A method for conveying dregs and soil for excavation of subway station foundation pit

A technology for subway stations and foundation pits, used in conveyors, mechanical conveyors, conveyor objects, etc., can solve the construction requirements that cannot meet the rapid slag discharge, slow slag outward transportation, and excavator construction speed. problems, to achieve the effect of reliable construction equipment and construction methods, improve the efficiency of muck transportation, and improve construction reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

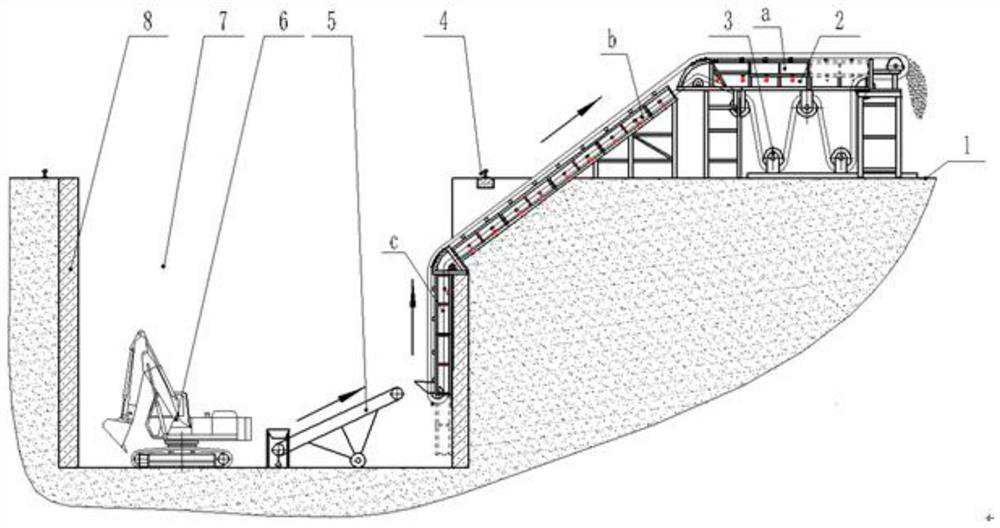

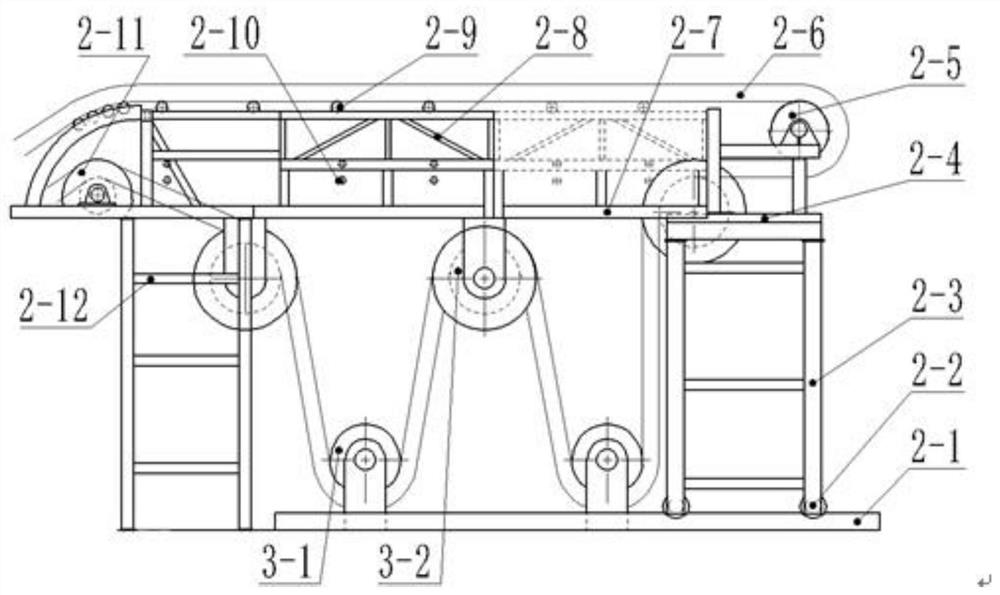

[0023] The present invention a kind of excavation dregs conveying method of subway station foundation pit, and this conveying method comprises as follows: figure 1 As shown, in step 1, a set of corrugated sidewall belt conveyor 2 is arranged, and the corrugated sidewall belt conveyor 2 includes a conveyor body and a belt storage mechanism 3;

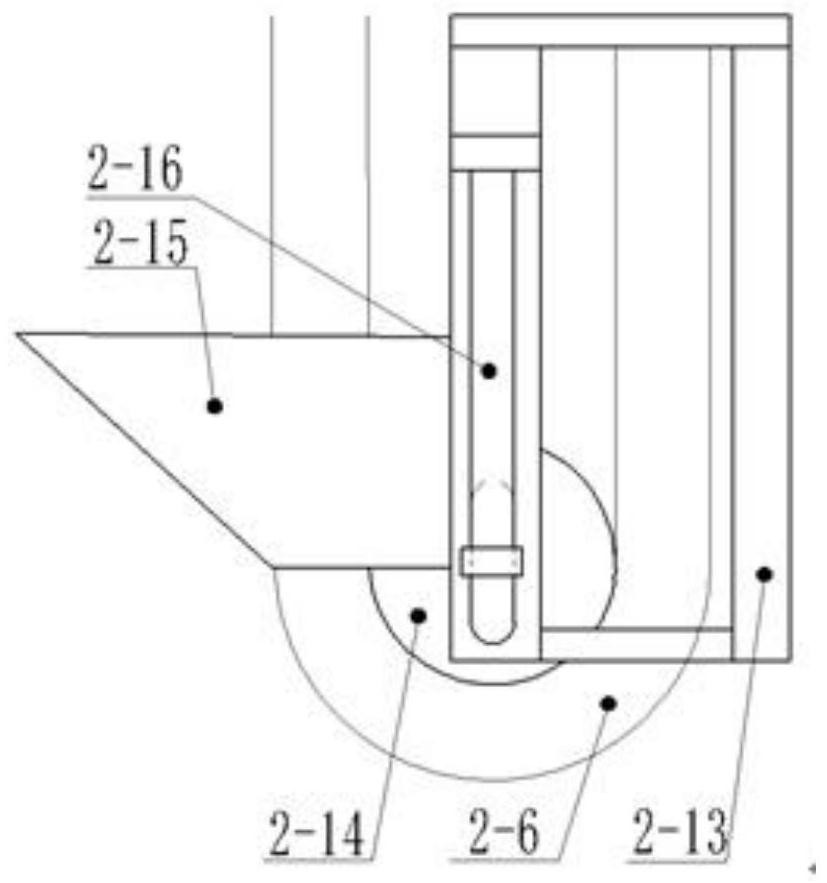

[0024] The conveyor body consists of the horizontal section a of the machine head, the inclined section b and the vertical section c of the machine body from the head end to the tail end of the machine body; the horizontal section a of the machine head is laid on the ground foundation 1 outside the foundation pit 7, and the vertical section c of the machine body It is arranged on the side wall of the continuous wall 8 along the vertical direction, and its end is close to the bottom of the foundation pit 7; the inclined section b of the body is connected between the horizontal section a of the machine head and the vertical section c of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com