Pen type liquid guiding and infiltration device

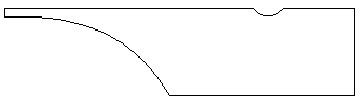

An infiltration device, pen-type technology, applied in the direction of the pen tip and the ink pen with an ink storage tube in the pen, printing, etc., can solve the problem of inability to draw continuous lines on a hard base.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

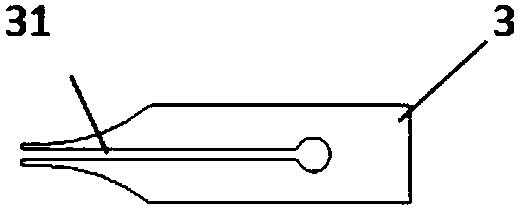

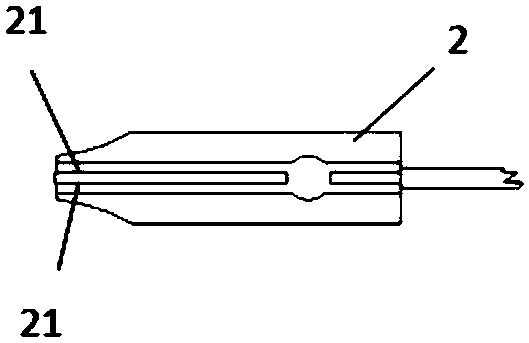

[0041] Design two circular grooves along the outer periphery of the inner tongue infusion tube of the pen. The nib ball of the hoop-type fountain pen head is fixed at the liquid inlet end of the water supply pipe inside the liquid outlet end. The opening of the side wall of the arc-shaped groove faces the liquid guide groove on the inner wall of the round hoop type pen tip. Select two rabbit hair fiber needles and place them in the two grooves of the inner tongue infusion tube of the pen respectively, and the distance between the head of the fiber hair needle and the head of the round hoop pen is 0.8mm. Inject a certain concentration of paint into the micro-liquid supply instrument, and draw an ultra-fine ultra-thin film with a width of 15.84 μm and a thickness of Figure 8 .

Embodiment 2

[0043]Design two circular grooves along the outer circumference of the inner tongue infusion tube of the pen. The nib ball of the hoop-type fountain pen head is fixed at the liquid inlet end of the water supply pipe inside the liquid outlet end. The opening of the side wall of the arc-shaped groove faces the liquid guide groove on the inner wall of the round hoop type pen tip. Select two stone badger hair needles and place them in the two grooves of the inner tongue infusion tube of the pen respectively. The head of the fiber hair needle is 1mm away from the head of the round hoop pen. A certain concentration of paint was injected into the micro-liquid supply instrument. Under the condition that the liquid supply rate was 1 μL / min, the tips of the two stone badger hair needles were in contact with the substrate, and the angle was 30°, the ultra-thin coating with a width of 35.45 μm and a thickness of Figure 9 .

Embodiment 3

[0045] Design two circular grooves along the outer circumference of the inner tongue infusion tube of the pen. The nib ball of the hoop-type fountain pen head is fixed at the liquid inlet end of the water supply pipe inside the liquid outlet end. The opening of the side wall of the arc-shaped groove faces the liquid guide groove on the inner wall of the round hoop type pen tip. Select two polymer fiber hair needles and place them in the two grooves of the inner tongue infusion tube of the pen respectively, and the distance between the head of the fiber hair needle and the head of the round hoop pen is 1.2mm. A certain concentration of paint is injected into the micro-liquid liquid supply instrument. Under the condition that the liquid supply speed is 1 μL / min, the tips of the two polymer hairs are in contact with the substrate, and the angle is 90°, a superplastic with a width of 49.02 μm and a thickness of Figure 10 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com