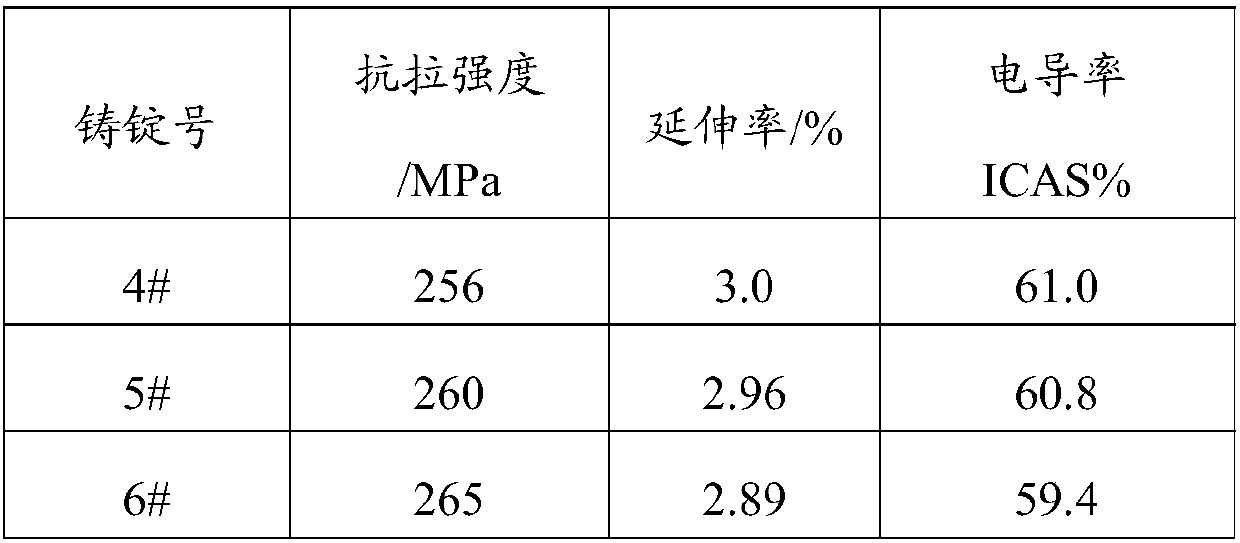

[0037] Table 3 shows the components and weight percentages of high-conductivity and medium-strength aluminum alloys.

[0038] table 3

[0039] Ingot No.

Mg

Zn

Cu

Zr

Er

B

Fe

Si

Al

4#

0.46

0.85

0.30

0.55

0.25

0.03

<0.15

<0.10

margin

5#

0.38

0.92

0.25

0.46

0.225

0.05

<0.15

<0.10

margin

6#

0.60

0.70

0.35

0.35

0.25

0.06

<0.15

<0.10

margin

[0040] The preparation process is:

[0041] (1) Carry out raw material batching according to component composition and weight percent shown in Table 3;

[0042] (2) Melting: Under the temperature condition of 750°C, first melt high-purity aluminum ingots, then add Al-Zr, Al-Er, Al-Cu, Al-B master alloys, and add pure zinc, Al-B after the master alloys are melted Pure magnesium and covering agent;

[0043] (3) Refining: Add hexachloroethane to the molten alloy for degassing treatment, and fully stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com