A method for treating waste gas with a biological trickling filter tower and its special device

A biological trickling filter tower, biological treatment technology, applied in the direction of separation methods, chemical instruments and methods, air quality improvement, etc., can solve the problems of unfavorable filter tower equipment production, packing blockage, short residence time of empty tower, etc., and achieve the goal of packing Easy to replace and backwash, improve the clogging problem, and avoid the effect of channeling phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

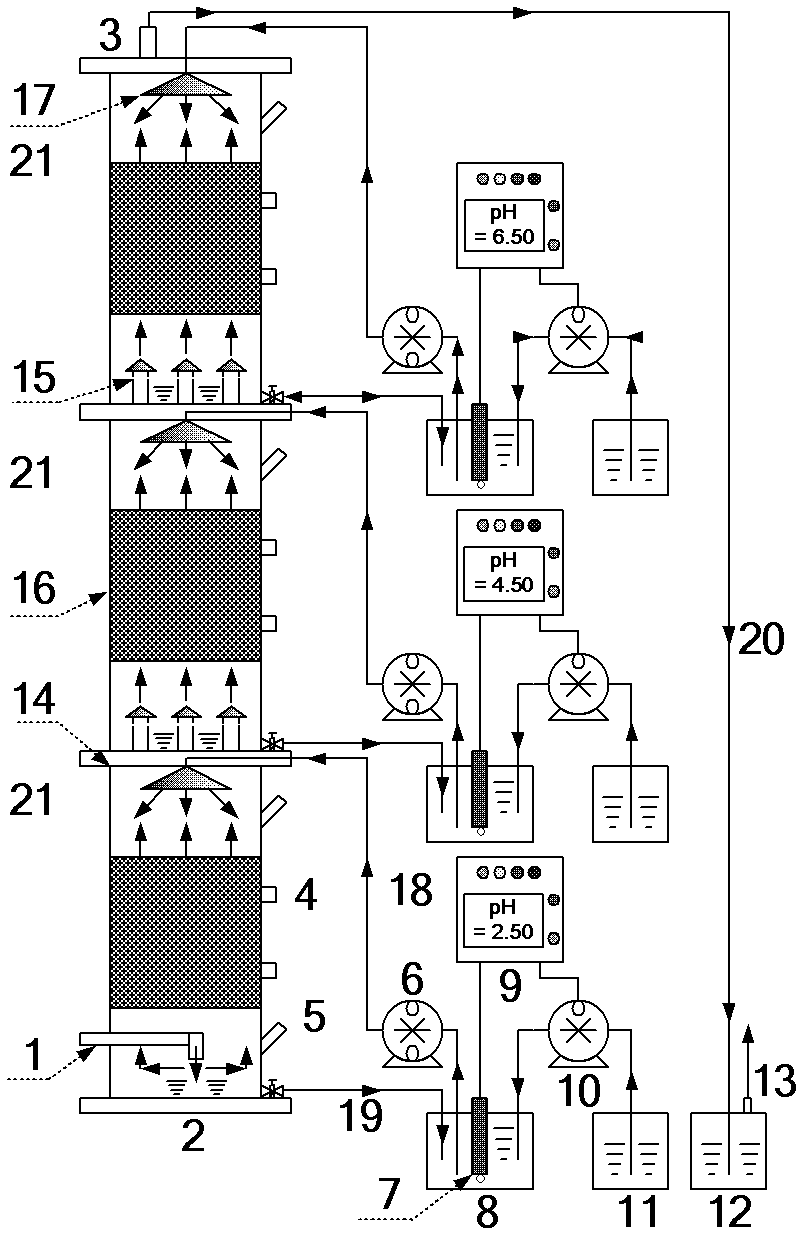

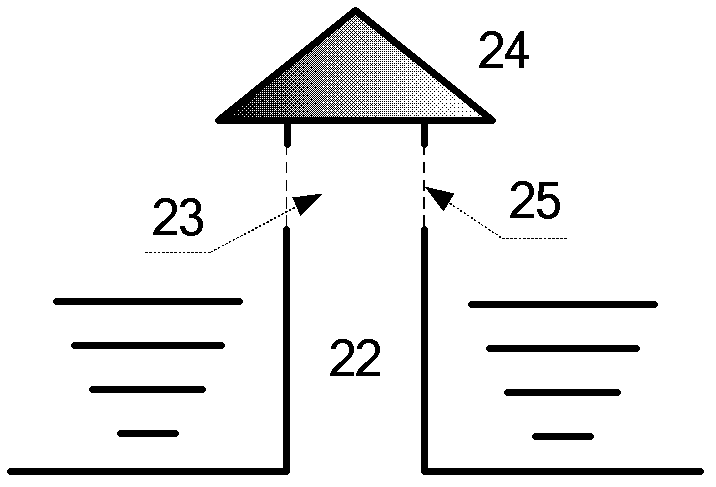

[0029] The waste gas to be treated is simulated with the mixed waste gas containing hydrogen sulfide, methyl sulfide, and tetrahydrofuran, and the waste gas is treated with the biological trickling filter tower according to the present invention. The tower body 2 of the biological trickling filter tower consists of a tower bottom, a tower body, The tower top is composed of a waste gas inlet 1 at the bottom of the tower, and an exhaust gas outlet 3 is installed at the top of the tower; the tower body is composed of a plurality of biological treatment units 21 stacked from bottom to top. A liquid interlayer 14 is arranged between the biological treatment units of adjacent layers, and a vent 23 for adjacent layers to communicate with each other is arranged on the liquid interlayer, and the vent is arranged on the liquid interlayer with a The tubular protrusion 22 of the conical top cap, the top of the tubular protrusion is connected with the conical top cap 24 whose bottom surface...

