Writing brush type liquid guide infiltration device

An infiltration device and writing brush technology are applied in the direction of microstructure devices, manufacturing microstructure devices, and nanostructure manufacturing. Achievement and repeatable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

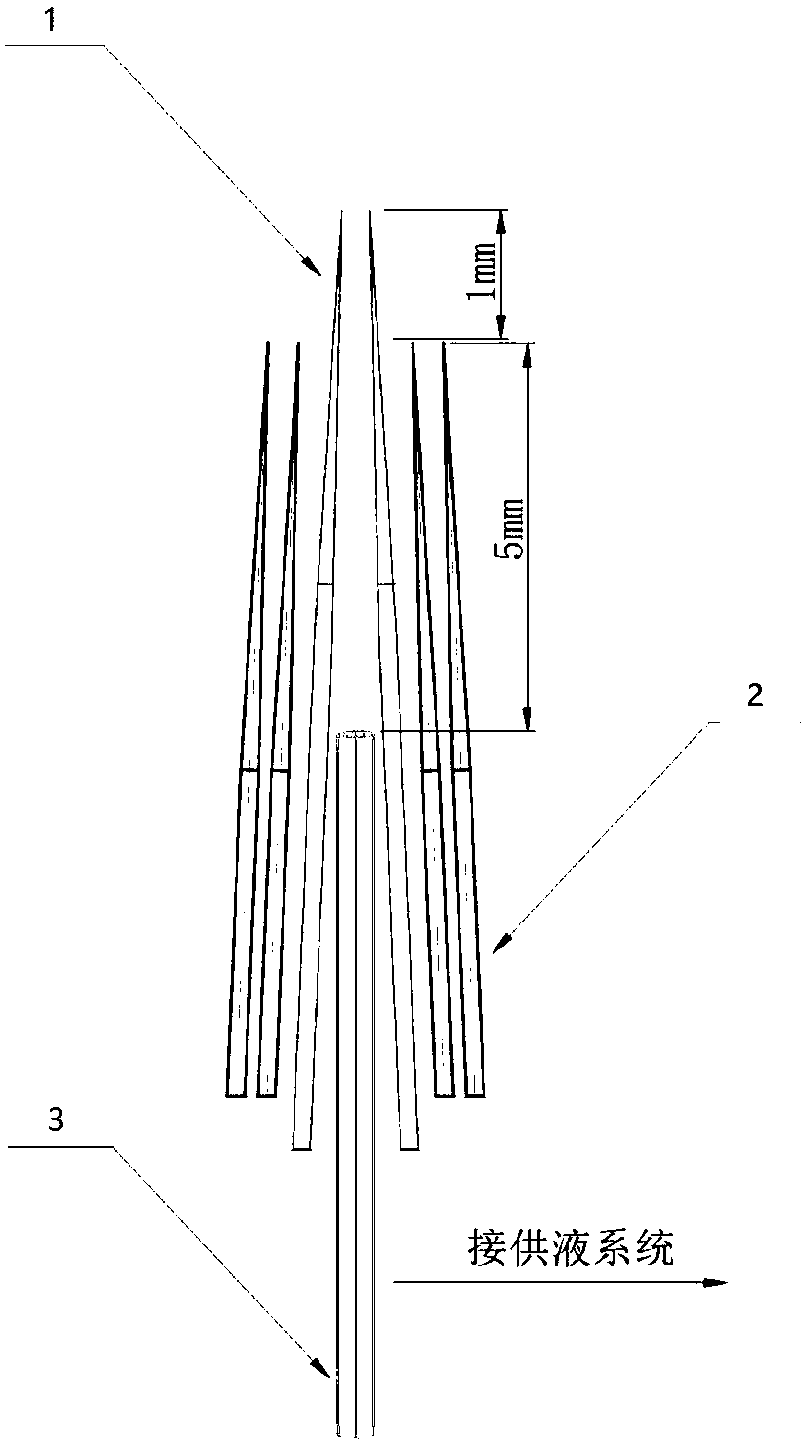

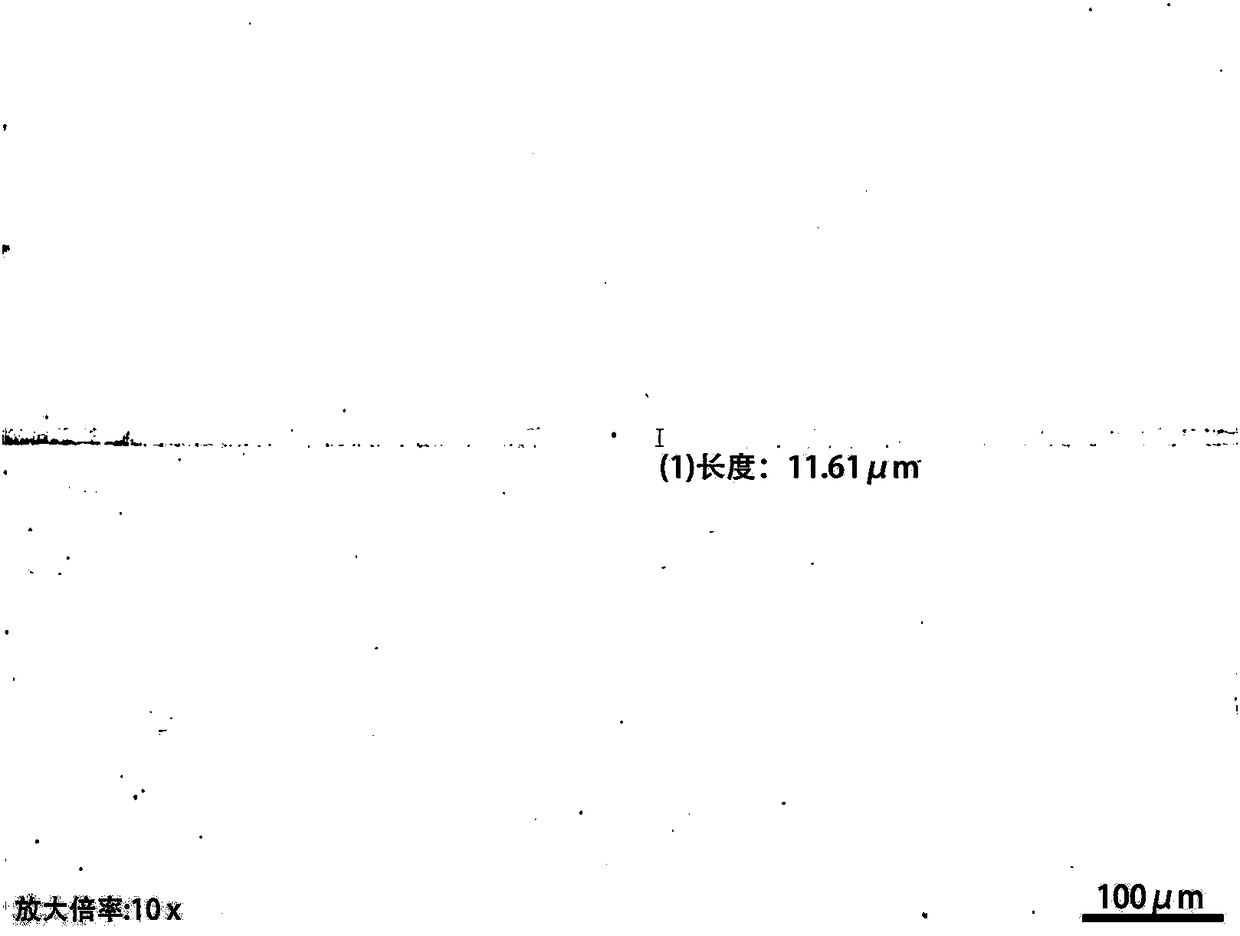

[0023] refer to figure 1 Wrap a trace liquid catheter (3) in the middle of a whole bundle of neat hairs (2), the head of the catheter is 5mm away from the tip of the whole bundle of neat hairs, and fix two catheters on both sides of the catheter that are longer than the tip of the catheter Rabbit hair (1) with a 6mm portion (1mm longer than the whole bundle of writing brushes), and a micro-liquid conduit connected to an automatic liquid supply device. Inject a certain concentration of ink into the micro-liquid supply instrument, and draw a superfine ink with a width of 11.61μm and a thickness of figure 2 .

