Water filter unit and filter method thereof

A water filtration and unit technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as secondary pollution, increased difficulty, blockage, etc., and achieve improved filtration efficiency, backwash simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

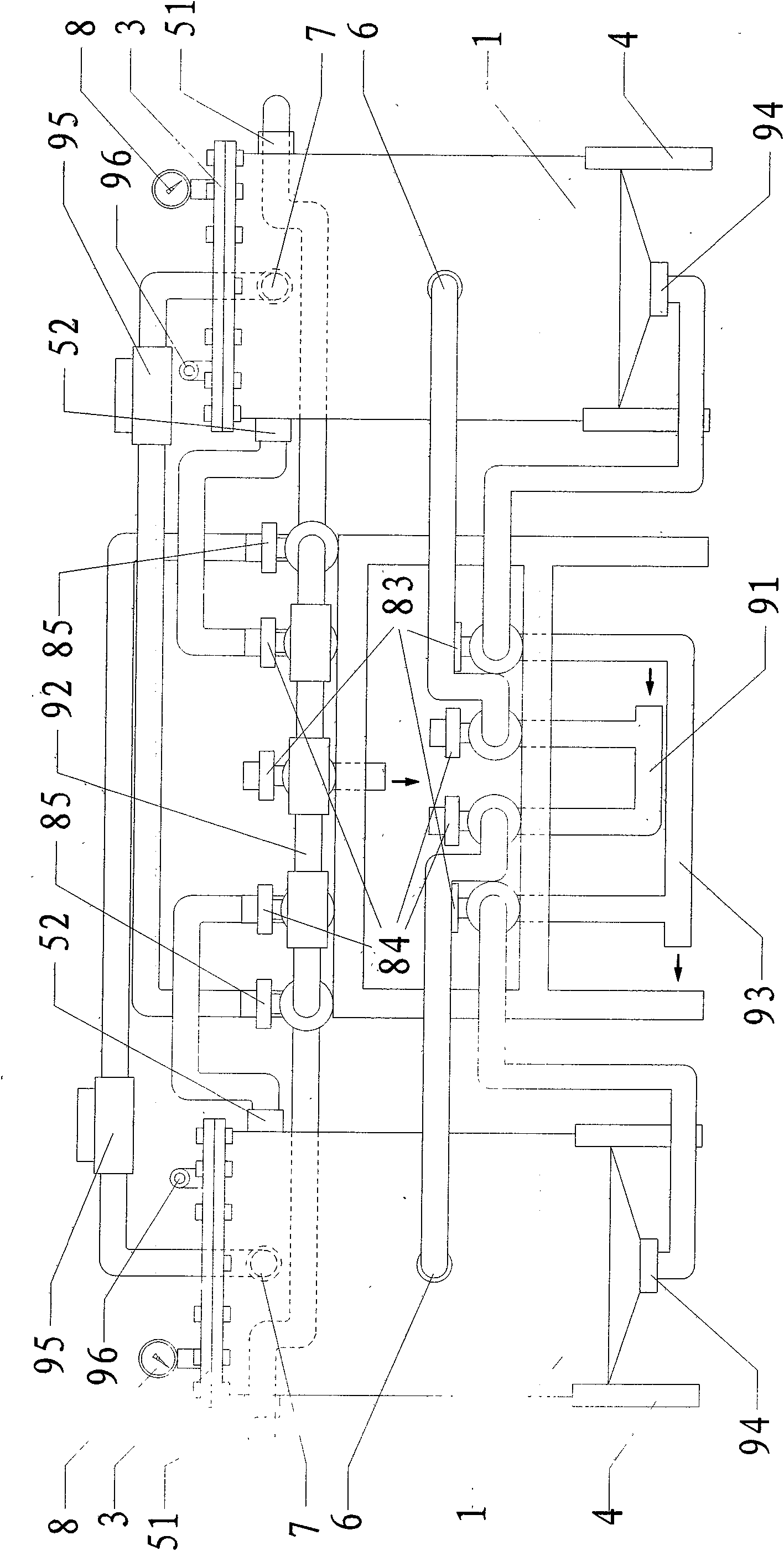

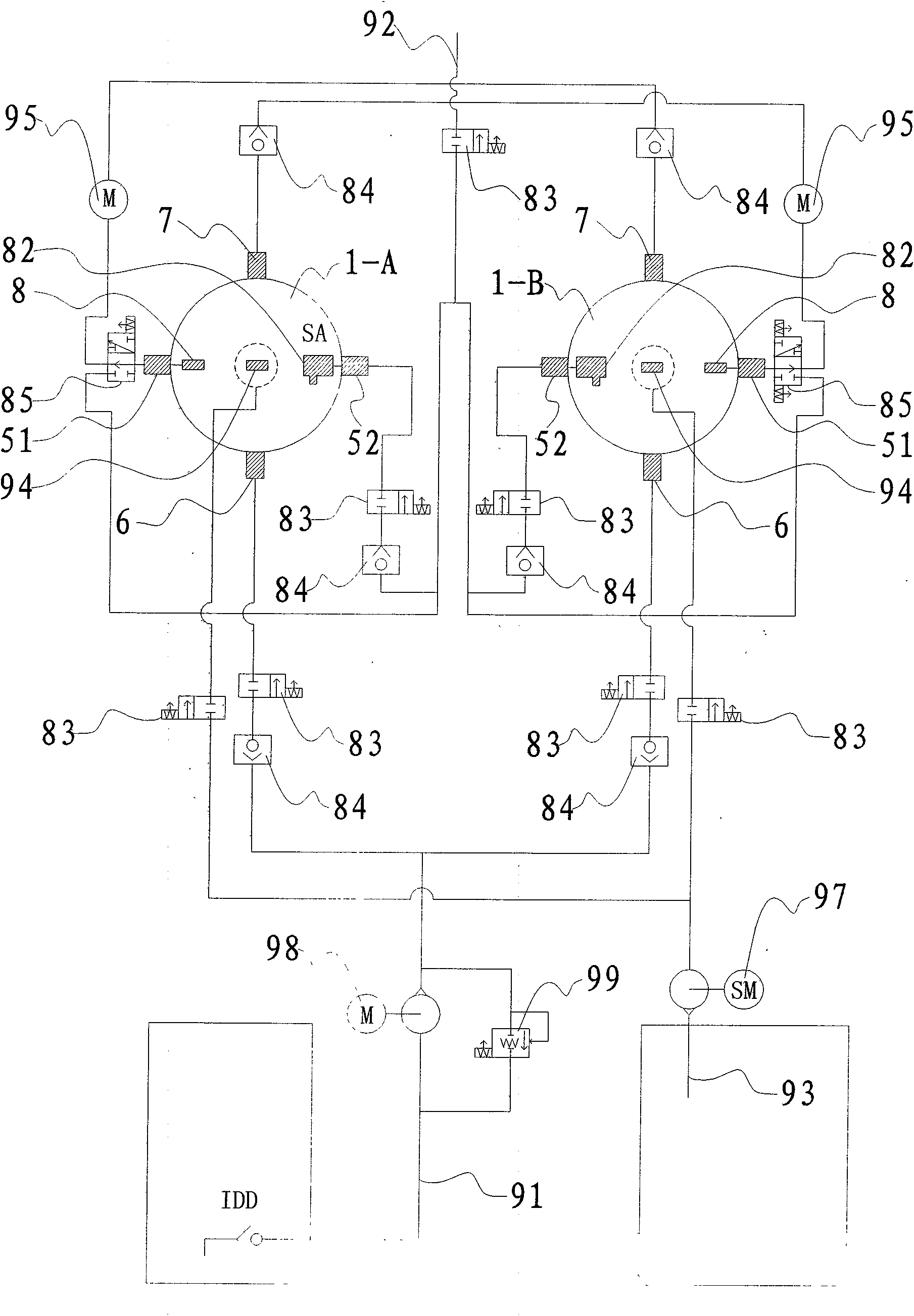

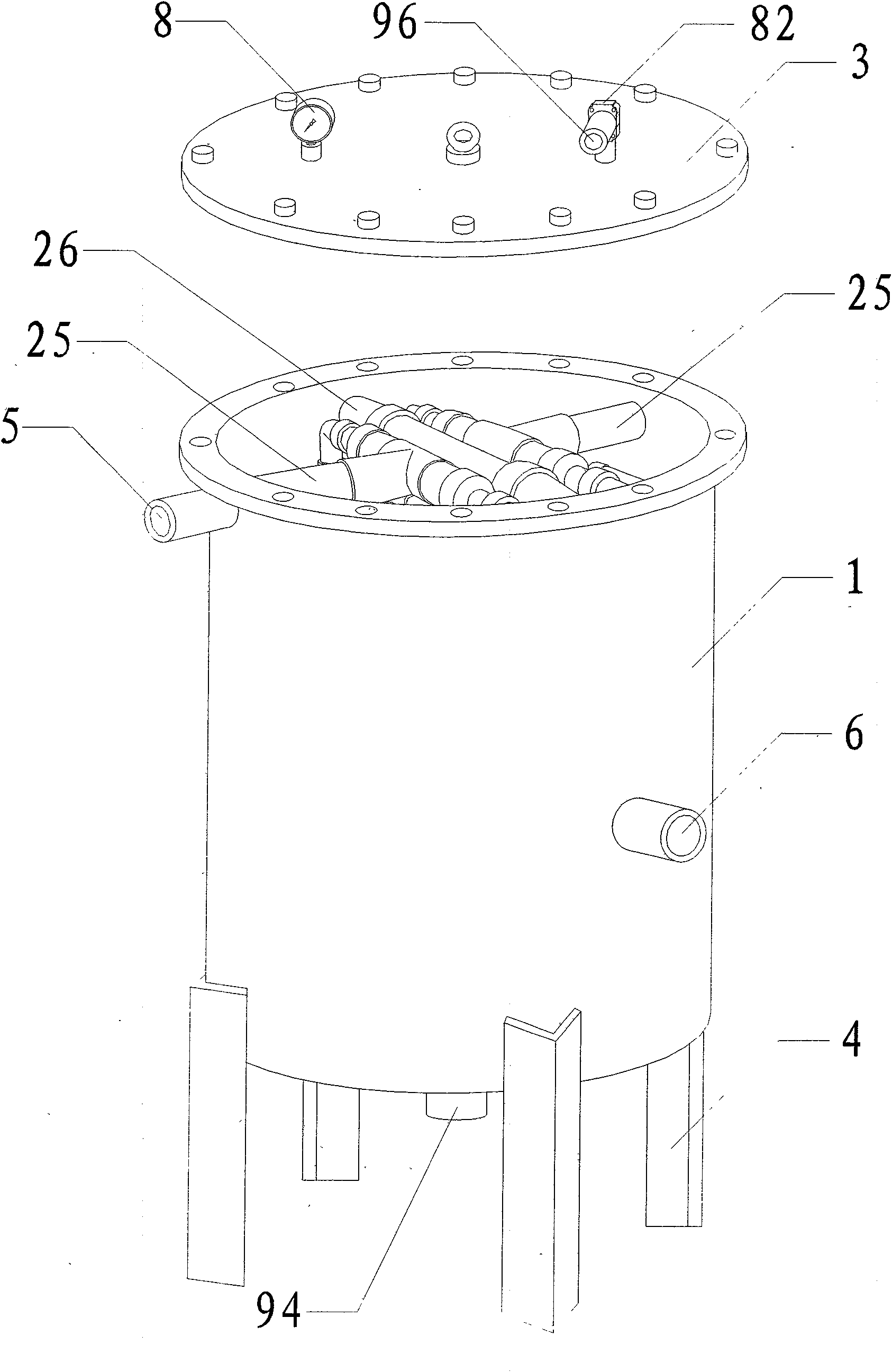

[0025] refer to Figure 1 to Figure 5 As shown, a water filter unit includes a filter tank and a water inlet pipeline 91 connected to the filter tank, an outlet pipeline 92 and a sewage pipeline 93, and the filter tank includes a first filter tank 1-A and a second filter tank 1 -B, each filter tank includes a shell 1, a filter element installed in the shell 1, an upper cover 3 set on the top of the shell 1, and a foot 4 set on the bottom of the shell 1, and the upper side of the shell 1 is respectively set There are a first water outlet hole 51, a second water outlet hole 52 and a cleaning hole 7. The lower side of the housing 1 is provided with a water inlet 6 for introducing raw water. The bottom of the housing 1 is provided with a sewage outlet 94 for the filtered The sewage is discharged, and the upper cover 3 is provided with a vent hole 96 and a water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com