Embodiment 2

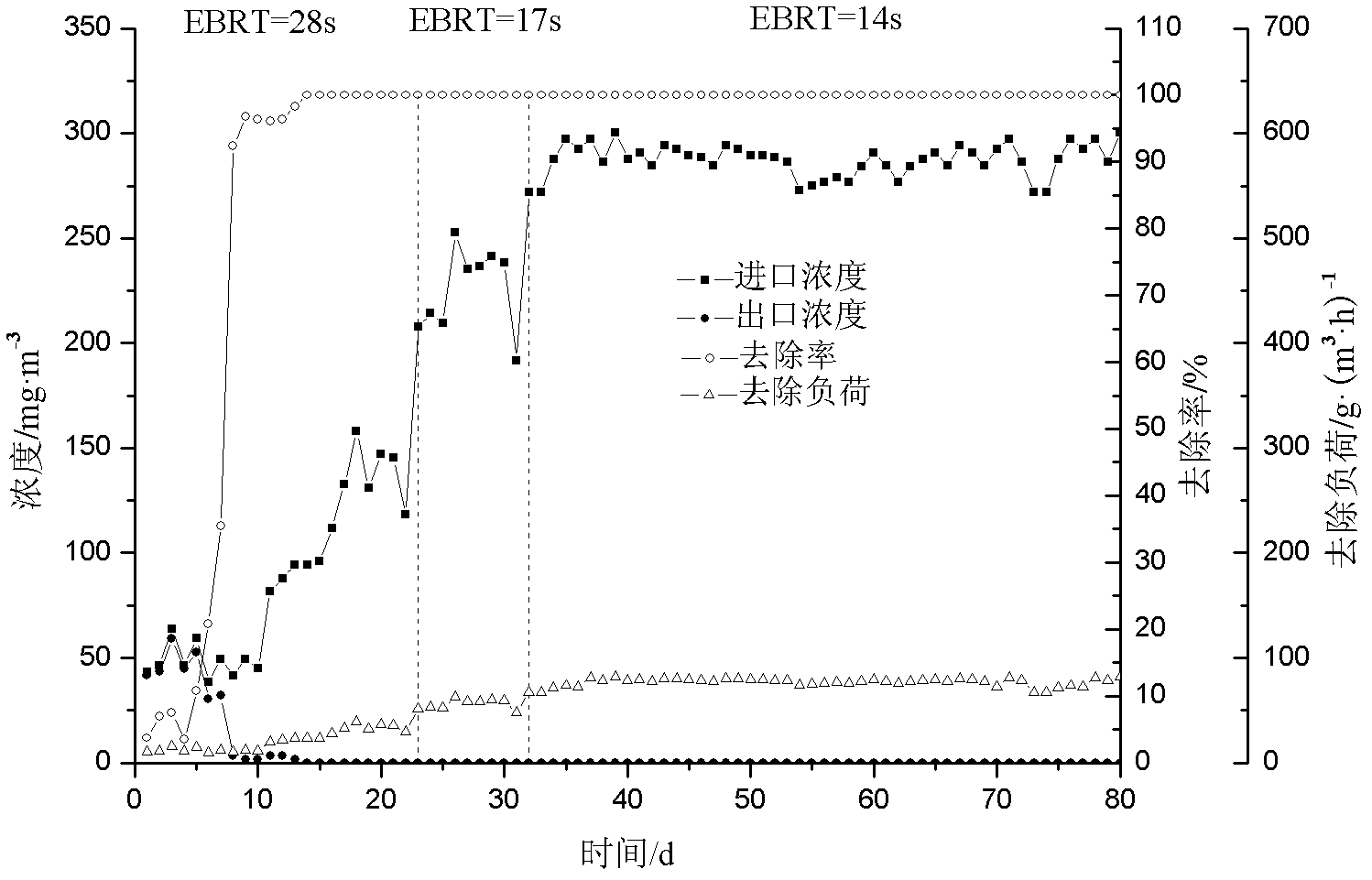

[0035] The structure and experimental operation of the bio-trickling filter tower are the same as in Example 1. After the film formation in the reactor is completed, the hydrogen sulfide concentration at the inlet is 250-300 mg m -3 , EBRT is 14s, investigate the purification of hydrogen sulfide gas by the exhaust gas purification system of the biological trickling filter tower, the results are as follows image 3 As shown, it can be seen that the concentration of hydrogen sulfide is 250mg·m -3 , When the EBRT is 14s, the hydrogen sulfide removal rate is always maintained at 100%; when the hydrogen sulfide concentration is suddenly increased to 300mg m -3 When the hydrogen sulfide removal rate is stable above 99.9%, it shows that the biological trickling filter system has a good and stable removal effect on hydrogen sulfide.

[0036] Depend on Figure 4 It can be seen that when the EBRT is 14s, the hydrogen sulfide entering the biotrickling filter system is mainly removed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com