Irregular glass ceiling connection structure and ceiling lamp connection structure matched with irregular glass ceiling connection structure

A connection structure and irregular technology, applied in the direction of ceiling, building components, building structure, etc., can solve the problems of lower crack strength, breakage, easy cracks, etc., and achieve the effect of low production cost, excellent elasticity, and easy molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

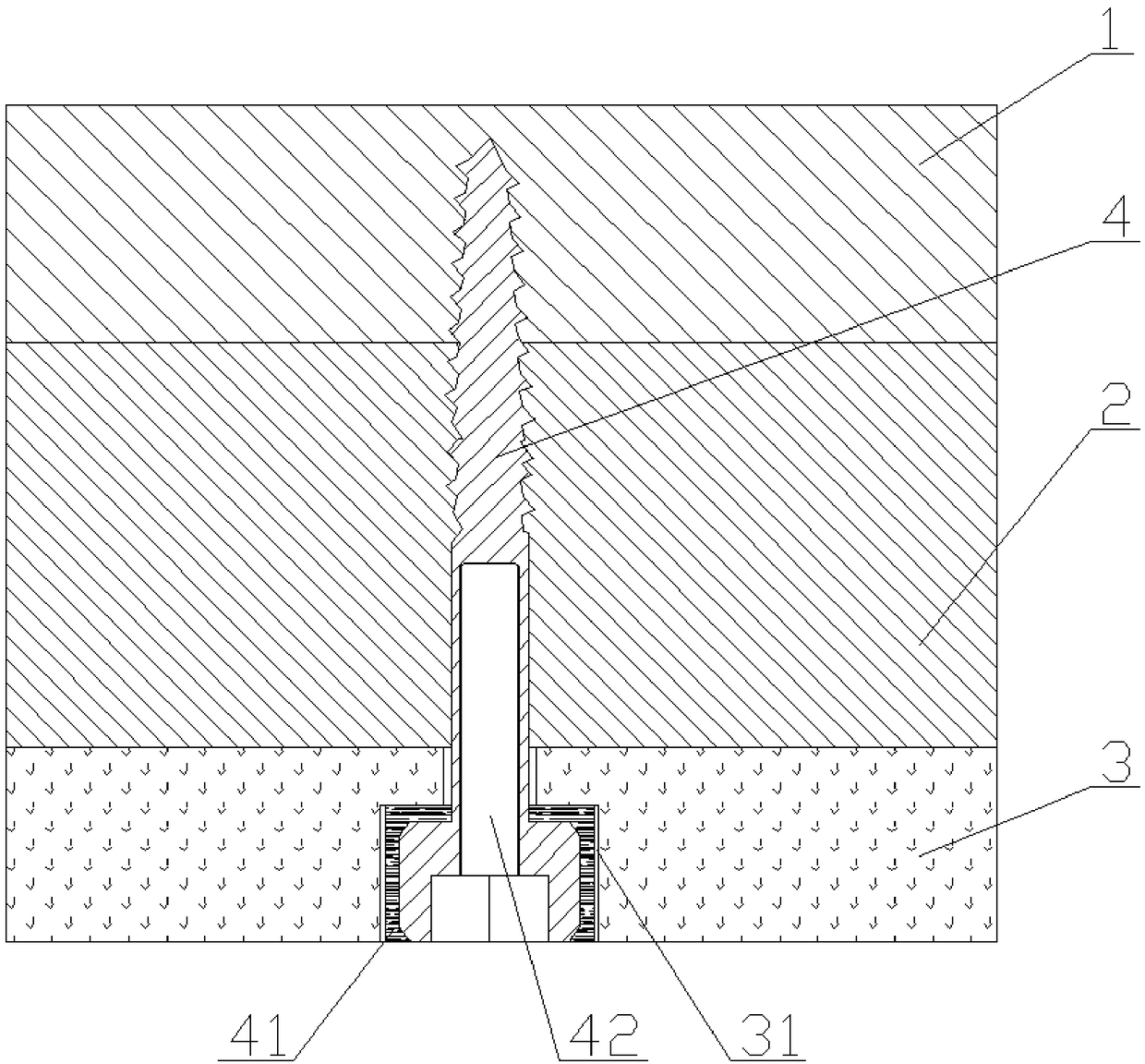

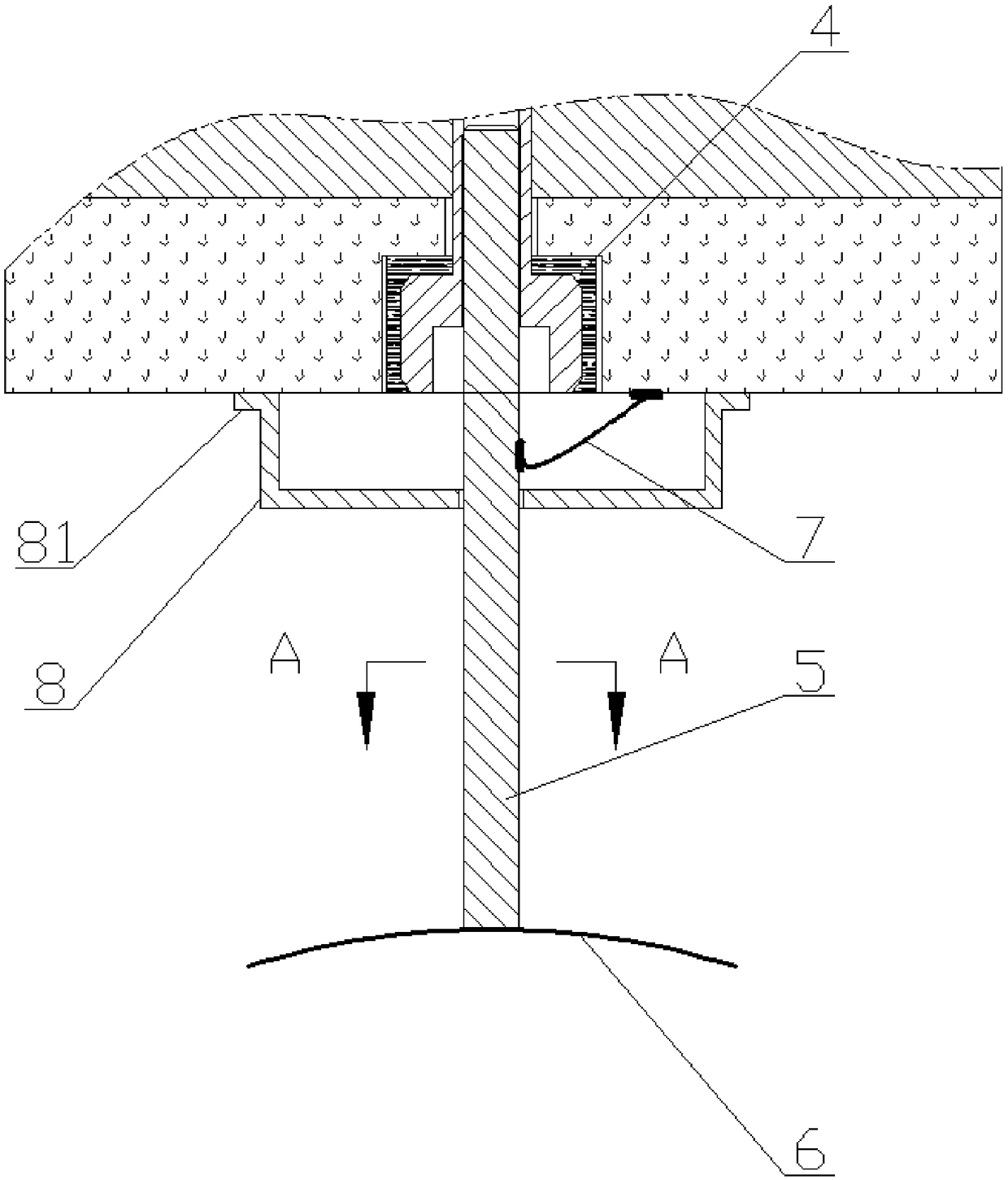

