Processing technology for digital printing of silk fabric

A digital printing and processing technology, applied in printing, printing devices, dyeing methods, etc., can solve the problems of poor pattern definition, low color yield, dye bleeding, etc., to improve precision, increase contact area, increase The effect of large bearing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

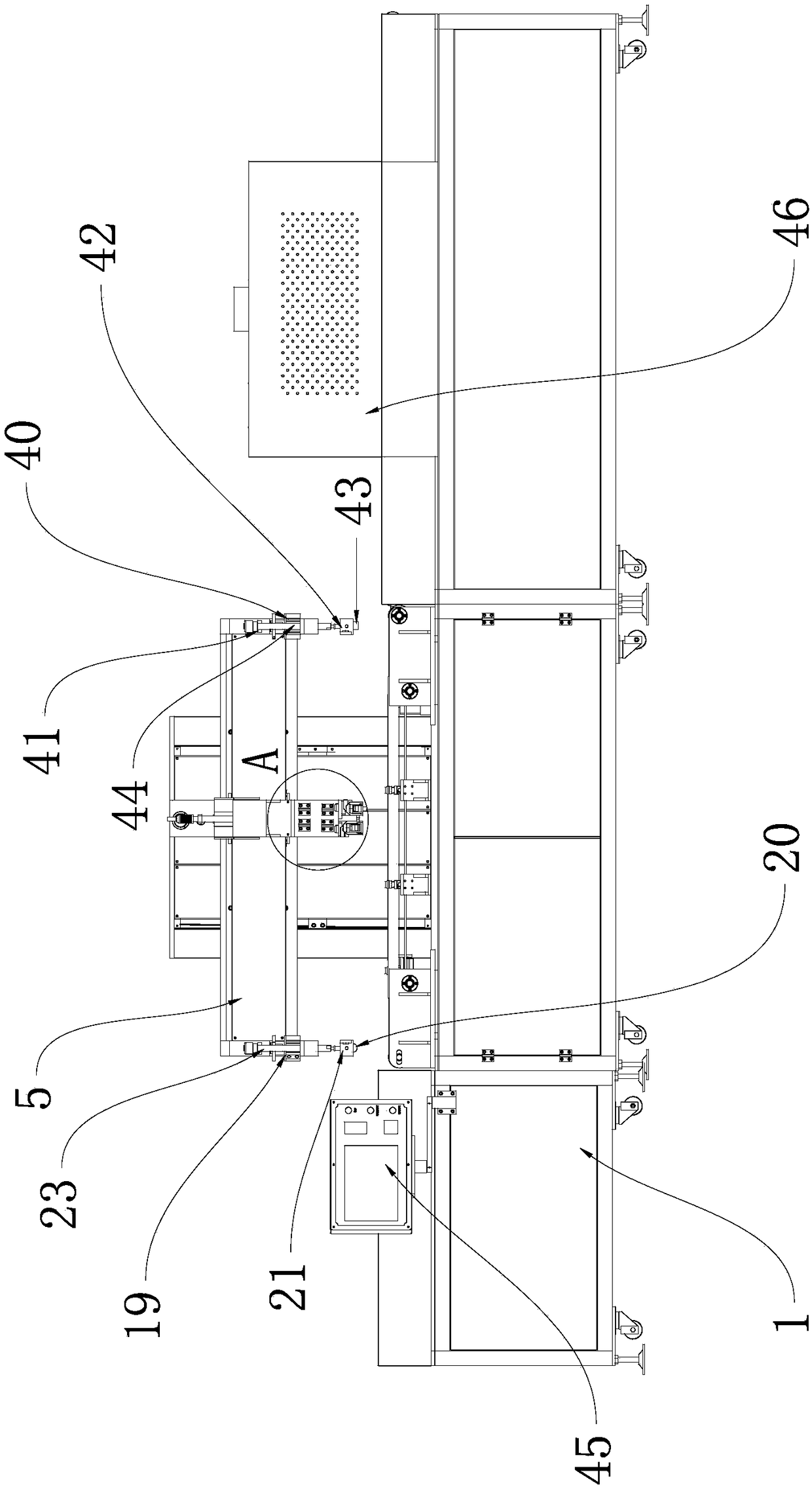

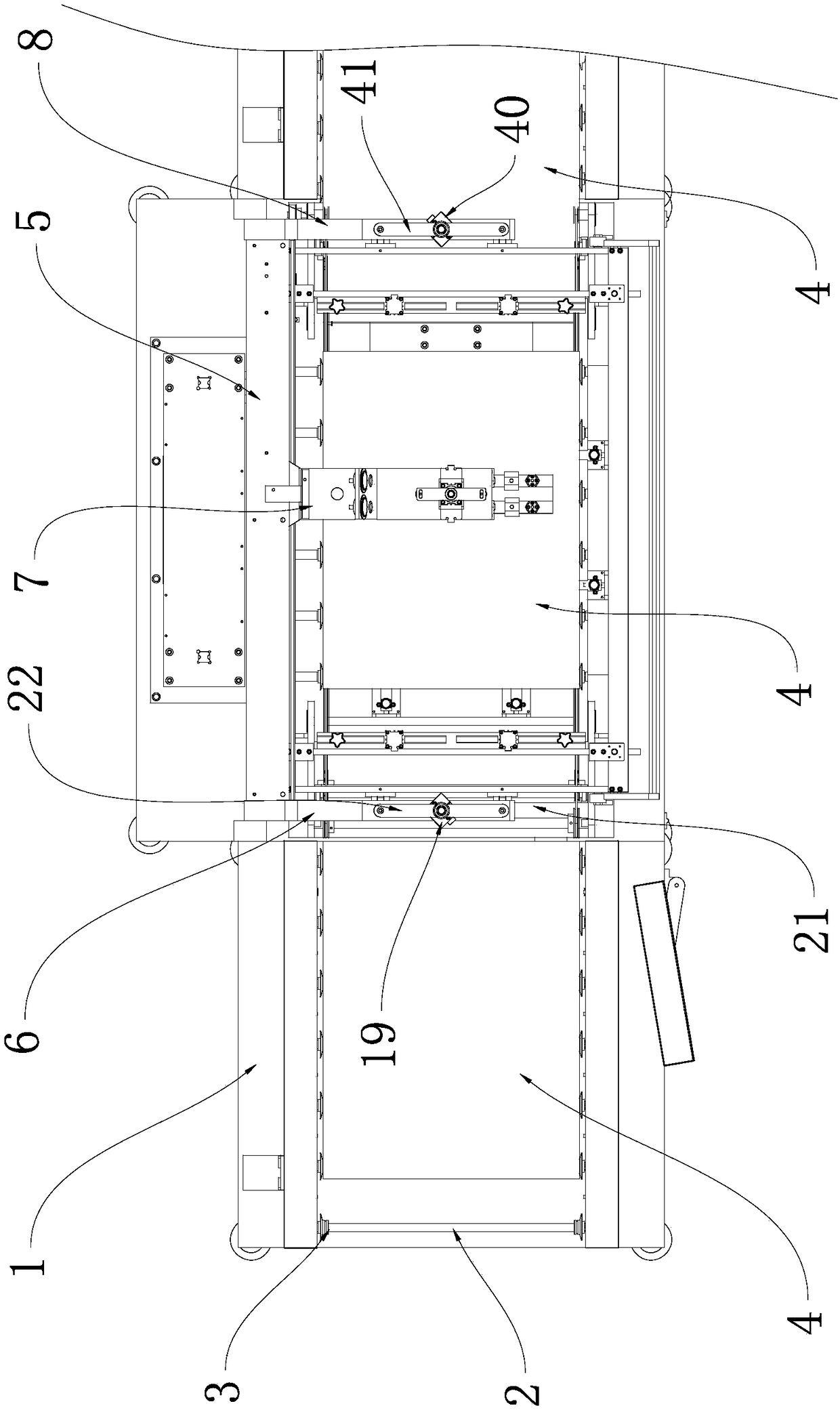

