Ultrahigh pressure and high temperature core holder

A core holder, ultra-high pressure technology, applied in the direction of instruments, scientific instruments, flow characteristics, etc., can solve the problems that the gas flow cannot be accurately measured, the saturation is not suitable for accurate calculation, and the quality of the holder is large

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

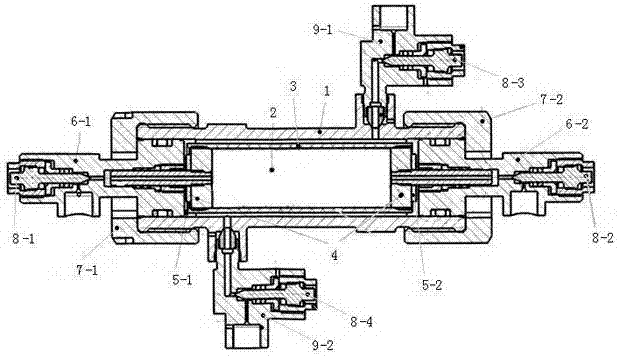

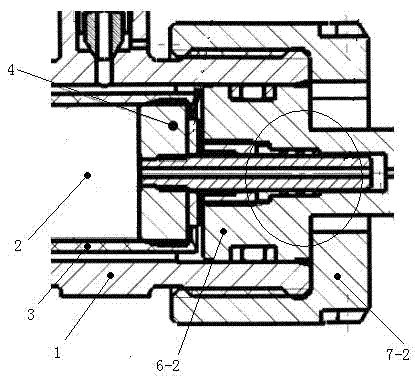

[0026] Such as figure 1 Shown:

[0027] The ultra-high-pressure high-temperature core holder of the present invention includes a core chamber 1, 2 sealing plugs, 2 compaction nuts, 2 valve accessories, 4 built-in needle valves, plugs, sleeves, and compensation gaskets.

[0028] The specific implementation is as follows: firstly select a plug of appropriate length according to the length of the core; then put the core into the sleeve, place a plug on each side of the sleeve, and use external force to make the plug and the core closely contact; cut the sleeve to make the sleeve The maximum distance between the outer edge and the plug should not exceed 1mm; when adding a compensation gasket, the thickness of the compensation gasket is equal to half of the difference between the distance between the left sealing plug and the right sealing plug and the close contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com