Prefabricated underground silo compound shaft construction method and silo structure

A prefabricated, underground silo technology, applied in underwater structures, infrastructure engineering, artificial islands, etc., can solve the problem that the force of the boot foot cannot meet the requirements, is not conducive to the layout of the building complex, and the boot foot of the caisson is not specified, etc. problems, to achieve the effect of increasing the scope and effectiveness, saving the construction period, and reducing the construction work surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

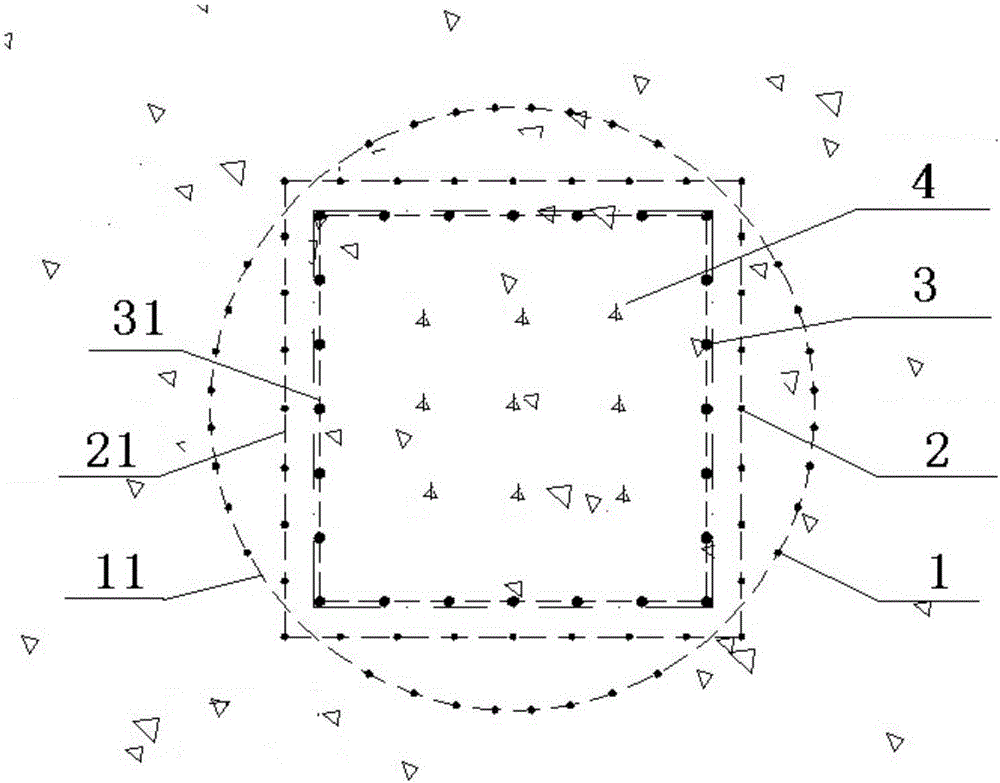

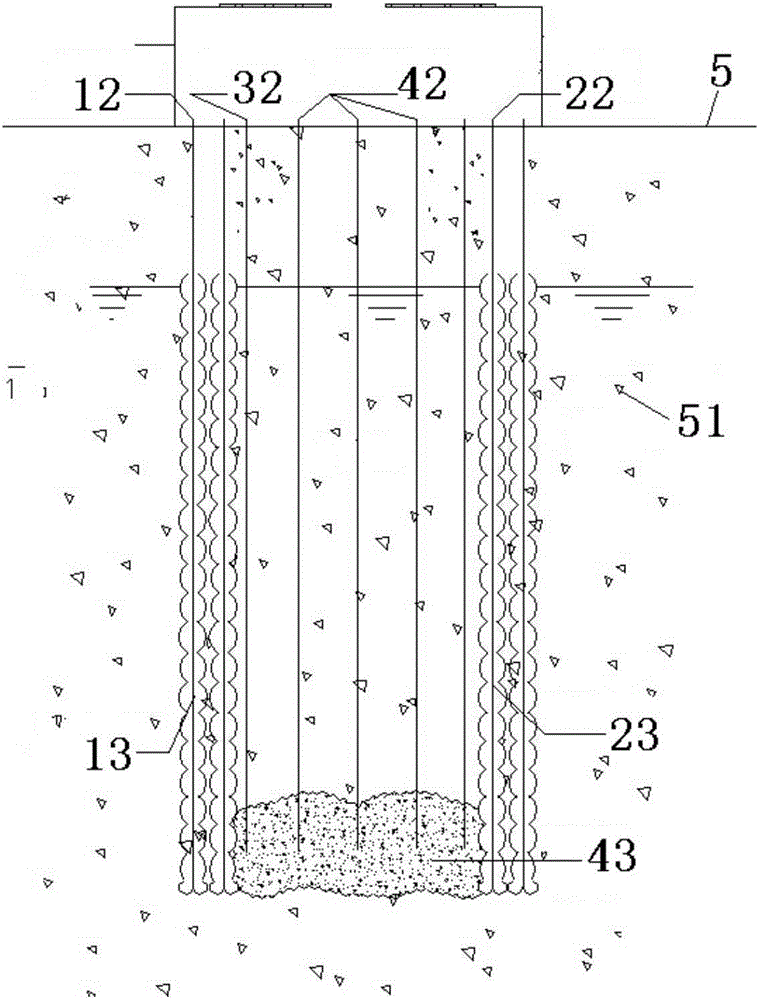

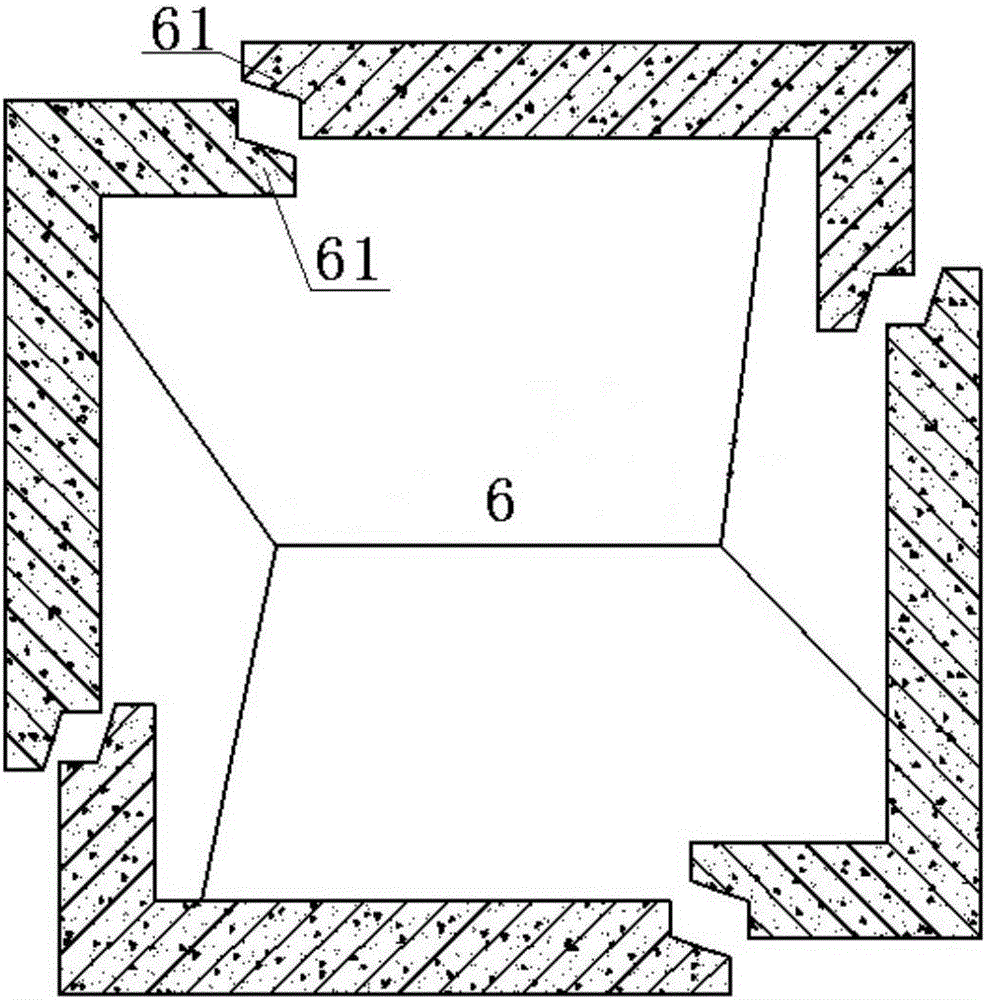

[0037] Such as Figure 1 to Figure 10 The shown prefabricated underground silo compound shaft construction method includes the following steps: a. Firstly, laying out lines at the silo construction site to locate and arrange boreholes, wherein the setting out lines are respectively: along the arched hole layout line 11 Arrange the arch ring freezing holes 1, arrange the rectangular ring freezing holes 2 along the rectangular hole layout line 21, arrange the sinking grouting holes 3 along the shaft wall layout hole line 31, the arch hole layout line 11, the rectangular hole layout line 21 and the well wall hole layout line 31 are arranged sequentially from outside to inside with reference to the excavation range line, and the survey grouting hole 4 is arranged in the well wall hole layout line 31; b, through the above-mentioned arch ring freezing hole 1 and rectangular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com