Lithium ion battery liquid injection method adopting polygonal double-hole liquid injection mode

A lithium-ion battery, polygonal technology, applied in battery pack parts, circuits, electrical components, etc., can solve problems such as bottlenecks in the injection process, achieve stable and fast injection, solve difficult injection and infiltration, and improve injection efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

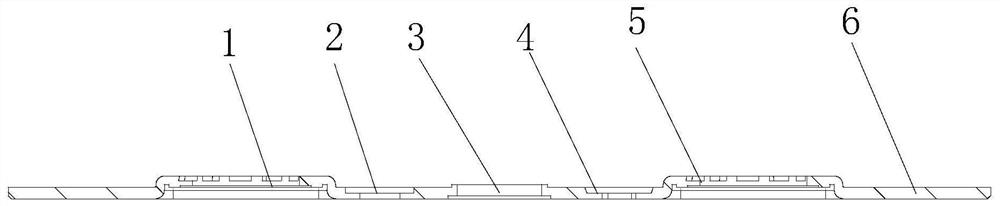

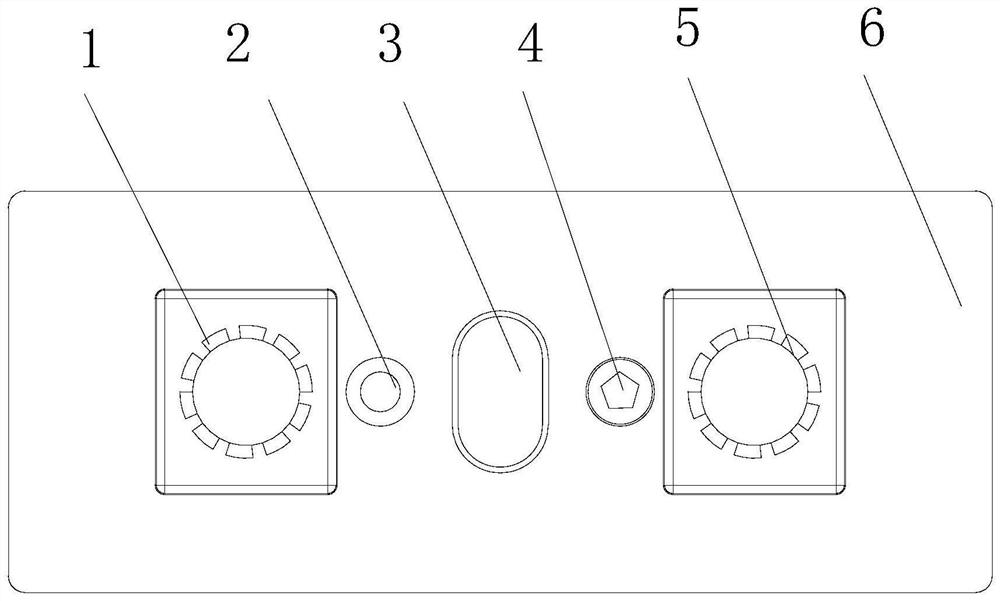

[0037] (1) See attached figure 1 , 2 , design and process the top cover of the 71173207 model battery, and process a polygonal liquid injection hole on the side of the positive pole. The liquid injection hole is a stepped circular platform through-hole structure in the shape of a concave platform. The bottom hole is an inscribed regular pentagon with a diameter of 7mm; a circular vent hole is processed near the negative pole side. The vent hole includes a large round hole and a small round hole in the shape of a stepped circular platform through-hole structure. The vent hole is large and round. The diameter of the hole is a circle with a diameter of 12mm, and the small hole is a circle with a diameter of 7mm;

[0038] (2) Process the battery to the state before liquid injection according to the conventional process;

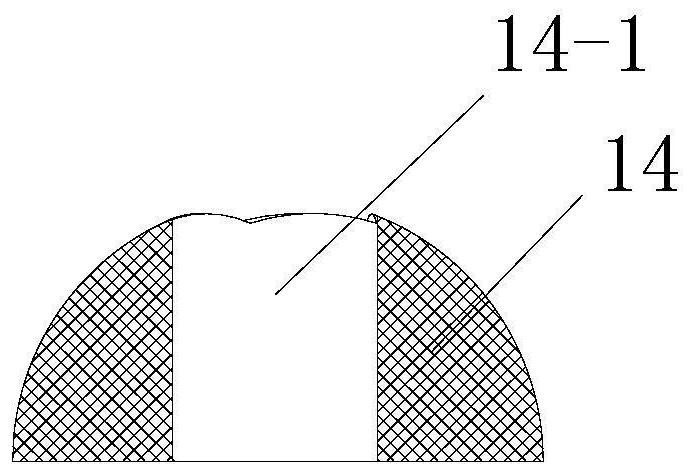

[0039] (3) See attached image 3 , 4 , process the liquid inlet sealing head of semicircular sphere, its ball head diameter is 16mm, and the inscribed regula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com