Method for processing sulfur-containing waste water

A treatment method and waste water technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of large chemical consumption and waste residue, poor environmental adaptability of gas wells, and improve desulfurization Operating costs and other issues, to achieve the effect of strong environmental adaptability, easy operation and maintenance, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

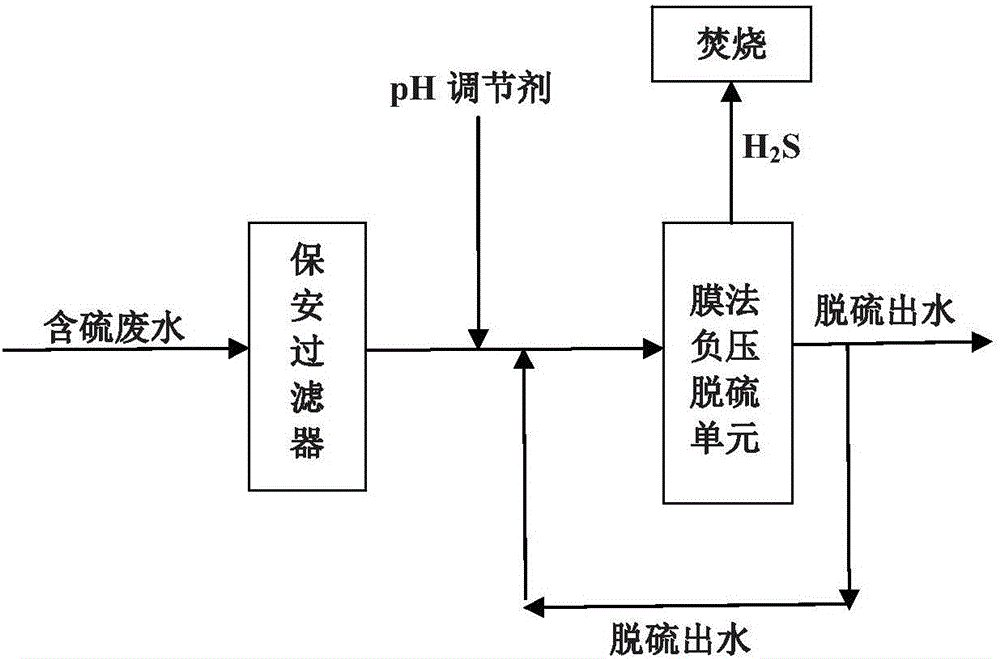

[0036] The main water quality characteristics of the sulfur-containing wastewater treated in this example are: sulfide 2000 mg / L, total dissolved solids 5000 mg / L, and suspended solids 0 mg / L.

[0037] The treatment method of the sulfur-containing wastewater of the present invention is as follows: first, the pH value of the sulfur-containing wastewater is adjusted to 6 by using sulfuric acid; The operating conditions of negative pressure desulfurization are as follows: the inlet water temperature is 35°C, the inlet water flow rate is 0.6m / s, and the operating negative pressure on the negative pressure side is -0.04MPa; the membrane material used in the membrane negative pressure desulfurization unit is polypropylene, and the membrane The pore size is 0.1 μm. Finally, the hydrogen sulfide generated after membrane negative pressure desulfurization is collected for incineration.

[0038] The sulfur-containing wastewater treated by the above method has a sulfur content of ≤30mg / L...

Embodiment 2

[0040] The main water quality characteristics of the sulfur-containing wastewater treated in this embodiment are: sulfide 5000 mg / L, total dissolved solids 15000 mg / L, and suspended solids 50 mg / L.

[0041] The treatment method of the sulfur-containing wastewater of the present invention is as follows: first, the pH value of the sulfur-containing wastewater is adjusted to 4.5 by using hydrochloric acid; The operating conditions of negative pressure desulfurization are as follows: the inlet water temperature is 40°C, the inlet water flow rate is 0.8m / s, and the operating negative pressure on the negative pressure side is -0.05MPa; the membrane material used in the membrane negative pressure desulfurization unit is polypropylene, and the membrane The pore size is 0.2 μm. Finally, the hydrogen sulfide generated after membrane negative pressure desulfurization is collected for incineration.

[0042] The sulfur-containing wastewater treated by the above method has a sulfur content o...

Embodiment 3

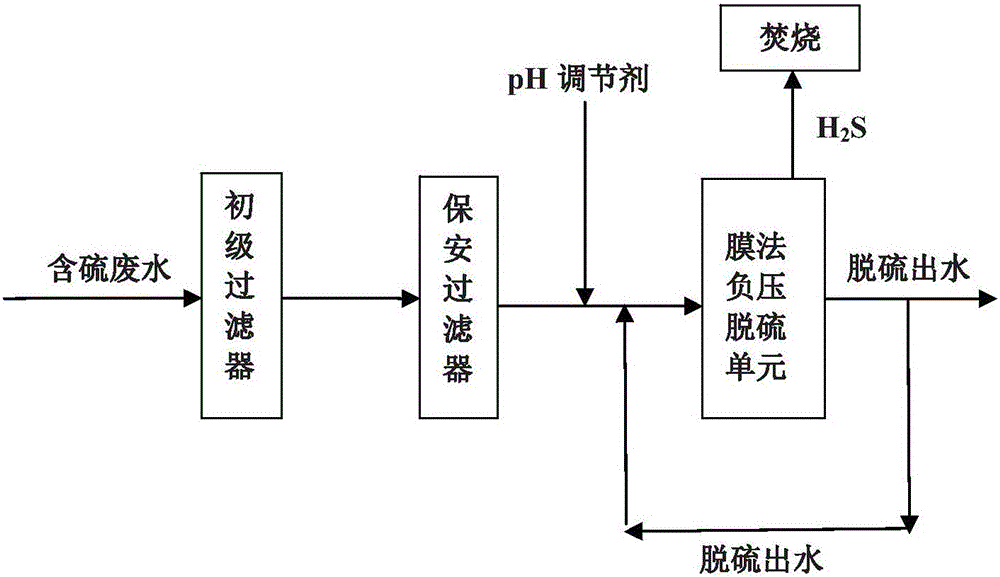

[0044] The main water quality characteristics of the sulfur-containing wastewater treated in this embodiment are: sulfide 10000 mg / L, total dissolved solids 30000 mg / L, and suspended solids 100 mg / L.

[0045] The treatment method of the sulfur-containing wastewater of the present invention is as follows: first, the sulfur-containing wastewater is input into a sand filter for primary filtration; secondly, the pH value of the sulfur-containing wastewater is adjusted to 5 by using nitric acid; Sulfur wastewater is input to the negative pressure desulfurization unit of membrane method for desulfurization treatment. The operating conditions of negative pressure desulfurization by membrane method are as follows: the inlet water temperature is 45°C, the inlet water flow rate is 0.9m / s, and the negative pressure on the negative pressure side is -0.06MPa; The material of the membrane used in the negative pressure desulfurization unit of the method is polytetrafluoroethylene, and the por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com