Negative electrode slurry and its preparation method and application

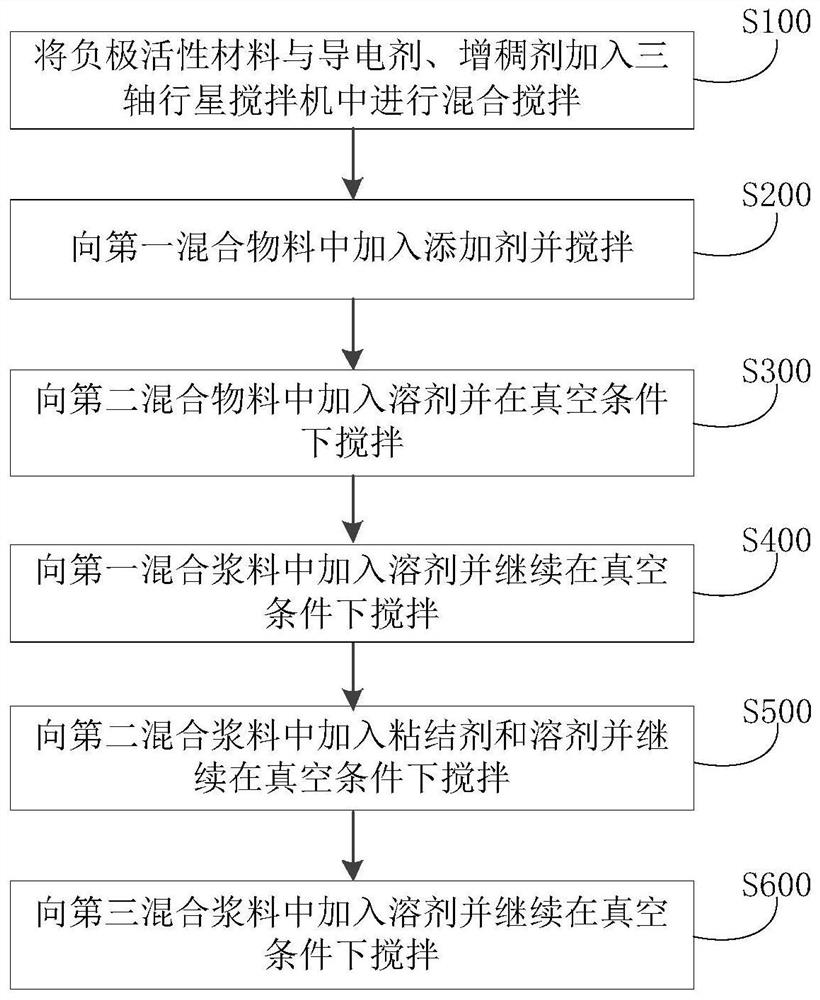

A technology of negative electrode slurry and negative active material, applied in the direction of negative electrode, battery electrode, active material electrode, etc., can solve the problems of negative electrode coating appearance, long stirring time, high energy consumption, etc., to avoid high-speed shear damage, Improve the effect of shear friction and promote the wetting of the particle surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] According to the method for preparing the negative electrode slurry in the embodiment of the present invention, by supplying the negative electrode active material, the conductive agent, and the thickener to the three-axis planetary mixer for mixing and stirring, the macroscopic mixing between the powders is realized, which is beneficial to the subsequent high-viscosity stirring Opening of powder particle agglomeration and infiltration of powder particle surface. At the same time, the mixing is carried out in a three-axis planetary mixer. Compared with the traditional double planetary mixer, there is no high-speed dispersion disc, which avoids high-speed shear damage to the molecular structure of the thickener in the slurry by the high-speed dispersion disc and damage to the subsequent binder. Destruction is conducive to improving the stability of the slurry and the adhesion of the pole piece. Furthermore, the revolving paddle of the three-axis planetary mixer has a str...

Embodiment 1

[0064] (1) Add the negative active material artificial graphite, the conductive agent super conductive carbon, and the thickener CMC powder into the three-axis planetary mixer for mixing according to the mass ratio of 96.5:1.0:1.0. The revolution speed of the three-axis planetary mixer is 8rpm, and the rotation speed The speed is 24rpm, and the stirring time is 9min to obtain the first mixed material;

[0065] (2) Add the additive 1,3-butanediol to the first mixed material and stir, the mass ratio of the additive to the first mixed material is 0.5:100, the revolution speed of the three-axis planetary mixer is 10rpm, and the rotation speed is 30rpm, The stirring time is 10 minutes, and the stirring temperature is 25° C. to obtain the second mixed material;

[0066] (3) Add solvent deionized water to the second mixed material and stir under vacuum conditions. The revolution speed of the three-axis planetary mixer is 15rpm, the rotation speed is 45rpm, the stirring time is 10min,...

Embodiment 2

[0072] (1) Add the negative active material natural graphite, conductive agent carbon nanotubes, and thickener CMC powder into the three-axis planetary mixer for mixing and stirring according to the mass ratio of 92:4:2. The revolution speed of the three-axis planetary mixer is 5rpm, and the rotation speed is The speed is 30rpm, and the stirring time is 5min to obtain the first mixed material;

[0073] (2) Add the additive acetone to the first mixed material and stir, the mass ratio of the additive to the first mixed material is 0.1:100, the revolution speed of the three-axis planetary mixer is 5rpm, the rotation speed is 45rpm, and the stirring time is 15min. The temperature is 0°C, and the second mixed material is obtained;

[0074] (3) Add solvent deionized water to the second mixed material and stir under vacuum conditions. The revolution speed of the three-axis planetary mixer is 5rpm, the rotation speed is 60rpm, the stirring time is 12min, and the stirring temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com