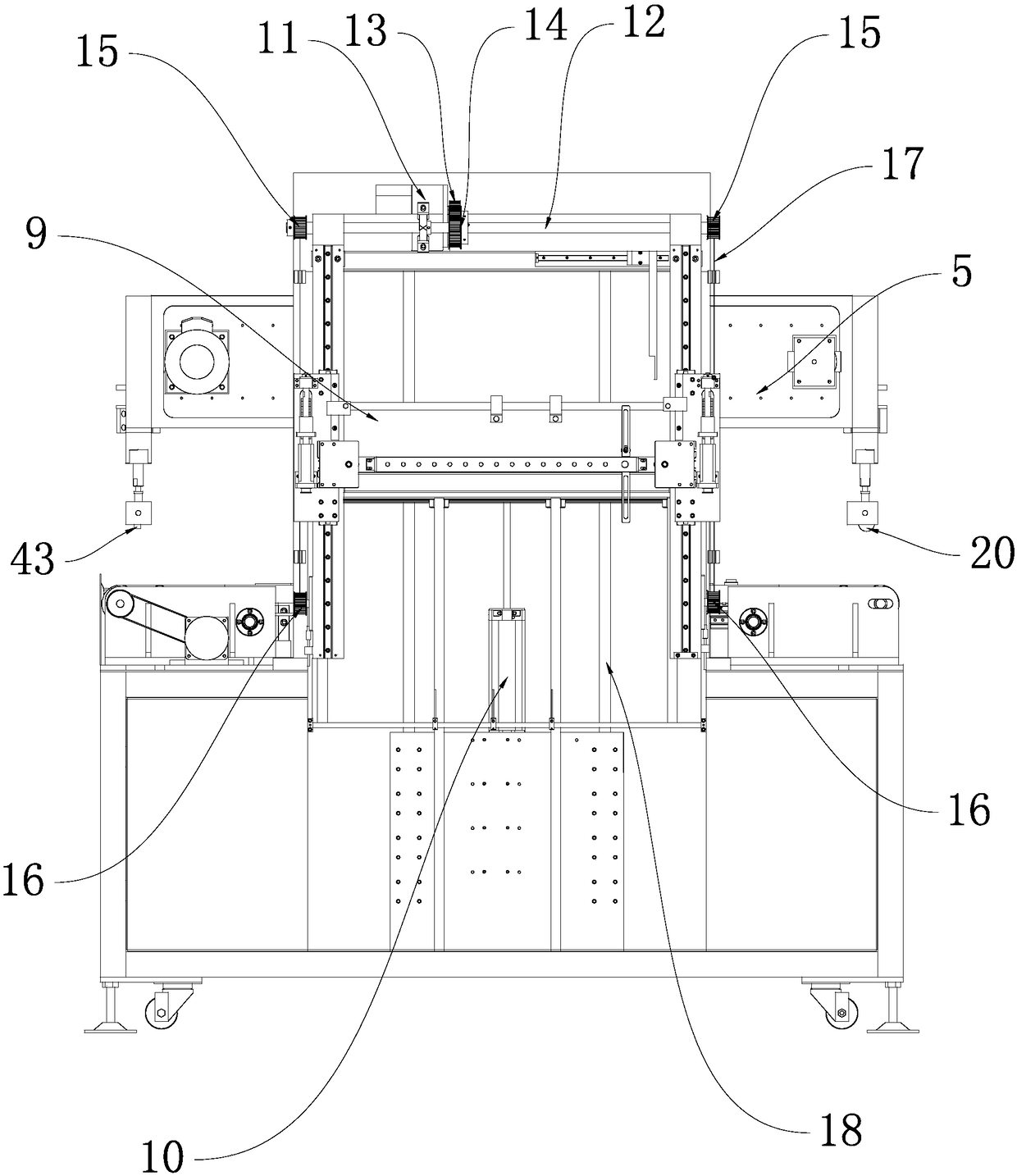

Image

Examples

Embodiment Construction

[0045] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0046] A processing technology for digital printing of silk fabrics, comprising the following steps:

[0047] S1, fabric preparation: weaving silk into silk fabric through a weaving machine;

[0048] S2. Cleaning and drying: Soak the silk fabric with warm water, control the water temperature at 50-60°C, add detergent, stir to remove surface grease, and then dry;

[0049] S3, fabric treatment: evenly spray the mixed solution on the surface of the silk fabric;

[0050] S4. Printing and color fixing: place the silk fabric on the digital printing machine for rapid printing; then heat the silk fabric to fix the color, the color fixing temperature is 140-160°C, and the heating time of the silk fabric is 40-60s;

[0051] S5. Al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com