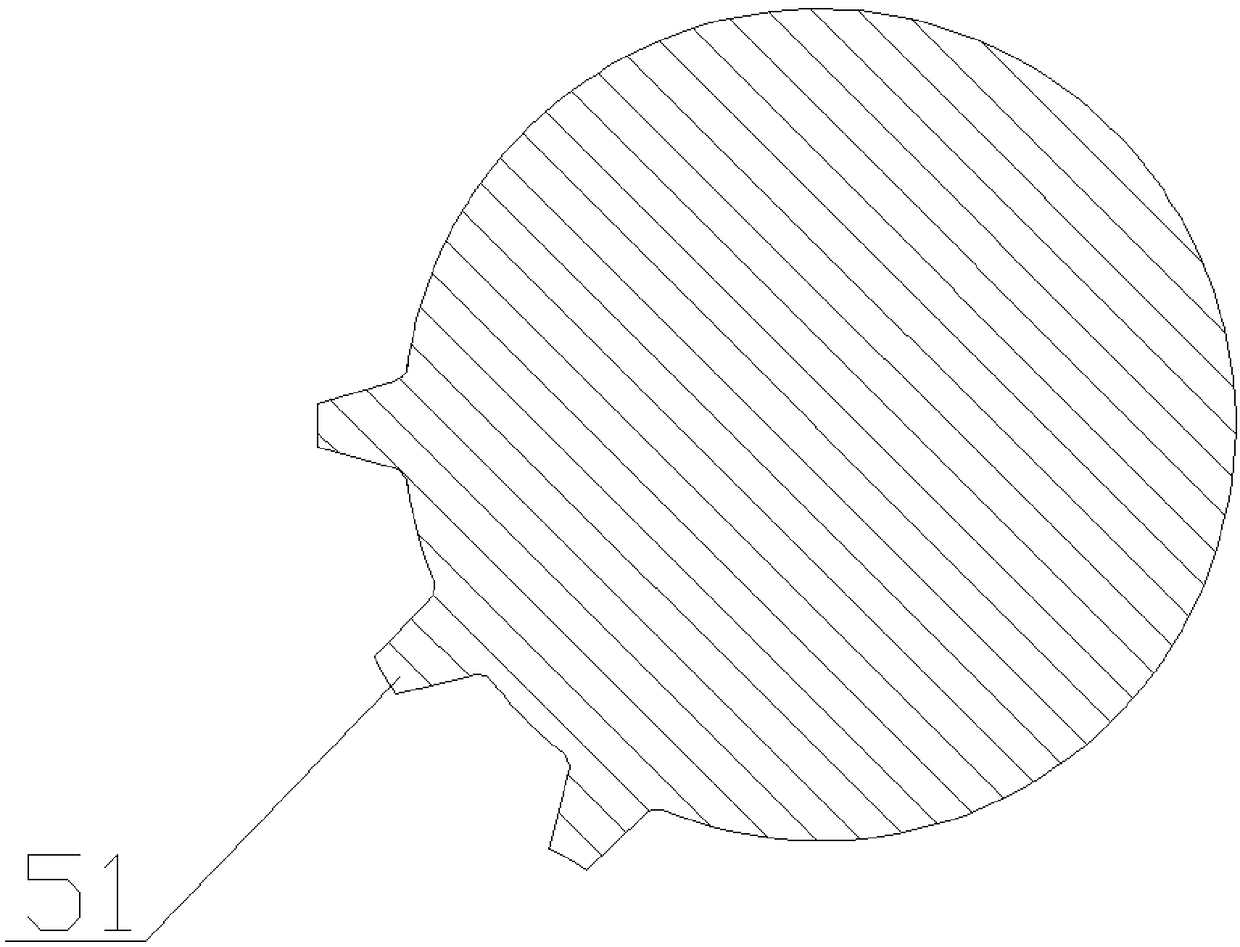

[0029] Below in conjunction with specific embodiment, content of the present invention is described in further detail, figure 1 It shows a schematic diagram of the connection structure of the irregular glass ceiling in the present invention, which is composed of keel 1, flame-retardant board 2, art glass 3 and self-tapping screws 4, which are arranged in close order from top to bottom. The art glass 2 is provided with a through hole for the self-tapping screw 4 to pass through, and the through hole is a countersunk hole 31 . In order to avoid stress unevenness in the contact position between the self-tapping screw 4 and the art glass 3 during the process of fastening the self-tapping screw 4, an elastic layer 41 is arranged on the head of the self-tapping screw 4, so that the self-tapping screw 4 and the countersunk hole 31 The bottom wall and the side wall are separated from each other. In addition, the above setting method also has the following effects: when the self-tappi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com