Embodiment 2

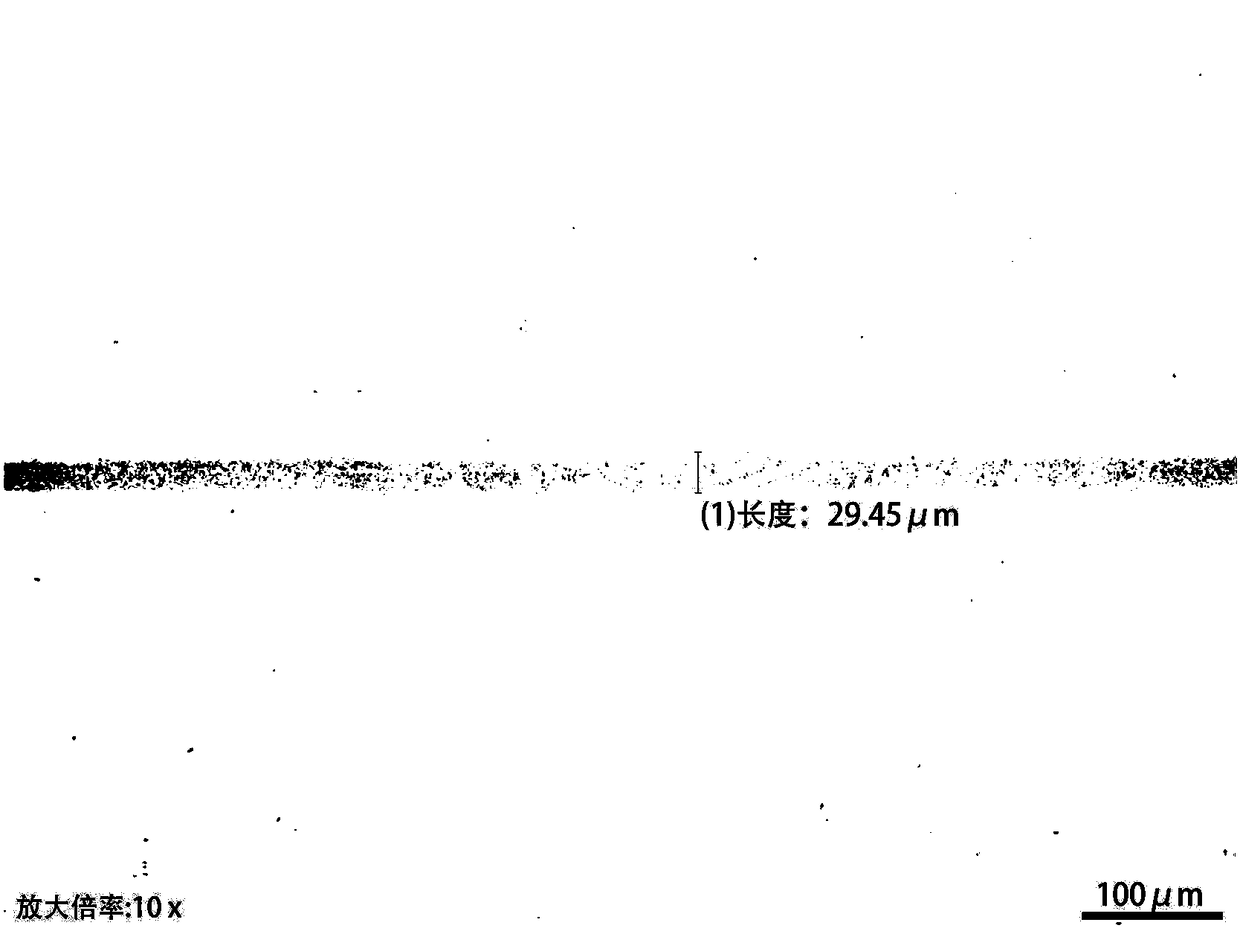

[0025] Wrap a micro-fluid catheter in the middle of a whole bunch of neat hairs, the head of the catheter is 3mm away from the tip of the whole bundle of neat hairs, and fix 4 tubes on both sides of the catheter that are 4mm longer than the head of the catheter (longer than the whole bundle). The hair of the badger with a writing brush of 1mm), and the micro-liquid catheter is connected to the automatic liquid supply device. Inject a certain concentration of ink into the micro-liquid supply instrument, and draw an ultra-fine ink with a width of 29.45 μm and a thickness of image 3 .

Embodiment 3

[0027] Wrap a micro-fluid catheter in the middle of a whole bunch of neat hairs, the head of the catheter is 7mm away from the tip of the whole bundle of neat hairs, and fix 4 tubes on both sides of the catheter that are 9mm longer than the head of the catheter (longer than the whole bundle). Brush 2mm) of polymer hair, micro-liquid conduit connected to the automatic liquid supply device. Inject a certain concentration of ink into the micro-liquid supply instrument, and draw a superfine ink with a width of 101.91μm and a thickness of Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com